Side cut type track switch cleaning machine

A technology of screen cleaning machine and turnout, which is applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of easily broken fingers and weakening the strength of fingers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solution and advantages of the present invention clearer, an embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

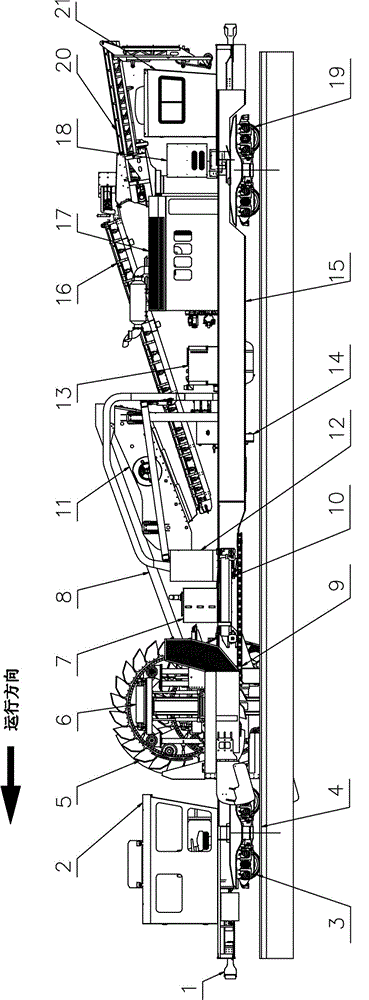

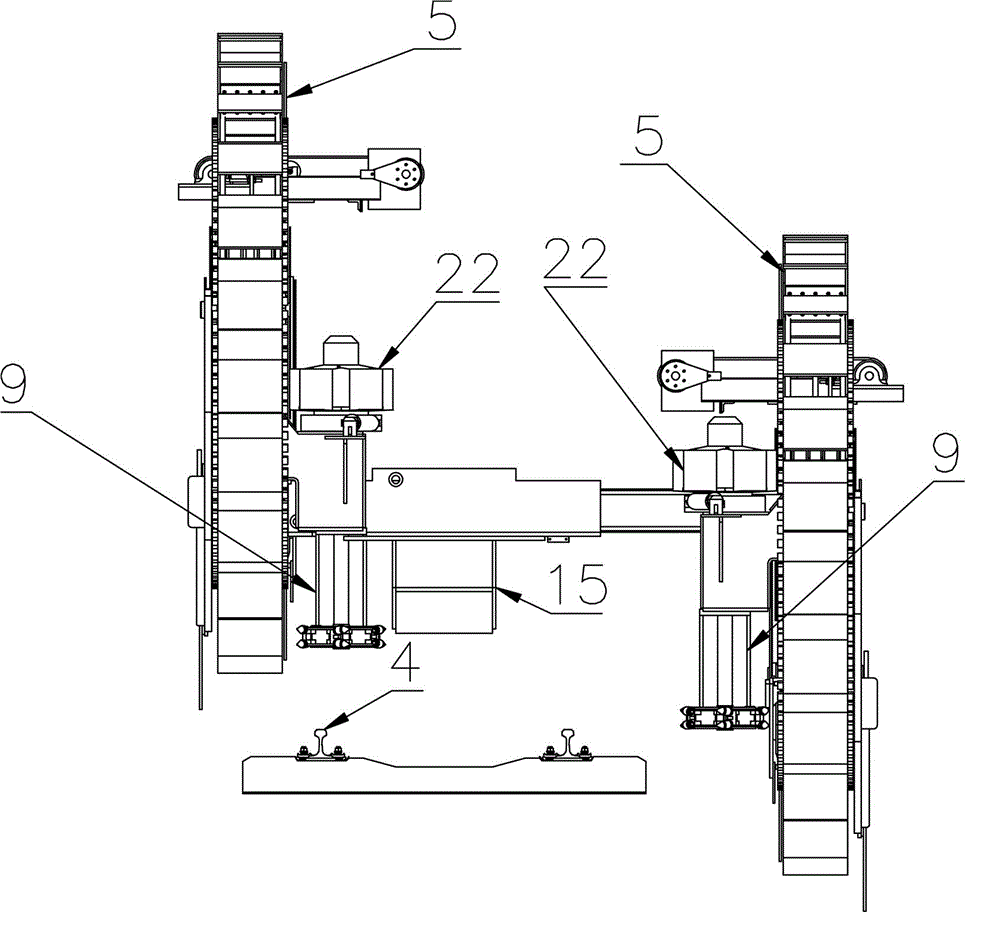

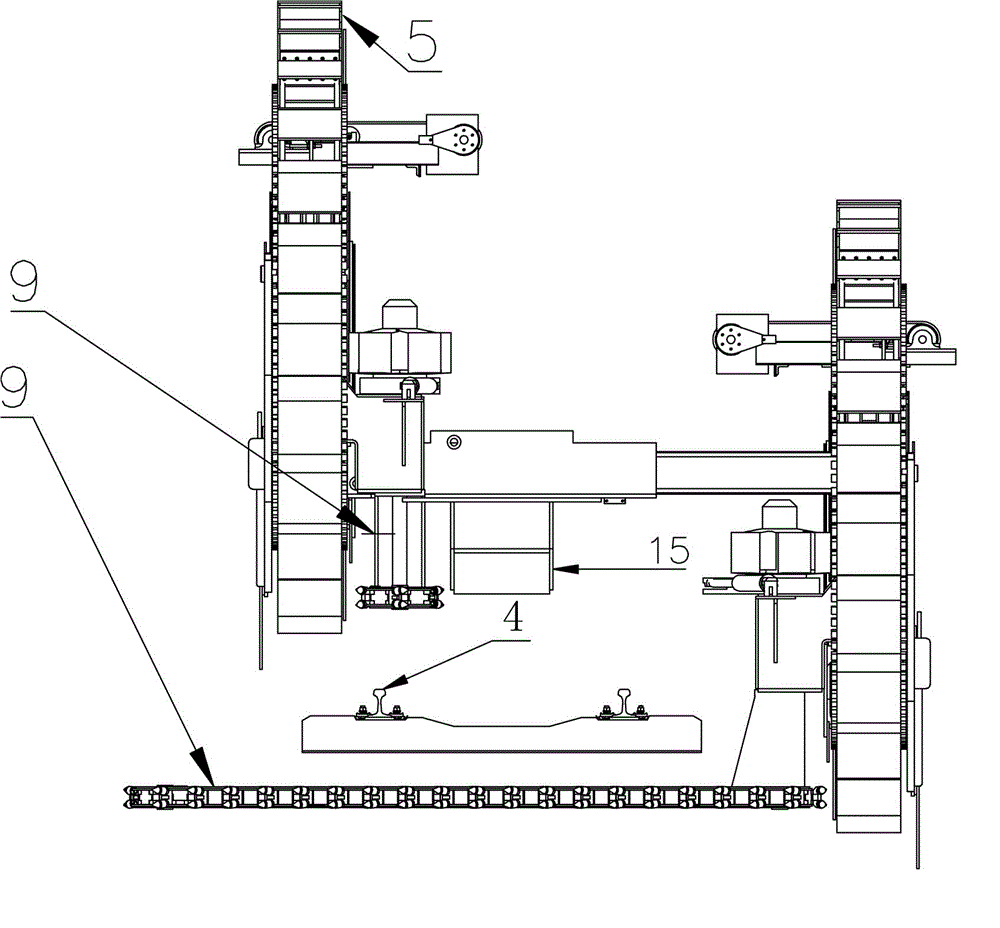

[0038] refer to figure 1(The direction of the arrow in the figure indicates the running direction of the screen cleaning machine), which shows a schematic structural view of a preferred embodiment of a side-cut type turnout screen cleaning machine according to the present invention. The turnout screen cleaning machine includes: operating cab 2, running cab 21, vehicle frame 15, and the excavating mechanism including bucket wheel 5, transverse conveyor belt 6, and bottom cutter plate 9 is installed on the vehicle frame 15; screening device 11. The ballast backfilling device of the backfill bucket 12 and the backfill belt 10, and the power transmission system of the engine room 17 and the hydraulic oil tank 13. Below the screening device 11, a bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com