Triangle leveling instrument

A level, triangle technology, applied in the field of measurement, can solve the problems of low measurement accuracy, inaccurate measurement, small measurement range, etc., to achieve the effect of high measurement accuracy and large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

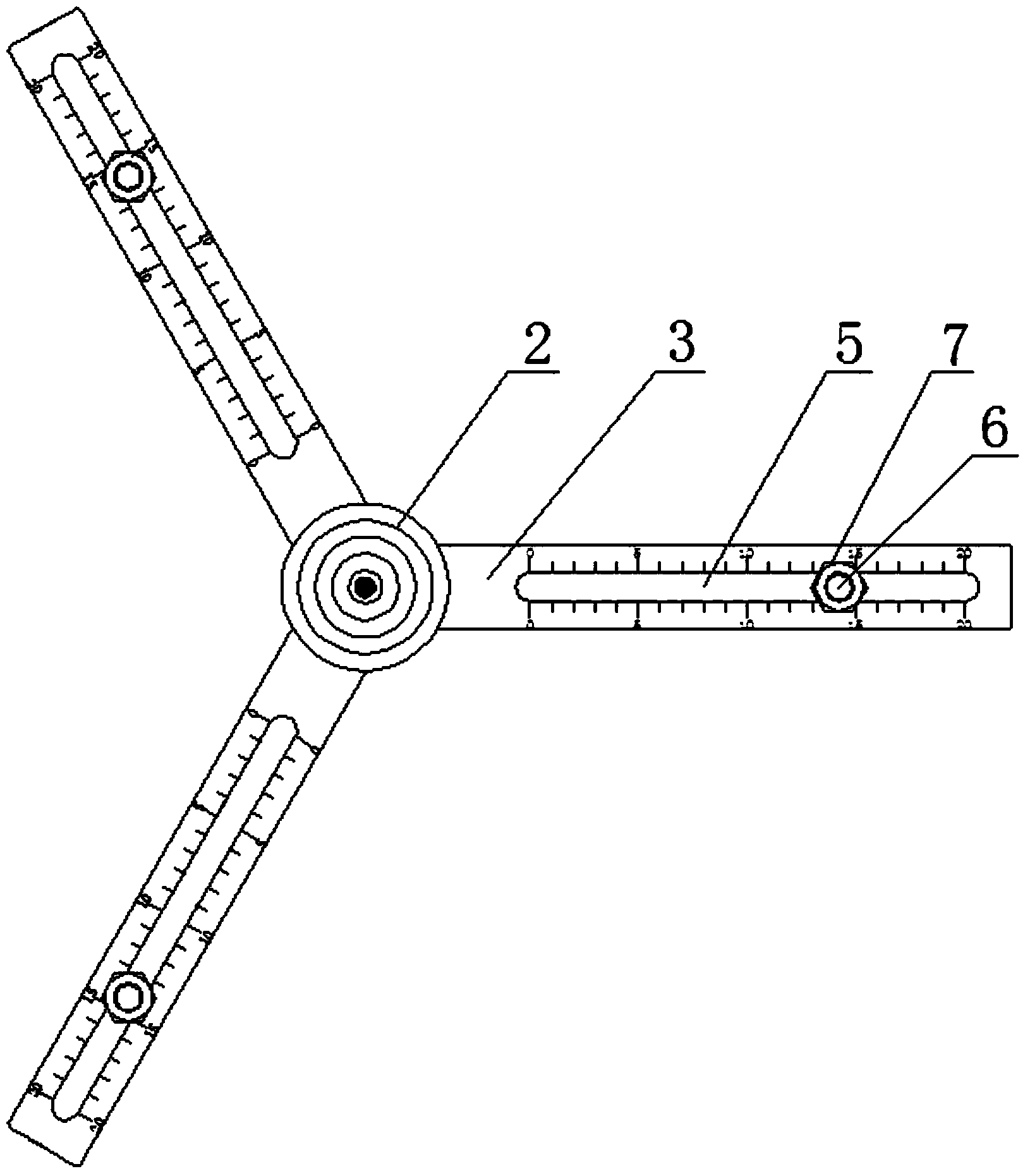

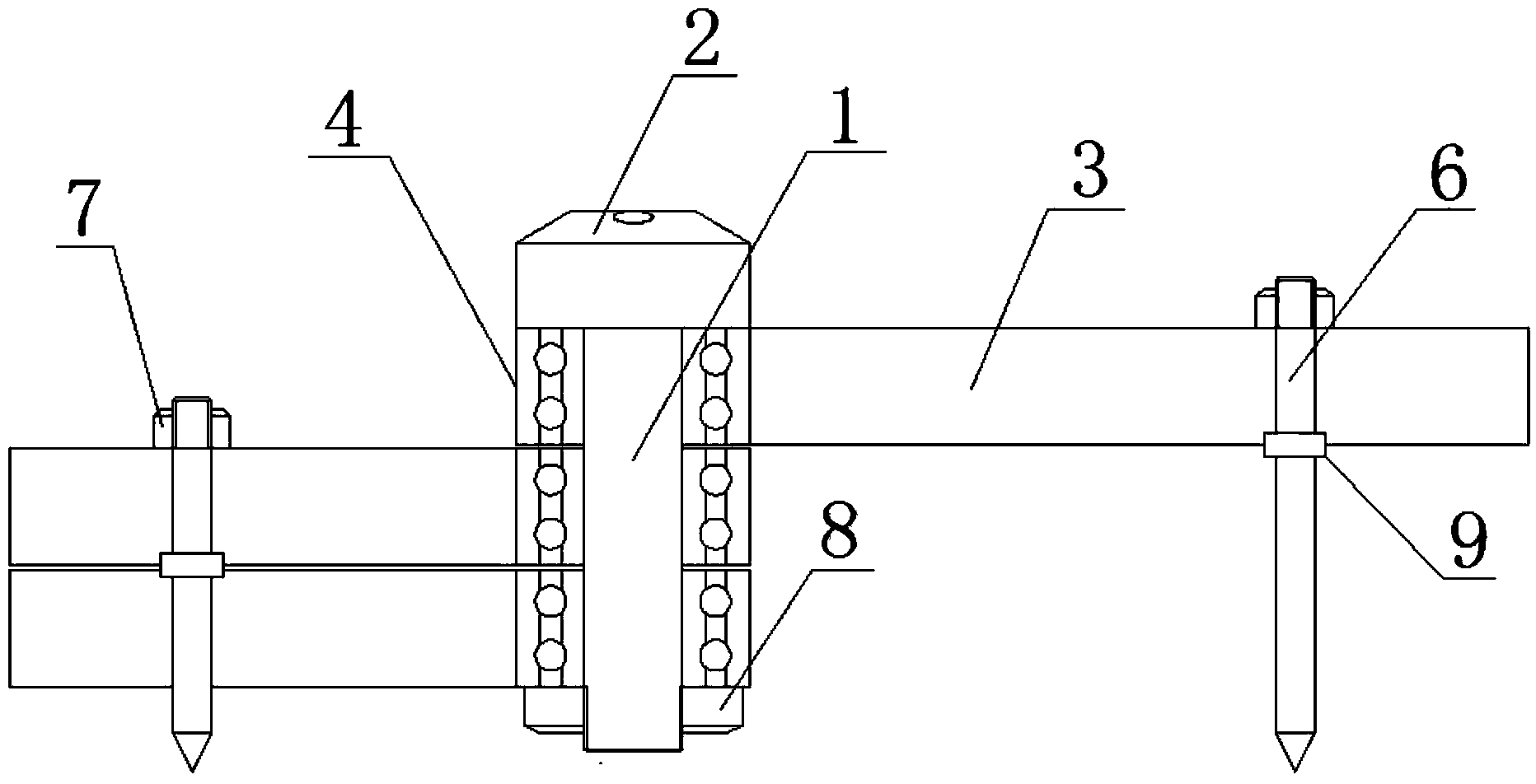

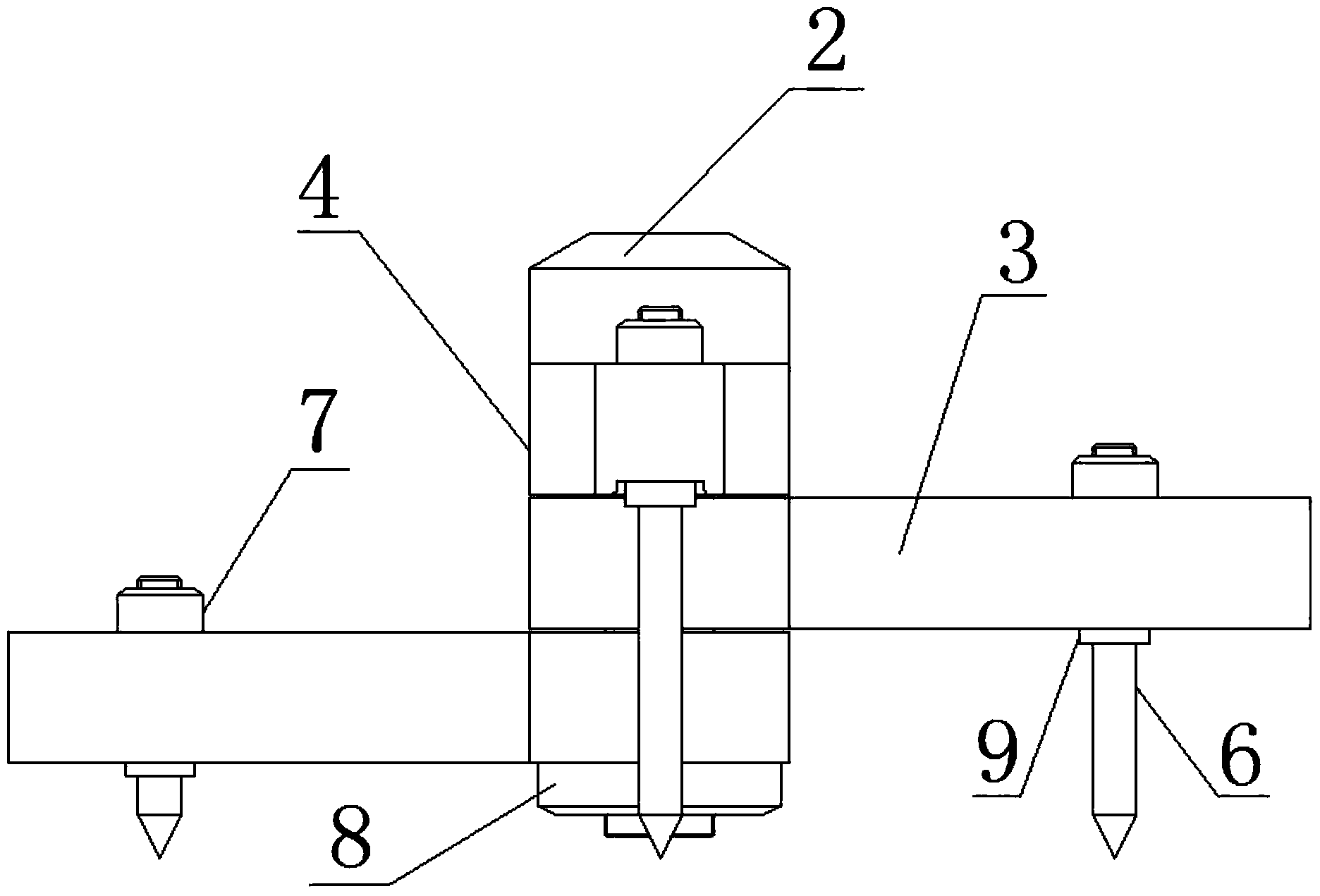

[0017] In conjunction with the accompanying drawings, a triangular level includes a rotating shaft 1, a circular level 2 arranged on the top of the rotating shaft 1, and a level bar 3. One end of the level bar 3 is connected to a bearing 4, and the bearing 4 is sleeved on the rotating shaft 1. The level 3 is provided with an elongated hole 5, and a support rod 6 that can slide on the elongated hole 5 is installed in the elongated hole 5, and the support rod 6 is in contact with the upper surface of the level 3 Nuts 7 are provided, and the number of said spirit level 3 is 3 and is set on the rotating shaft 1 through the bearing 4 from top to bottom in turn, and a main shaft nut for preventing the bearing 4 from falling is provided at the bottom of the rotating shaft 1 8. The bottoms of the three support rods 6 are on the same level and lower than the lowest pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com