Metamorphic mechanism type mechanical loading mechanism

A mechanical loading and racking technology, applied in mechanically driven excavators/dredgers, etc., can solve the problems of poor hydraulic system reliability, poor transmission stability, low mechanical efficiency, etc., to improve work efficiency, compact structure, and improve resistance Effects of Overload Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical scheme of the present invention will be further explained below with the accompanying drawings.

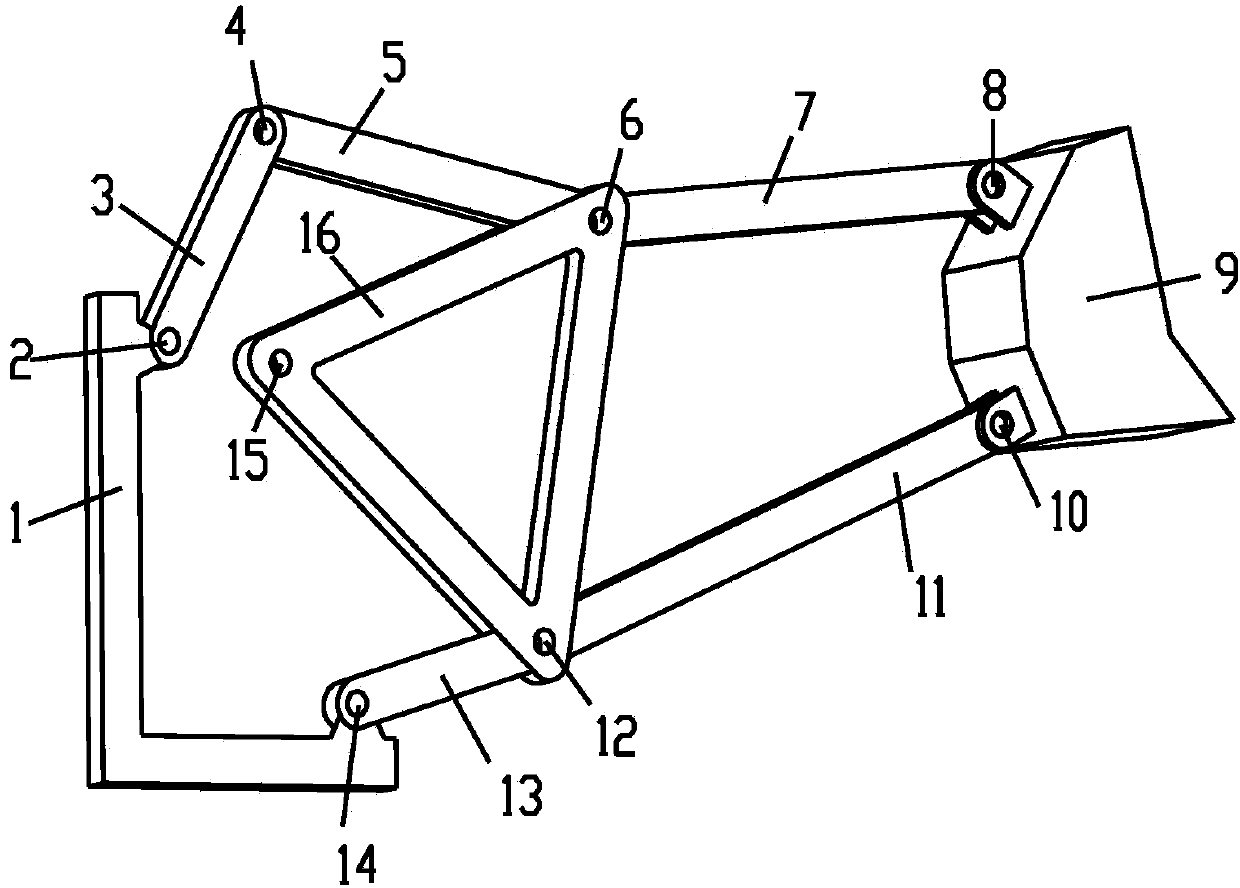

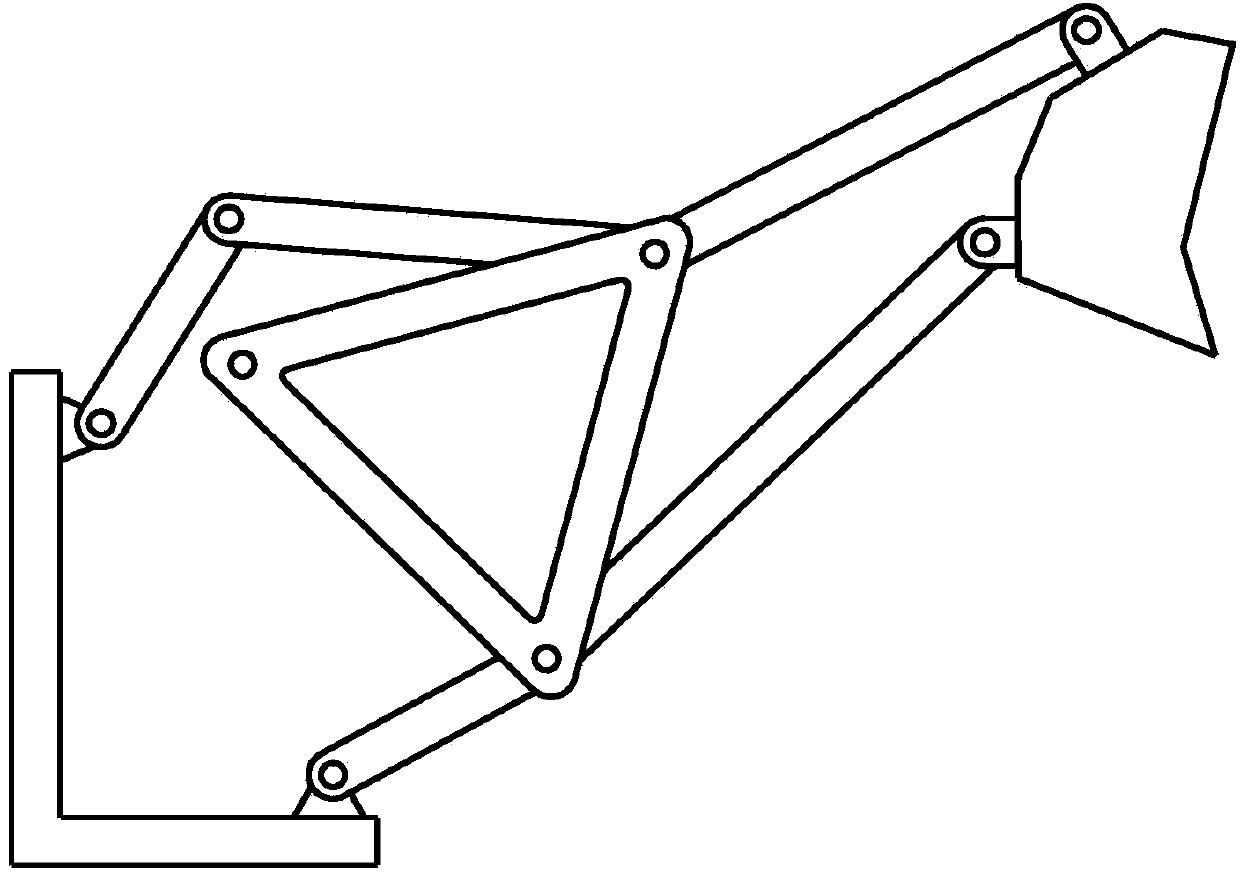

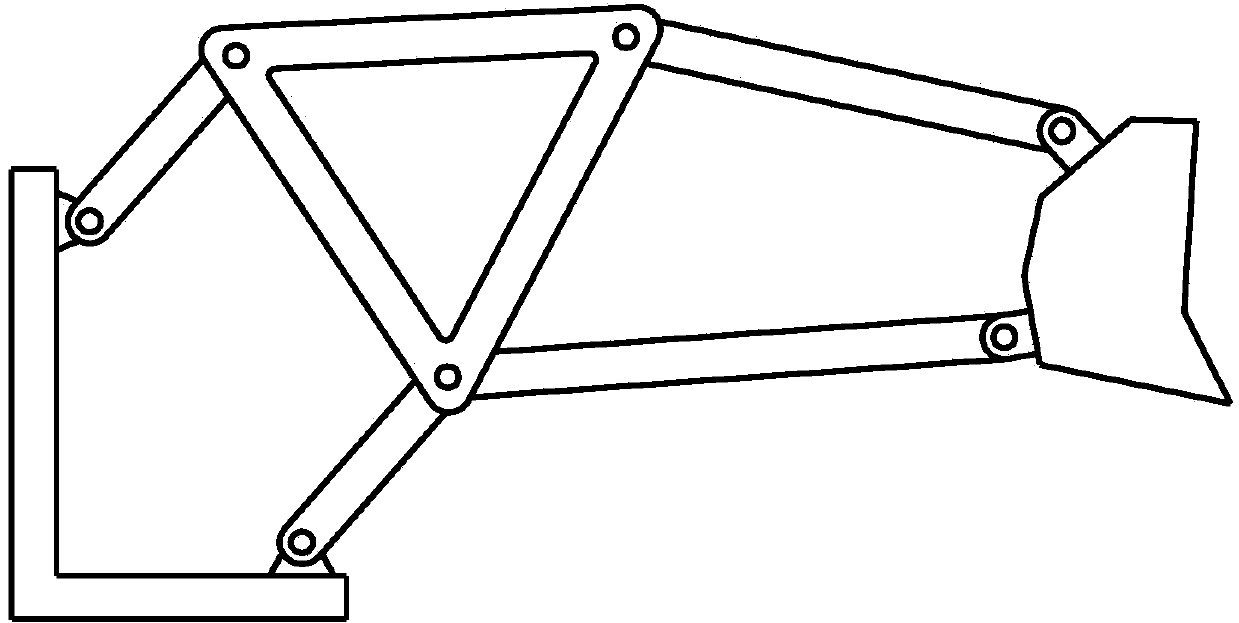

[0017] Control figure 1 , figure 2 , image 3 , A metamorphic mechanical loading mechanism, comprising a frame 1, a boom control branch chain, a bucket control branch chain and a bucket 9.

[0018] Control figure 1 The boom control branch chain includes a first active rod 3, a first connecting rod 5 and a second connecting rod 7. One end of the first active rod 3 is connected to the frame 1 through the first rotating pair 2, the other end is connected to the first connecting rod 5 through the third rotating pair 4, and the other end of the first connecting rod 5 is connected through the fourth rotating pair 6 It is connected to the second connecting rod 7, and the other end of the second connecting rod 7 is connected to the bucket 9 through the fifth rotating pair 8.

[0019] Control figure 1 , The bucket control branch chain includes a second active rod 13, a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com