Precise instrument placement box

A technology of precision instrument and box placement, applied in supporting machines, non-rotational vibration suppression, mechanical equipment, etc., can solve the problems of tension spring metal fatigue, inability to protect internal instruments well, and unreasonable structure, etc. The effect of secondary protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described below with reference to the drawings.

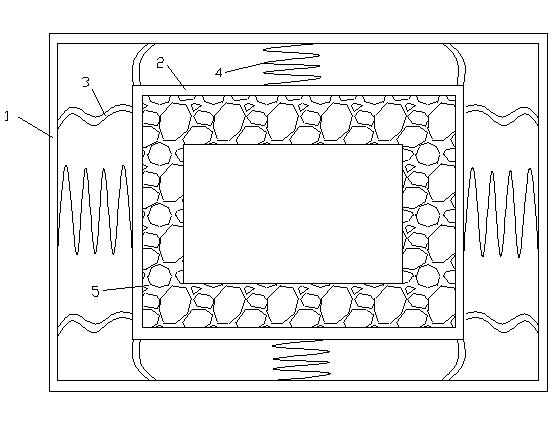

[0013] Refer to figure 1 As shown, a precision instrument placement box includes an outer box 1 and an inner box 2. The outer box 1 is connected to the inner box 2 by an elastic cord 3 and an elastic member 4, and the elastic cord 3 and the elastic member 4 are both Horizontally or vertically, the elastic cords 3 are provided with eight, and the elastic members 4 are provided with four. The single elastic member 4 is located on the two elastic cords 3. And the structure is matched as a set to be fixedly connected to the outer box 1 and the inner box 2, specifically the elastic cord 3, the elastic member 4, and the elastic cord 3 are arranged in sequence, and the inner box 2 is also filled with a buffer Layer 5.

[0014] The elastic member 4 is a spring, and can also be replaced with other elastic structural parts.

[0015] The buffer layer 5 is a cotton buffer layer, which can also be replaced b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com