Assembling and welding method for back-chipping-free T-shaped penetration welding joint

A technology of penetration welding and welding method, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of waste and increase of materials, and achieve the effect of simple method, easy operation, and improved welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific implementation, the embodiment of the present invention is further described:

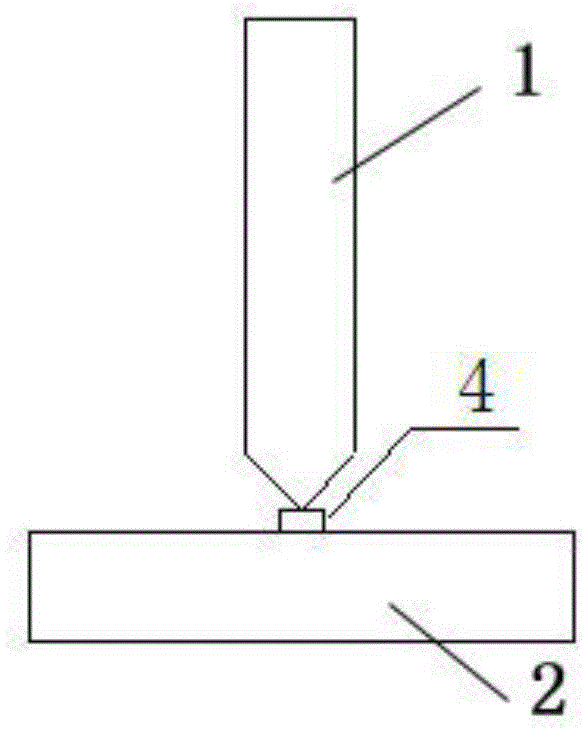

[0028] Such as Figure 1 to Figure 8 The method for assembling and welding the root-free T-type penetration welding joint includes the following steps:

[0029] Step 1. Prepare the parts to be welded, welding consumables and auxiliary materials, including: 1 piece of web, 1 piece of wing plate, CO 2 Gas shielded welding equipment, submerged arc welding equipment, φ1.2mm solid-core welding wire, φ5.0mm solid-core welding wire, flux, some φ4.0mm×50mm welding wire heads, some anti-deformation supports, other auxiliary materials, etc.;

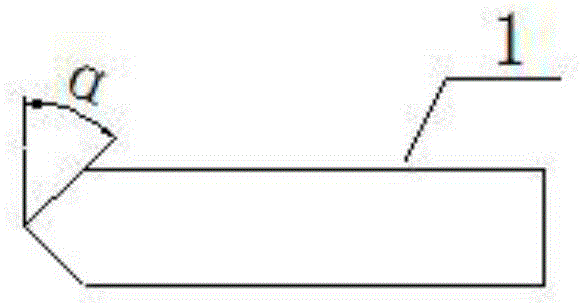

[0030] Step 2. Complete the groove processing of web 1 according to the design drawing, as attached figure 1 As shown, the groove angle α on both sides must meet the requirements (25°≤α≤35°), and the blunt edge of the groove should not be greater than 2mm;

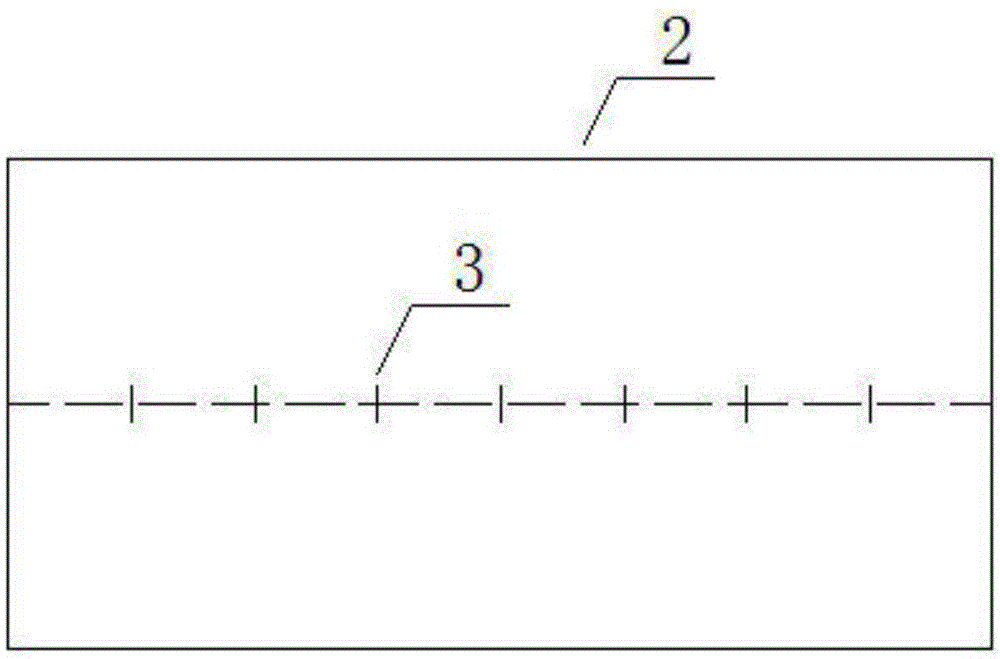

[0031] Step 3. Place the wing plate 2 on the platform and draw the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com