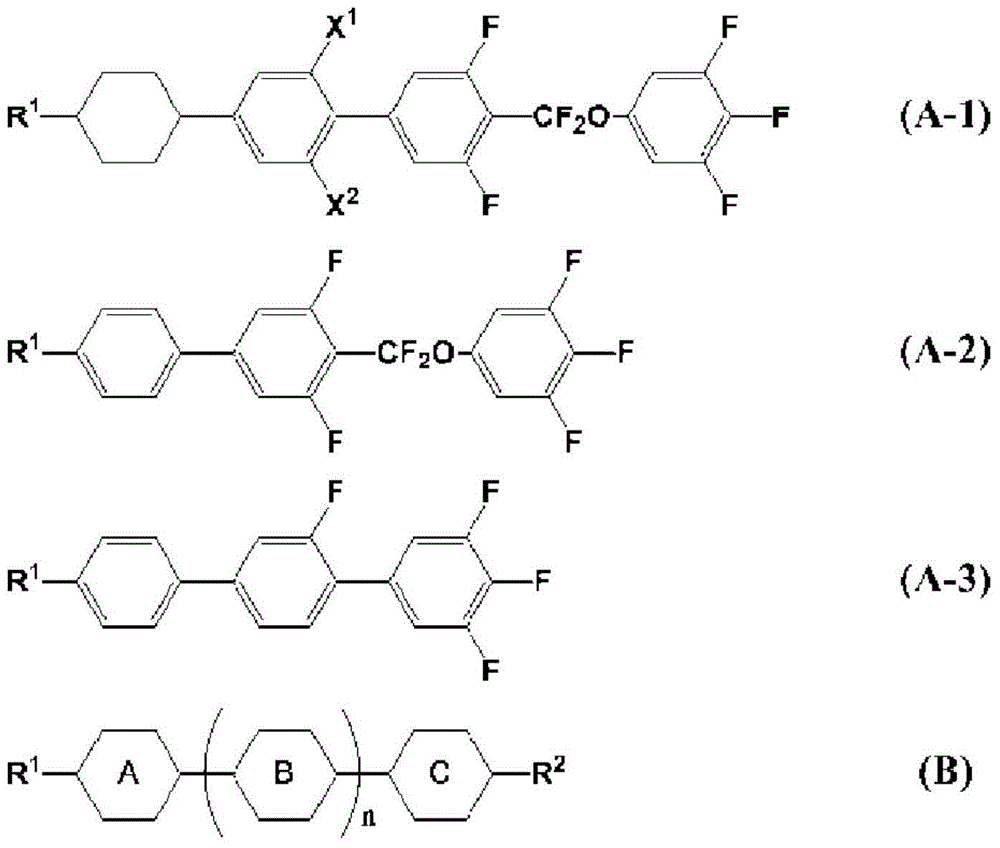

Liquid crystal composition and liquid crystal display element produced using same

一种液晶组合物、化合物的技术,应用在液晶显示元件,向列液晶组合物领域,能够解决液晶显示元件折射率驱动电场平衡崩溃、对比度不良、困难等问题,达到实现高速响应、显示不良抑制、低粘性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0424] The liquid crystal composition LC-1 shown below was prepared.

[0425] [chem 98]

[0426]

[0427] The physical property values of LC-1 are shown below.

[0428] [Table 2]

[0429] Tni

74.3

Δn

0.121

Δε

4.1

n

10.3

gamma 1

42

[0430] The initial VHR of the liquid crystal composition LC-1 was 99.2%, while the VHR after standing at a high temperature of 150° C. for 1 hour was 98.8%. When the solubility at low temperature was evaluated, it showed excellent performance as shown in the following table. In addition, a liquid crystal display device was produced by an ODF process using the liquid crystal composition LC-1, and burn-in, drop marks, and process suitability were studied using the above-mentioned method, and the results showed excellent results as shown below.

[0431] [table 3]

[0432] Screen burn evaluation

Embodiment 2

[0445] Liquid crystal composition LC-3 shown below was prepared.

[0446] [chemical 100]

[0447]

[0448] The physical property values of LC-3 are as follows.

[0449] [Table 6]

[0450] Tni

75.1

Δn

0.120

Δε

4.6

n

13

gamma 1

44

[0451] The initial VHR of the liquid crystal composition LC-3 was 99.4%, while the VHR after standing at a high temperature of 150° C. for 1 hour was 99.0%. When the solubility at low temperature was evaluated, it showed excellent performance as shown in the following table. In addition, a liquid crystal display element was fabricated by an ODF process using the liquid crystal composition LC-3, and burn-in, drop marks, and process suitability were studied using the above-mentioned method, and as a result, excellent results were shown as shown below.

[0452] [Table 7]

[0453] Screen burn evaluation

Embodiment 3~ Embodiment 4

[0466] Liquid crystal compositions LC-5 to LC-6 shown below were prepared, and their physical property values were measured. The results are shown in the table below.

[0467] [Table 10]

[0468]

[0469] The low-temperature solubility of the liquid crystal compositions LC-5 to LC-6 was good, and there was almost no change between the initial VHR and the VHR after standing at a high temperature of 150° C. for 1 hour. Furthermore, when the burn-in, drop marks, and process suitability of the liquid crystal display elements produced using the liquid crystal compositions LC-5 to LC-6 were examined, excellent results were shown as follows.

[0470] [Table 11]

[0471]

LC-5

LC-6

Initial VHR(%)

98.6

98.5

VHR(%) after 1 hour at 150℃

98.3

98.3

Screen burn evaluation

◎

◎

Drop mark evaluation

◎

◎

Process suitability evaluation

◎

◎

Solubility evaluation at low temperature

◎

◎ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com