Auxiliary device for measuring detonation velocity of emulsified explosive in blast hole

An auxiliary device, the technology of emulsion explosives, which is applied in the direction of using a device for measuring the time required to move a certain distance, can solve the problems of unable to measure the detonation velocity of emulsion explosives and is expensive, and achieve the effect of simple structure, low price, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

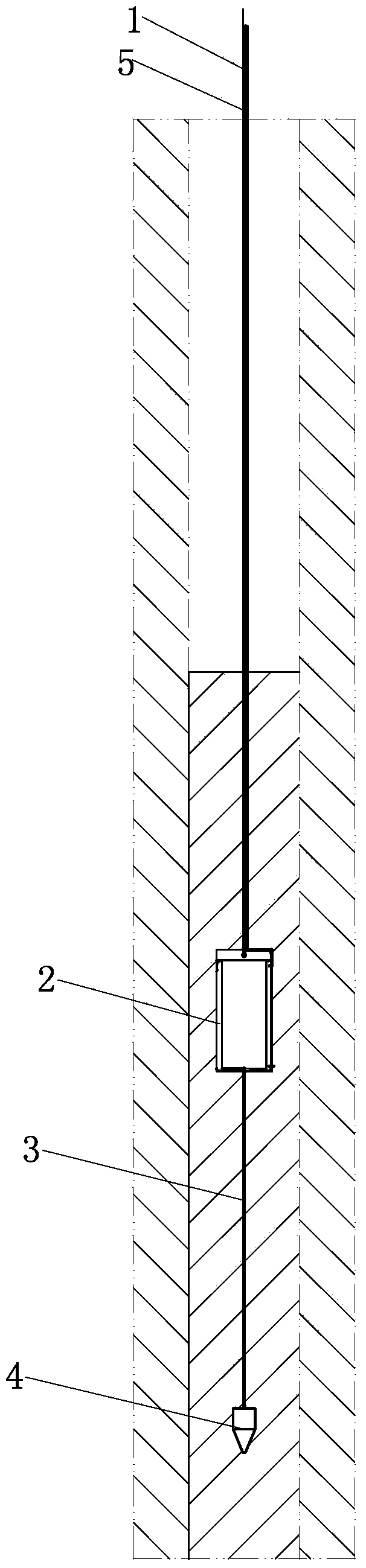

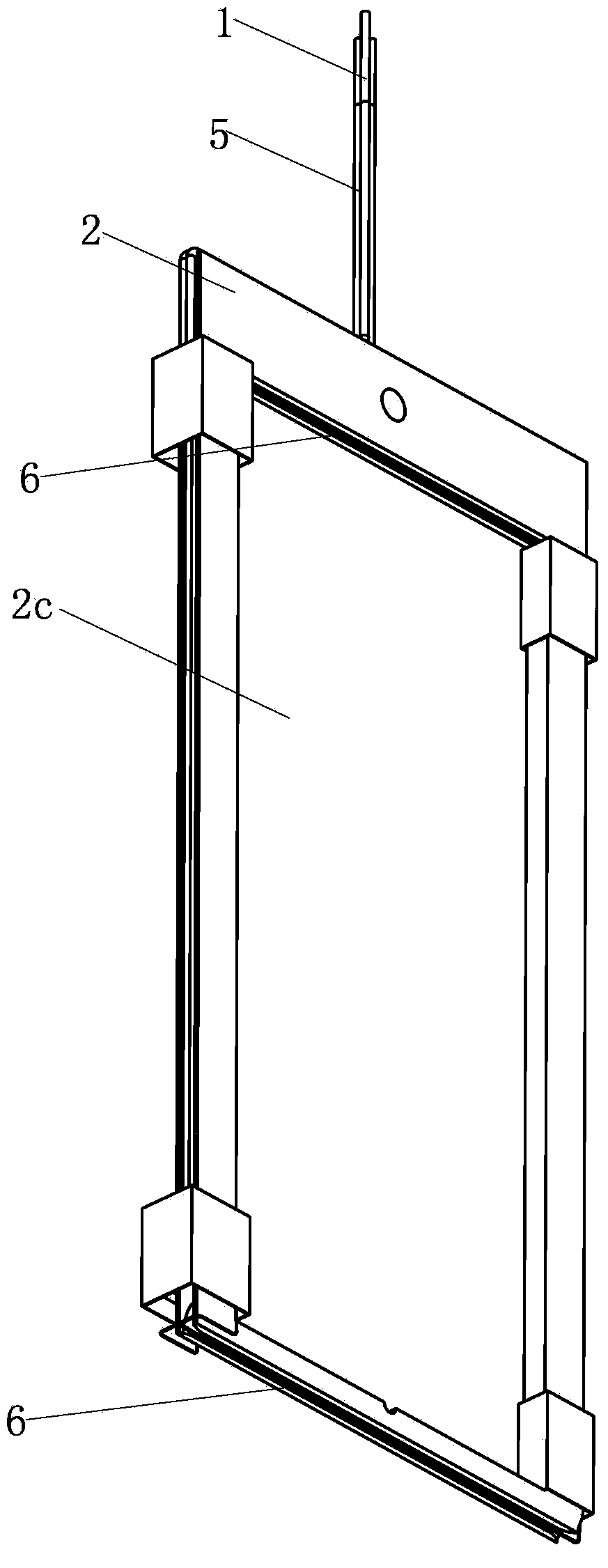

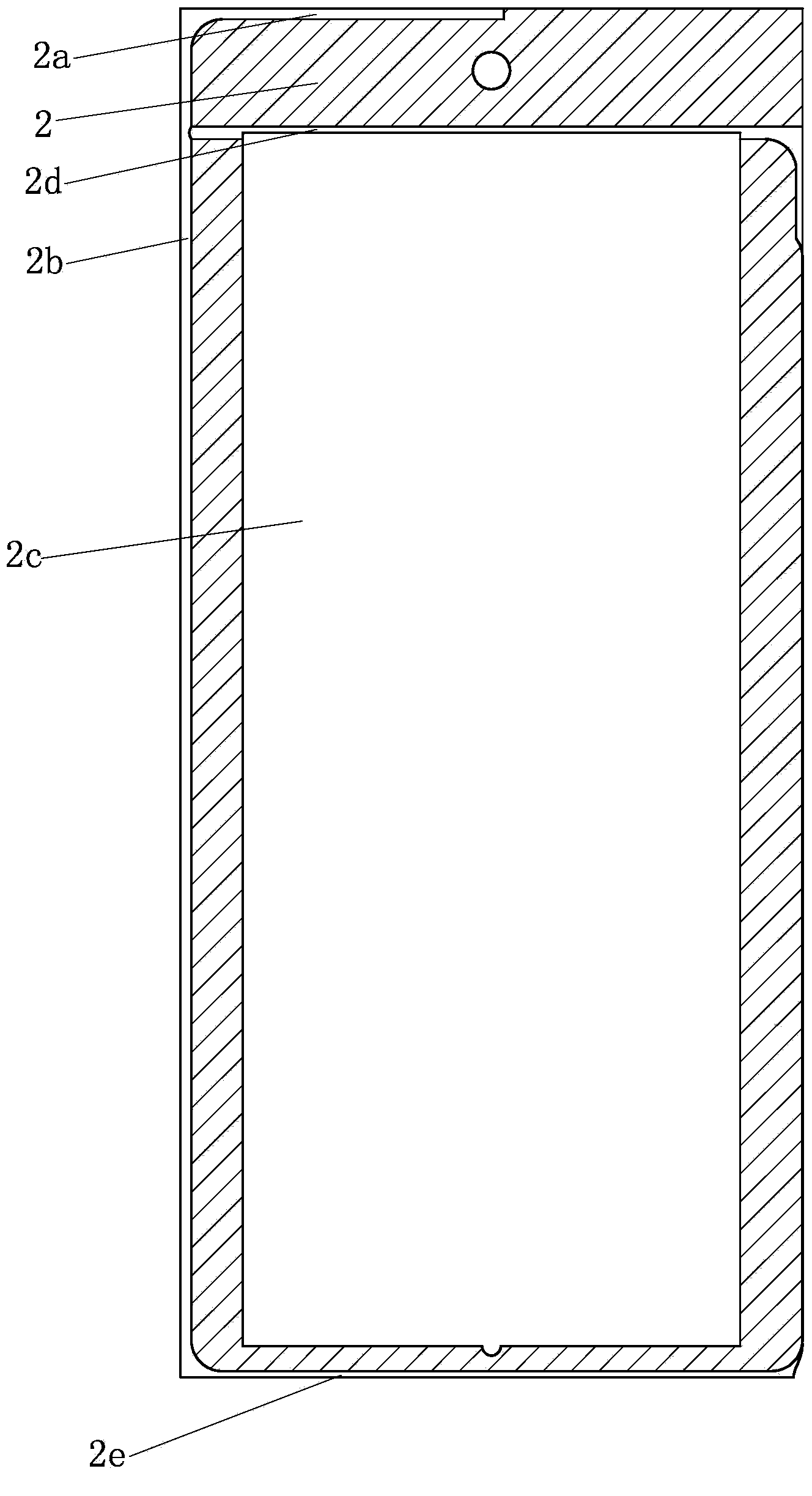

[0015] Such as figure 1 , 2 As shown in and 3, an auxiliary device for measuring the detonation velocity of emulsion explosives in a blasthole mainly consists of a fixed wire 1, a target wire plate 2, a pull wire 3, a weight 4, a wire 5 and an enamelled copper wire 6, wherein The upper end of the fixed line 1 is suspended in the air, and the suspended end of the fixed line 1 is fixed at the hole of the blasthole before the measurement, and the lower end of the fixed line 1 is fixed with the upper part of the target line plate 2, thereby fixing the auxiliary device in the blasthole. The bottom of the target line board 2 is hung with a weight 4 through a stay wire 3, the material of the weight 4 can be iron or stone, etc., and the fixed line 1 and the stay wire 3 are all located In the center, it can ensure that the target line board 2 does not deflect, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com