Air-cooled steel outer template

An external formwork and air-cooling technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of complex fixed connection of construction formwork, unfavorable popularity of air-cooled columns, and many formwork interfaces, etc., to achieve Perfect construction technology, convenient installation and fixation, avoiding the effect of multiple interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are further elaborated below in conjunction with accompanying drawings:

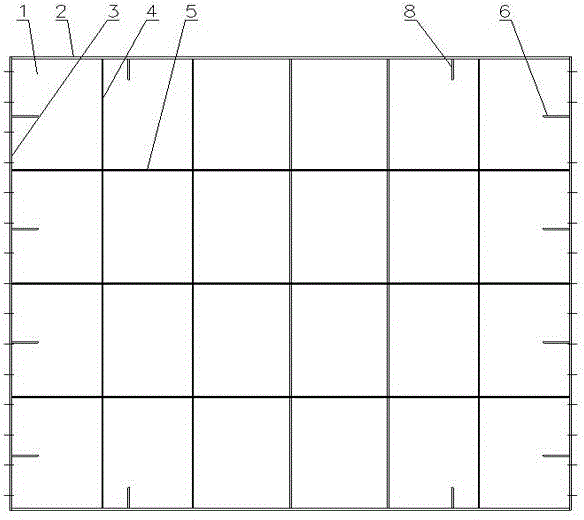

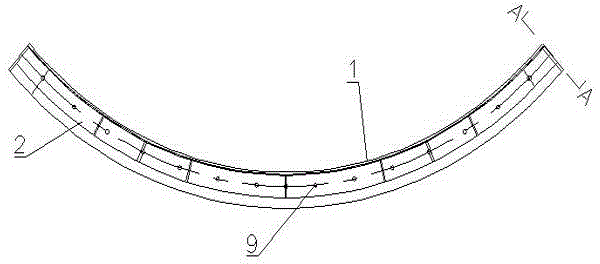

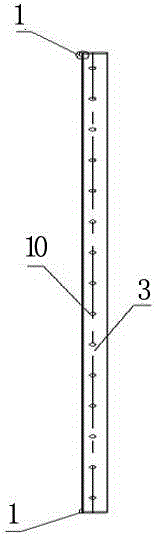

[0015] 1 in the figure is an air-cooled steel outer formwork, including a number of arc-shaped flange holes 9 and straight flanges 3 uniformly opened in the arc-shaped flange 2 along its length direction, and several vertical flanges 3 are evenly arranged along its vertical direction. to the flange hole 10; the arc flange 2 and the straight flange 3 are respectively welded on the arc steel panel 1, the vertical rib 4 and the arc rib 5 are respectively welded on the outside of the arc steel panel 1, and the triangular rib 6 is welded on the arc At the corner of the shaped steel panel 1 and the vertical rib 4, the upper panel 7 is welded on the inner side of the arc-shaped steel panel 1, and is flush with the upper and lower horizontal lines, and the lifting lug is welded at the corner of the arc-shaped steel panel 1 and the arc-shaped flange 2 .

[0016] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com