Piezoelectric transformer for outputting voltages based on stress change

A piezoelectric transformer and output voltage technology, applied in the field of piezoelectric transformers, can solve the problems of easy damage, difficult polarization, high process requirements such as the combination of layers and layers, achieve high power output, and simplify the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] Embodiment 1

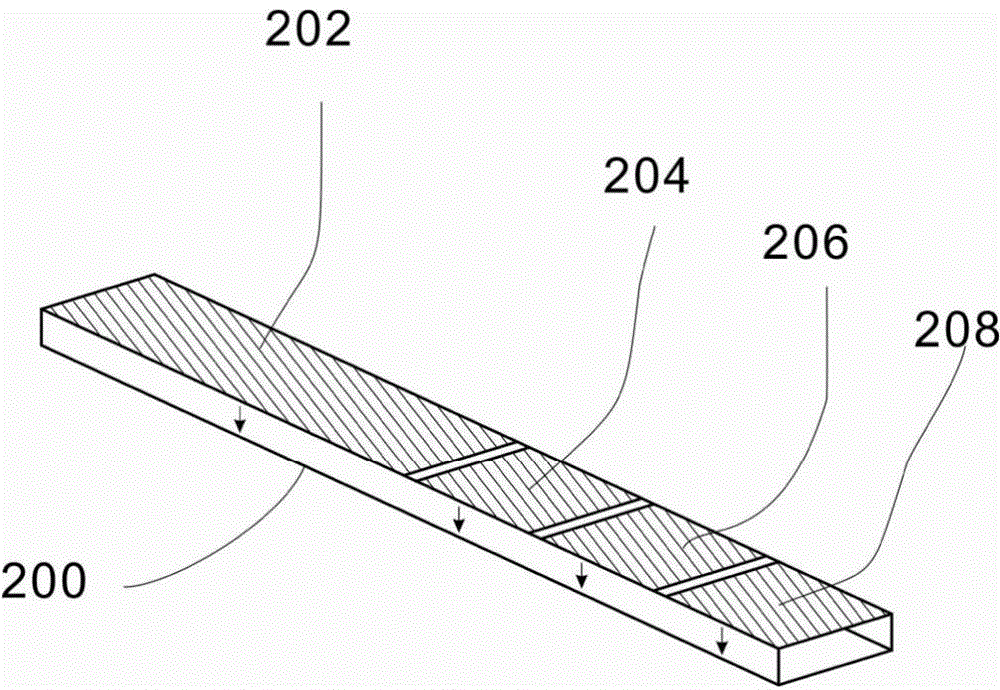

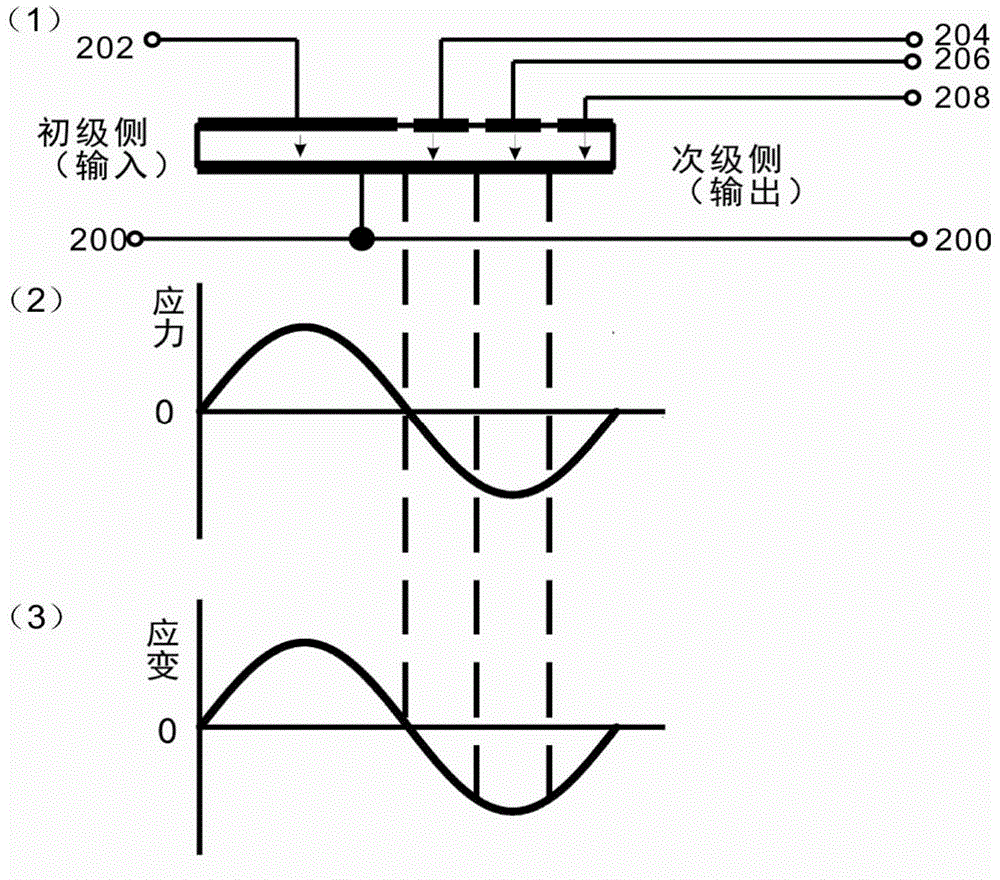

[0041] figure 1 The isometric view of the piezoelectric transformer of the full-wavelength vibration model in Embodiment 1 of the present invention, figure 2 (1) Yes figure 1 Side view of the piezoelectric transformer shown. in figure 1 with figure 2 In (1), two main surfaces perpendicular to the thickness direction of the rectangular piezoelectric plate are plated with electrodes. Of these two main surfaces, the electrode 202 on one main surface and the other main surface electrode 200 form the primary side (input end) electrode, and the main surface electrodes 204, 206, 208 and the electrode 200 can form the secondary side (output end) respectively. ) Three sub-electrodes of the electrode. The interval between the electrodes 202 and 204 (that is, the boundary point between the primary measuring electrode and the secondary side electrode) is selected at the center of the rectangular plate where the stress direction changes positively and negatively (that...

Example Embodiment

[0045] Embodiment 2

[0046] Figure 5 It is an axonometric view of the piezoelectric transformer of the full-wavelength vibration model in Embodiment 2 of the present invention, Image 6 (1) Yes Figure 5 Side view of the piezoelectric transformer shown. in Figure 5 with Image 6 In (1), a primary