Adaptive Control Irrigation and Drainage System of Bottom Lysimeter Pit

A self-adaptive control, irrigation and drainage technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as high labor intensity, unfavorable irrigation test development, undisturbed soil layer damage, etc., to reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

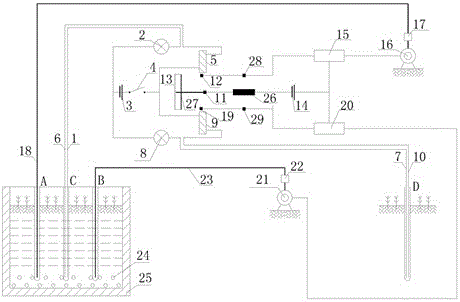

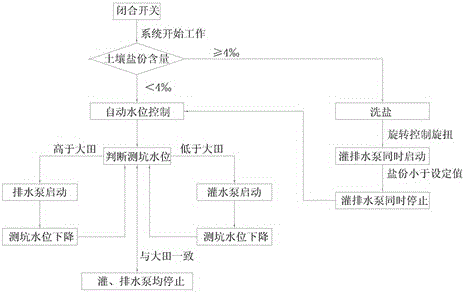

[0032] like figure 2As shown, open and close the judging circuit switch 4, the judging circuit pit measuring indicator 2 and the judging circuit field indicator 8 all light up, the system starts to work, the soil salinity is less than 4%, and the water level in the measuring pit is lower than the water level in the field, then measuring The total length of the negative pit metal probe wire 1 and the anode pit metal probe wire 6 exposed to the water surface in the pit judging circuit is greater than the total length of the cathode field metal probe wire 7 and the anode field metal probe wire 10 exposed to the water surface in the field judgment circuit, As a result, the resistance value in the pit judgment circuit is greater than the resistance value in the field judgment circuit. Since both the pit-testing judgment circuit and the field judgment circuit are powered by the judgment circuit power supply 3, under the same voltage, the current value with the larger resistance val...

Embodiment 2

[0034] like figure 2 As shown, the judgment circuit switch 4 is closed, the judgment circuit pit indicator light 2, and the judgment circuit field indicator light 8 all light up, the system starts to work, the soil salinity is <4%, and when the water level in the test pit is higher than the water level in the field, then The total length of the negative pit metal probe wire 1 and the anode pit metal probe wire 6 exposed to the water surface in the pit judgment circuit is less than the total length of the cathode field metal probe wire 7 and the anode field metal probe wire 10 exposed to the water surface in the field judgment circuit , causing the resistance value in the pit judgment circuit to be smaller than the resistance value in the field judgment circuit. Since both the pit-testing judgment circuit and the field judgment circuit are powered by the judgment circuit power supply 3, under the same voltage, the current value with the smaller resistance value is larger. For...

Embodiment 3

[0036] During the test, if it is found that the soil salt content in the test pit is ≥ 4%, which is unfavorable for the irrigation test, the control circuit closing knob 26 can be directly rotated, so that the control circuit drainage contact 28 and the control circuit irrigation contact 29 are short-circuited, and the control circuit closure. The irrigation pumping station 21 and the drainage pumping station 16 work at the same time, and the bottomed lysimeter pit 25 is washed with salt while irrigating and draining, so as to reduce the salt content in the soil in the bottomed lysimeter pit 25 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com