A modified pvc non-excavation special communication pipe for buried and its preparation method

A special communication and non-excavation technology, which is applied in the field of buried modified PVC non-excavation special communication pipe and its preparation, can solve the problems of brittleness and impact on service life, etc., and achieve extended service life and long-term strength impact The effect of reducing the size and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

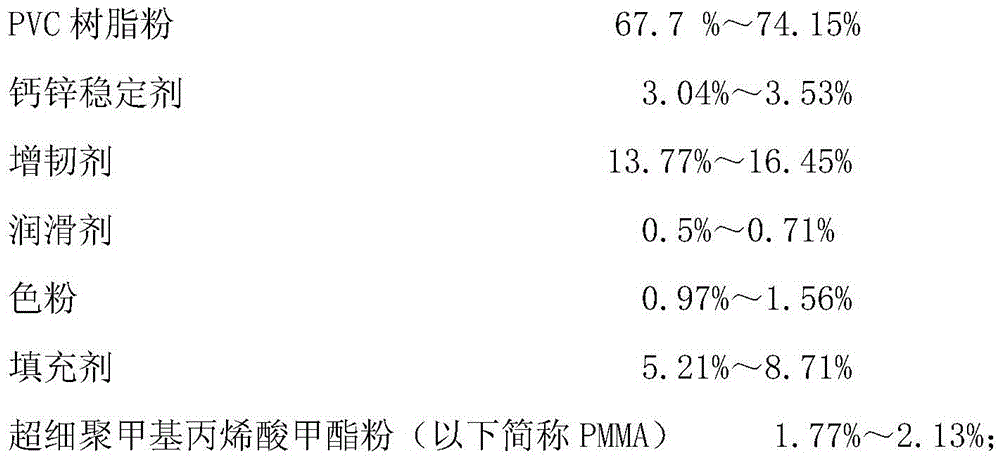

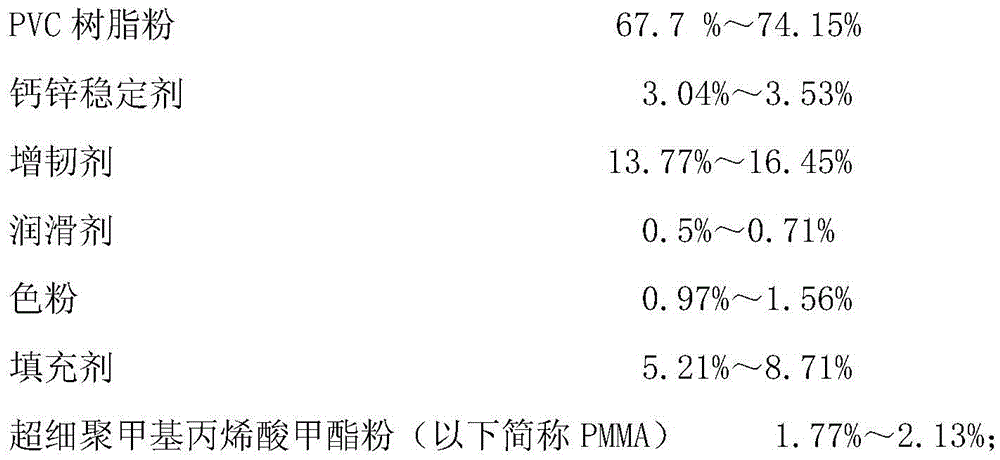

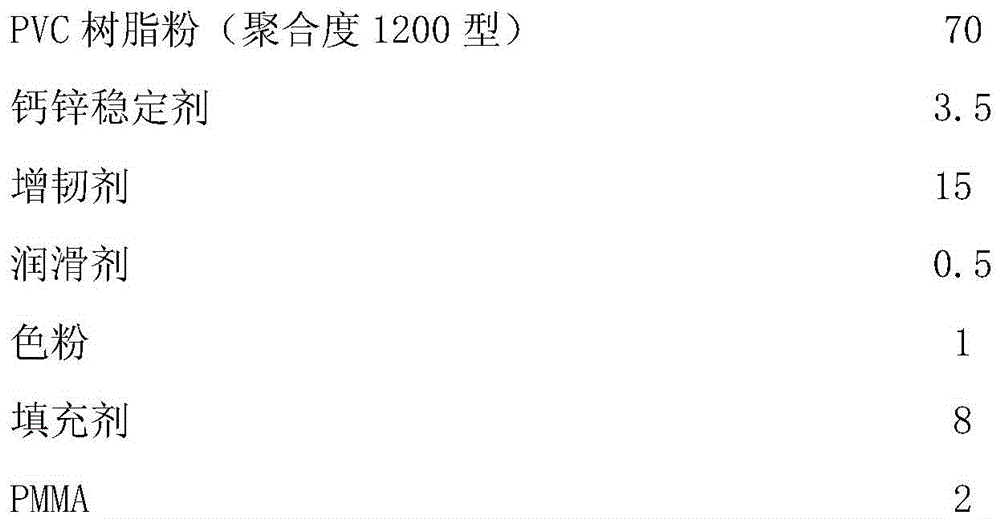

[0022] A modified PVC non-excavation dedicated communication pipe for buried use, which weighs raw materials (unit: part) according to the following formula:

[0023]

[0024] Wherein, the toughening agent contains 2 parts of CPE, 10 parts of MBS, 2 parts of ABS, 1 part of ACR; the lubricant contains 3 parts of PEWAX, 2 parts of HST; the filler contains 3 parts of SiO 2 and 5 parts CaCO 3 .

[0025] The method for preparing the above-mentioned modified PVC non-excavation special communication pipe for buried use comprises the following steps:

[0026] 1) Material mixing: Mix PVC resin powder, stabilizer, toughener, lubricant, toner and PMMA in proportion, control the system temperature at 120°C and stir at high speed for 2.5 minutes, then add filler, control the system temperature at 39°C Continue stirring at low temperature for 3 minutes.

[0027] 2) Extrusion molding: extrude the mixed material through an extruder.

Embodiment 2~6

[0029] Using the same raw materials and preparation method as in Example 1, the difference is that the addition amount of different components listed in Table 1, the reaction temperature in the preparation step 1, and the reaction time are used to replace the corresponding numerical values adopted in Example 1 , wherein the parts of CPE, MBS, ABS and ACR in the toughening agent are the total parts of the toughening agent distributed according to the weight ratio of 2:10:2:1, and the parts of PEWAX and HST in the lubricant are the total parts of the lubricant The number is distributed according to the weight ratio of 3:2; the SiO in the filler 2 and CaCO 3 The number of parts is the total number of fillers distributed in a weight ratio of 3:5.

[0030] Table 1

[0031]

[0032] In the embodiment, the degree of polymerization of the PVC resin powder is not limited, and the type of PVC resin powder with a degree of polymerization of 1200 is the best.

[0033] The various ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com