Planetary gear transmission with at least two planetary gear sets arranged axially side by side

A planetary gear set, planetary gear technology, applied in belt/chain/gear, gear vibration/noise attenuation, transmission, etc., can solve the problem of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

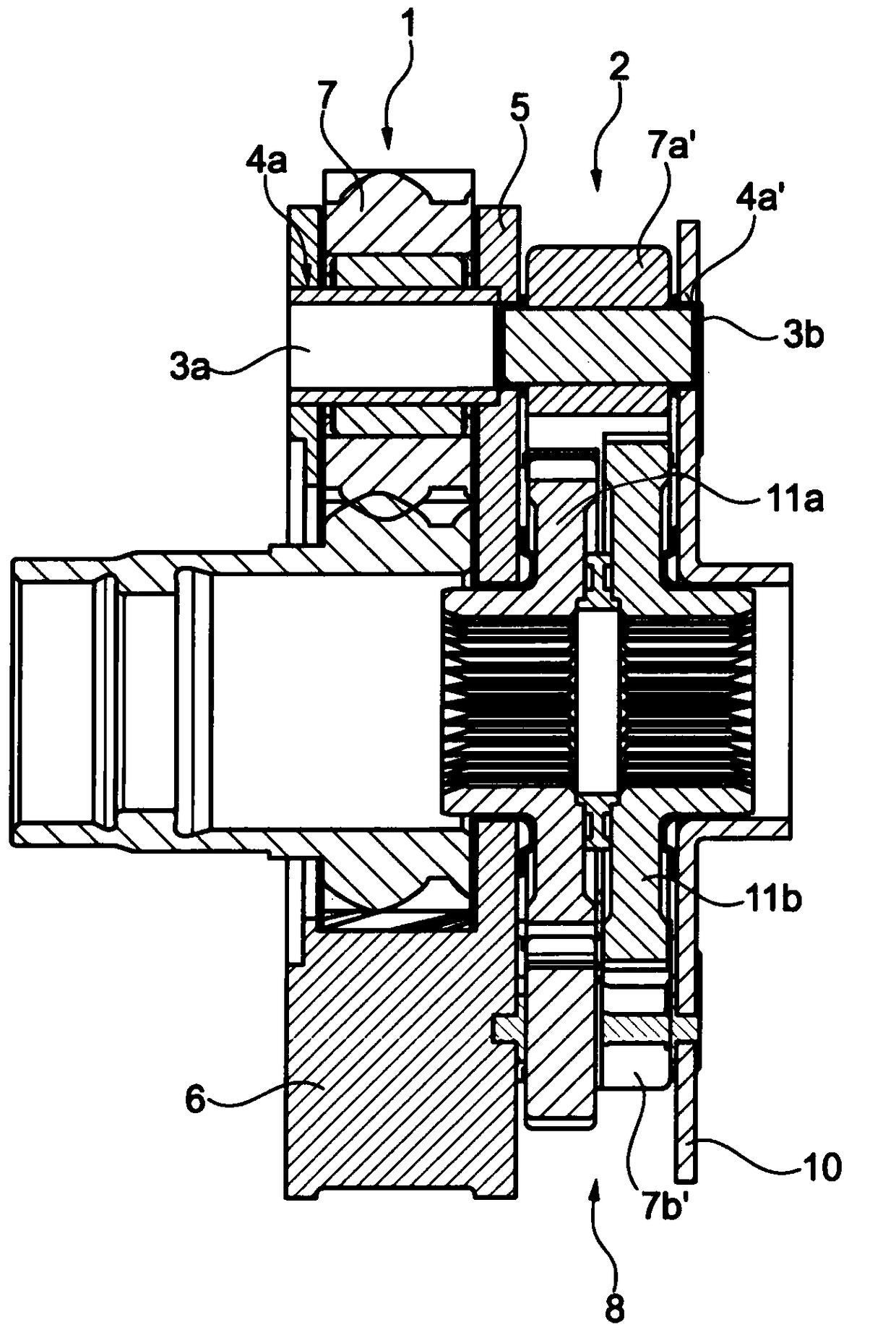

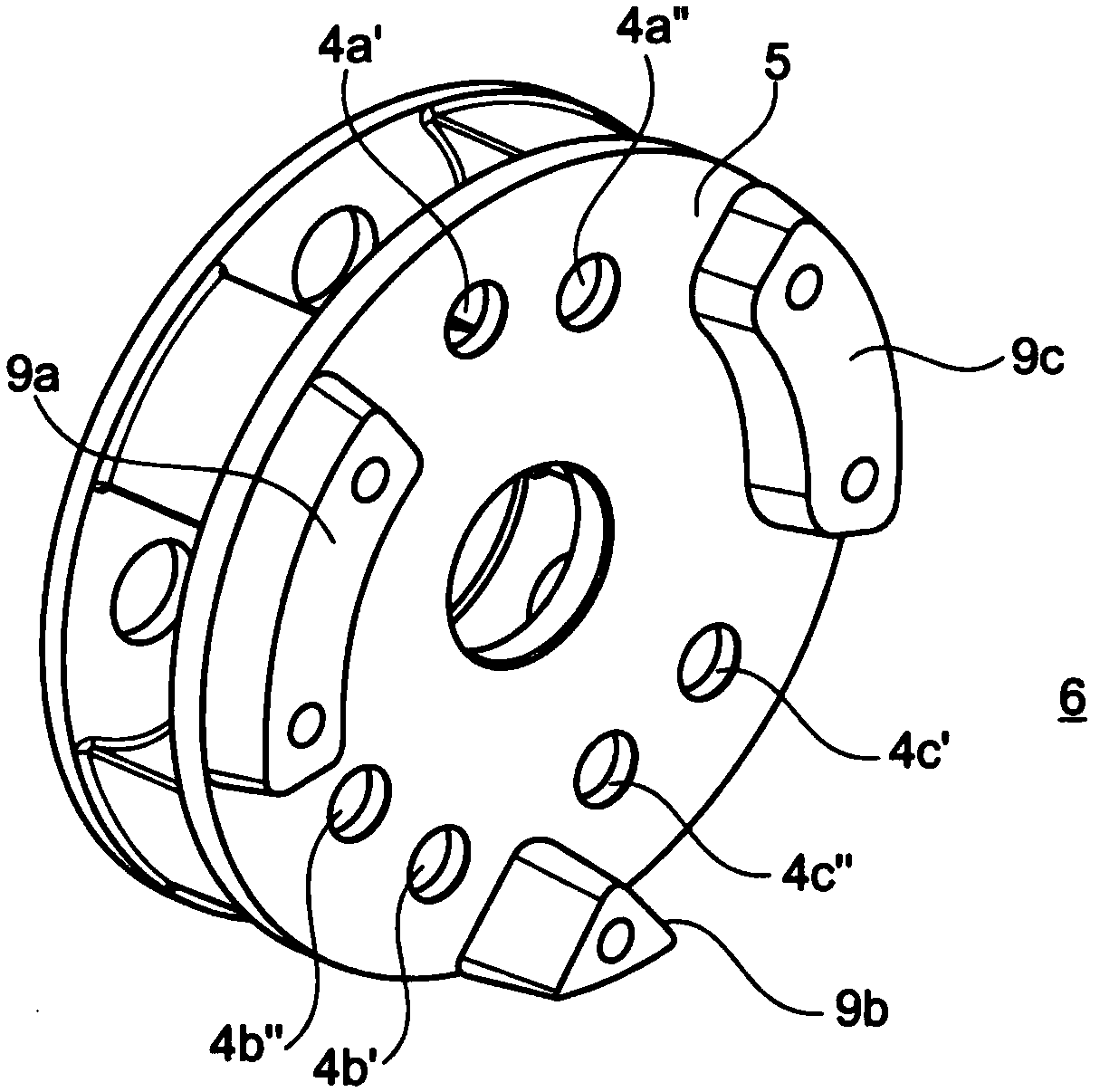

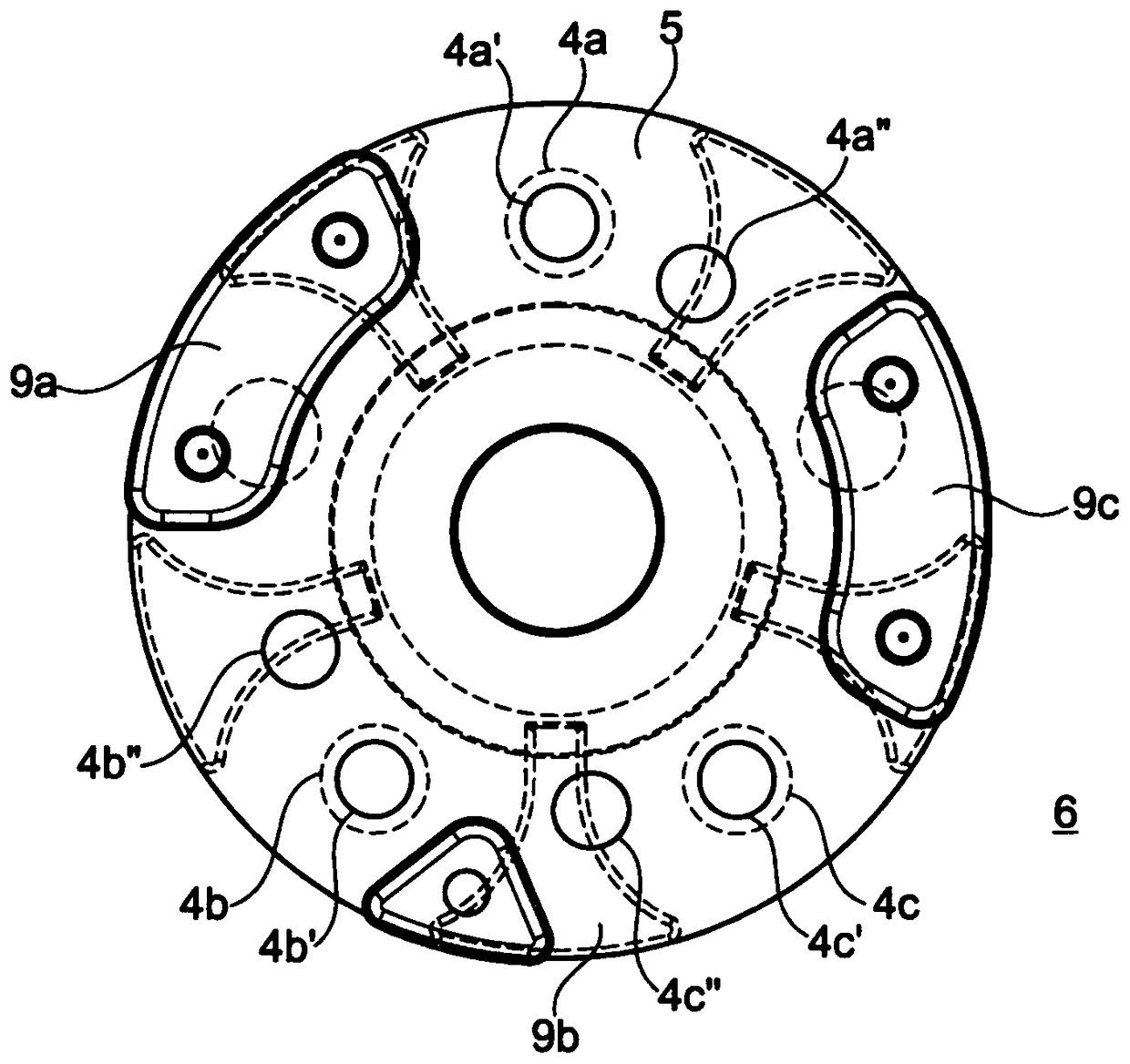

[0021] according to figure 1 , the planetary stage with integrated spur gear differential comprises two planetary gearsets 1 and 2 arranged axially side by side, which are rotatably mounted via planet pins 3a, 3b respectively, more precisely to one side The respective associated bores 4a, 4a' are supported on a common central carrier disk 5 of the planet carrier 6 which surrounds the first planetary gear set 1 in the form of a cage. The first planetary gearset 1 has a total of five planetary gears 7 arranged equidistantly from one another on the circumference of the planetary carrier 6 , which form planetary stages. In contrast, the second planetary gear set 2 is formed from a total of three intermeshing planetary gear pairs 8 of different diameters for forming a differential stage.

[0022] While one planet gear 7a' of each planet gear pair 8 cooperates with the first sun gear 11a, the other planet gear 7b' cooperates with the second sun gear 11b. A driven shaft (not shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com