Hollow built-in shutter glass window

A technology of glass windows and louvers, which is applied in the field of hollow built-in louvered glass windows, can solve the problems that the hollow built-in louvered glass windows are not maintainable, the louvered glass windows are not maintainable, and the fixed spacers cannot be removed again. Achieve the effects of good clamping effect, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

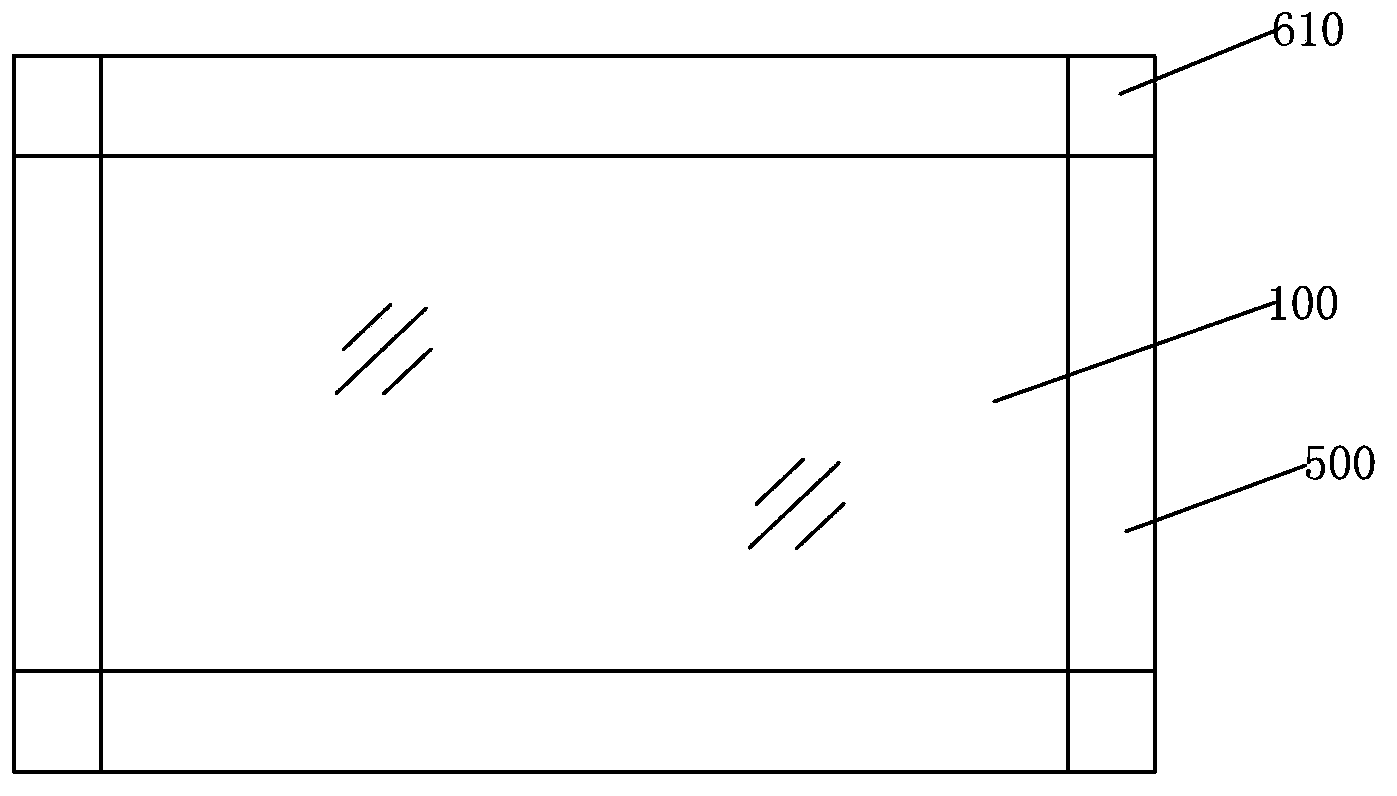

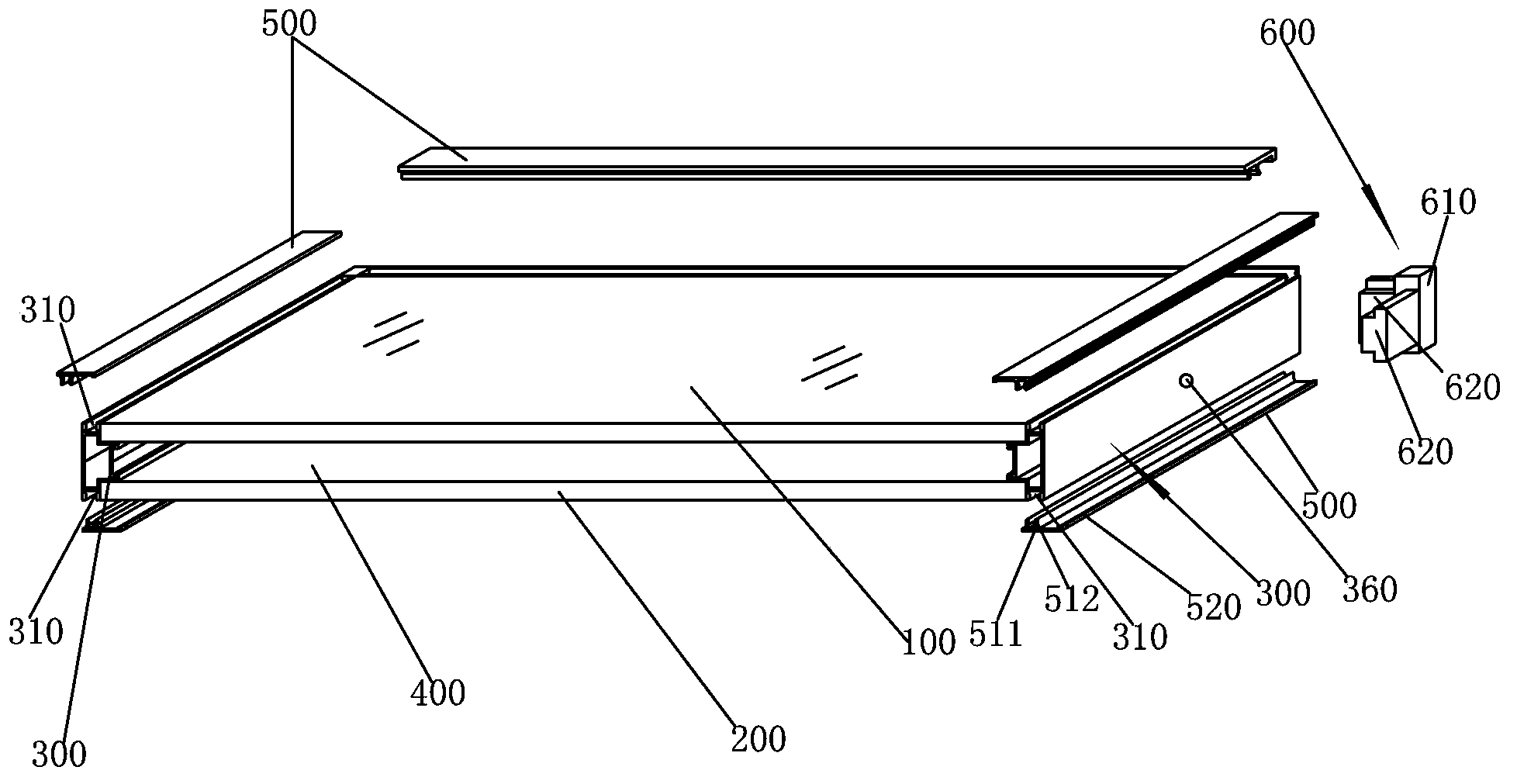

[0029] Please check Figure 1 to Figure 4 , the first preferred embodiment of the hollow built-in shutter glass window, the hollow built-in shutter glass window includes a first glass 100 , a second glass 200 , several spacers 300 and several fixing pieces 500 .

