Device for monitoring temperature of oil tank by FBG (Fiber Bragg Grating)

A fiber grating and oil tank technology, applied in measuring devices, thermometers, thermometers with physical/chemical changes, etc., can solve the problems of complex equipment and low sensitivity, and achieve the effects of increasing reliability, reducing costs, and measuring quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

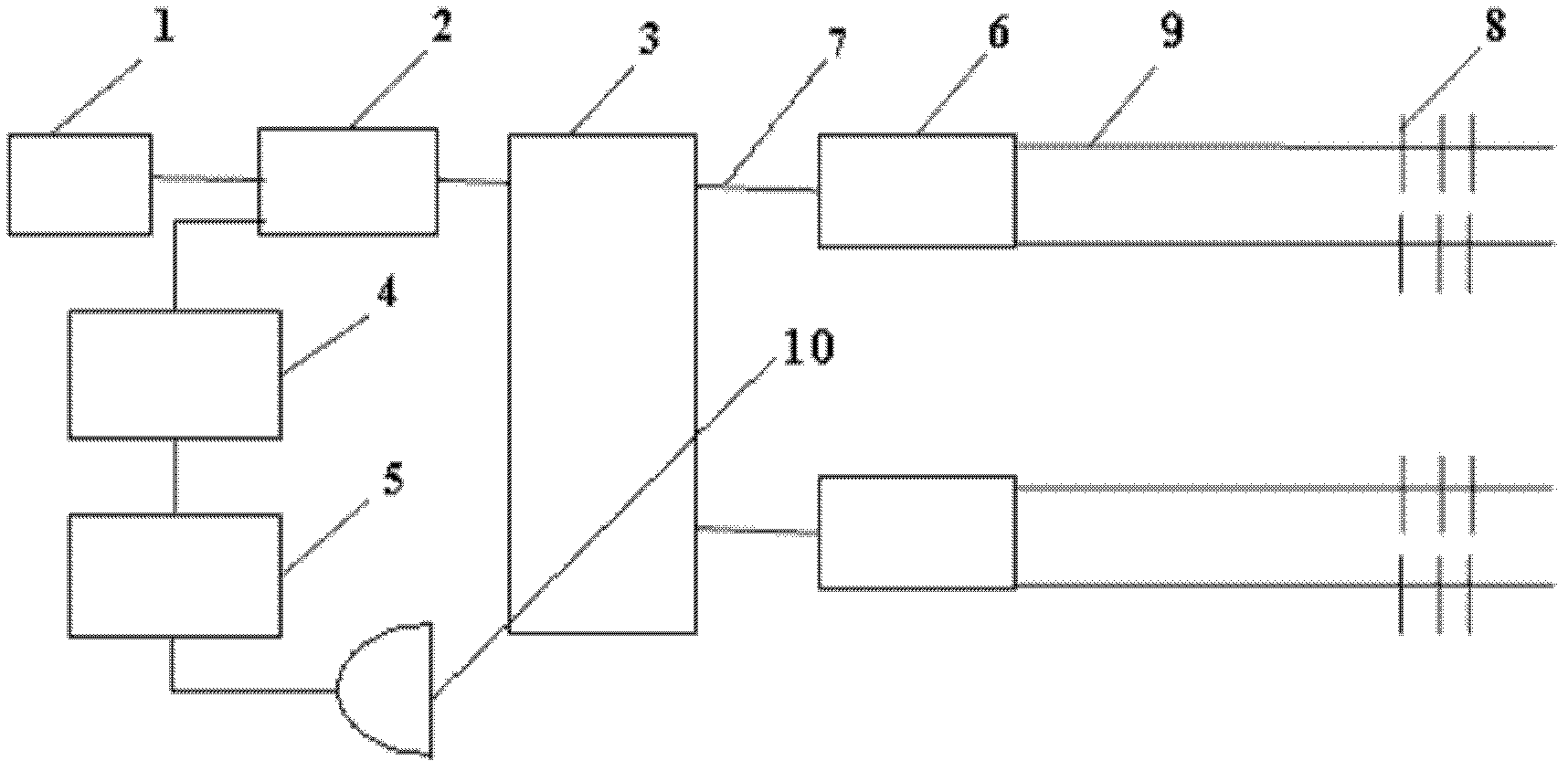

[0036] Embodiment 1 of the present invention such as figure 1 As shown, a device for monitoring the temperature of an oil tank with an optical fiber grating includes an ASE light source 1, a 3db coupler 2, an optical switch 3, a spectrum demodulator 4, a computer 5, a splitter 6, and an optical fiber grating 8. The feature is that the ASE light source 1 is connected to the input end of the 3db coupler 2 through an optical fiber, the output end of the 3db coupler 2 is connected to the optical switch 3 by an optical fiber, and the output end of the optical switch 3 is connected to the 6-phase splitter through an optical cable. connection, the output end of the splitter 6 is connected to the multi-channel fiber grating 8 through the optical cable 7; the other output end of the 3db coupler 2 is connected to the spectrum demodulator 4 by an optical fiber, the spectrum demodulator 4 and the computer 5 Connected; computer 5 and alarm 10 are connected.

[0037] The fiber grating 8 is...

Embodiment 2

[0040] Same as embodiment 1, except that the number of optical fiber gratings is 64, and each oil tank is provided with 4 optical fiber grating monitoring points, and 16 oil tanks are monitored simultaneously by switching the optical switch 3 .

Embodiment 3

[0042] The method for using the above-mentioned device to monitor temperature, the steps are as follows:

[0043] 1. Temperature calibration of fiber grating

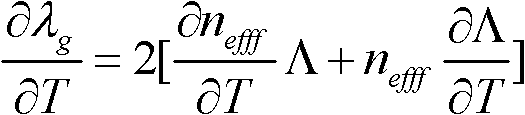

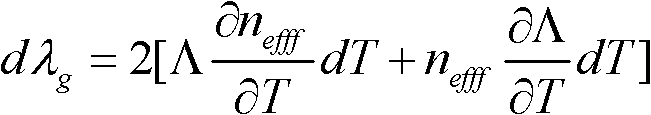

[0044] Connect the device well, place the fiber grating for temperature measurement in the constant temperature device, change the temperature in the constant temperature device, and use the temperature characteristic curve T of the fiber grating 0 -λ 0 Measure and determine the one-to-one correspondence between the central wavelength of the fiber grating and the temperature, and record it by the computer; determine the drift range of the central wavelength of the fiber grating according to the safe oil temperature value of the oil tank, and set the safe oil temperature as T min -T max , corresponding to the central wavelength of the fiber grating is λ min -λ max Repeat the above-mentioned calibration process for each fiber grating for temperature measurement, and complete the temperature calibration of the fiber gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com