Preparation method of metal probe applicable to AFM (Atomic Force Microscope)

An atomic force microscope, metal probe technology, applied in the field of nano-scale sharp probe preparation, can solve the problems of high process requirements, difficult to obtain solutions, difficult to commercial production, etc., to achieve low noise, avoid negative effects, end-to-end sharp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention will be described below by taking the production of AFM gold probes as an example.

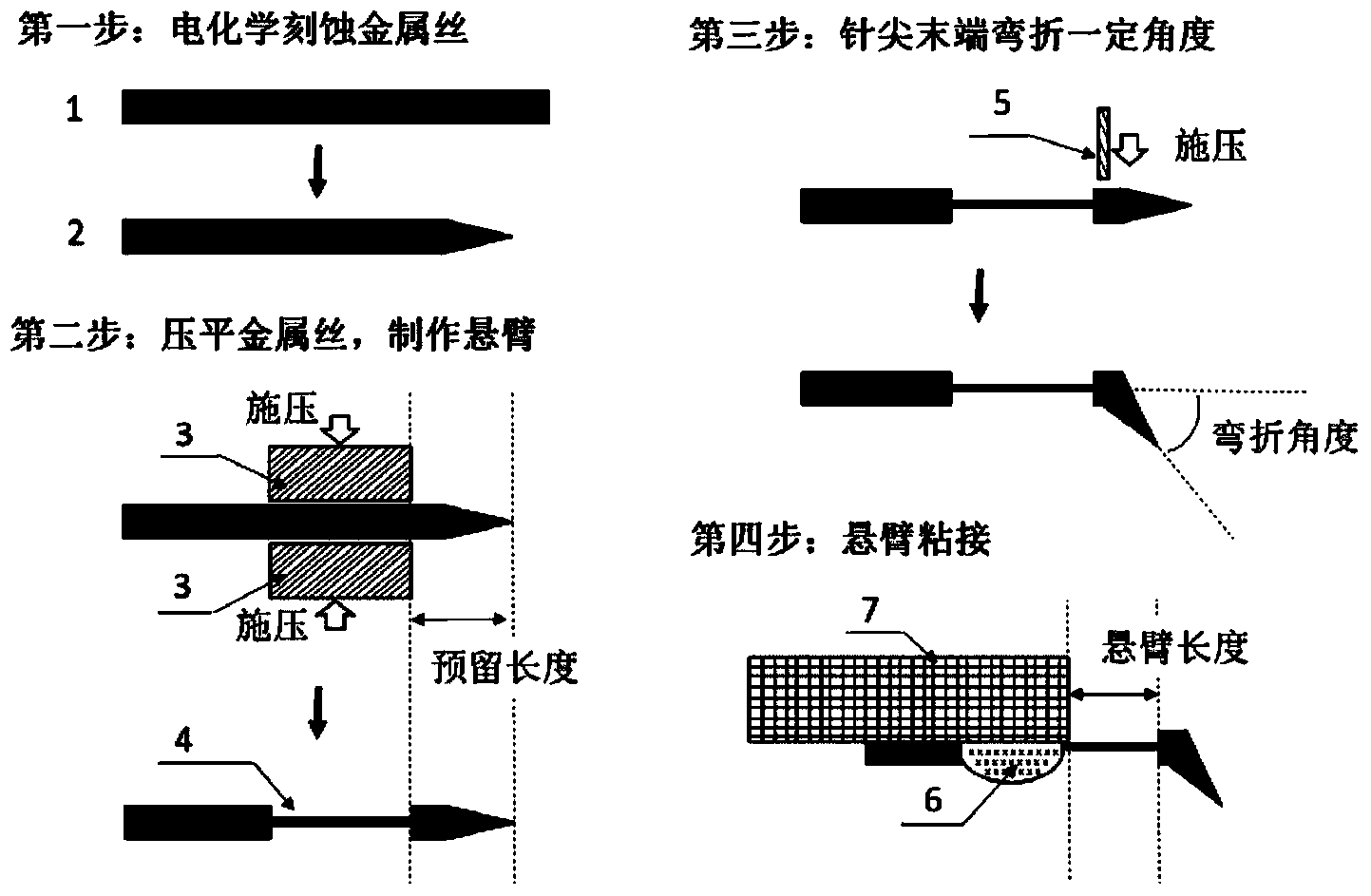

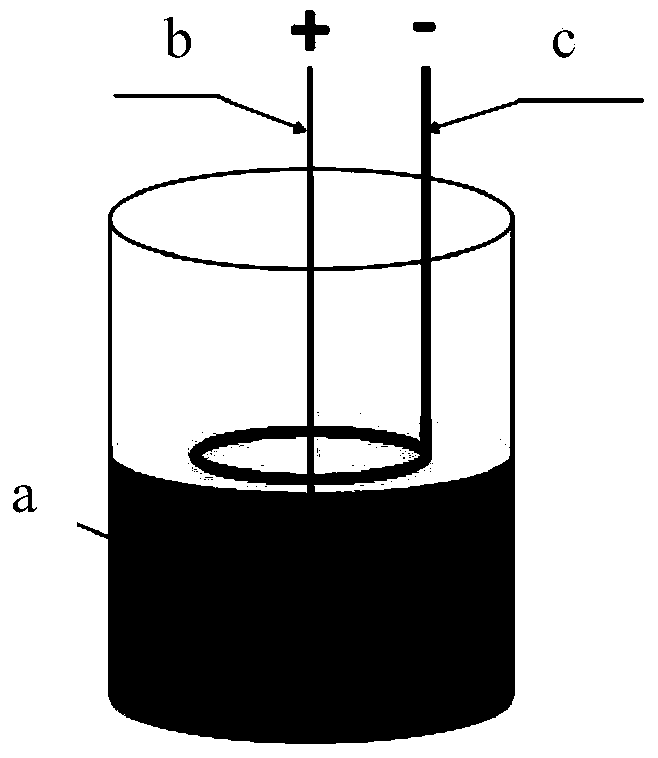

[0040] (1) Electrochemical etching of gold wire

[0041] In this example, a gold wire (Alfa Aesar Company) with a diameter of 50 μm was used, which was ultrasonically cleaned in acetone before use. The etchant is concentrated hydrochloric acid+absolute ethanol with a volume ratio of 1:1. figure 2 For the etching scheme, the gold wire is used as the working electrode, and the gold ring is used as the counter electrode to form a two-electrode system. Apply a voltage of 2.2V with a DC power supply. After about 30 seconds, the part of the gold wire immersed in the etchant falls off, and the etching stops automatically. The obtained gold needle tip was rinsed with ultrapure water.

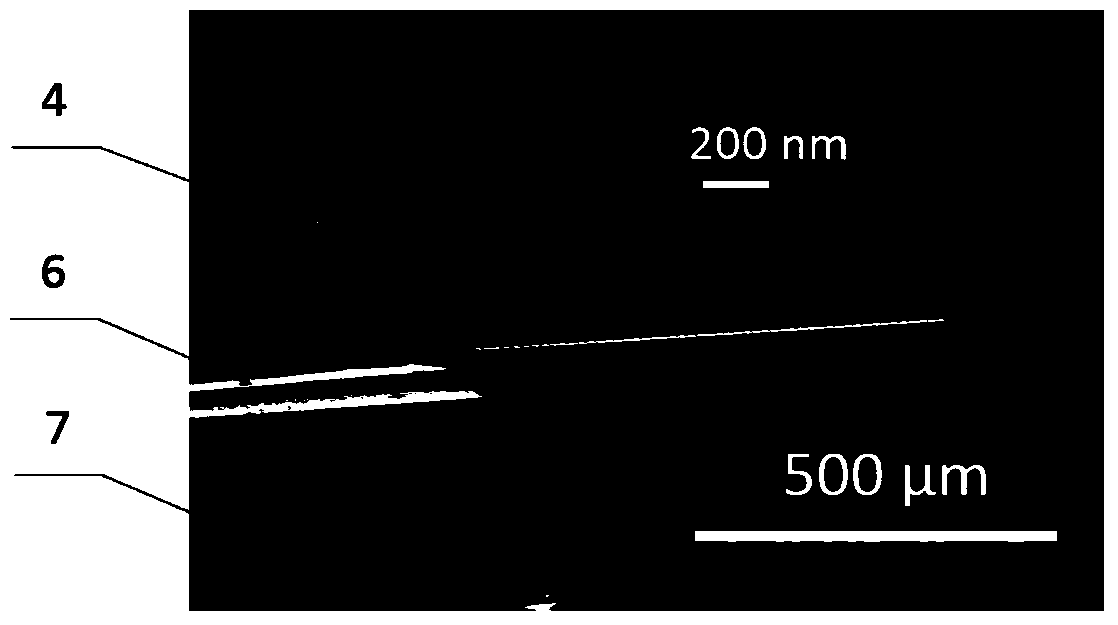

[0042] (2) Use a silicon wafer to flatten the gold wire near the end of the needle tip

[0043] The silicon wafer is a polished silicon wafer (Zhejiang Lijing Silicon Material Co., Ltd....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com