Heat treatment and quenching equipment for small and medium bearing rings

A technology of bearing rings and quenching equipment, which is applied in heat treatment equipment, heat treatment furnaces, quenching devices, etc., can solve the problems of high manual labor intensity and easy damage to workpieces, so as to improve production efficiency, improve quality, and avoid manual labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

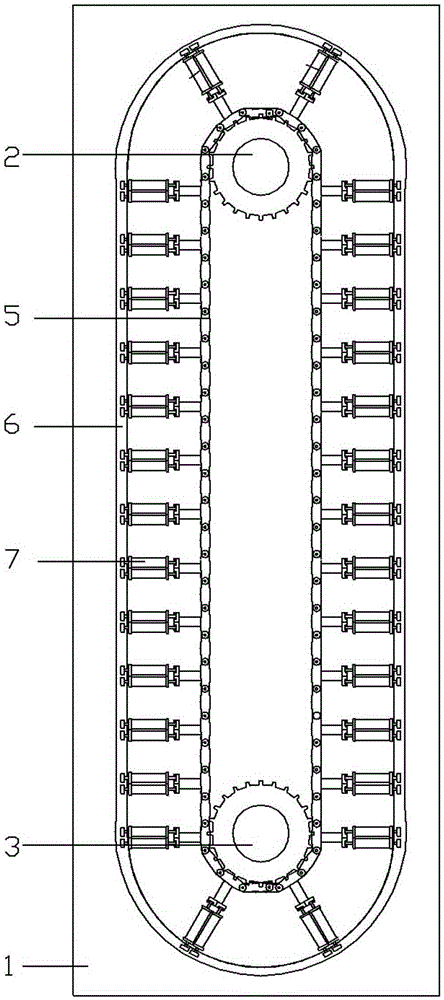

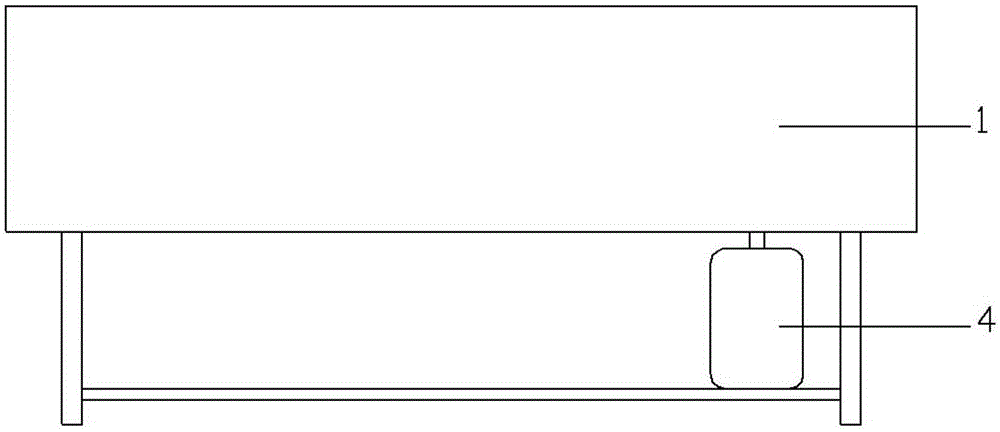

[0017] Example: see Figures 1 to 3 As shown, the heat treatment and quenching equipment for small and medium-sized bearing rings includes an oil tank 1, and a driving sprocket 2 and a driven sprocket 3 are arranged in the oil tank 1. The driving sprocket 2 and the rotating shaft of the motor 4 are fixed together, and the motor 4 is placed in The lower part of the oil tank 1, the chain 5 is tensioned on the driving sprocket 2 and the driven sprocket 3, and the guide rail 6 is fixed in the oil tank 1;

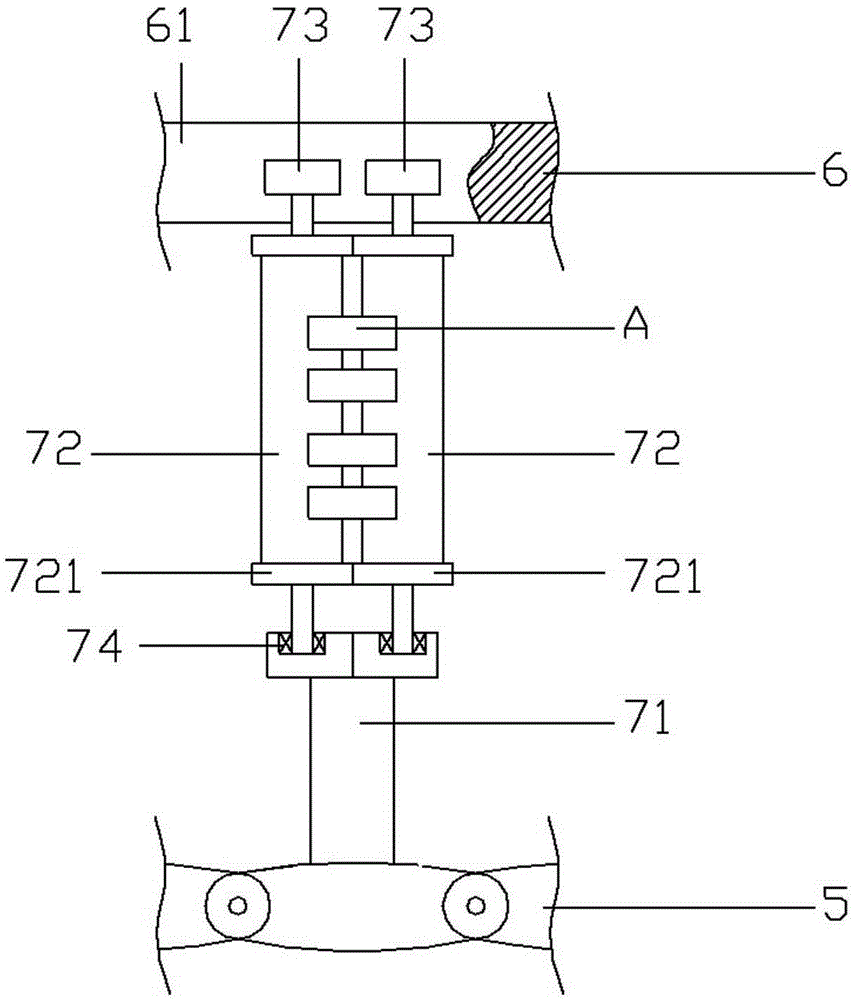

[0018] Each heat treatment device 7 is composed of a connecting plate 71, two roller shafts 72, two rollers 73 and two high-temperature-resistant bearings 74. The connecting plate 71 is welded and fixed on the chain 5, and the connecting plate 71 is welded and fixed with a high-temperature-resistant bearing 74. The outer ring of the high temperature resistant bearing 74 is welded and fixed with a roller shaft 72, the other end of the roller shaft 72 is fixed with a roller 73, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com