Ultralow bath ratio beam dyeing method

A warp dyeing, ultra-low bath technology, applied in dyeing, textiles and papermaking, fiber treatment, etc., can solve the problems of high energy consumption, high cost, large bath ratio, etc., and achieve high gross efficiency, high product yield, The effect of preventing flower staining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with embodiment, the specific embodiment provided according to the present invention is described in detail as follows:

[0054] The ultra-low bath ratio warp beam dyeing method of the present invention embodies the characteristics of short process and low energy consumption, effectively uses the advantages of the dyeing process to solve the oil removal and refining in the yarn dyeing process, meets the requirements of whiteness, strength, and wool. Efficiency requirements, to meet the quality requirements of dyed cloth.

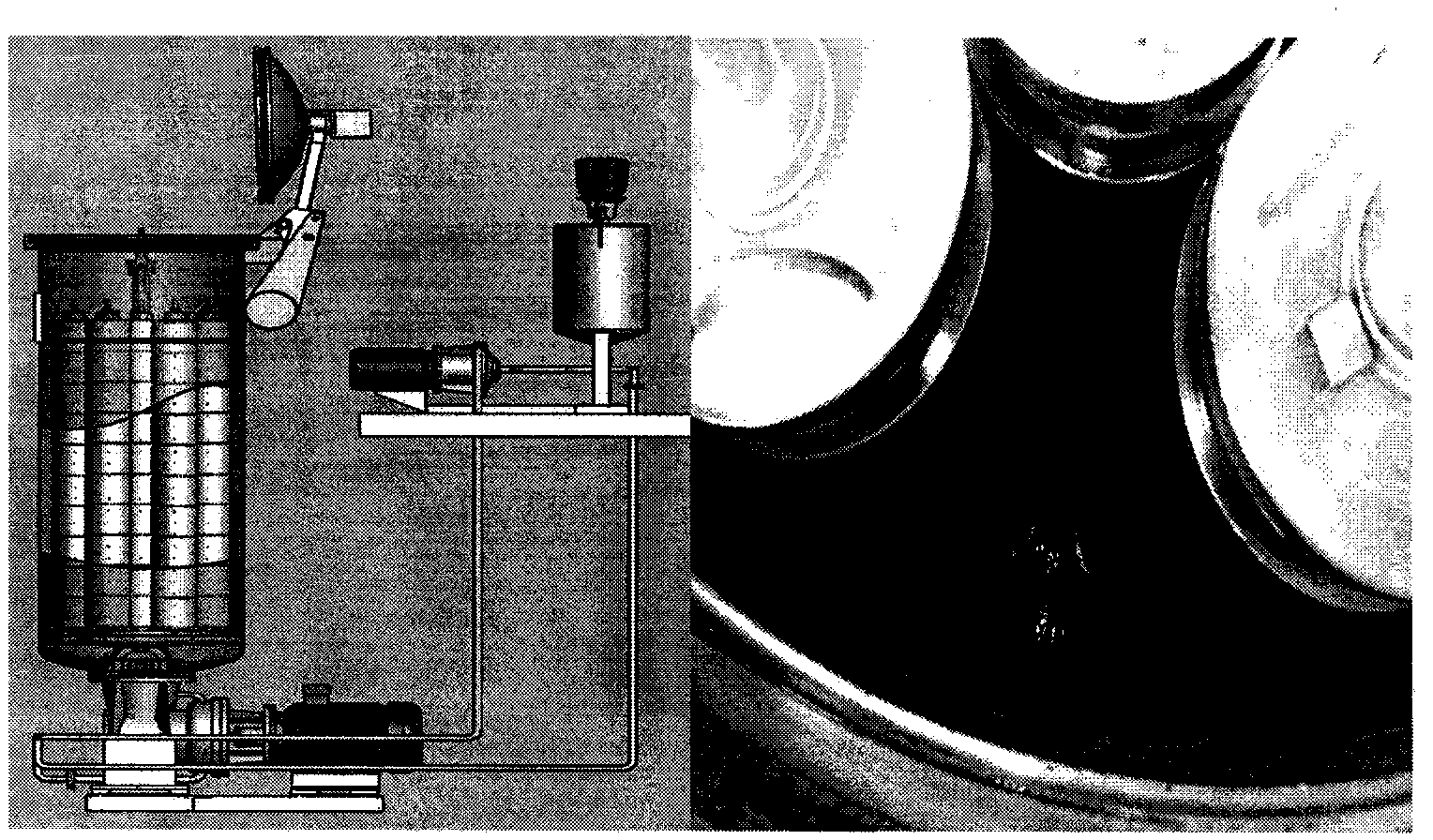

[0055] One, operation steps: a kind of ultra-low liquor ratio warp beam dyeing method, comprises pretreatment, dyeing and aftertreatment, liquor ratio is 1: 4-6, and its pretreatment comprises the following steps:

[0056] (1) Add auxiliary agent, described auxiliary agent comprises refining enzyme, degassing agent and dispersant;

[0057] (2) Add auxiliary agent 27.5-50% hydrogen peroxide;

[0058] (3) Raise the temperature to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com