System and method for automatic adjustment of substrate glass pulling roller

A technology of automatic adjustment and pulling rollers, applied in the control/adjustment system, glass forming, glass forming, etc., can solve problems such as the inability to achieve the best state, the adjustment error of the parameters of the pulling rollers, and the inability to improve the quality of the substrate glass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in further detail below in conjunction with accompanying drawing:

[0041] The automatic adjustment system of the substrate glass traction roller of the present invention includes a data acquisition module, a data processing and analysis module, an adjustment module, and a feedback module.

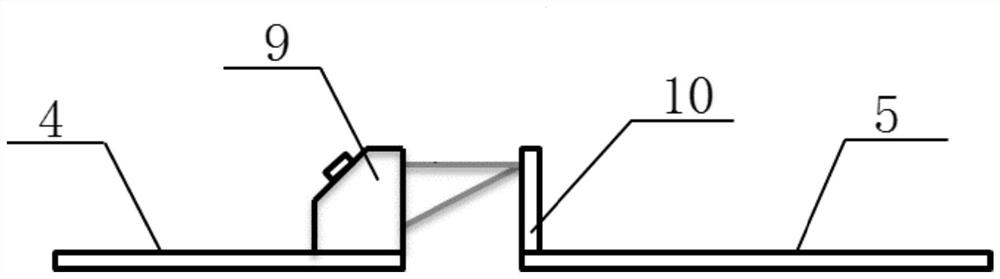

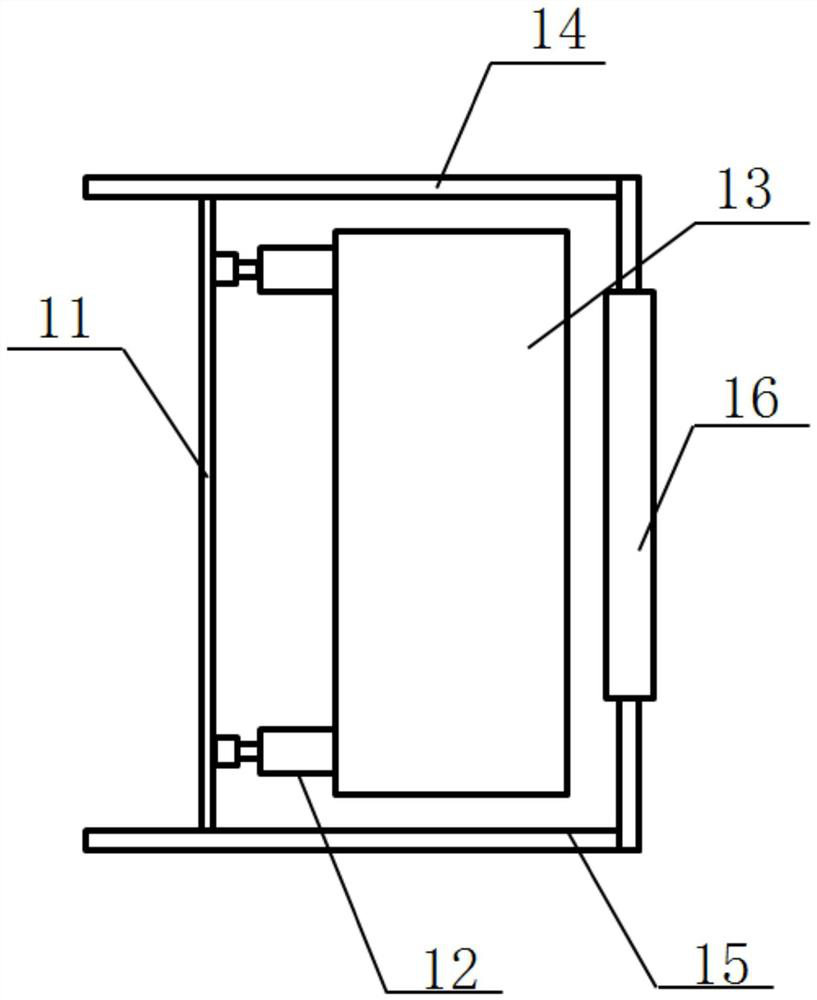

[0042] The data acquisition module is used to collect the distance between the pulling rollers 1 and the length data of the substrate glass 11; the data acquisition module includes a laser displacement sensor 9 and a plate length measuring device.

