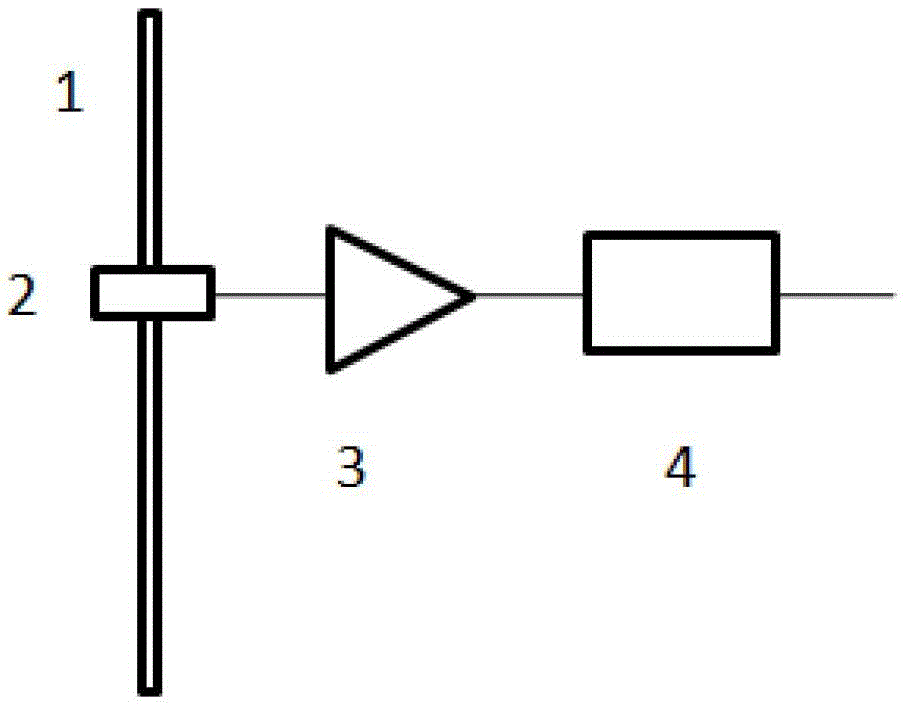

A calibration-free optical current sensor and method based on dual probes

A current sensor, calibration-free technology, applied in the direction of voltage/current isolation, measuring current/voltage, instruments, etc., to achieve the effect of simple installation and operation, convenient hanging network, and low requirements for the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

