Method for producing ultrathin quartz crystal phase retardation plate

A technology of phase retardation plates and quartz crystals, applied in stone processing equipment, surface polishing machine tools, fine working devices, etc., can solve problems such as unstable product quality, affecting industrial development, and low yield, and achieve anti-light damage High threshold, attractive market prospects, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

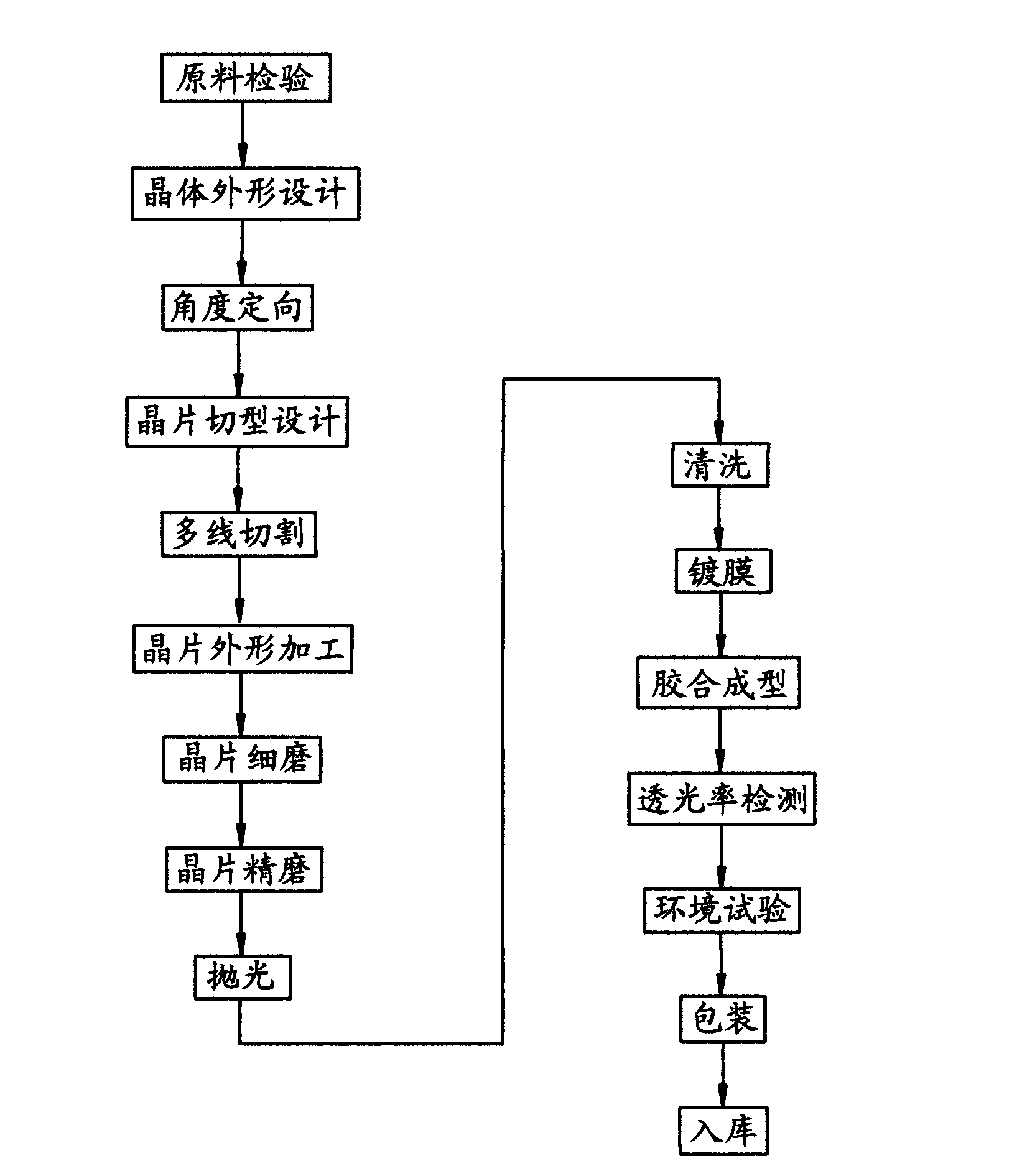

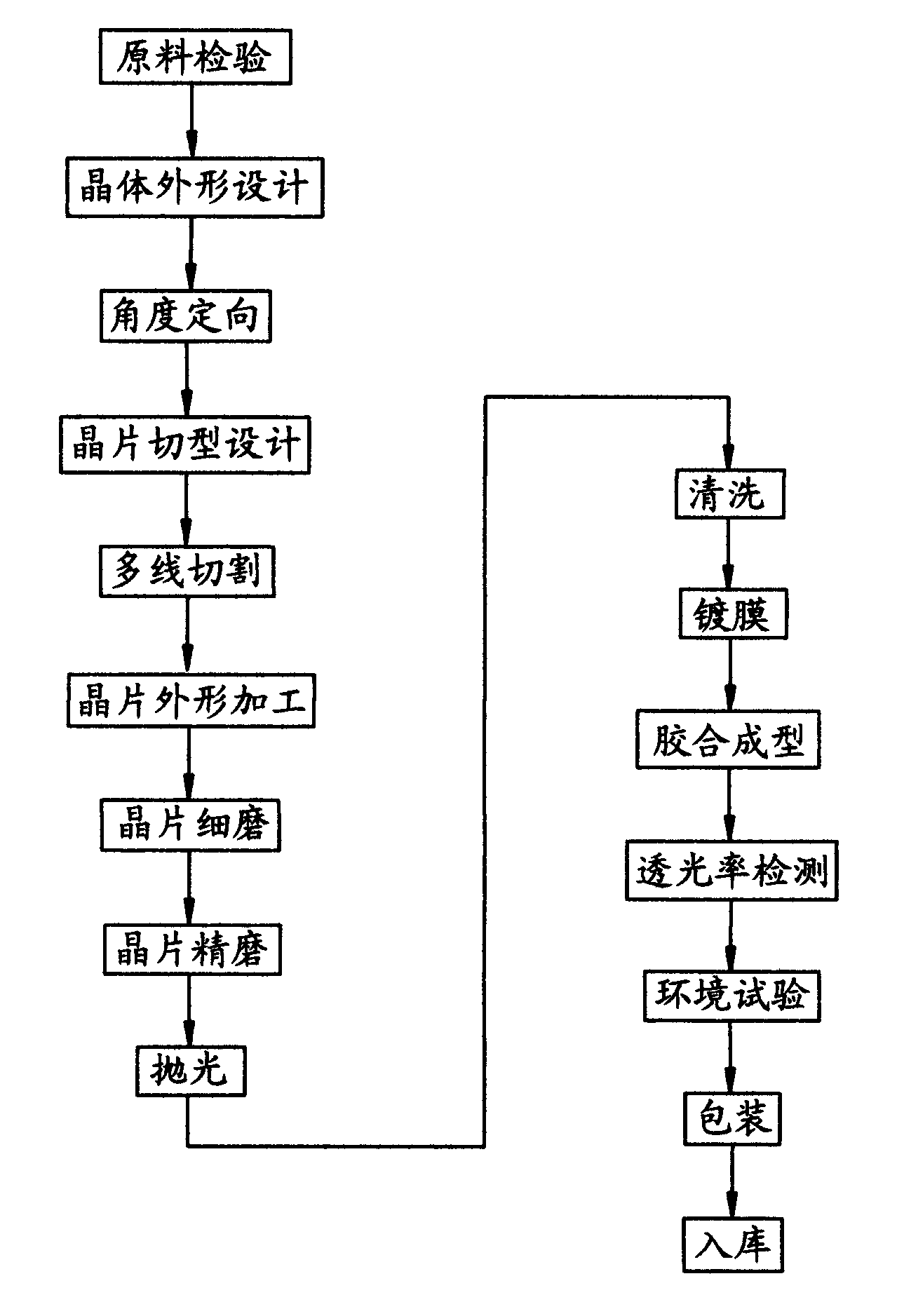

[0018] Such as figure 1 As shown, the production method of the ultra-thin quartz crystal phase retardation plate in this embodiment sequentially includes raw material inspection, crystal shape design, angle orientation, wafer cutting design, multi-wire cutting, wafer shape processing, wafer fine grinding, wafer fine grinding, Polishing, cleaning, coating, gluing, light transmittance detection, environmental testing, packaging, and warehousing processes; in the polishing process, the wafer to be polished is first glued to the substrate, and then the polishing operation is performed; in the cleaning process , the substrate is first separated from the wafer, and then the wafer is cleaned.

[0019] Among them, the standard indicators for raw material inspection are: Z-axis direction size: 30-50 mm; inclusion number: Ia standard; corrosion tunnel density in the crystal seed: 2 ;Q value: ≥2.6*10 6 ; Optical uniformity: Δn≤5*10 -6 .

[0020] In the above-mentioned polishing proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com