Automatic feeding device of thicknesser

A technology of automatic feeding and planer, applied in the direction of planer, workpiece feeding device, etc., can solve the problems of wasting labor force and reducing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

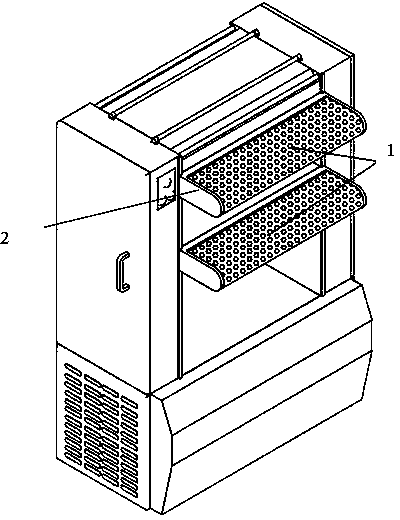

[0010] Films 1 are fixed on the upper and lower feeding belt surfaces of the feed inlet 2 of the original planer, forming a conveyor wheel structure with films.

[0011] In order to increase the frictional force of the film, the feed surface of the film 1 is processed with a plurality of bumps to form a concave-convex surface.

[0012] Once the processed wood is placed on the feed port, the upper and lower film wheels press the processed wood, and the processed wood is automatically sent into the planer by the friction of the film wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com