A kind of ultra-low bath ratio polyester cheese fiber dyeing method

A dyeing method and package yarn technology, applied in the textile field, can solve the problems of high cost, pollution, high energy consumption, and large liquor ratio, and achieve the effects of low water consumption, increased exchange times, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

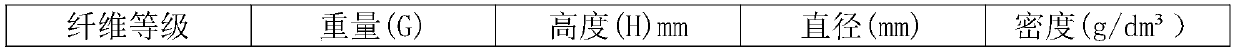

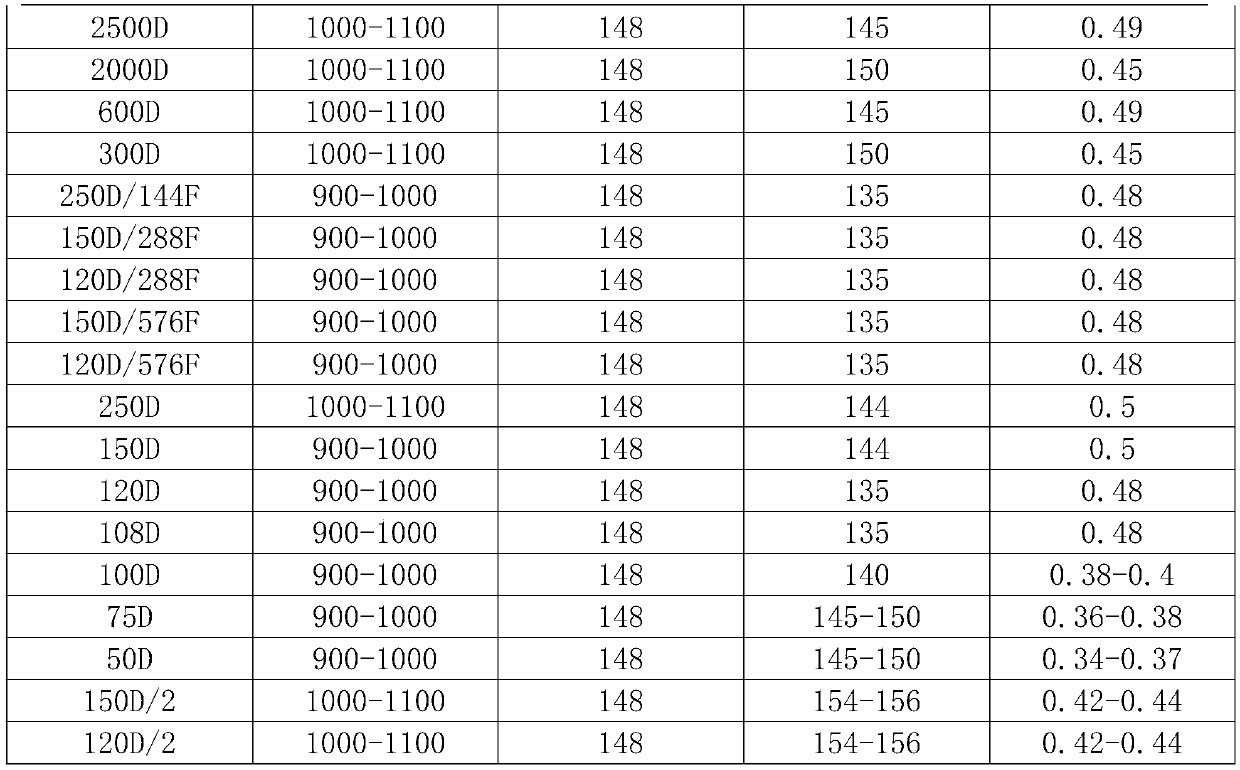

Method used

Image

Examples

Embodiment 1

[0035] A kind of ultra-low liquor ratio polyester cheese fiber dyeing method, comprises pretreatment, dyeing and aftertreatment, and bath ratio is 1:2.5, it is characterized in that, pretreatment comprises the following steps:

[0036] a. Change and screening, adding auxiliary agents, said auxiliary agents include penetrating agent, soft water dispersant and glacial acetic acid, directly added or all added in a one-time cycle;

[0037] b. Control the winding density of the polyester fiber package yarn at 0.30g / dm 3 Between, to meet the high sealing requirements in the cyclic dyeing process, the dyeing pressure difference is not less than 1.0bar;

[0038] c. Raise the temperature to 80°C at 0 speed, and drain water after running for 10 minutes;

[0039] d. After the drainage is completed, add high-temperature leveling agent, repair agent and glacial acetic acid; the pH value is controlled at 3.5;

[0040] Preferably, the additives are added in an amount of 0.5 g / L penetrating...

Embodiment 2

[0045] A kind of ultra-low bath ratio polyester cheese fiber dyeing method, comprises pretreatment, dyeing and aftertreatment, bath ratio is 1:2.8, it is characterized in that, pretreatment comprises the following steps:

[0046] a. Change and screening, adding auxiliary agents, said auxiliary agents include penetrating agent, soft water dispersant and glacial acetic acid, directly added or all added in a one-time cycle;

[0047] b. Control the winding density of polyester fiber cheese to 0.4g / dm 3 Between, to meet the high sealing requirements in the cyclic dyeing process, the dyeing pressure difference is not less than 1.0bar;

[0048] c. Heat up to 90°C at 0 speed, run for 20 minutes and then drain;

[0049] d. After the drainage is completed, add high-temperature leveling agent, repair agent and glacial acetic acid; the pH value is controlled at 4.5.

[0050] Preferably, the additives are added in an amount of 1.3 g / L of penetrant, 1.3 g / L of soft water dispersant, and 1...

Embodiment 3

[0055] A kind of ultra-low bath ratio polyester cheese fiber dyeing method, comprises pretreatment, dyeing and aftertreatment, and bath ratio is 1:2.5-3, it is characterized in that, pretreatment comprises the following steps:

[0056] a. Change and screening, adding auxiliary agents, said auxiliary agents include penetrating agent, soft water dispersant and glacial acetic acid, directly added or all added in a one-time cycle;

[0057] b. Control the winding density of polyester fiber package yarn at 0.53g / dm 3 Between, to meet the high sealing requirements in the cyclic dyeing process, the dyeing pressure difference is not less than 1.0bar;

[0058] c. Raise the temperature to 100°C at 0 speed, and drain water after running for 30 minutes;

[0059] d. After the drainage is completed, add high-temperature leveling agent, repair agent and glacial acetic acid; the pH value is controlled at 5.5;

[0060] Preferably, the additives are added in an amount of penetrant 2g / L, soft wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com