Dismounting device for inverted vertical disc of copper pipe inverted vertical wire drawing machine

A coil pulling machine and inverted technology, which is applied in the field of copper tube inverted coil pulling machine inverted disc disassembly and assembly, can solve the problems of hidden safety hazards, labor and labor, etc., and achieve the effect of high safety and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A kind of copper tube upside-down type disc drawing machine inverted disc dismounting device of the patent of the present invention is described in detail below.

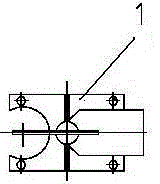

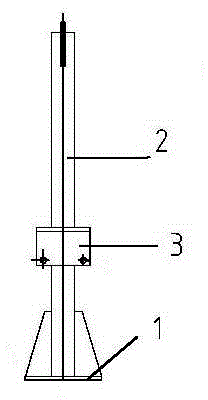

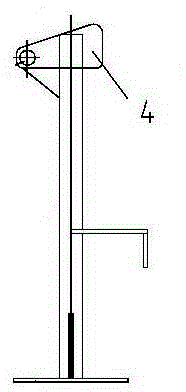

[0011] The patented copper pipe inverted disc pulling machine inverted disc dismantling device requires technical parameters: it includes a base 1, a pillar 2, a side reinforcement steel plate 3 and a top reinforcement pendant 4, and the base 1 is used for fixing On the coiling machine, the pillar 2 is welded to the base 1, the side reinforced steel plate 3 is welded to the middle and lower part of the bracket 2 to ensure stability, and the top reinforcement pendant 4 is installed on the top of the bracket 2 for Hoist the inverted disk of the inverted disk pulling machine.

[0012] When disassembling, first fix the base 1 and the side reinforcement plate 3 with M30*110mm hexagonal bolts, then hang the 3T chain hoist on the top reinforcement pendant 4, connect the large plate with a wire rope, and connect the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap