Glue nail installing device of automotive chassis plate

A technology for installing devices and bottom plates, which is applied in the direction of nailing tools, hand-held tools, manufacturing tools, etc., can solve the problems of low work efficiency, high labor intensity, unstable quality, etc., and achieve simple structure, quality assurance, and labor-saving use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

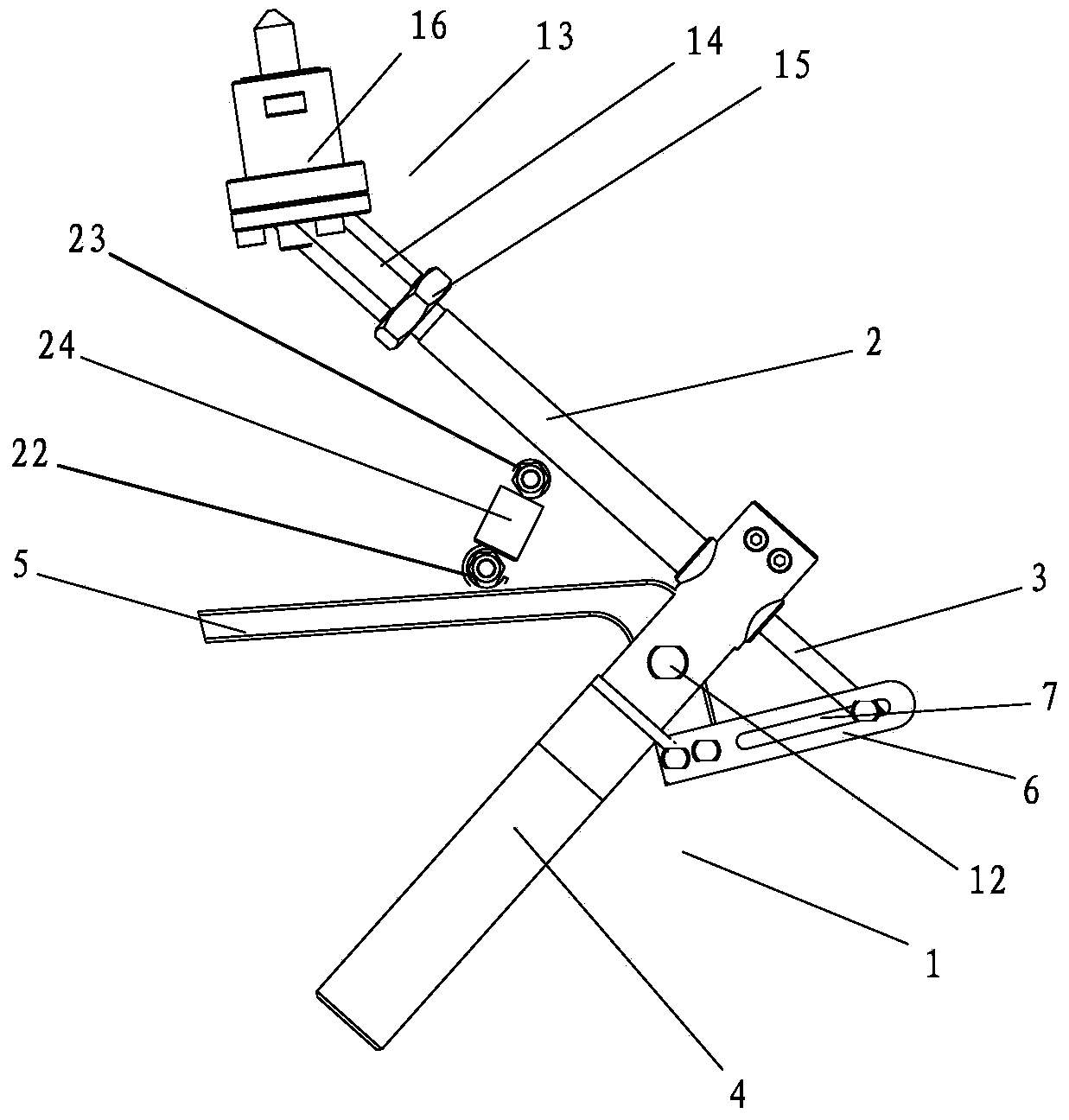

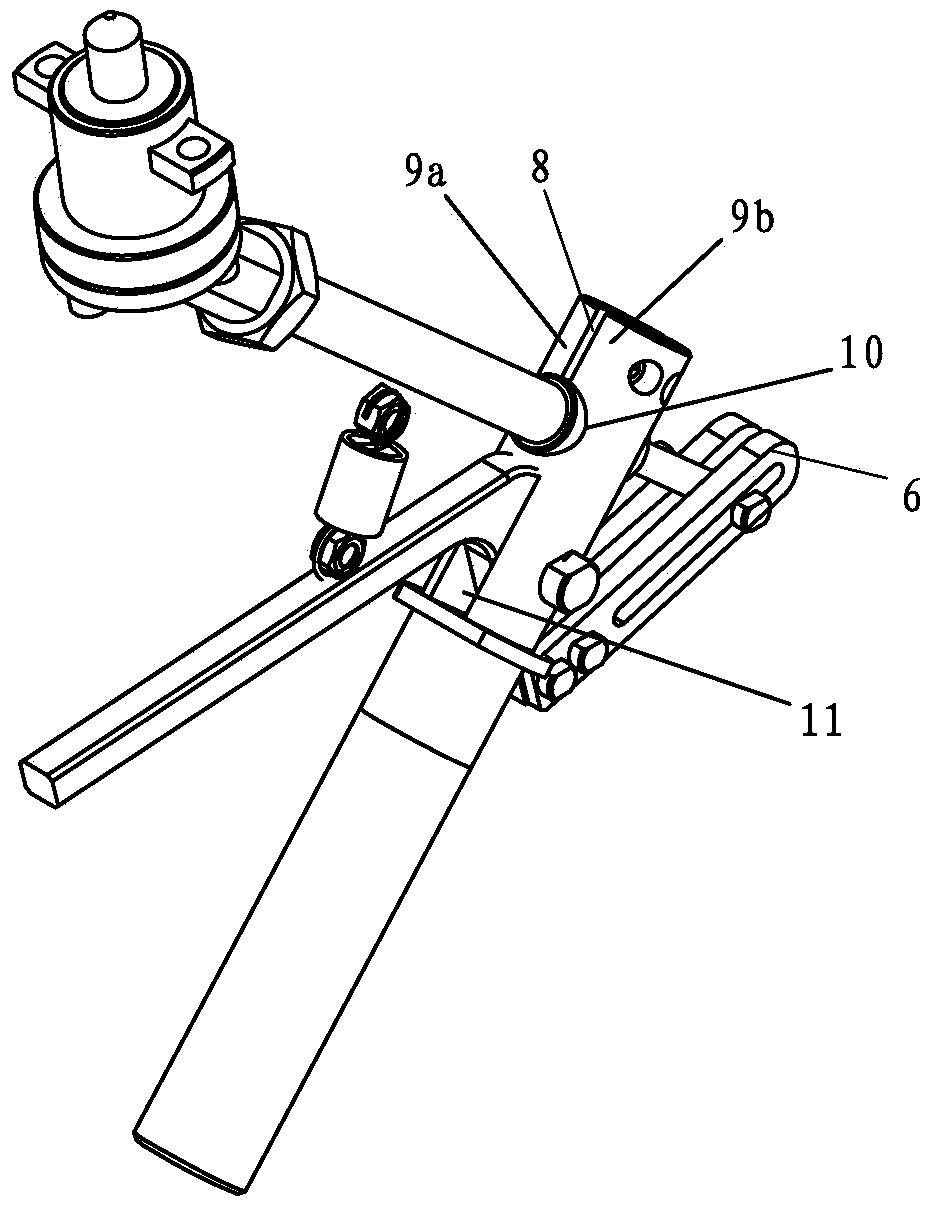

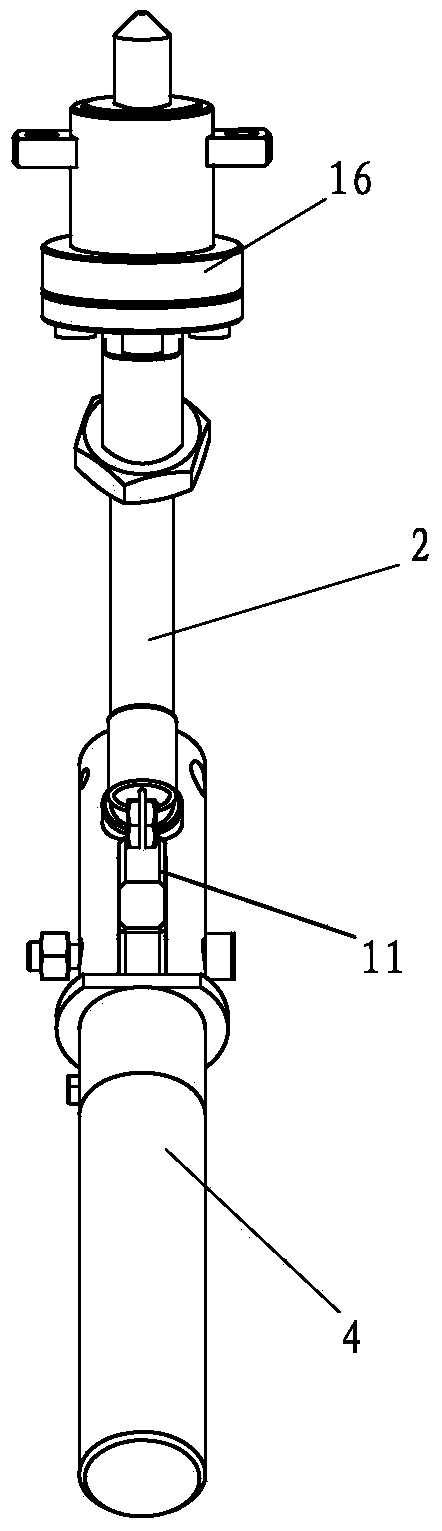

[0027] see figure 1 , this embodiment includes a lever drive assembly 1, a guide sleeve 2 and a sliding rod 3, one end of the guide sleeve 2 is fixedly connected to the upper end of the drive assembly 1; the slide rod 3 is slidably sleeved on the guide The sleeve 2 and both ends are extended; the power input end of the sliding rod 3 is connected with the power output end of the lever drive assembly 1, and its power output end pushes the rubber nails into the car floor; the lever drive assembly 1 includes Handle 4, handle 5 and guide block 6, described handle 5 is located at the guide sleeve below, and middle part offers through hole and is hinged with described handle 4 through described through hole; Described guide block 6 and described handle 5. The power output end is fixedly connected and is provided with a slotted hole 7, and one end of the sliding rod 3 is sleeved in the slotted hole 7.

[0028] The lever assembly 1 of the present invention adopts a swing structure hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com