A non-slip pressure roller

A pressing roller and roller technology, applied in the field of crushing equipment, can solve the problems of looseness, axial movement and high production cost, and achieve the effects of convenient maintenance, avoiding axial movement and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

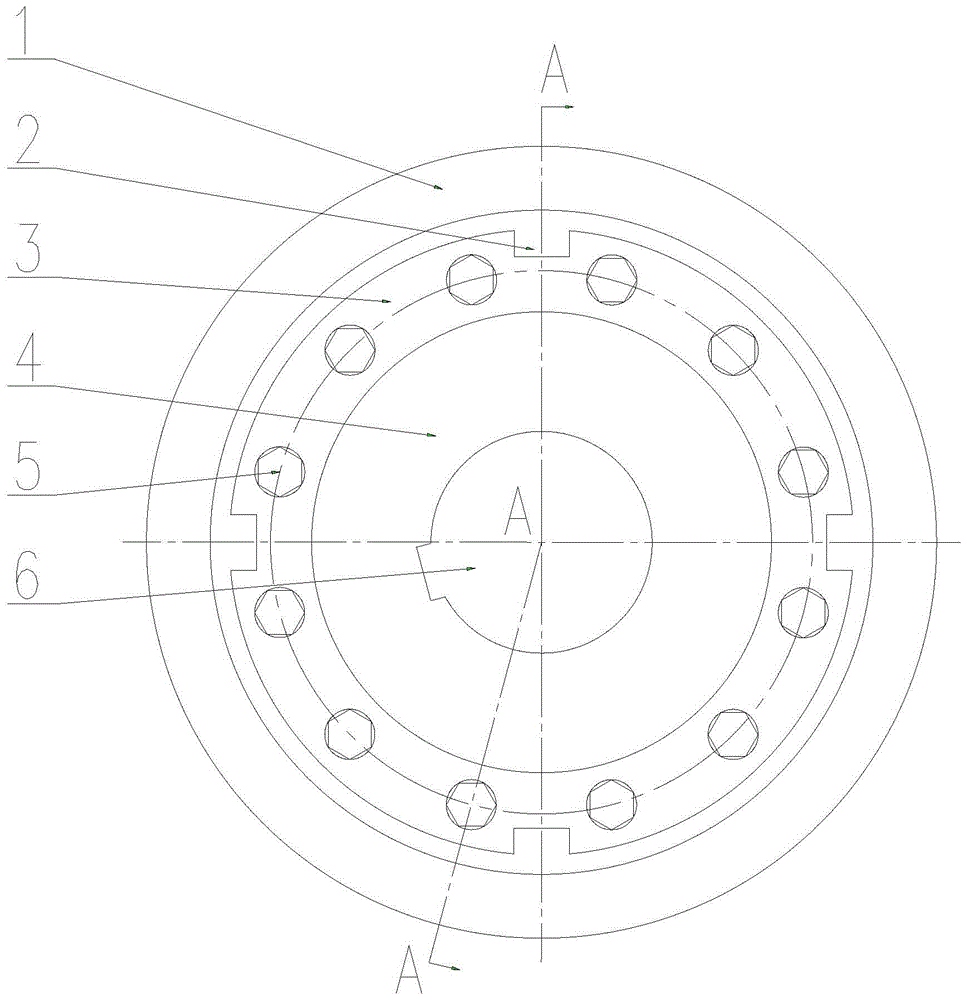

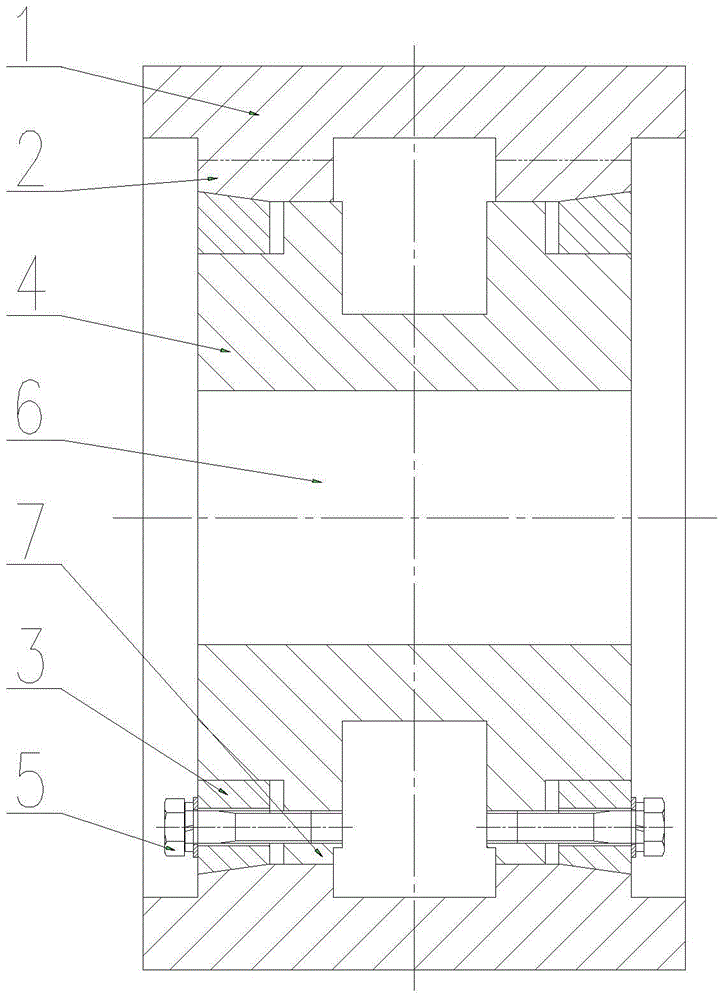

[0011] The present embodiment is made up of roller 1, wheel hub 4 and conical pressure ring 3.

[0012] Roller 1 is a cylinder made of high wear-resistant material, and four (or two or three or more) axial convex strips 2 (the cross-section of the axial convex strips are usually Rectangular shape, also can be other shapes); At the two ends of the inner hole of the roller 1, respectively form a slope-like inner cone with a large outside diameter and a small inside diameter.

[0013] The conical pressure ring 3 is a circular ring whose outer cylindrical surface is a conical surface and the inner wall is a cylindrical surface. 2 notches).

[0014] In the middle of the hub 4, there is a hub shaft hole 6 for wearing the hub shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com