Vacuum cleaner

A vacuum cleaner and dust collection technology, which is applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of inconvenient transportation and storage, occupying a large space, etc., and achieve the effects of convenient transportation and storage, large dust collection capacity, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

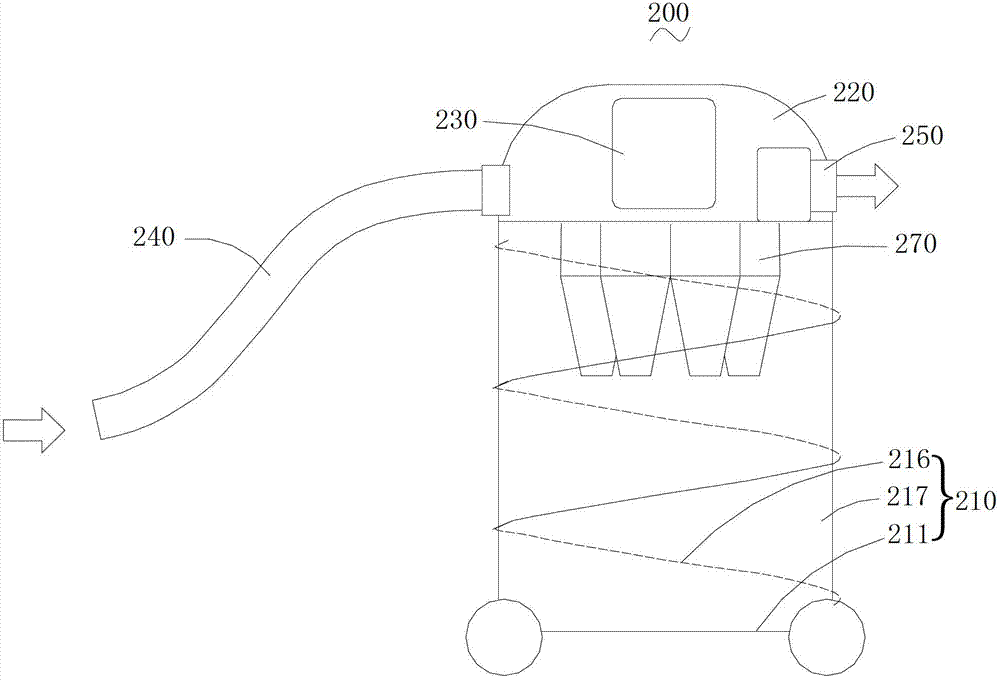

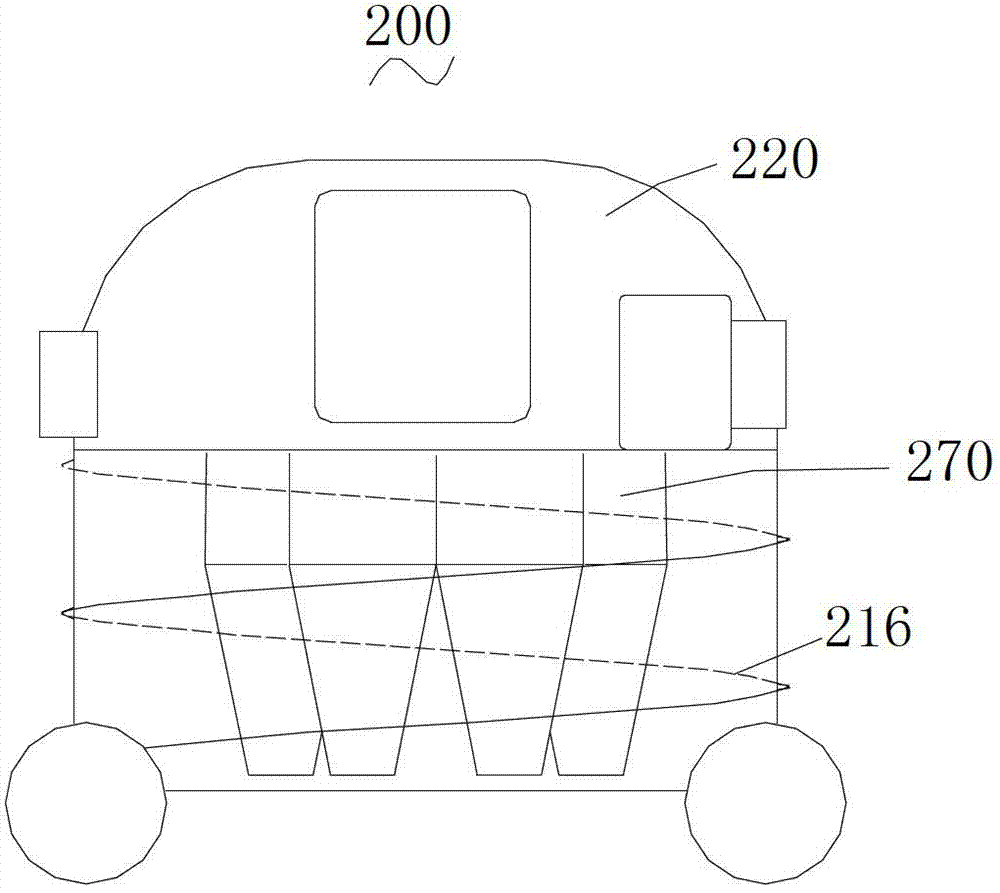

[0034] Please refer to figure 2 , The vacuum cleaner 200 in this embodiment includes a housing, an air inlet 240 and an air outlet 250 disposed on the housing, and a motor 230 disposed in the housing. The casing includes an upper casing 220 and a dust collection container 210 , and the upper casing 220 is fixed on the dust collection container 210 . The vacuum cleaner 200 also includes a cyclone filter 270 disposed in the housing to filter the gas entering the vacuum cleaner. In addition, the dust collection container 210 of the vacuum cleaner 200 is a telescopic dust collection container with variable volume.

[0035] The dust collecting container 210 includes a chassis 211 , an elastic supporting member 216 and a flexible shell 217 . The elastic supporting member 216 is fixed between the chassis 211 and the upper casing 220 , and the flexible shell 217 surrounds the elastic supporting member 216 . The flexible shell 217 , the chassis 211 and the upper shell 220 together ...

Embodiment 2

[0039] Please refer to Figure 4 , the vacuum cleaner 300 in this embodiment is similar to the vacuum cleaner 200 in the first embodiment, the difference is that, on the basis of the vacuum cleaner 200 in the first embodiment, the vacuum cleaner 300 adds a support column. details as follows.

