Adaptive fan-cooled LED lamp tube

An LED lamp tube and self-adaptive technology, applied in the field of non-portable indoor lighting lamps, to achieve the effects of improving heat dissipation efficiency, good air intake effect and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

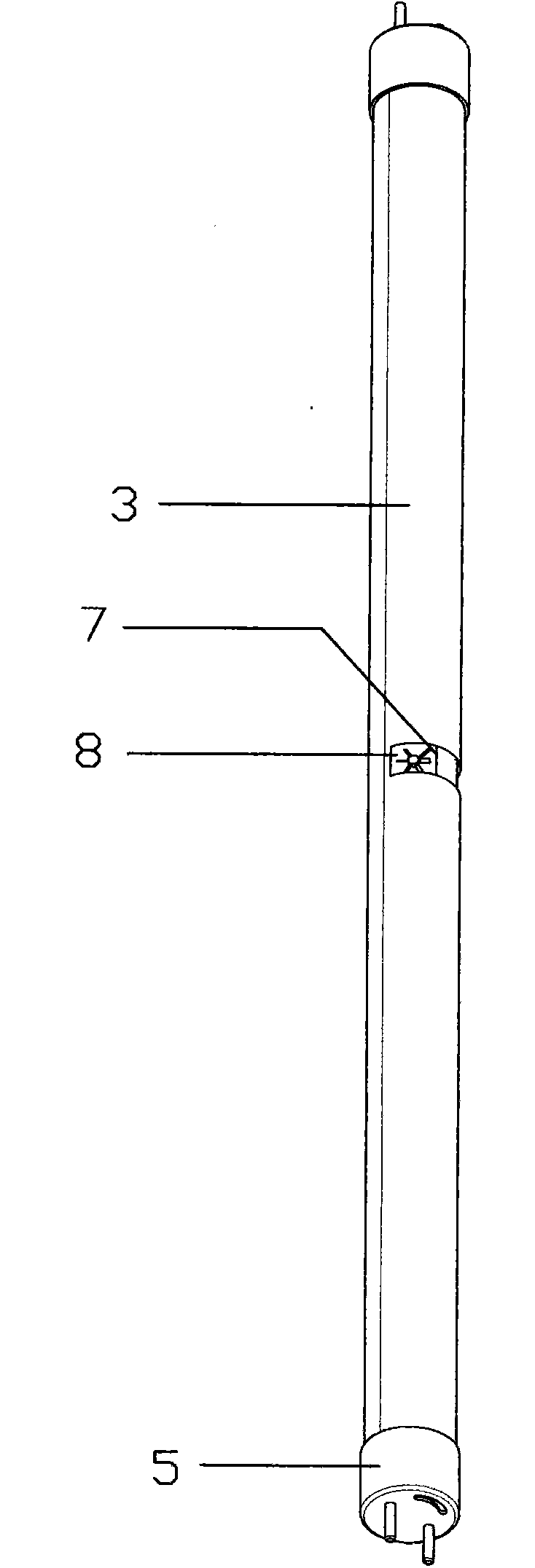

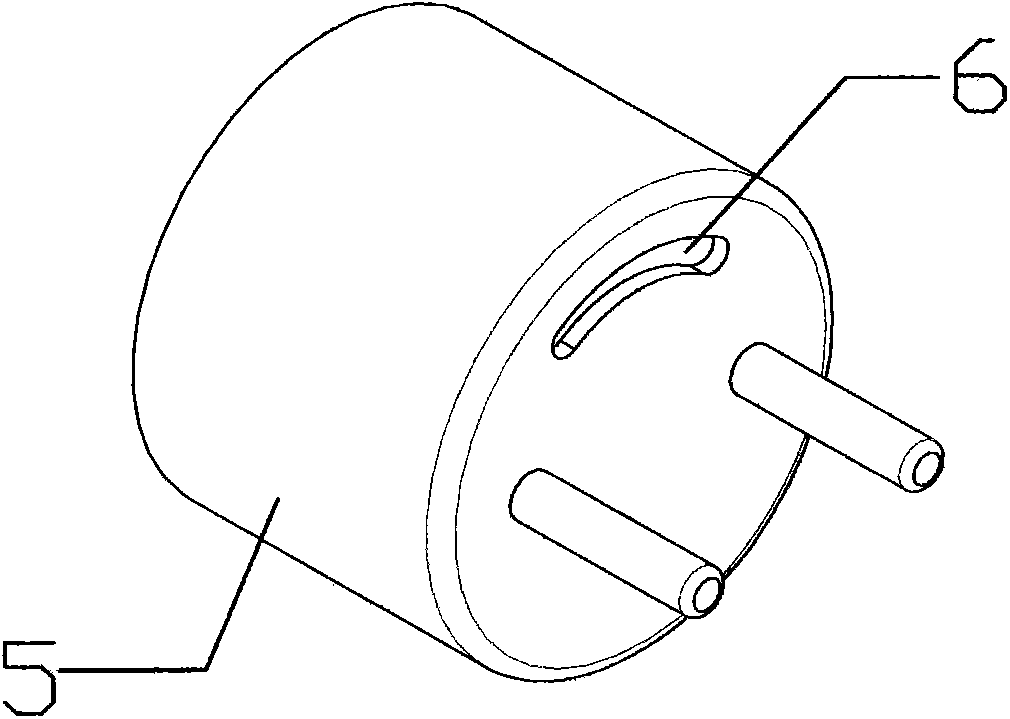

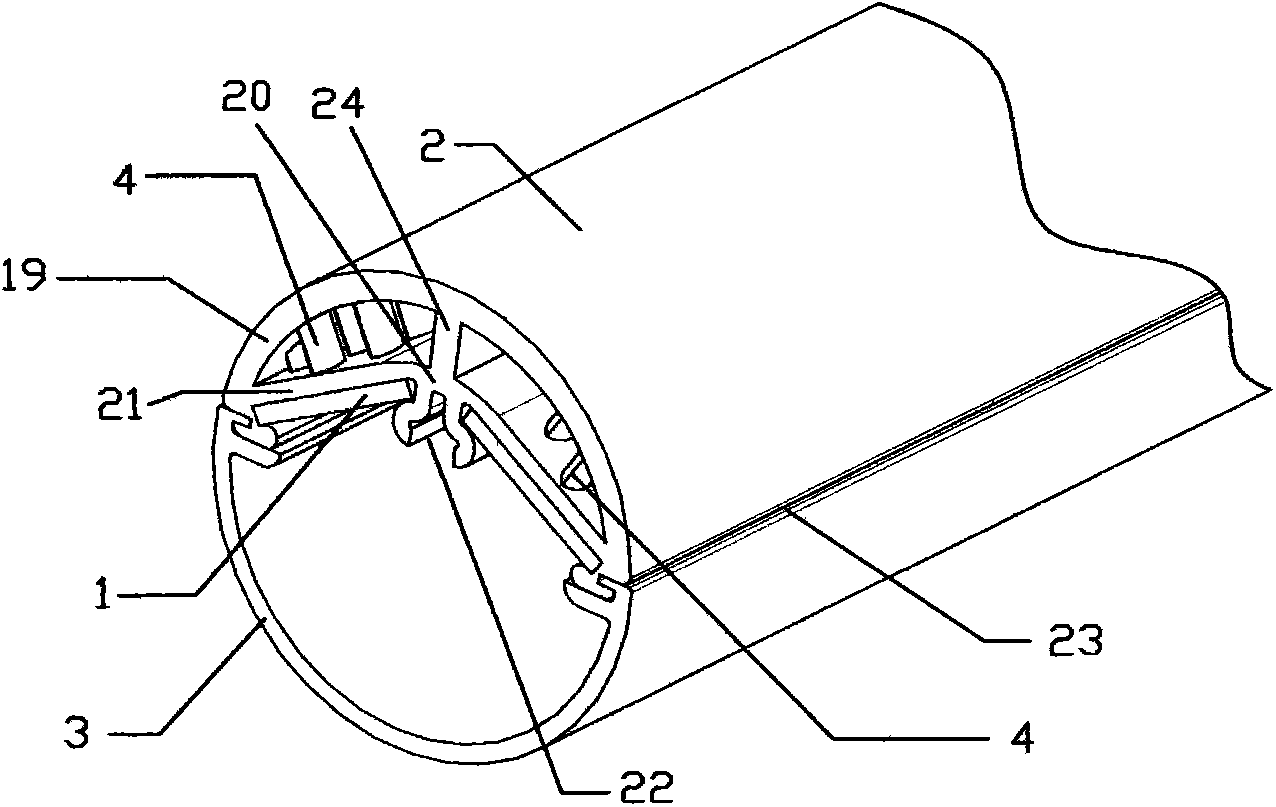

[0025] The LED light tube with self-adaptive fan cooling includes two LED light emitting circuit boards 1, a cooling frame 2 and a semi-tubular lampshade 3, and the angle between the two LED light emitting circuit boards 1 is 120° to 160°. The heat sink 2 includes an arc structure 19, the lower end of the arc structure 19 is connected with a herringbone structure 20, and the partition 24 at the upper end of the middle of the herringbone structure 20 divides the inner cavity of the heat sink 2 into two parts, the left and right, and the two sides of the herringbone structure 20 It is a slope partition 21; the upper surfaces of the two LED light-emitting circuit boards 1 are respectively attached to the lower surfaces of the two slope partitions 21; the lower end of the middle part of the herringbone structure 20 is provided with a threaded groove 22; A groove 23 is respectively provided under the end; the threaded groove 22 is used for threaded connection with the cover pin 5; t...

Embodiment 2

[0032] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that a one-way exhaust window 9 is fixed at each exhaust hole 7; 10 components; two double-pole double-throw switches 16 are also fixed on the heat dissipation frame 2; the double-pole double-throw switch 16 can be fixed on the top of the heat dissipation frame 2; Towards.

[0033] When the present invention is installed on the vertical wall, the double pole double throw switch 16 of top cooling fan 8 is toggled to the exhaust position, and the double pole double throw switch 16 of bottom cooling fan 8 is toggled to the intake state. The radiating fan 8 positioned at the bottom blows toward the top like this, and the hot air is blown to the top of the inside of the cooling frame 2; discharged to the outside. When the cooling fan 8 at the lower part rotates in reverse, the one-way exhaust window 9 at the lower part forms a negative pressure in the cooling frame 2, and the blades 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com