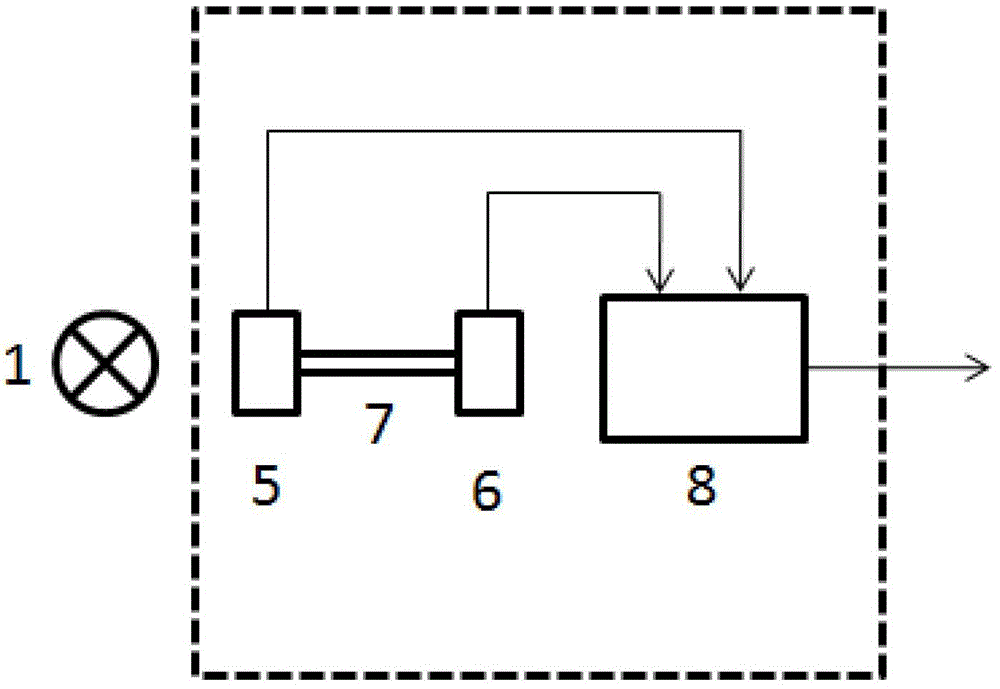

[0056] Such as figure 2 As shown, the magneto-optical current sensor for automatic distance calibration of the present invention is composed of two magneto-optical current sensing heads respectively [5] and [6], a fixed bracket [7] and a measuring unit [8].

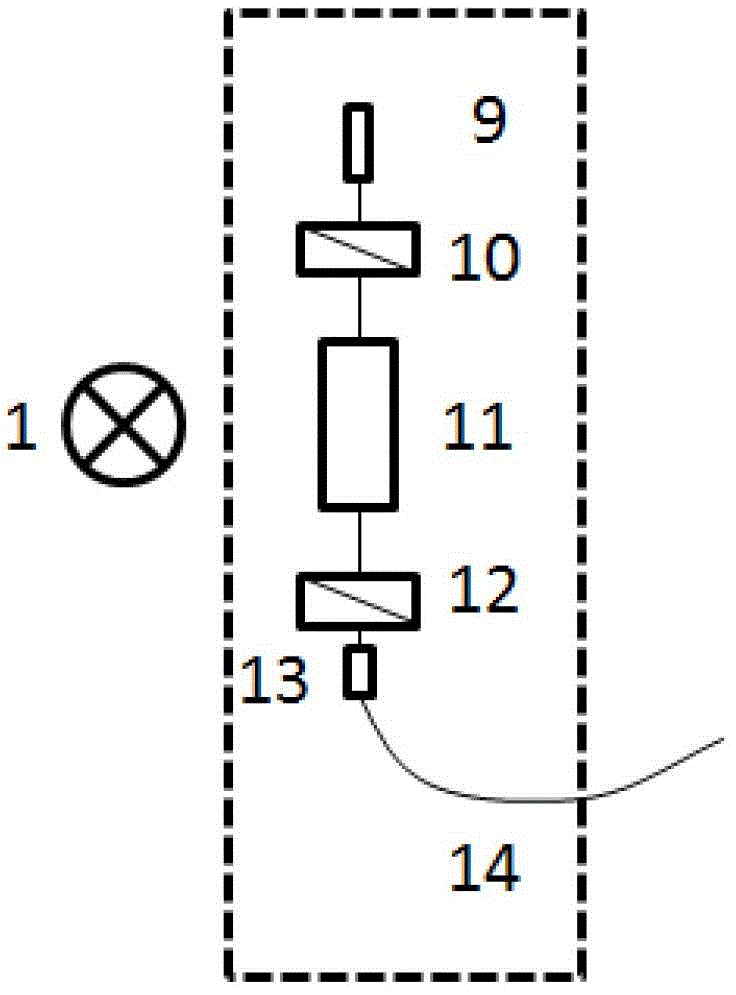

[0057] image 3 Schematic diagram of the sensor head [5], [6], the magneto-optical sensor head [5], [6] consists of a light source [9], a polarizer [10], a magneto-optical material [11], a polarizer [12], fiber collimator [13] and guiding fiber [14]. The light emitted by the light source [9] passes through the polarizer [10], the magneto-optical material [11], the analyzer [12] and the fiber collimator [13] and enters the conduction light [14] from one end, and the conduction fiber [14] The other end is used as the output end of the sensing head [5], [6].

[0058] Place the sensor near the current-carrying wire [1], make the fixed bracket [7] point to the current-carrying wire [1], and make the magneto-optical materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com