System for detecting partial discharge direction of compound eye type optical fiber EFPI

A direction detection and partial discharge technology, applied in the direction of testing dielectric strength, etc., can solve the problems of low sensitivity of the Michelson method detection system, unsuitable for high-frequency and fast partial discharge detection, and insufficient demodulation frequency response. The effect of strong interference ability, good directionality and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

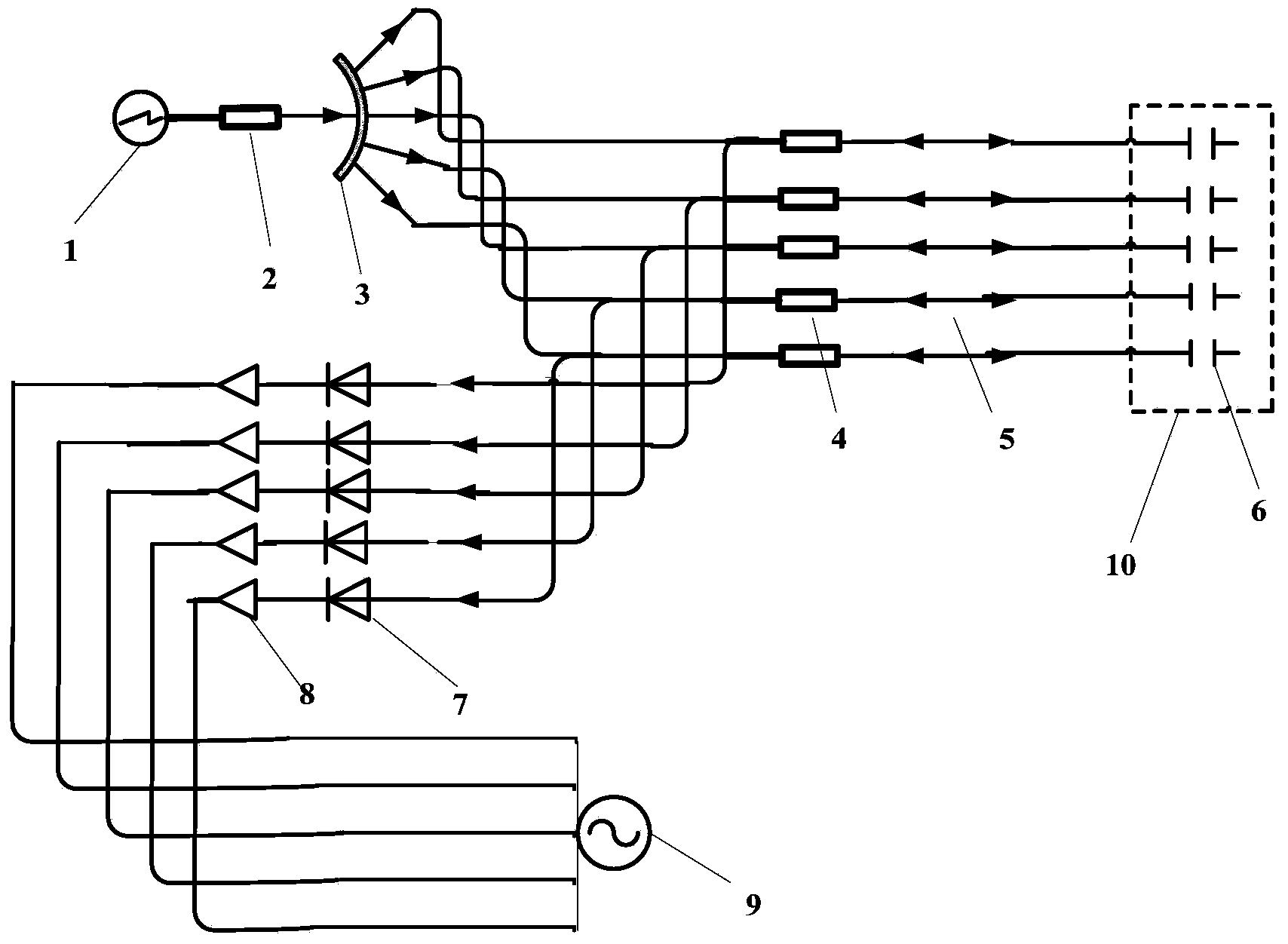

[0033] figure 1 It is a schematic diagram of the structure of the compound-eye optical fiber EFPI partial discharge direction detection system. Such as figure 1 As shown, taking a monochromatic light source with a wavelength of 1310nm as an example, a compound-eye optical fiber EFPI partial discharge direction detection system, the system structure is:

[0034] 1) A monochromatic light source with a wavelength of 1310nm is obtained by filtering the narrowband light source 1 through an optical fiber filter to obtain a monochromatic wavelength light source. The narrow-band light source 1 is an SLED light source, and the filter is a 1310nm optical fiber band-pass filter.

