Device for accurately measuring vehicle wheel slip ratio

An accurate measurement and slip rate technology, applied in wheel testing and other directions, can solve the problems of no device for direct measurement of slip rate, inaccurate wheel center speed, no direct measurement, etc., and achieves simple structure, low cost, and installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

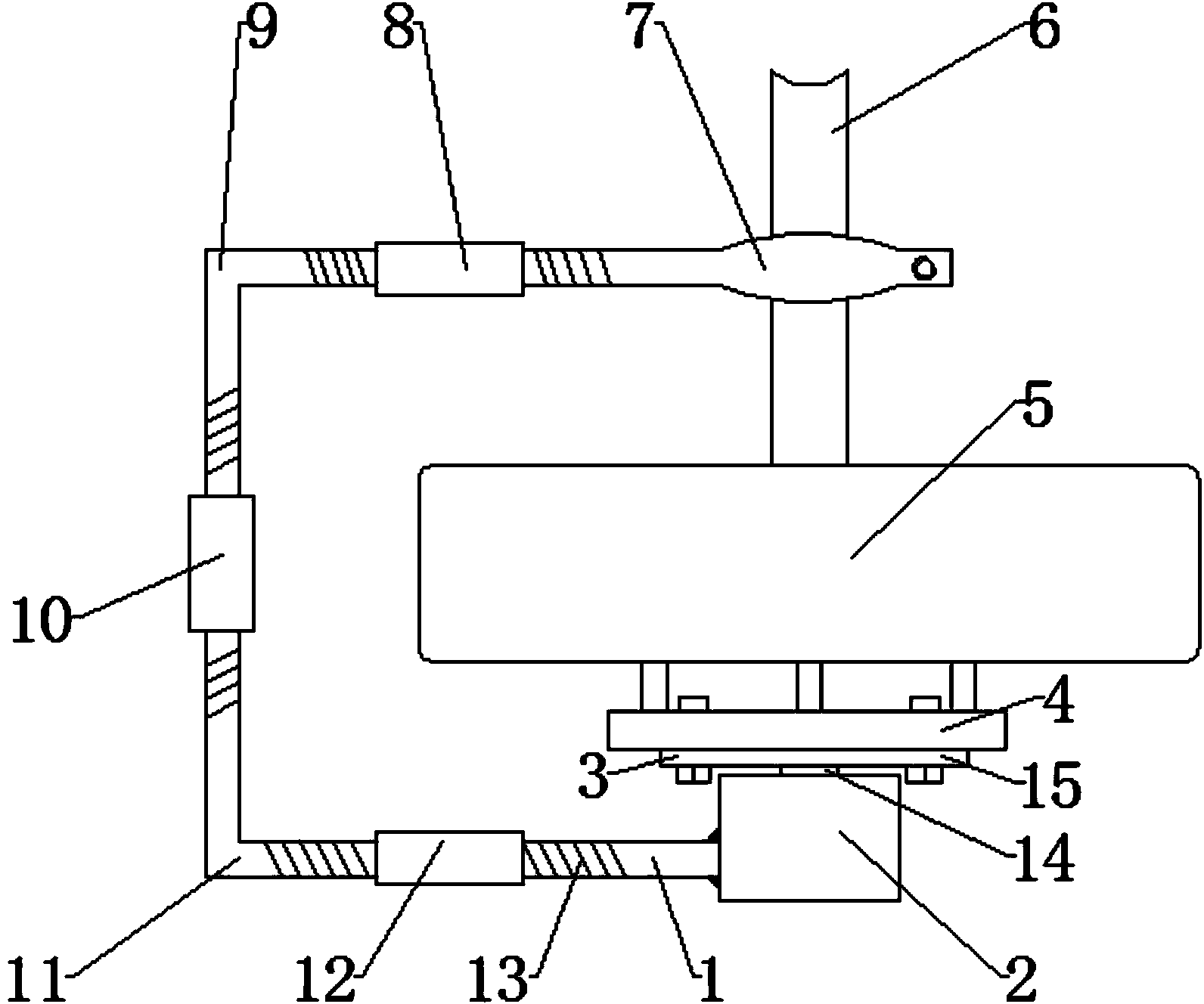

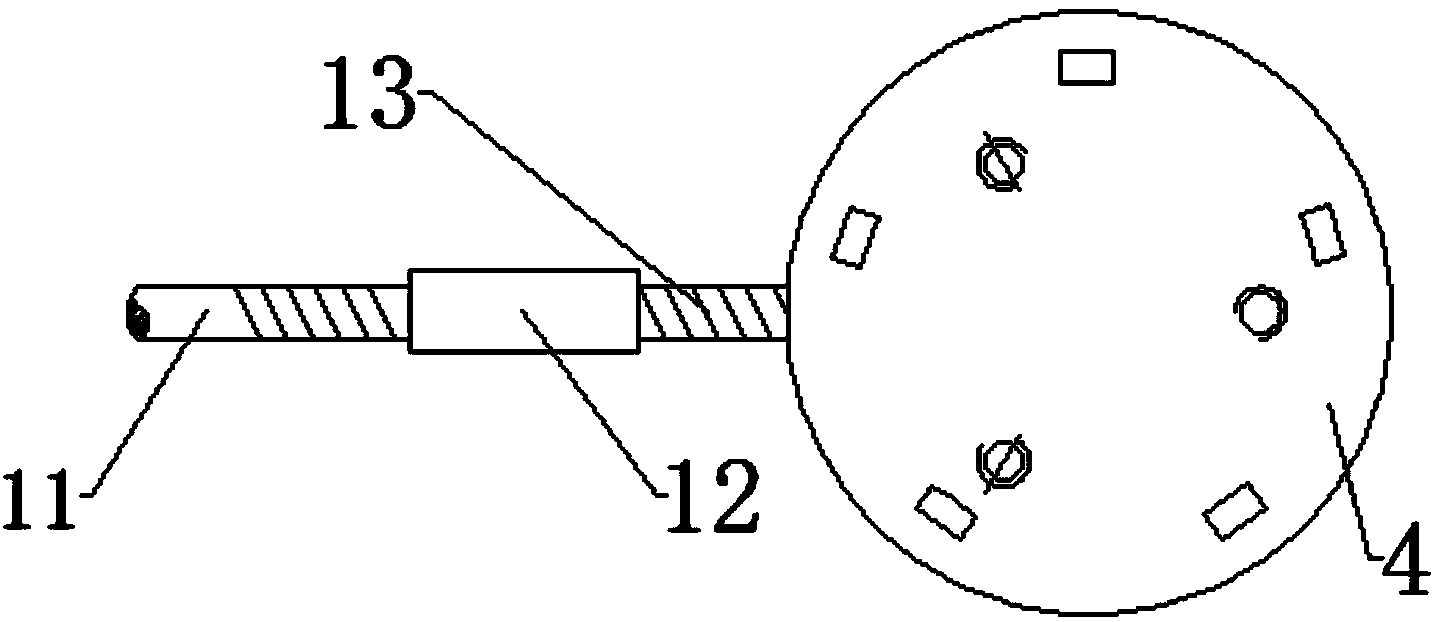

[0030] refer to figure 1 and figure 2 , the device for accurately measuring the slip ratio of automobile wheels according to the present invention includes a telescopic adjustment mechanism 1 , a sensor acquisition and processing unit 2 , a sensor rotating part 3 and a wheel connecting part 4 .

