Silica gel bottle cap

A technology of silica gel and bottle caps, applied in the field of bottle caps, can solve the problems of inconvenient use of bottle caps and unsatisfactory sealing effect, and achieve the effects of enhanced sealing effect, good elasticity and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

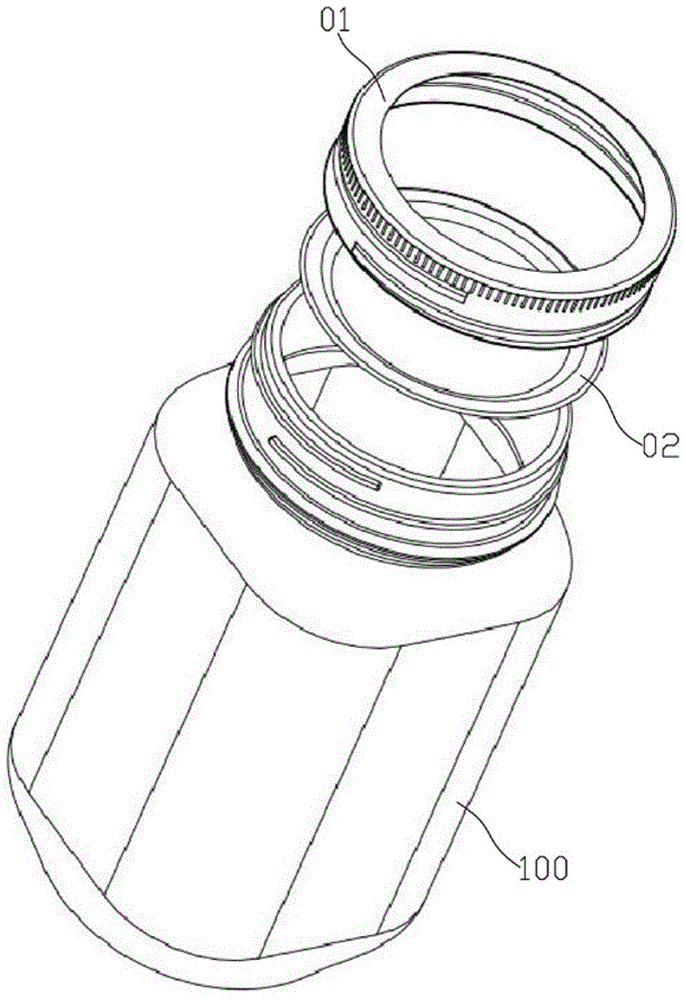

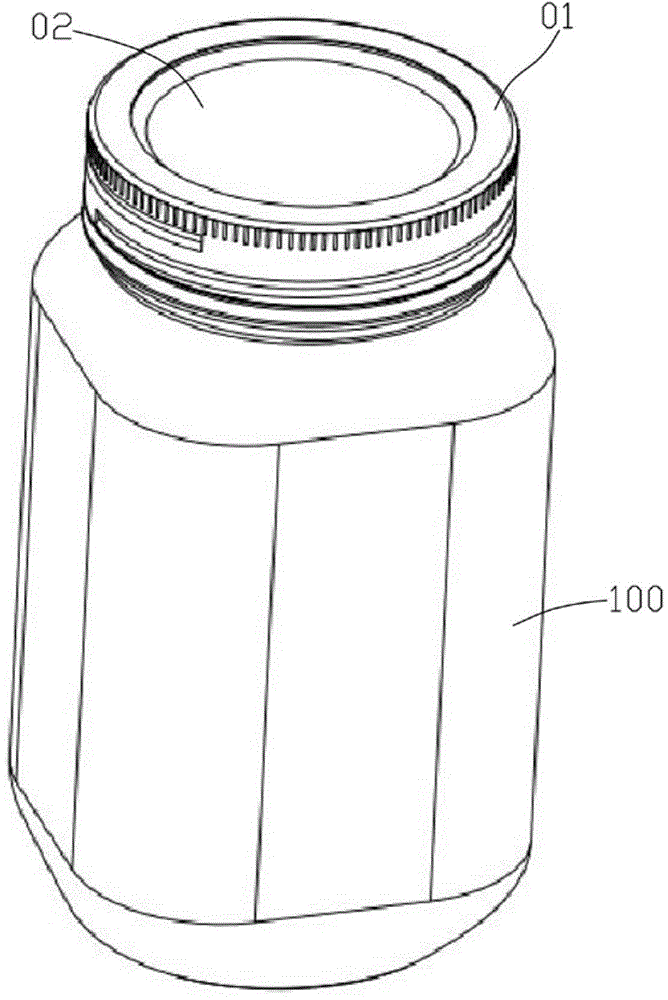

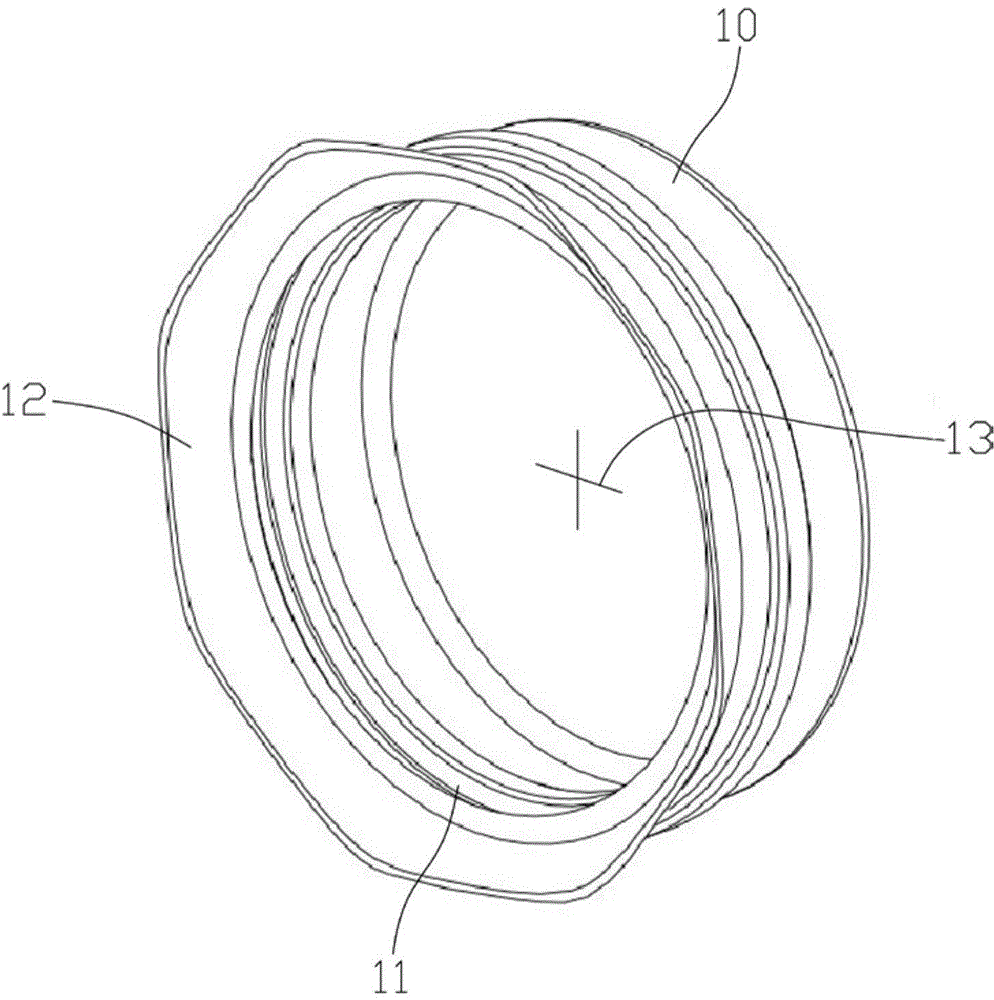

[0019] See Figure 3 to Figure 6 As shown: the silicone bottle cap of the present invention includes a cover body 10 made of silicone material. The cover body 10 is in the shape of a cylinder as a whole, and its lower end is formed with an outwardly folded skirt 12 in a flaring shape, so as to facilitate 10 sets of cover bodies. Close on the bottleneck of bottle 100. The skirt 12 is wave-shaped, and when the user takes off the bottle cap, he only needs to grasp the skirt 12 outwards and upwards, and the bottle cap can be easily removed from the bottle mouth of the bottle 100 .

[0020] More than two parallel ring-shaped sealing ribs 11 are formed on the inner side of the cap body 10 , and the sealing ribs 11 are engaged with the threads 101 on the outside of the bottle mouth of the bottle 100 . Due to the characteristics of the silicone material, the cap body 10 can tightly cover the mouth of the bottle, even if the bottle 100 is turned upside down and shaken vigorously, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com