Pressure pump for automatically rising still water to lift height

An automatic lifting and pressure pump technology, applied in the field of piston pressure pumps, can solve the problems of time-consuming, high cost of pumping water, waste of resources, etc., and achieve the effects of convenient construction, labor-saving construction, convenient and flexible maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

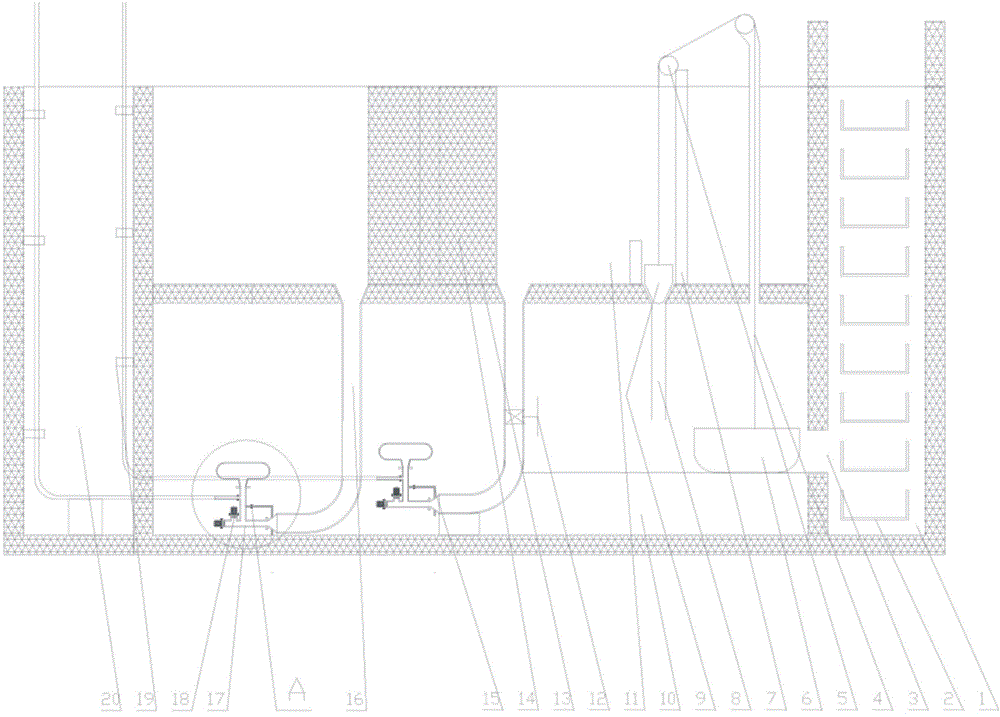

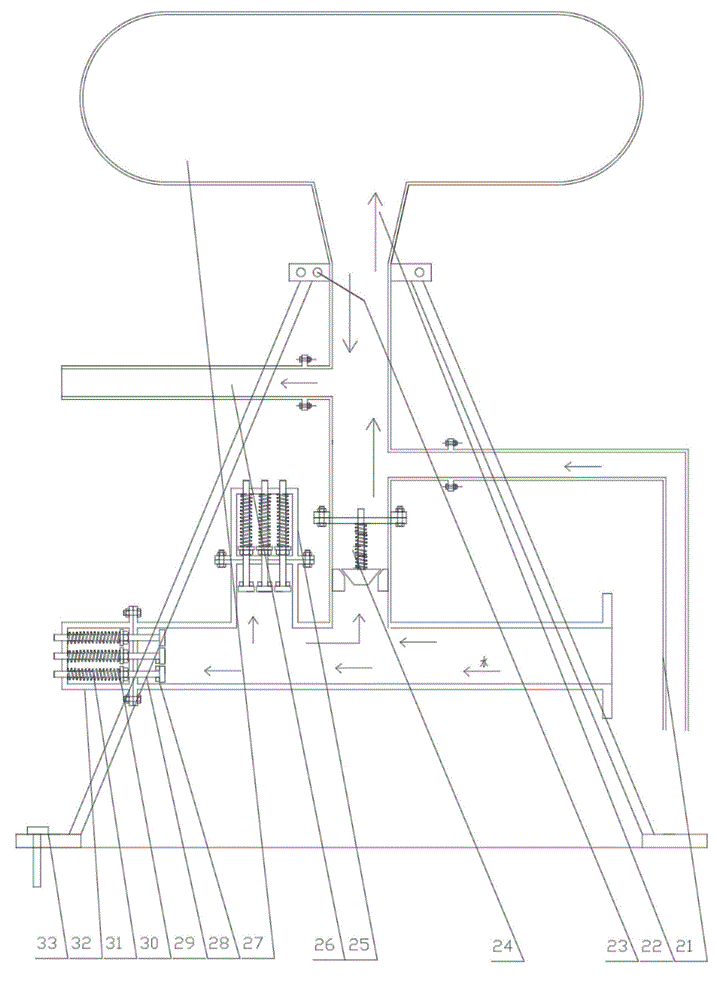

[0010] figure 1 Shown: The still water automatically rises to the pressure pump with a high lift. First, dig a pit by the reservoir or the river, install the surrounding columns connected by multi-layer metal scissors, and the wall sealed by the plate, and the upper and lower reservoirs welded and sealed by the plastic plate. On the right side of the upper and lower reservoirs, there is a passage well (1) connected from the bottom to the highest flood level. The inner wall of the passage well (1) is equidistantly connected with several ∩-shaped steel ladders (2), and the bottom end is provided with a doorway (3 ), the left side is provided with a rectangular channel (20) connecting the installation pipeline, and the bottom of the upper reservoir (11) is 1-2 meters lower than the lowest water level in the reservoir or river, and the side of the upper reservoir (11) close to the water source is then provided with a vertical Rectangular water inlet tank (14), the wall front end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com