Molding method of resin container

A molding method and resin-made technology, which are applied in the field of molding resin-made containers, can solve problems such as increased manufacturing cost and poor molding, and achieve the effects of suppressing manufacturing cost, preventing eccentricity, and not easy to form poor molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

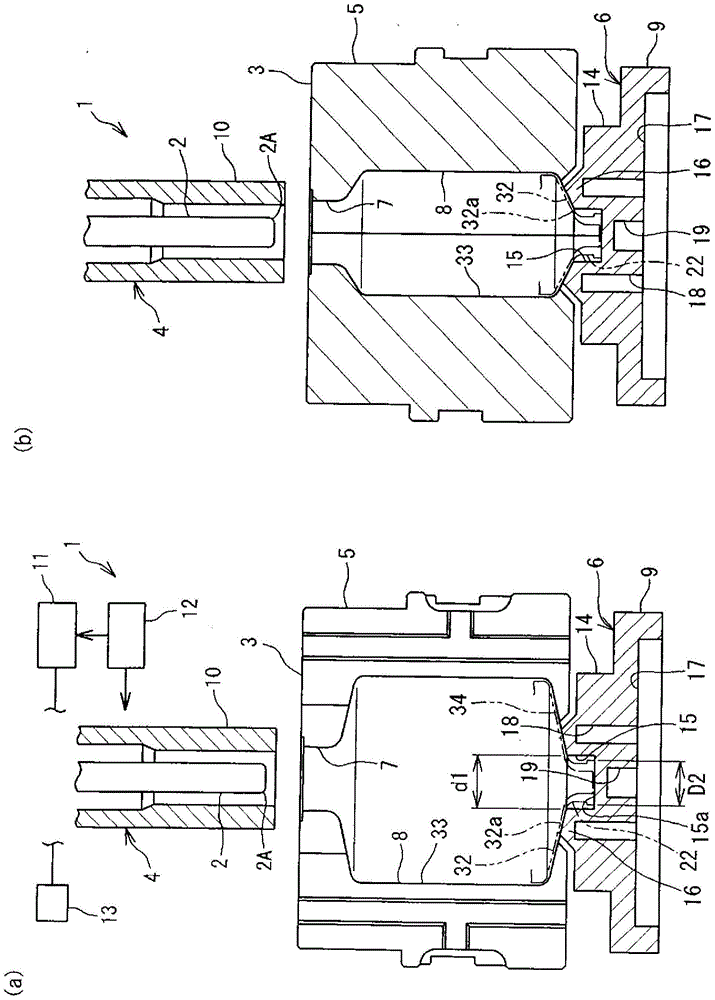

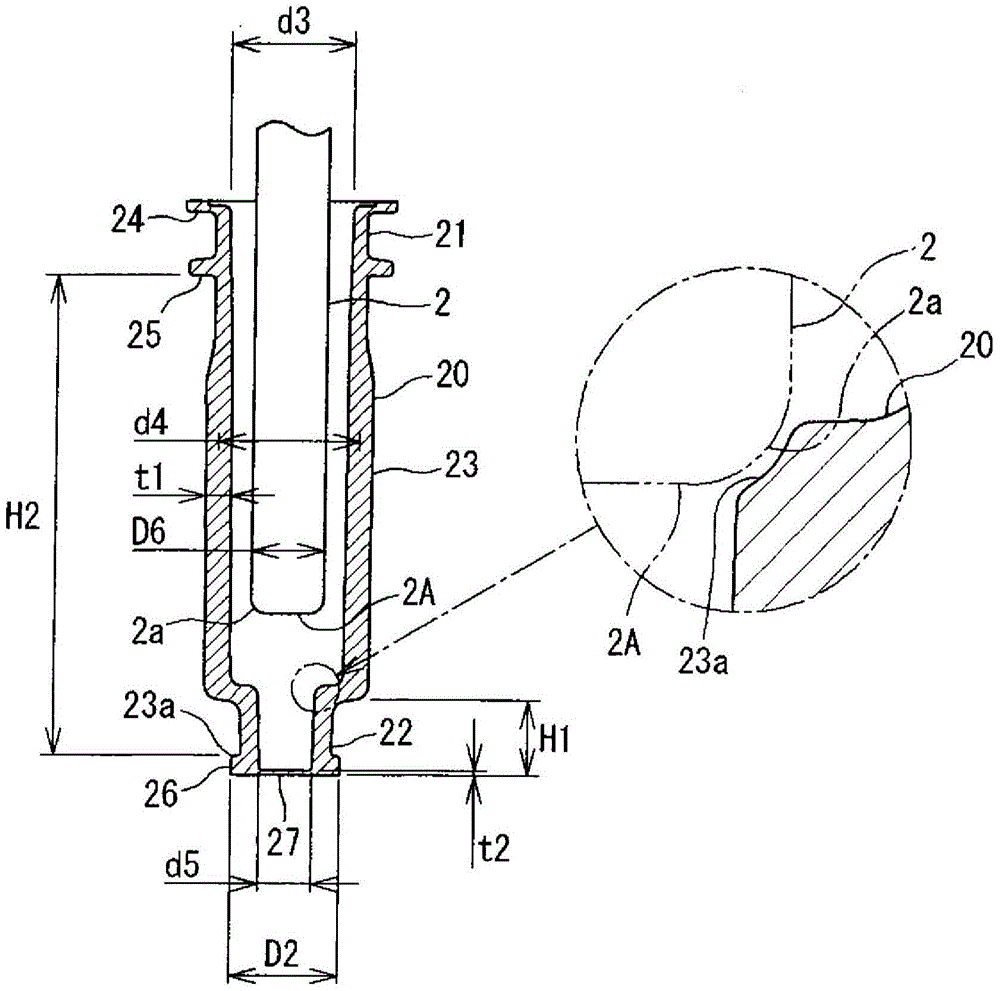

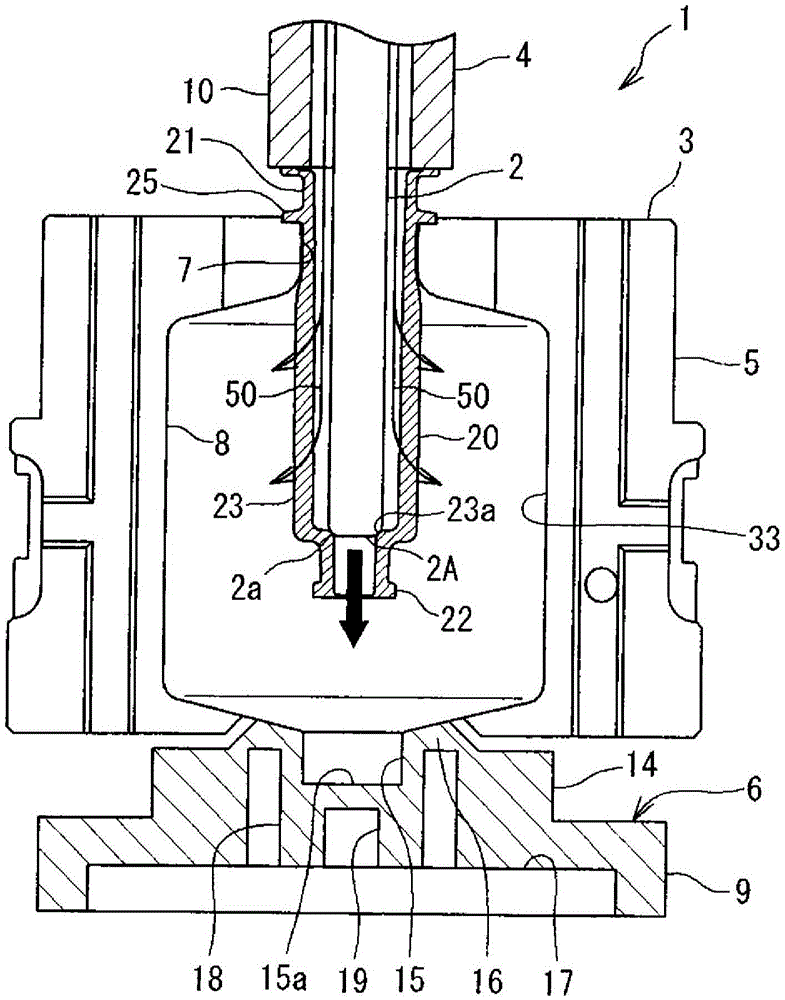

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a schematic transverse sectional view and a schematic longitudinal sectional view of a molding machine 1 for carrying out a molding method of a resin container according to an embodiment of the present invention, figure 2 It is a sectional view of a preform 20 used in a molding method of a resin container and a drawing of a stretching rod 2 inserted into the preform 20 . In the description below, the figure 1 and figure 2 The two sides corresponding to the up and down are referred to as up and down for short. figure 1 The shown molding machine 1 has an equipment structure for implementing a blow molding method, which mainly consists of a blow molding mold 3, a stretching rod device 4 positioned above the blow molding mold 3, a blow molding blower for supplying blow molding air. The molding air device 11 and the control part 12 which controls these stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com