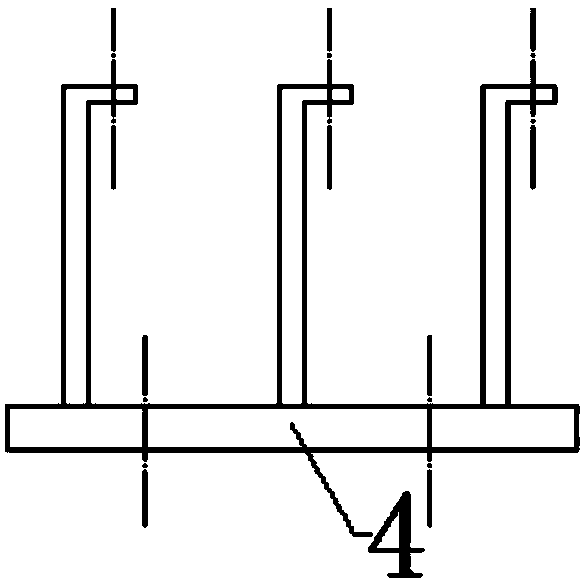

[0031] The upper end of the rotating shaft 14 is integrated with the bottom surface of the connecting disc 15, the lower end of the rotating shaft 14 is connected with the bottom plate of the device housing 19 in the sensor acquisition processing unit 2 by bearings, and the wheel connecting part 4 is installed on the connecting disc 15 And adopt bolt connection, the right end of the D screw rod 13 in the telescopic adjustment mechanism 1 is welded with the left side of the device casing 19 in the sensor acquisition processing unit 2, and the rotation axis of the wheel connecting par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com