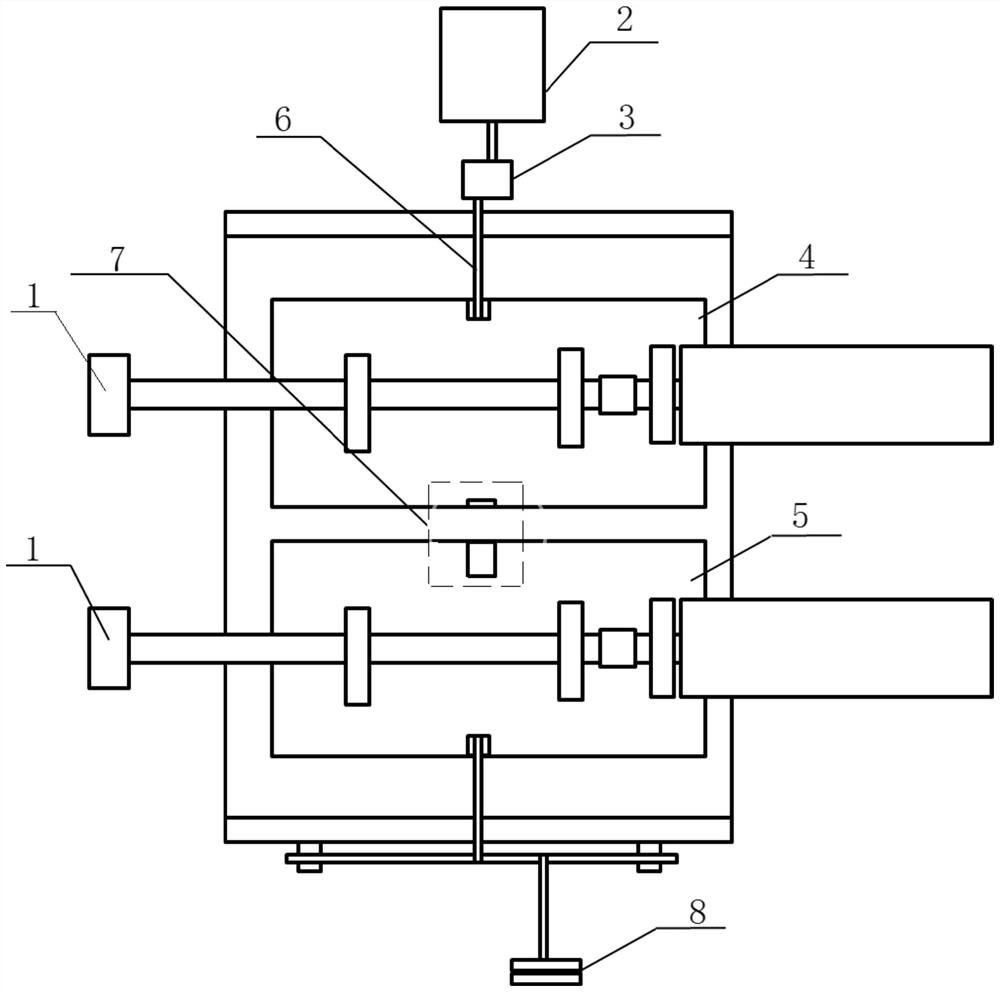

[0043] Such as figure 1As shown, a pair of traction rollers 1 includes two rollers, and the two rollers are respectively arranged on the fixed end slide plate 4 and the floating end slide plate 5, and the fixed end slide plate 4 and the floating end slide plate 5 are both arranged on the base plate and are slidably connected with the base plate. The fixed end slide 4 is connected with the centering mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com