Semiconductor epitaxial equipment and base assembly thereof

A semiconductor and susceptor technology, applied in the field of semiconductor epitaxy equipment, can solve the problems affecting the uniformity of the semiconductor epitaxial layer and the severe jitter of the rotating device, and achieve the effect of improving the accuracy and improving the process effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

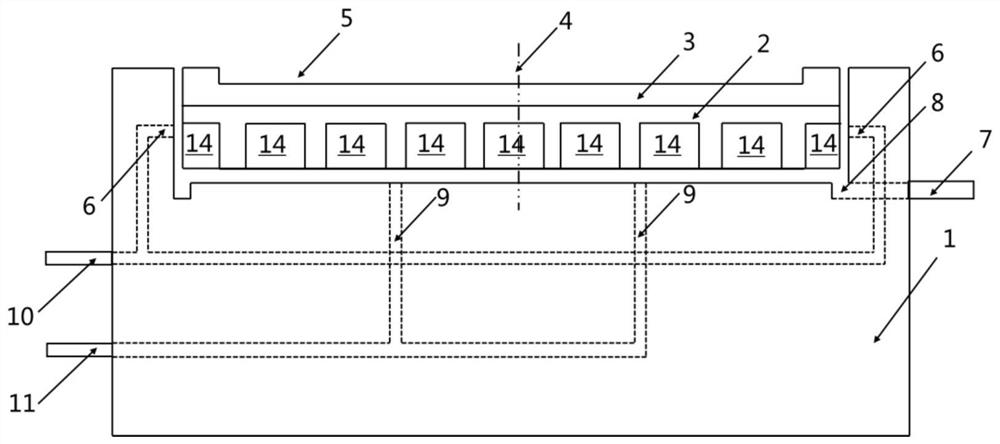

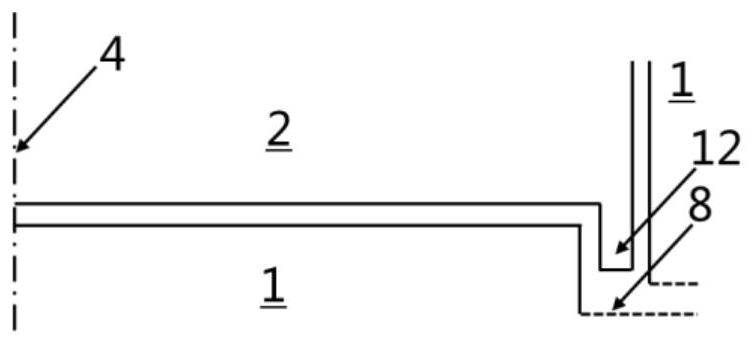

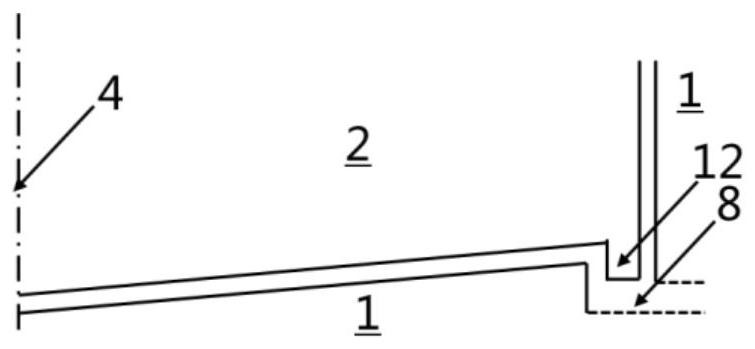

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0042] In the prior art, a rotating device for semiconductor epitaxy usually includes a fixed base and a support for placing a tray, a rotating groove is formed in the fixed base, and the supporting member is disposed in the rotating groove. An air passage is also provided inside the fixed base, the opening of the air passage is located at the bottom of the rotating tank, and the air passage is used to spray air into the gap between the bottom of the support member and the bottom of the rotating tank. The airflow flows through the channel at the bottom of the support member that is inclined relative to the radial direction, thereby applying a circumferential dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com