How to form a test line

A test line and test pattern technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of small area, unable to make long test lines, etc., to achieve simple process, neat test pattern, easy to find. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

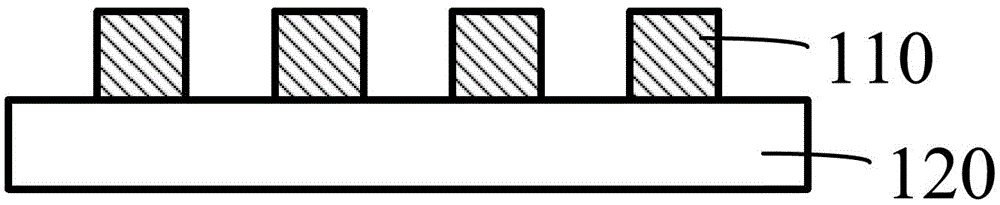

[0024] The manufacturing method of the existing test line is usually a photolithography process, and the corresponding test line is formed by steps such as exposure and development. Due to the influence of the resolution of the photolithography process, the line width of the test lines formed by the photolithography process is usually more than 400 angstroms, and the distance between two parallel test lines is more than 800 angstroms. Therefore, using the existing method to fabricate a test line has a low area utilization rate for the surface area of the wafer, and it is impossible to fabricate a test line with a large length in an area with a small area.

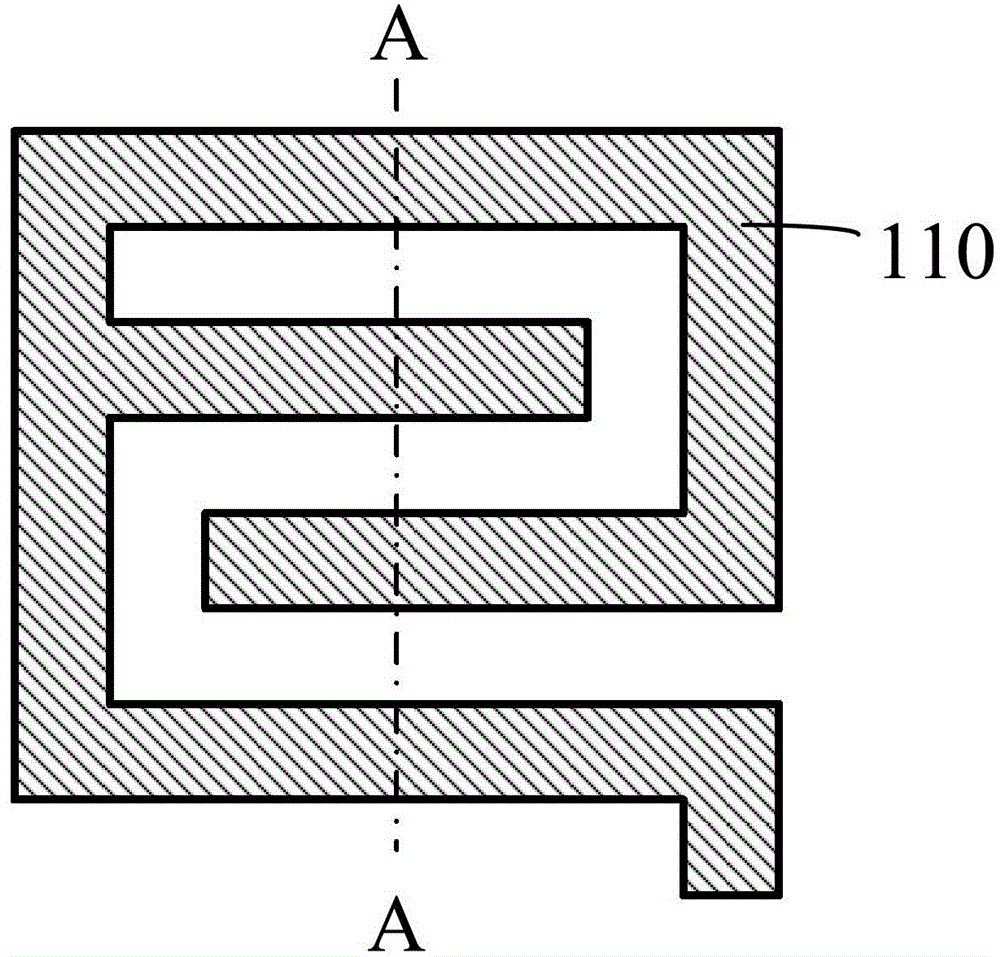

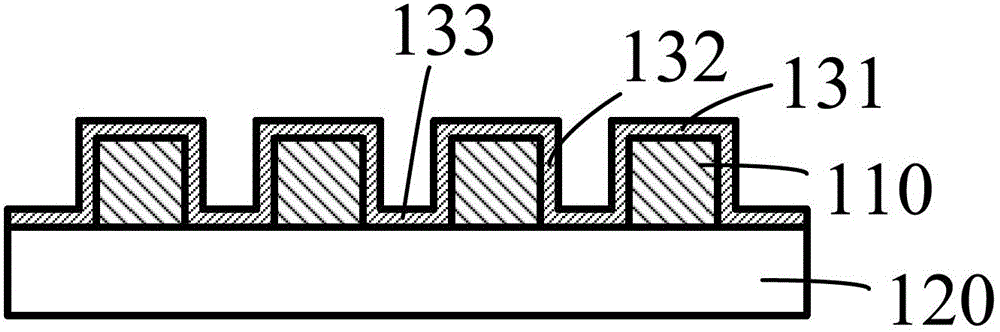

[0025] The present invention provides a method for manufacturing a test line, which comprises forming a first test pattern on a test material layer, then forming a first spacer on the sidewall of the test pattern, then removing the test pattern, and placing the first spacer on the sidewall of the test pattern. A notch is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com