Foam plate perforating machine

A foam board, punching machine technology, applied in metal processing and other directions, can solve the problems of broken, affecting hole quality, unable to meet large-scale production, etc., to achieve the effect of rapid hole making and ensuring molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

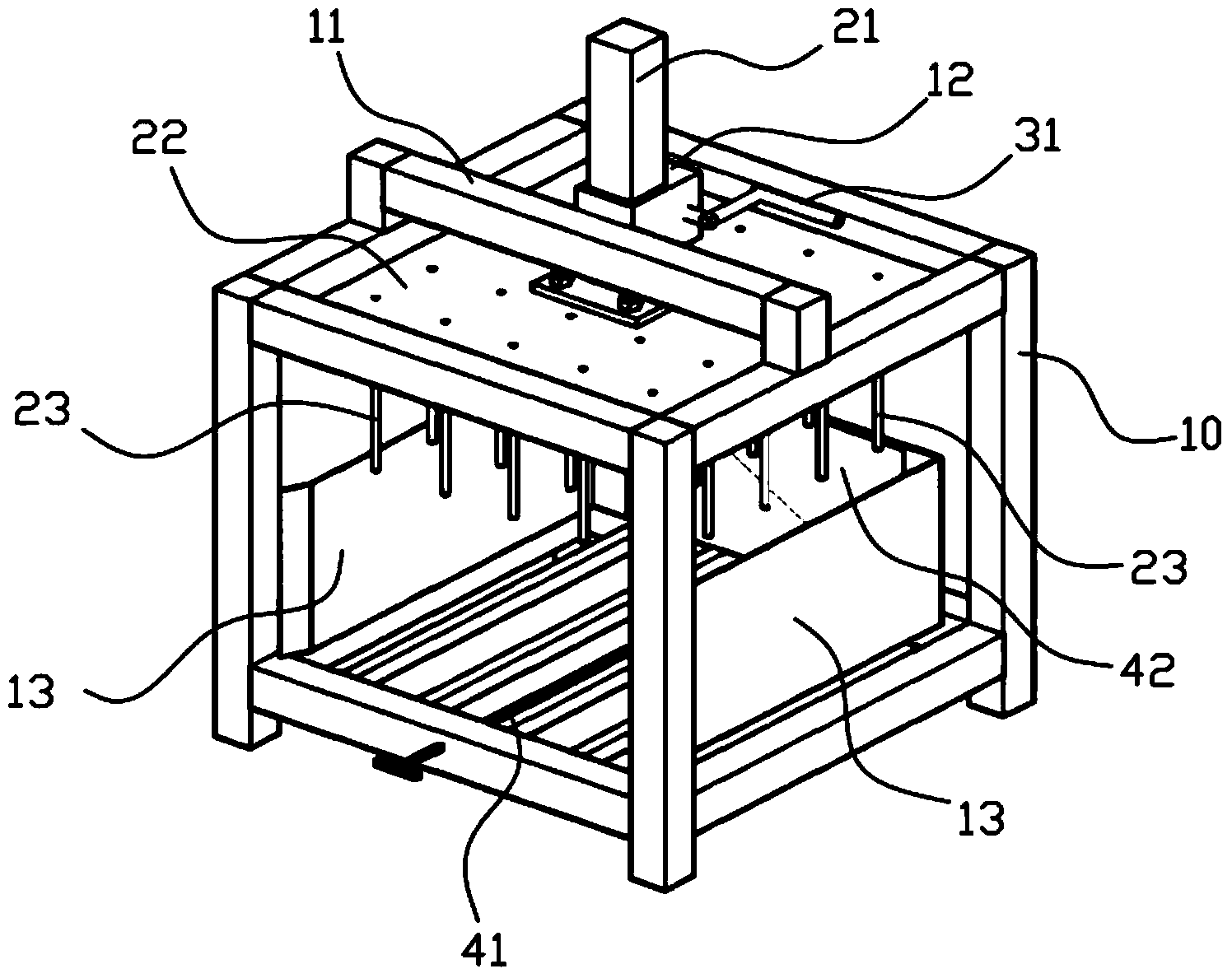

[0017] see figure 1 , the present invention discloses a foam board punching machine, which includes a frame 10, a hole-making space (not shown in the figure) is provided inside the frame 10, and the bottom of the hole-making space is used to stack and place foam boards to be punched; The hole-making assembly arranged on the frame 10, the hole-making assembly includes a transmission shaft 21, a connection plate 22 fixed on the bottom of the transmission shaft 21 and a number of heating rods 23 fixed on the bottom surface of the connection plate 22, and the transmission shaft 21 can be up and down Mobilely installed on the top of the frame 10, the heating rod 23 is electrically connected to a heating device (not shown in the figure), and the heating device is used to heat the heating rod 23; 21 lifting devices that move up and down.

[0018] The working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com