Cryopump and method for evacuation

A cryopump and cryopanel technology, applied in pumps, liquid variable capacity machinery, machines/engines, etc., can solve the problem that cryopumps cannot fully function, and achieve the effect of increasing gas retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

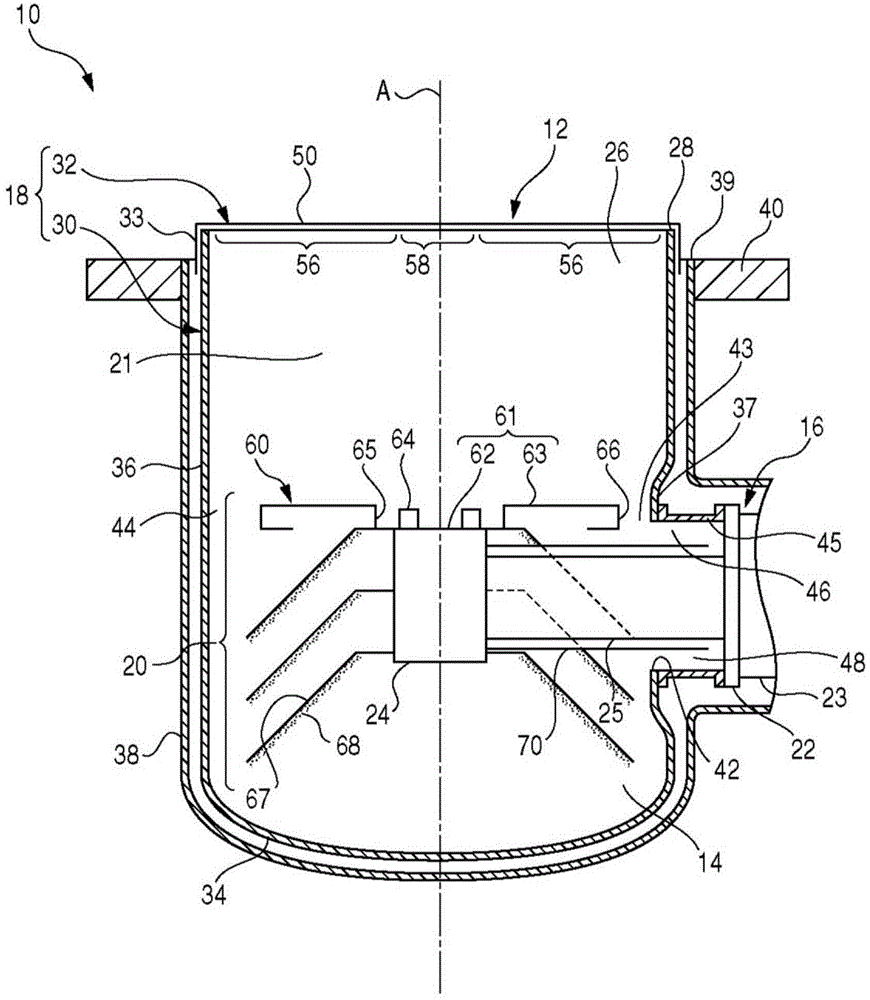

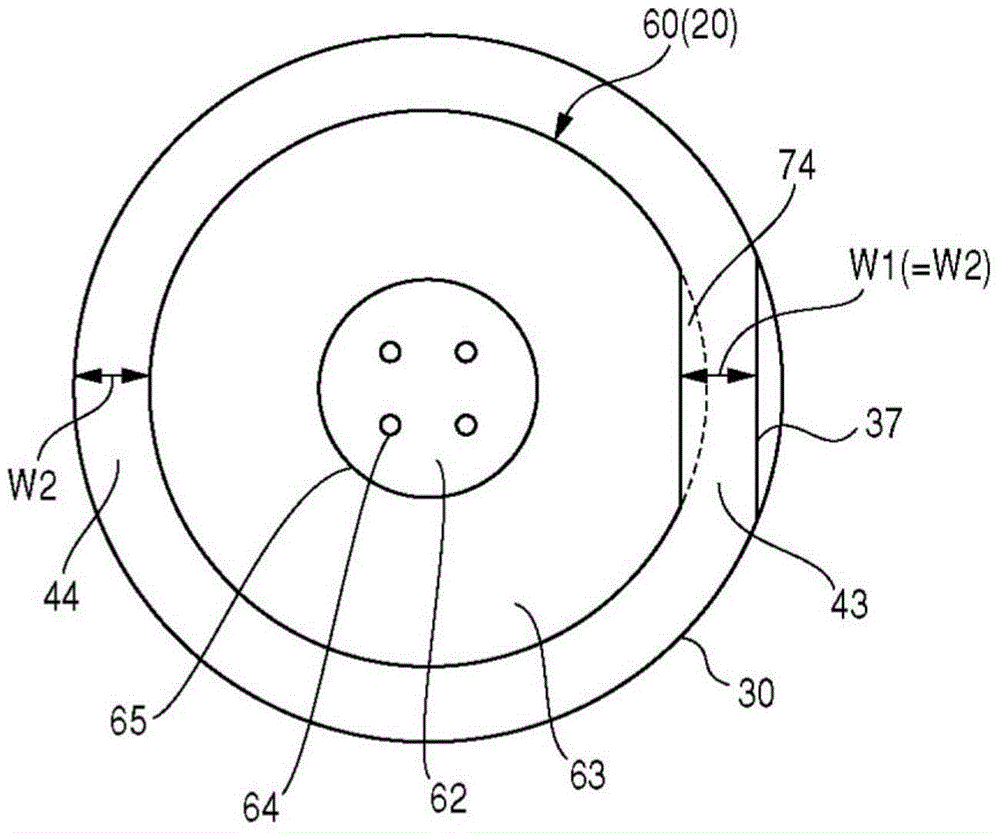

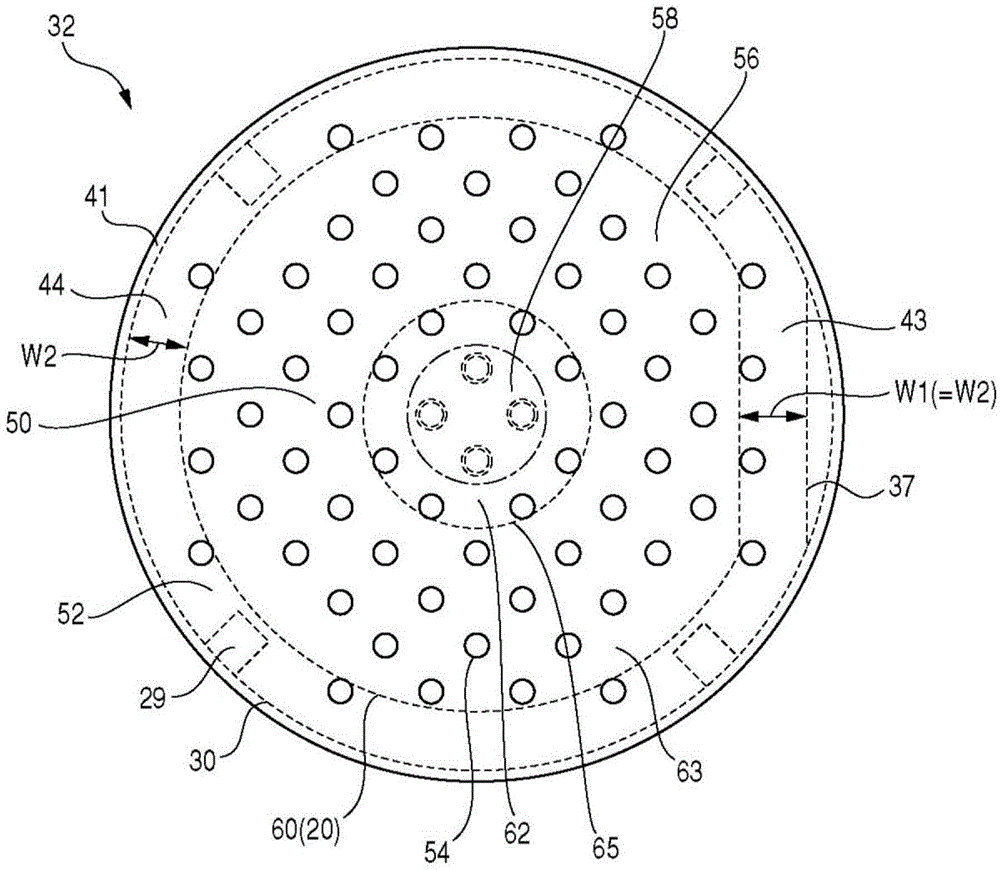

[0016] figure 1 It is a side cross-sectional view schematically showing main parts of the cryopump 10 according to the first embodiment of the present invention. The cryopump 10 is installed in, for example, a vacuum chamber of an ion implantation device or a sputtering device, and is used to increase the degree of vacuum inside the vacuum chamber to a level required for a desired process. The cryopump 10 has a suction port 12 for receiving gas. The gas to be exhausted enters the inner space 14 of the cryopump 10 from the vacuum chamber in which the cryopump 10 is installed through the suction port 12 . figure 1 A cross section including the central axis A of the inner space 14 of the cryopump 10 is shown.

[0017] In addition, terms such as “axial direction” and “radial direction” may be used below in order to facilitate understanding of the positional relationship of the components of the cryopump 10 . Axial represents the direction through the suction port 12 ( figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com