[0040] The vacuum cleaner 300 includes a housing, an air inlet 340 and an air outlet 350 disposed on the housing, and a motor 330 disposed in the housing. The casing includes an upper casing 320 and a dust collection container 310 , and the upper casing 320 is fixed on the dust collection container 310 . The vacuum cleaner 300 also includes a cyclone filter 370 disposed in the housing to filter the gas entering the vacuum cleaner.

[0041]The dust collecting container 310 includes a base plate 311 , an elastic supporting member 316 and a flexible shell 317 . The elastic supporting member 316 is fixed between the chassis 311 and the upper casing 320 , and the flexible shell 317 surroun...

Embodiment 3

[0046] Please refer to Figure 6 and Figure 7 , the vacuum cleaner 400 in this embodiment is similar to the vacuum cleaner 200 in the first embodiment, the difference is that the vacuum cleaner 400 adds a telescopic support on the basis of the vacuum cleaner 200 in the first embodiment. details as follows.

[0047] The vacuum cleaner 400 includes a housing, an air inlet 440 and an air outlet 450 disposed on the housing, and a motor 430 disposed in the housing. The casing includes an upper casing 420 and a dust collection container 410 , and the upper casing 420 is fixed on the dust collection container 410 . The vacuum cleaner 400 also includes a cyclone filter 470 disposed in the casing to filter the gas entering the vacuum cleaner.

[0048] The dust collecting container 410 includes a chassis 411 , an elastic support 416 and a flexible shell 417 . The elastic supporting member 416 is fixed between the chassis 411 and the upper casing 420 , and the flexible shell 417 sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com