side (input side) electrode composed of multiple electrodes and a secondary side (output side) electrode composed of multiple electrodes are formed along the length direction and thickness direction of the rectangular plate of the piezoelectric transformer. This is a laminated structure in which a piezoelectric body layer made of piezoelectric materials such as piezoelectric ceramics and an internal electrode layer made of metal materials are stacked on each other in the thickness direction of a rectangular plate.

[0047] Image 6 In (1), there are five piezoelectric body layers and four electrode layers between the electrodes formed opposite to the two main surfaces perpendicular to t...

Example Embodiment

[0051] Embodiment 3

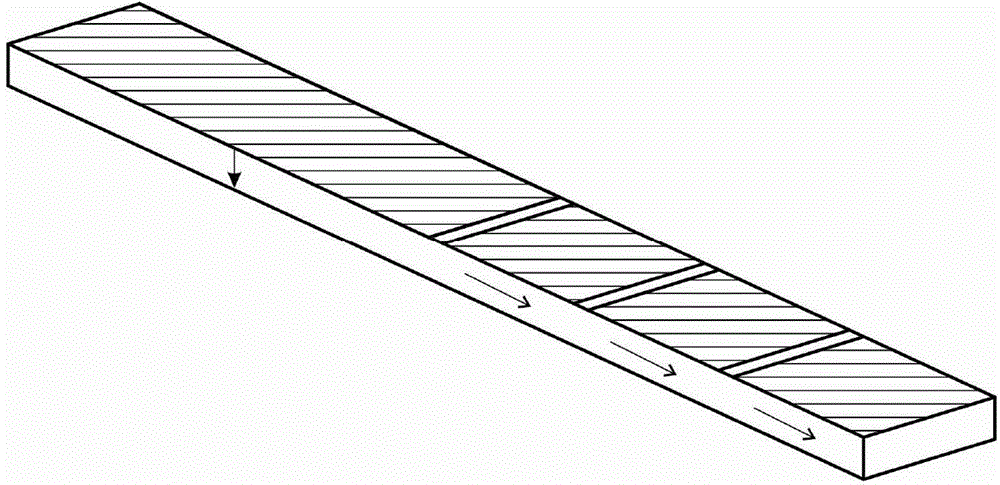

[0052] Figure 7 The isometric view of the piezoelectric transformer of the full-wavelength vibration model in the third embodiment of the present invention, Figure 8 (1) Yes Figure 7 Side view of the piezoelectric transformer shown. in Figure 7 with Figure 8 In (1), a secondary side (output side) electrode composed of a plurality of electrodes is formed along the length direction and the thickness direction of the rectangular plate of the piezoelectric transformer. This is a laminated structure in which a piezoelectric body layer made of piezoelectric materials such as piezoelectric ceramics and an internal electrode layer made of metal materials are stacked on each other in the thickness direction of a rectangular plate.

[0053] Figure 8 In (1), there are five piezoelectric body layers and four electrode layers between the primary side electrodes formed on two main surfaces perpendicular to the thickness direction of the rectangular plate. Electrodes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com