Adjusting device for free end of crankshaft and adjusting method thereof

A free end and calibration technology, which is applied to the parts of grinding machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problem that it is difficult to ensure the runout of the free end journal of the crankshaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

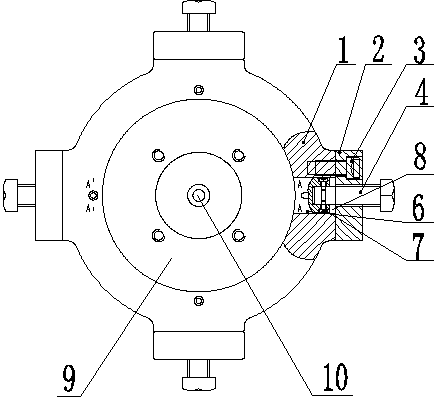

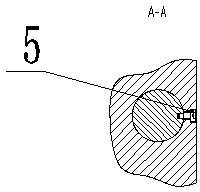

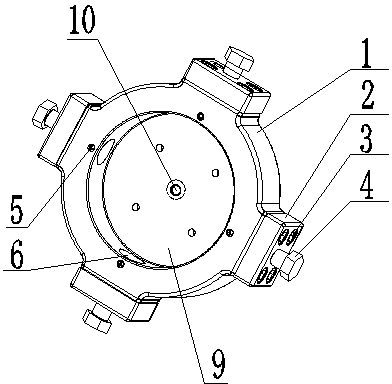

[0021] Such as figure 1 It is a schematic diagram of the structure of the present invention, a crankshaft free end adjustment device, the inner side of the drive disc body 1 is provided with a baffle plate 9, the outer side of the said baffle plate 9 is provided with a central hole 10, and the drive disc body 1 is evenly arranged with 4 cover plates 2, the cover plates 2 are fixed on the drive disk body 1 by fastening screws 3, the inside of the drive disk body 1 is provided with a cavity 8, and the pressure head 6 is arranged in the cavity 8, so The pressure head 6 is connected to the compression bolt 4 , a guide screw 1 5 is provided between the driving disc body 1 and the pressure head 6 , and a guide screw 2 7 is provided between the pressure head 6 and the compression bolt 4 .

[0022] A crankshaft free end calibration method:

[0023] a. According to the size of the journal 12 at the free end, roughly adjust the four compression bolts 4 of the adjustment device, and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com