Electrostatic atomizer

An electrostatic atomization and side electrode technology, applied in the field of electrostatic atomization devices, can solve problems such as equipment enlargement, and achieve the effect of improving cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be described with reference to the embodiments shown in the drawings.

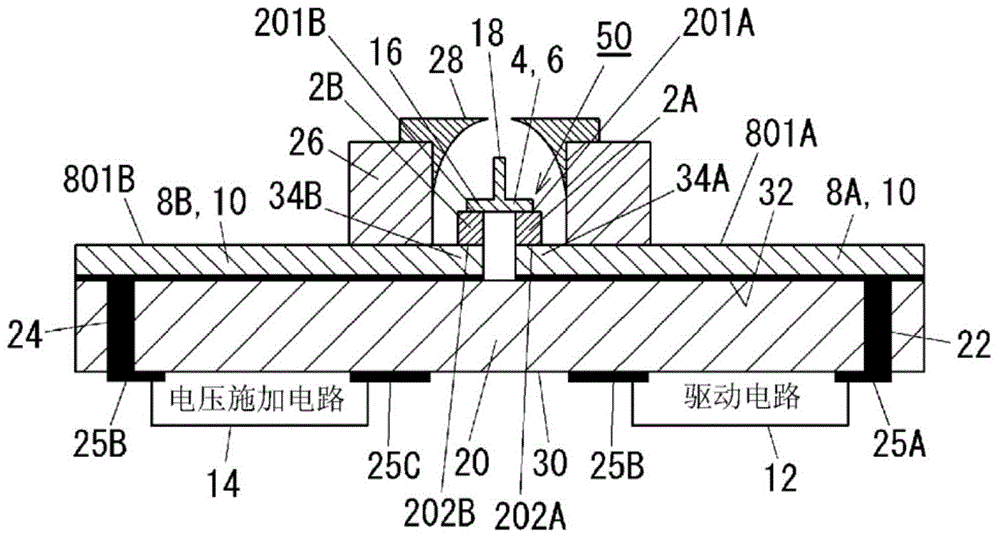

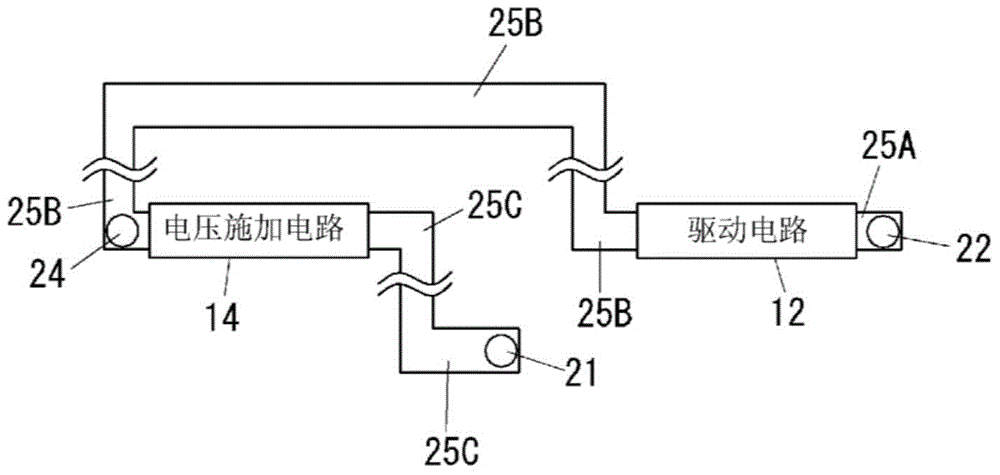

[0024] In FIG. 1( a ), a cross section of an electrostatic atomizing device according to Example 1 of the present invention is illustrated.

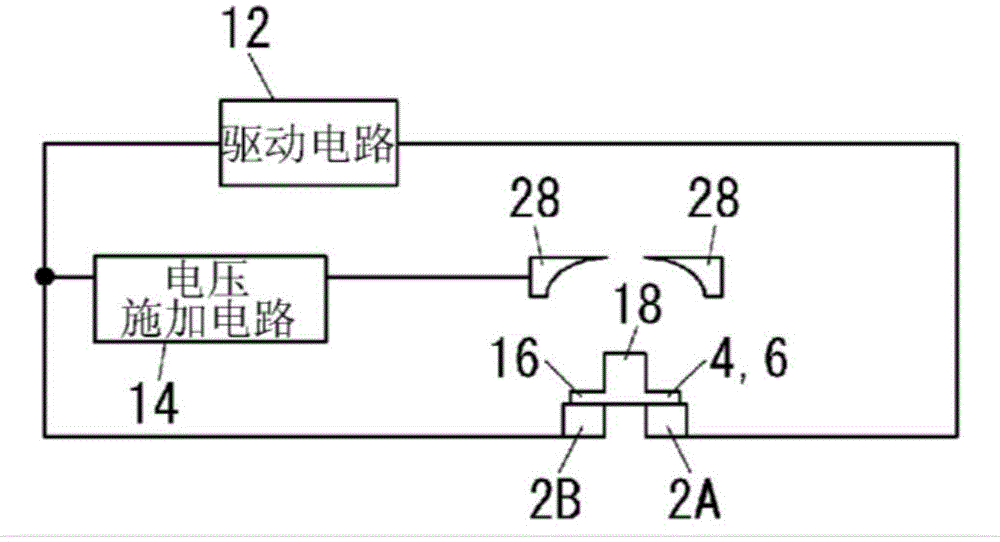

[0025] In the electrostatic atomization device of the present embodiment, a pair of thermoelectric elements 2A and 2B respectively composed of P-type and N-type Peltier elements are used as heat exchangers for cooling discharge electrode 6 . By energizing the pair of thermoelectric elements 2A and 2B, the side (upper side in the figure) of one end (first end 201A and 201B) of each of the thermoelectric elements 2A and 2B becomes a heat-absorbing side, and the other end (the pair of thermoelectric elements The second end 202A and 202B) side (lower side in the figure) of 2A and 2B becomes the heat dissipation side.

[0026] The heat-absorbing-side electrode body 4 also serving as the discharge electrode 6 for electrostatic atomization is join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com