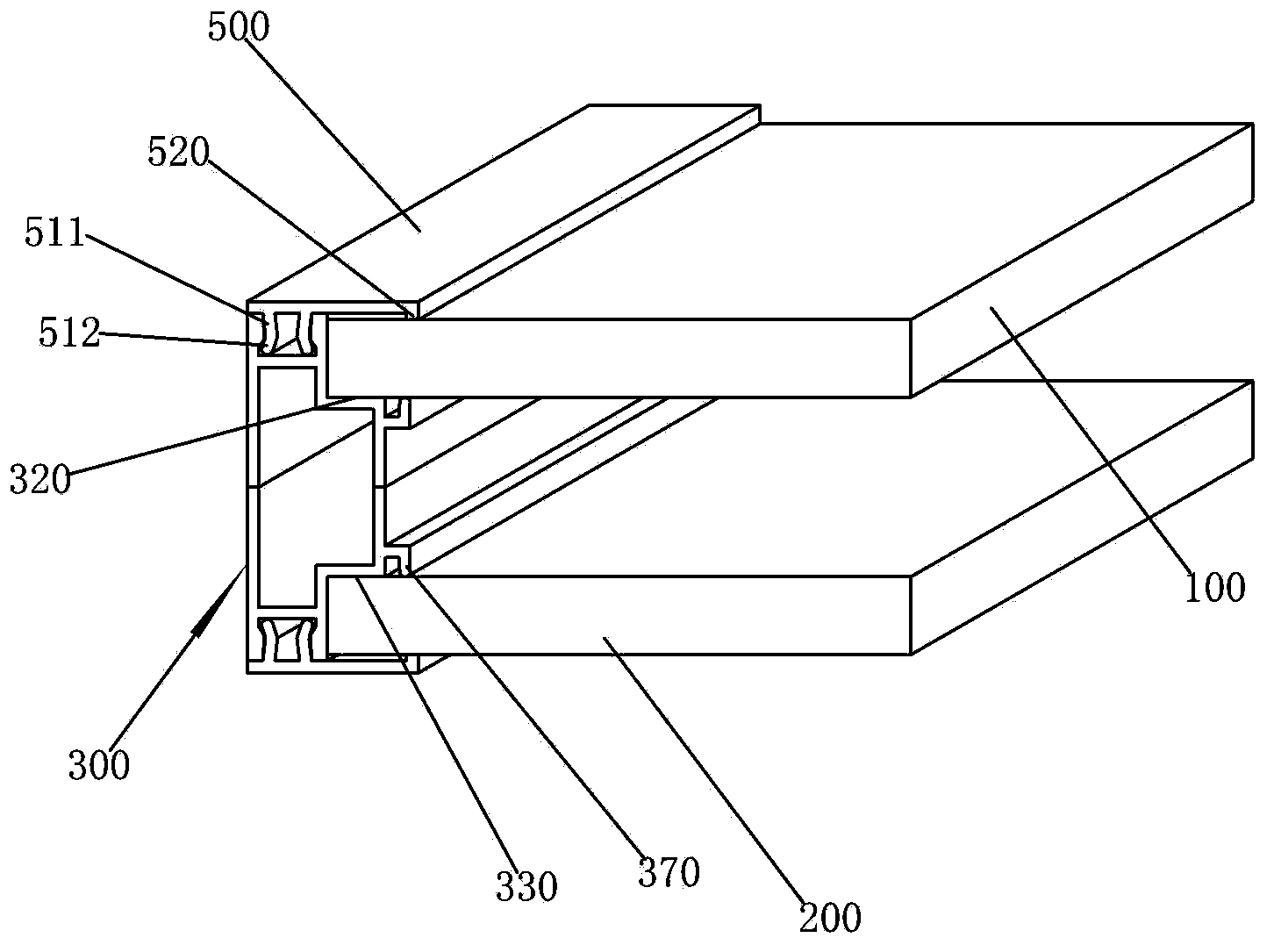

[0030] Several spacers 300 are connected in pairs, and a closed cavity 400 is formed between the spacers 300 and the first glass 100 and the second glass 200 , and the spacers 300 are provided with at least one assembly groove 310 . In this embodiment, the assembly groove 310 is a long dovetail groove. In this embodiment, the number of 300 spacers is set to four.

[0031] In this embodiment, the spacer 300 includes an upper half 340 and a lower half 350, the upper half 340 and the lower half 350 are connected together by welding, screwing or gluing, and the upper half 340 and the lower half 350 are connected together. The first glass 100 cooperates and the lower half 350 cooperates with the second glass 200 . In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com