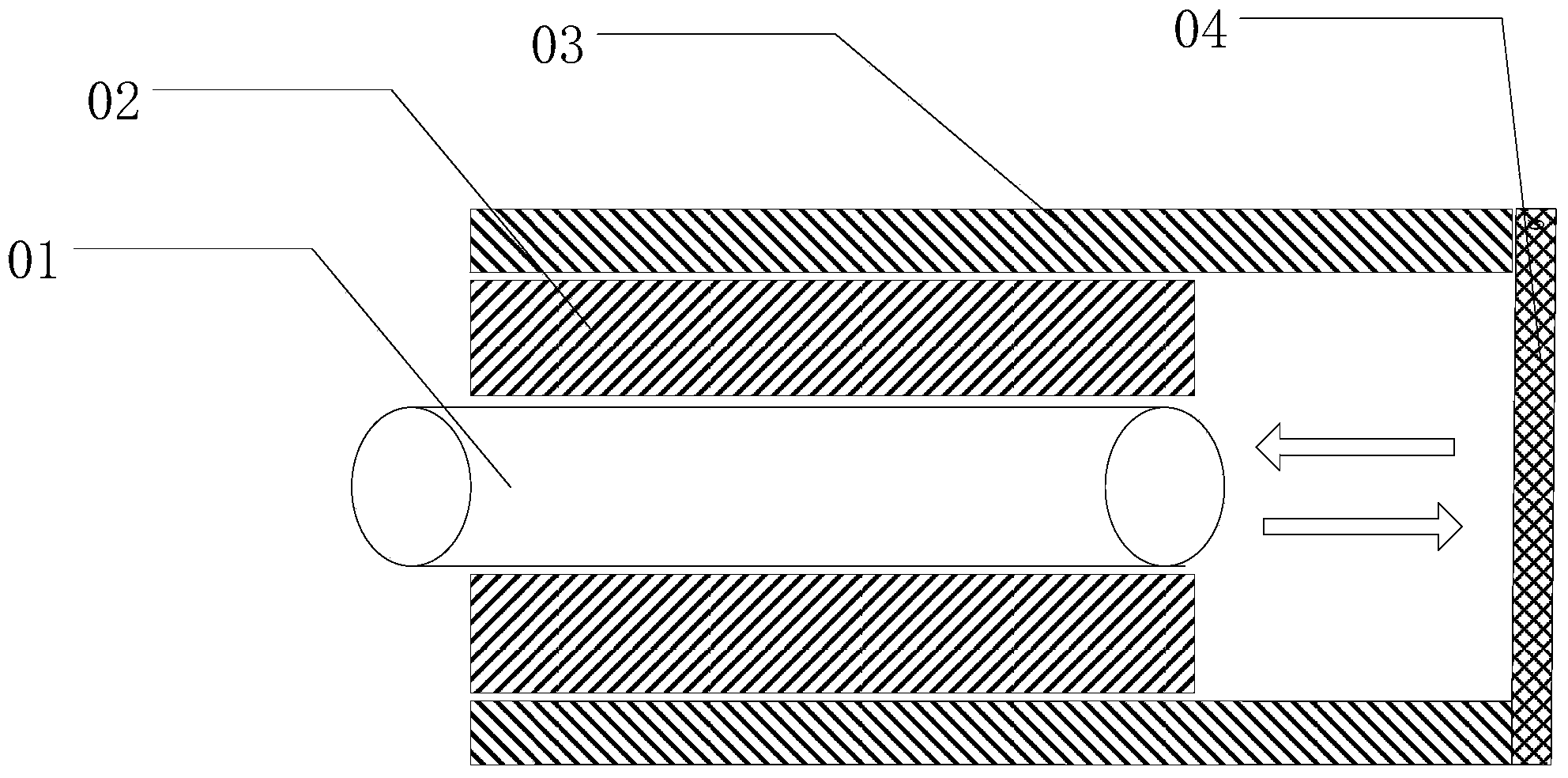

[0035] 2) The optical fiber is a 1310nm single-mode optical fiber, the diameter of the central glass core is 9um, and the outer diameter of the cladding is 125um. After testing, it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap