Patents

Literature

99 results about "Optical current transducer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

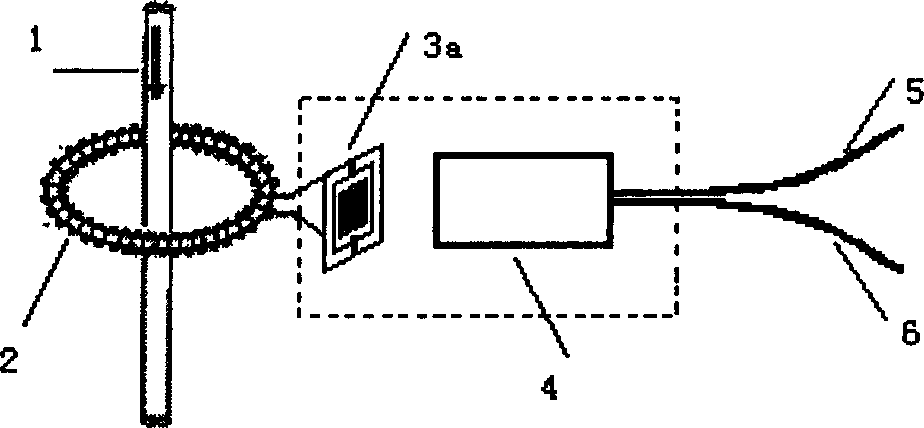

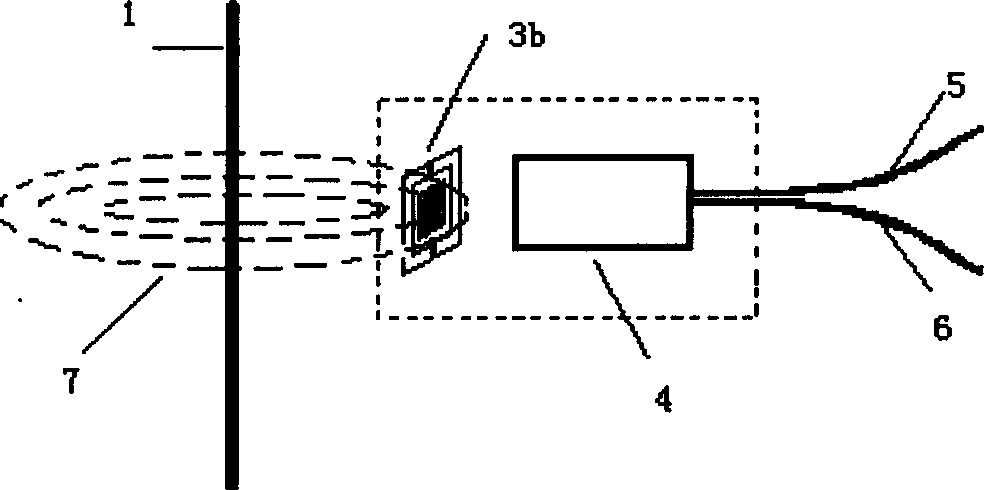

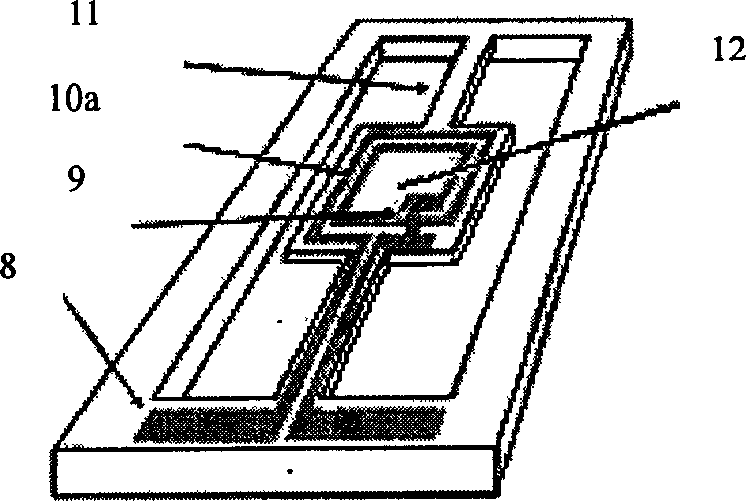

Optical current sensor based on microelectronic mechanical system, making and detecting method thereof

ActiveCN1844938AAvoid defects that are greatly affected by temperatureTransmission fitEffective value measurementsCurrent sensorEngineering

The invention relates to an optical current sensor based on micro electric mechanical system. It is characterized in that: it uses micro mechanical technique to prepare the MEMS metallic coil on the MEMS torsion micro lens; the Rogowski coil with non-magnetic skeleton and the MEMS metallic coil will guide the high-voltage alternative-current electric signal as induced current into the coil of MEMS torsion micro lens; a reflector is prepared on the back of MEMS torsion micro lens, which can swing around the axle by the electromagnetic torque; the swing angle can be measured by optical beam couple method that sensitive to the angle to attain the current valve. The invention uses the MEMS technique in the detection of high-voltage and large current, to be driven by induced current, and avoid driving power at the high-voltage end, to realize optical electric separation. It has small volume, lower cost, bath production and anti-disturb ability, with high test accuracy.

Owner:ANHUI CHINA SCI MW ELECTRONIC TECH CO LTD

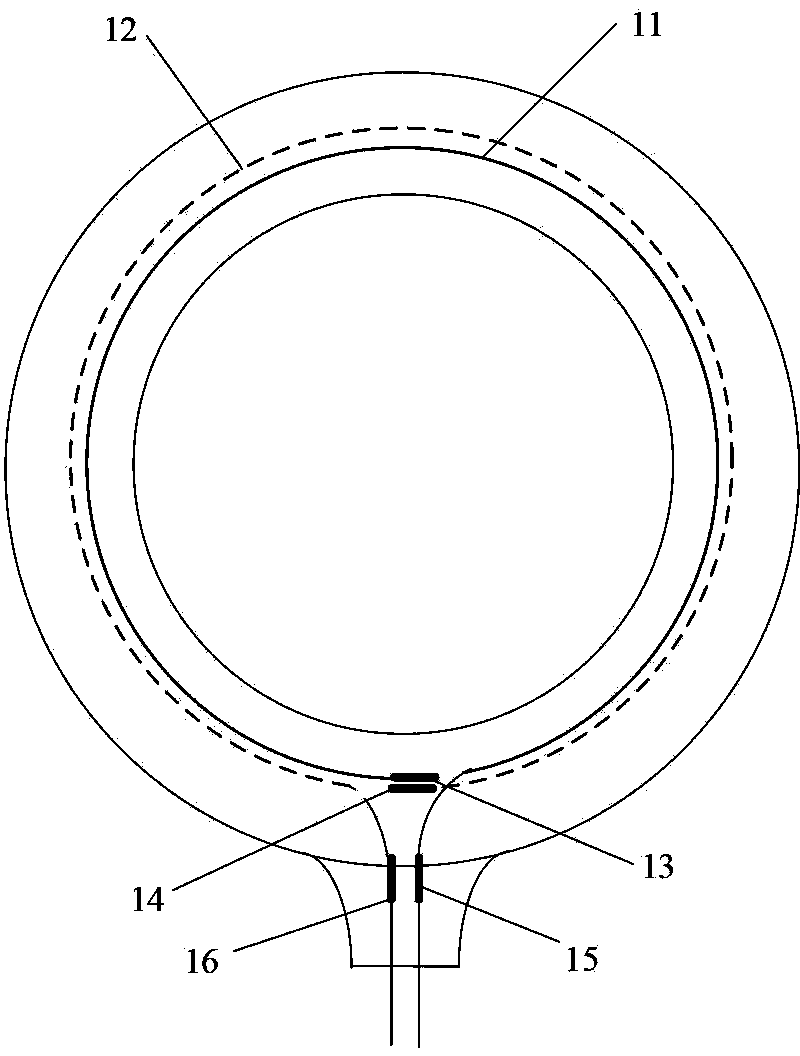

Optical current sensor

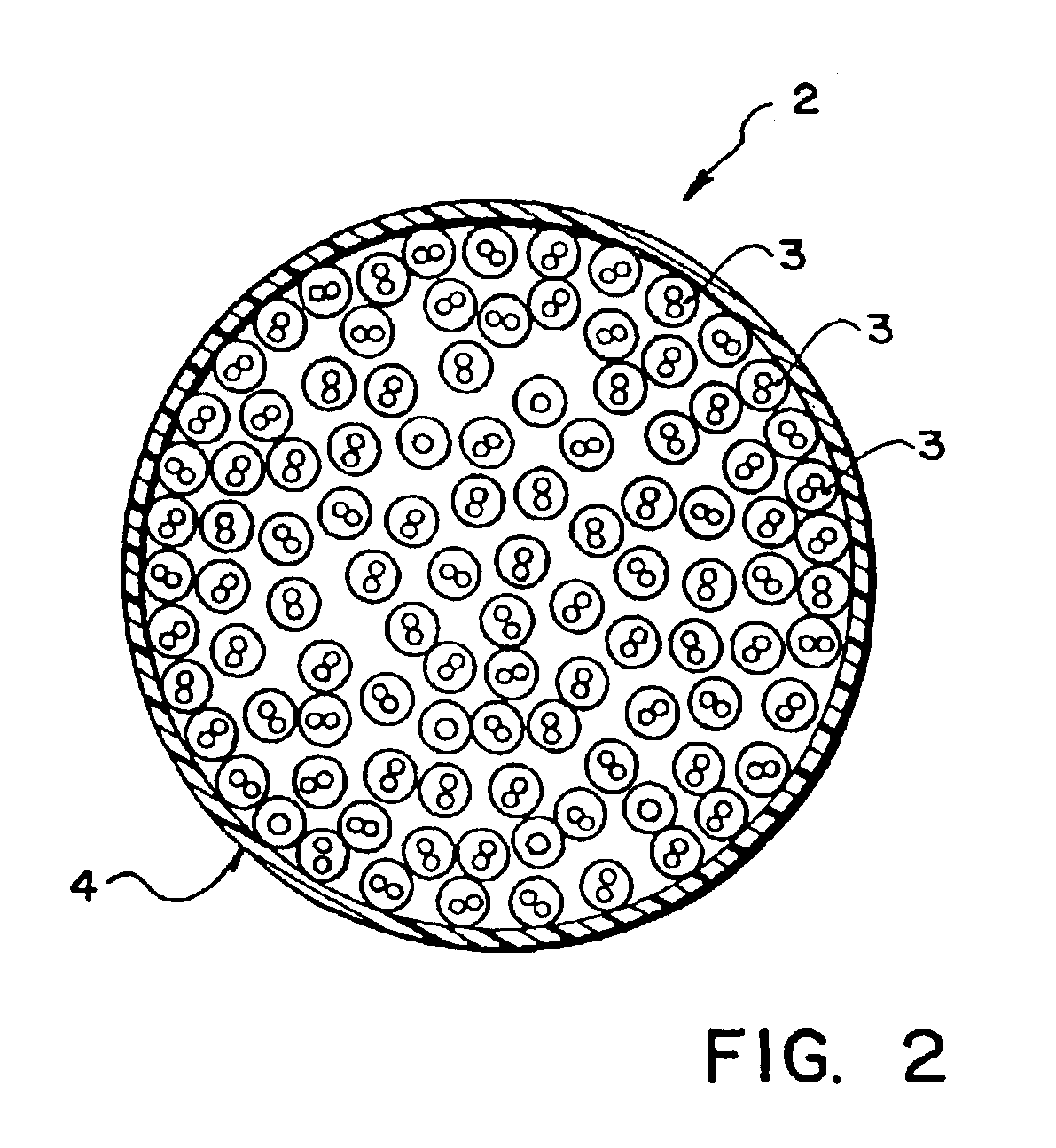

InactiveCN101354409ASuperparamagneticWith hysteresisCurrent/voltage measurementVoltage/current isolationElectrical conductorElectric power system

The invention provides an optical current sensor, relating to current detection equipment. The optical current sensor mainly comprises four parts: a magnet collecting ring optical sensing head, a polarized light system, a signal detection system and a power supply; as the optical current sensor of the invention has the advantages of high sensitiveness, quick response, high measurement exactness, low cost, online monitoring changes of the current amplitude and frequency of conductors to be measured in real time, facilitating the connection with digitizer, realizing the real-time online monitoring of computer and the like, the optical current sensor of the invention can be widely applied to the detection of power system transmission currents and currents used for large mine enterprises, especially for the current detection of high voltage and ultra-high high voltage power network.

Owner:CHONGQING UNIV

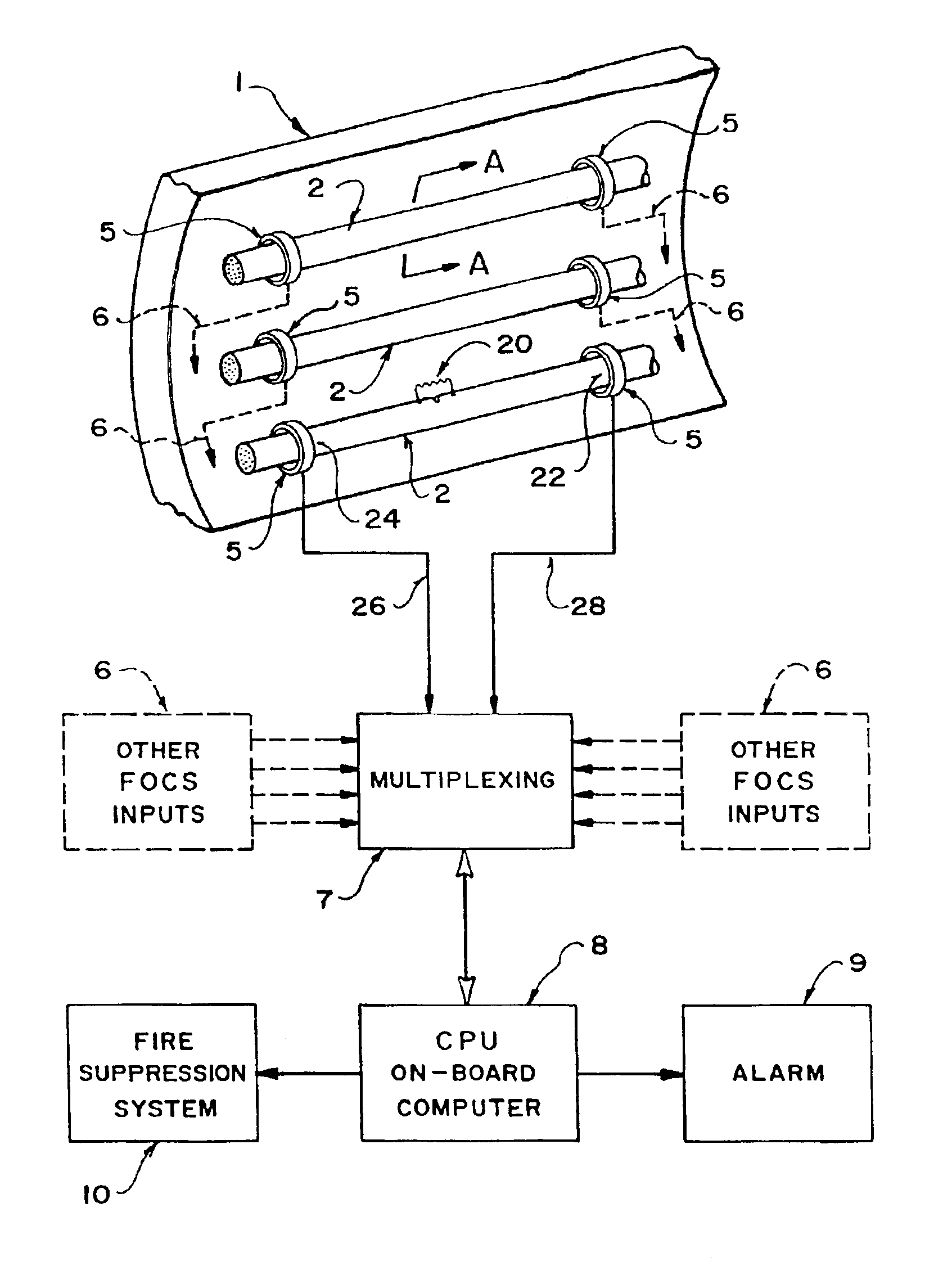

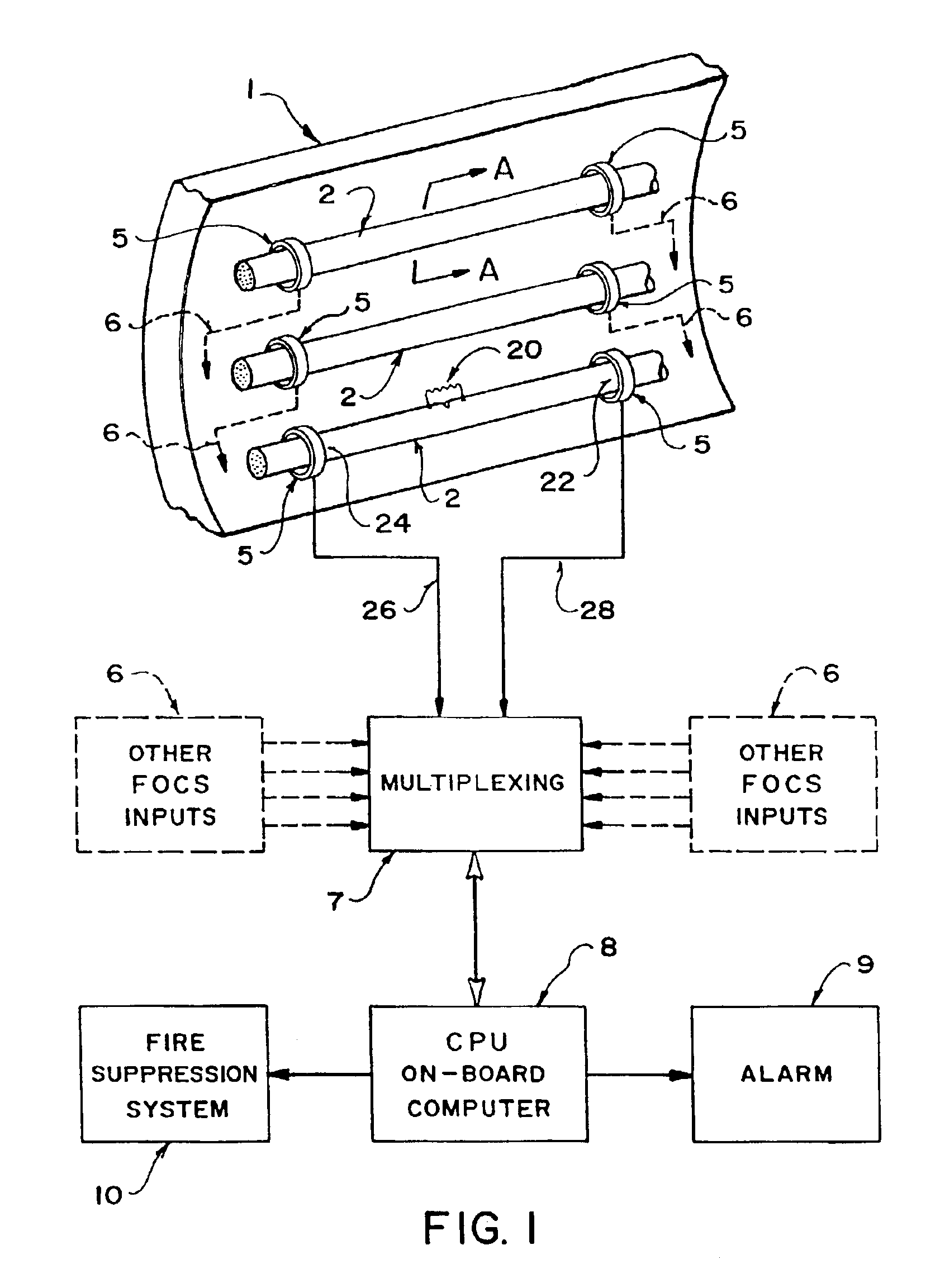

Method for diagnosing degradation in aircraft wiring

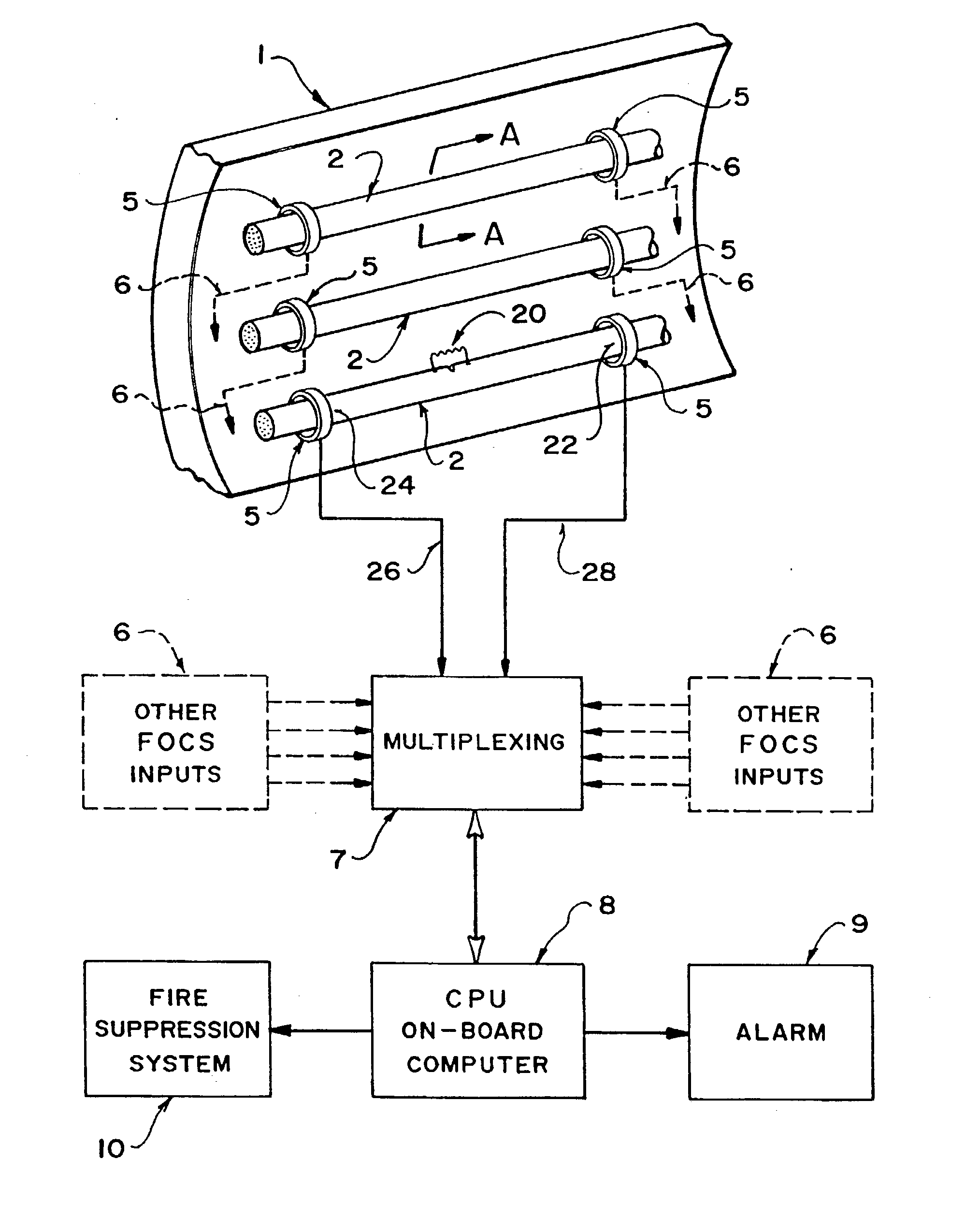

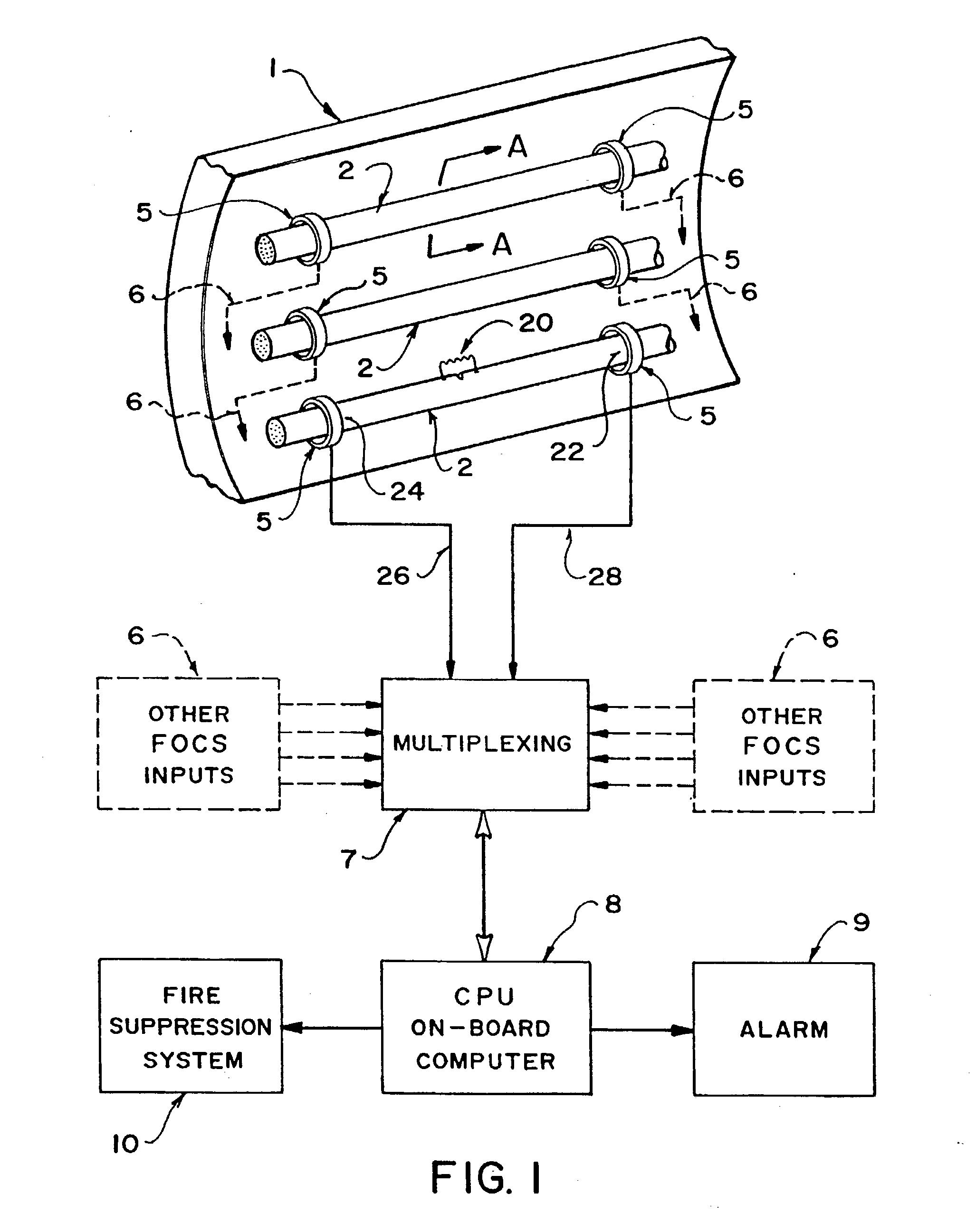

Wiring in new and older aircraft use bundled insulated conductors that are subject to deterioration overtime that can result in on-board fires, loss of in-flight control and eventual crashes of the aircraft. The present invention provides a diagnostic method which permits the on-line and non-destructive diagnosis of the insulation degradation in a portion of the wiring comprising: a) measuring the current flow at locations of the aircraft wiring utilizing an optical current sensor with a bandwidth of dc to 50 kHz; b) determining the current flow within a high frequency bandwidth; and c) analyzing the results of the current flow differential determination and initiate the following: i) detect and locate the point of cable failure; ii) initiate an alarm annunciation; and iii) initiate an on-board sectionalized fire suppression system.

Owner:ORTON HARRY E

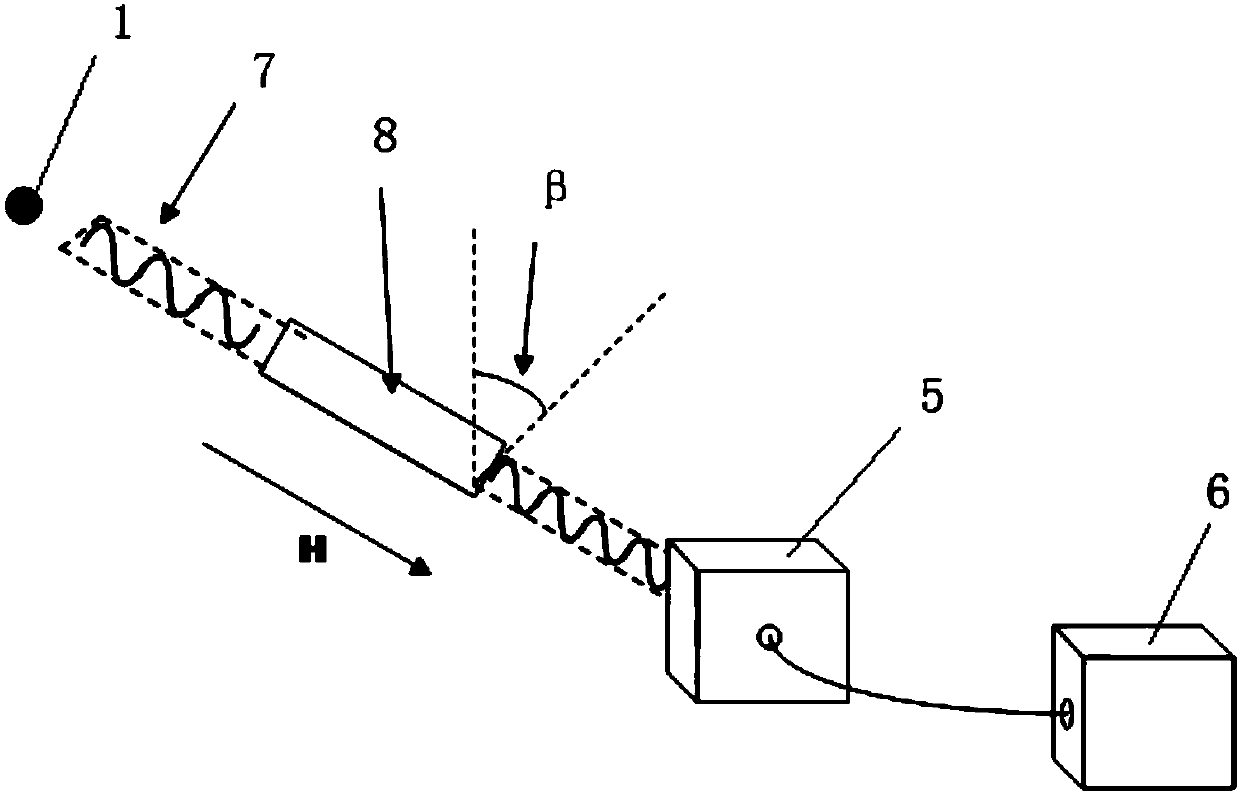

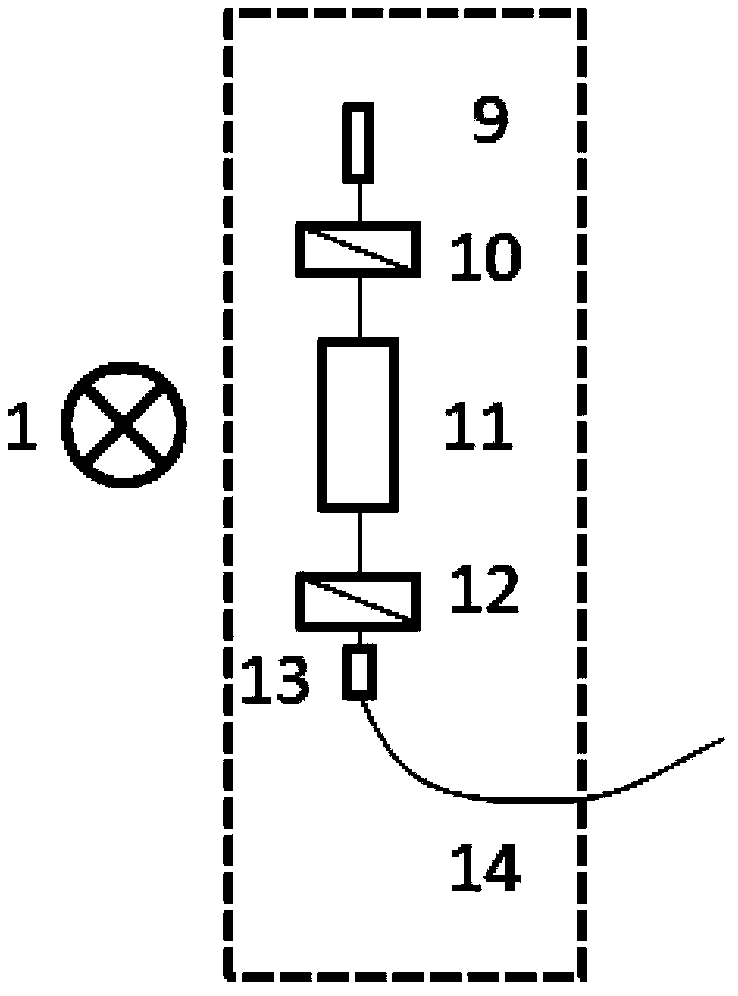

Optical current sensor based on Faraday magneto-optic effect and current measurement method thereof

InactiveCN107643438AImprove responsivenessInsulation effectCurrent/voltage measurementPhotodetectorCurrent sensor

The invention discloses an optical current sensor based on the Faraday magneto-optic effect. The optical current sensor comprises a laser generator which is used to generate polarized laser of a set wavelength, an integrated probe which comprises a magneto-optical medium, a photodetector which is used to convert an optical signal into an electrical signal, and a data analyzing and processing device which filters out noise through the combination of hardware filtering and software filtering to acquire a good response effect. A polarizer and an analyzer are arranged on two ends of the magneto-optical medium respectively, and are insulatedly packaged on both ends of the magneto-optical medium respectively. The laser generator and the polarizer are connected through an optical fiber path, andthe photodetector and the analyzer are connected through an optical fiber path. The invention further discloses a current measurement method of the optical current sensor based on the Faraday magneto-optic effect.

Owner:CHONGQING UNIV

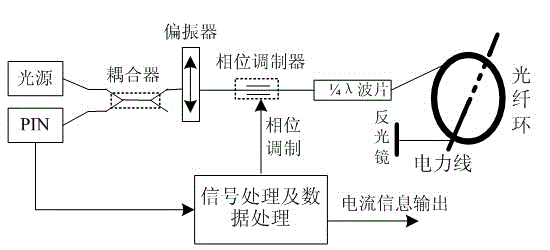

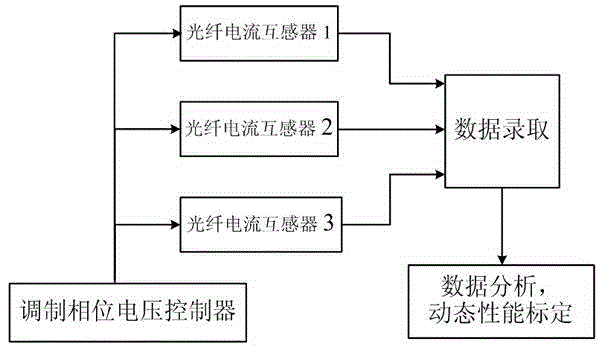

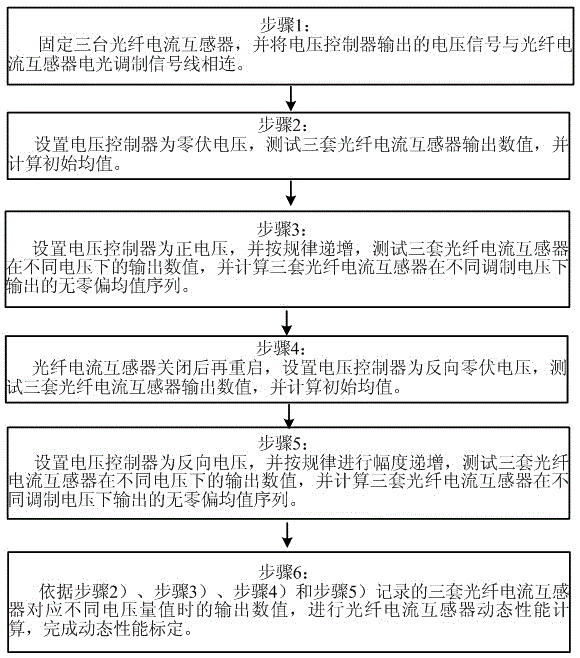

Method for calibrating dynamic performances of fiber optical current transducer (FOCT) based on voltage modulation

The invention discloses a method for calibrating dynamic performances of an FOCT based on voltage modulation. Additional voltage modulation phases are introduced in a digital closed-loop signal processing process of the FOCT to simulate optical nonreciprocity Farady phases caused by power line currents, segment treatment is performed to output data of the FOCT by using a segment modulation phase method to calibrate scale factors of the FOCT, and the linearity, the symmetry and the repeatability of the scale factors of the FOCT are analyzed. According to the method, the method starts from a digital closed-loop signal processing process of the FOCT, dynamic performances of the FOCT are estimated overall, the method has the advantages of being simple and direct in testing process and high in calibration accuracy, and test calibration of a plurality of sets of FOCTs can be completed for one time.

Owner:SOUTHEAST UNIV

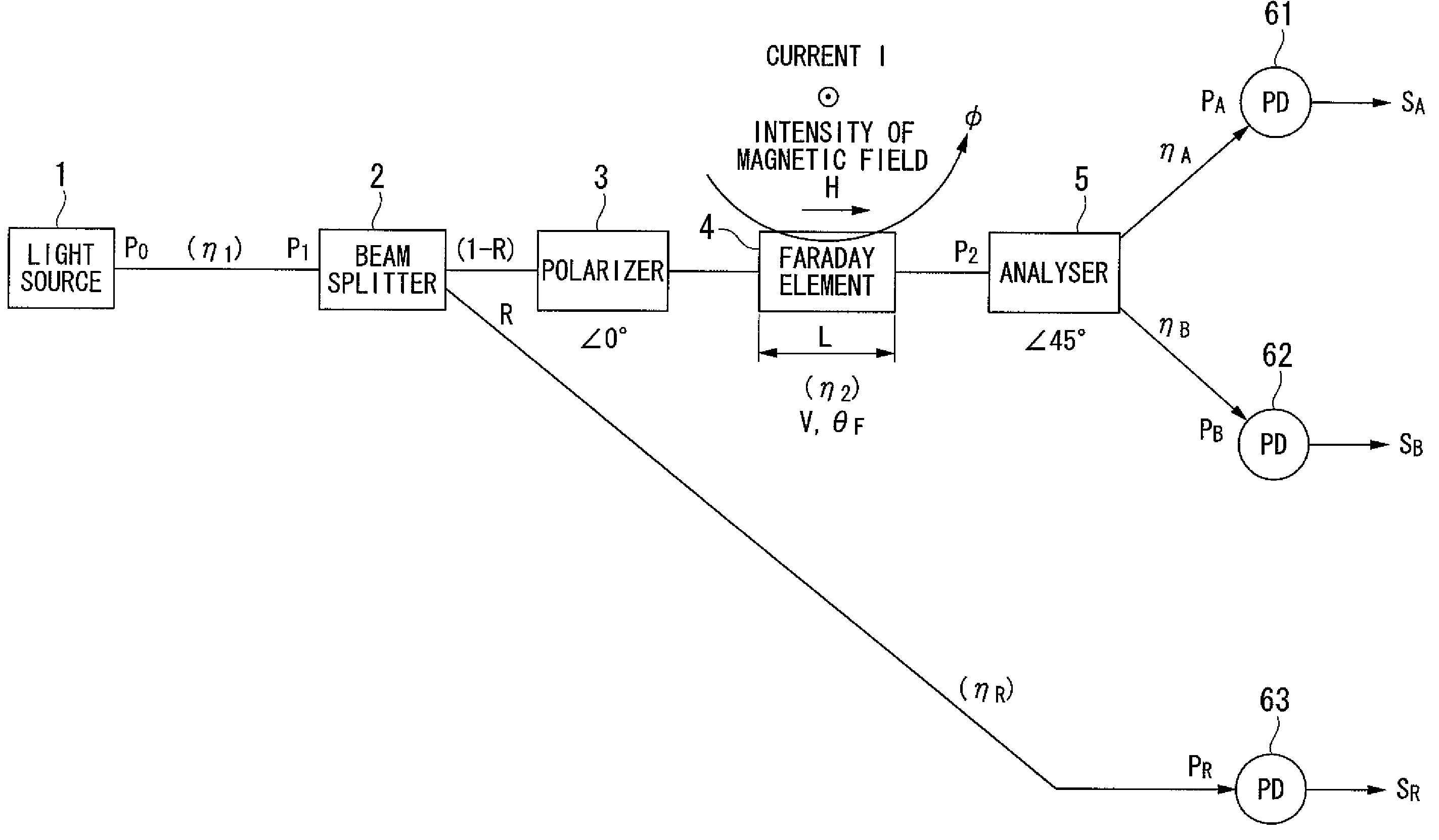

Optical sensor, optical current sensor and optical voltage sensor

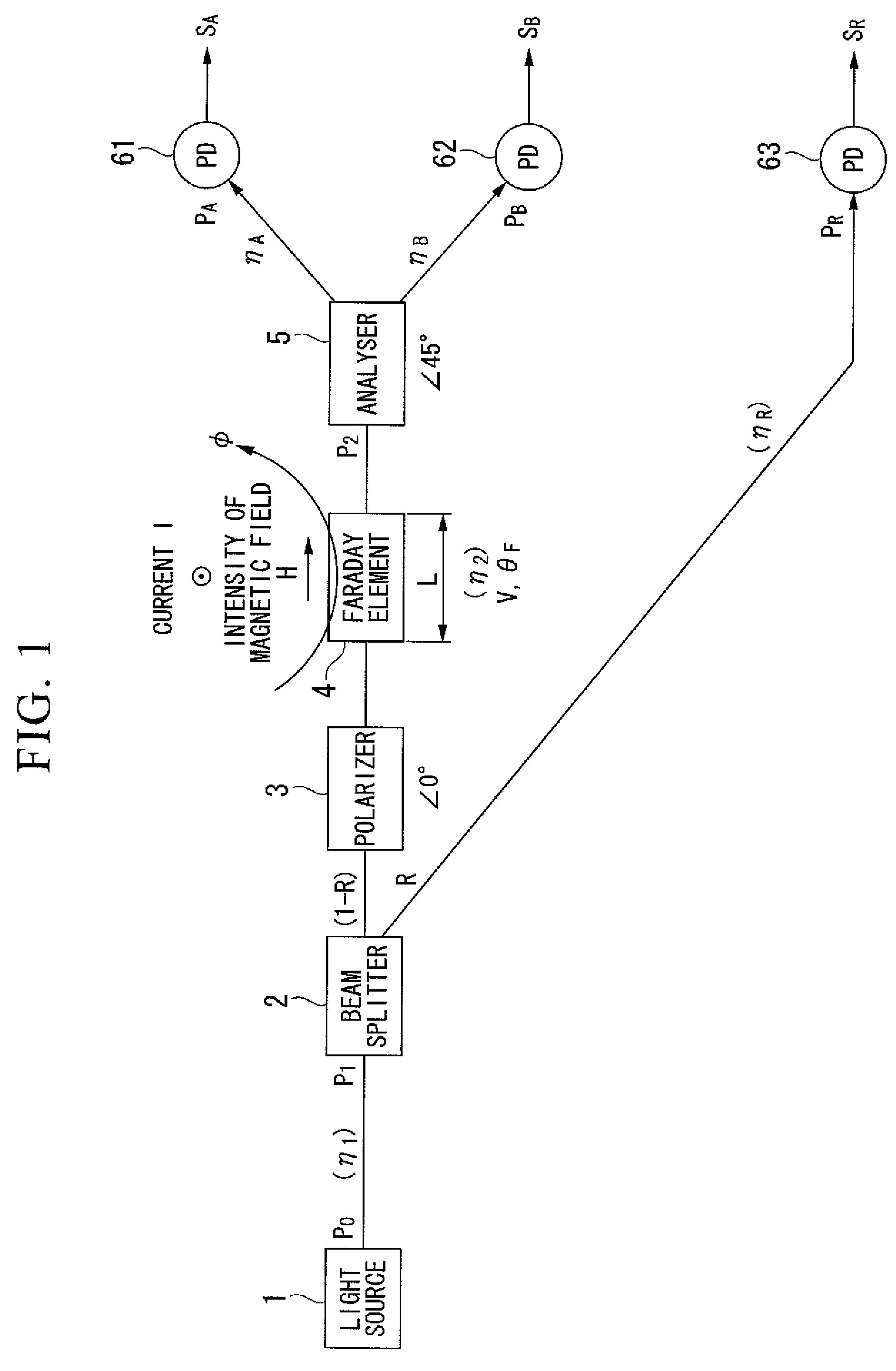

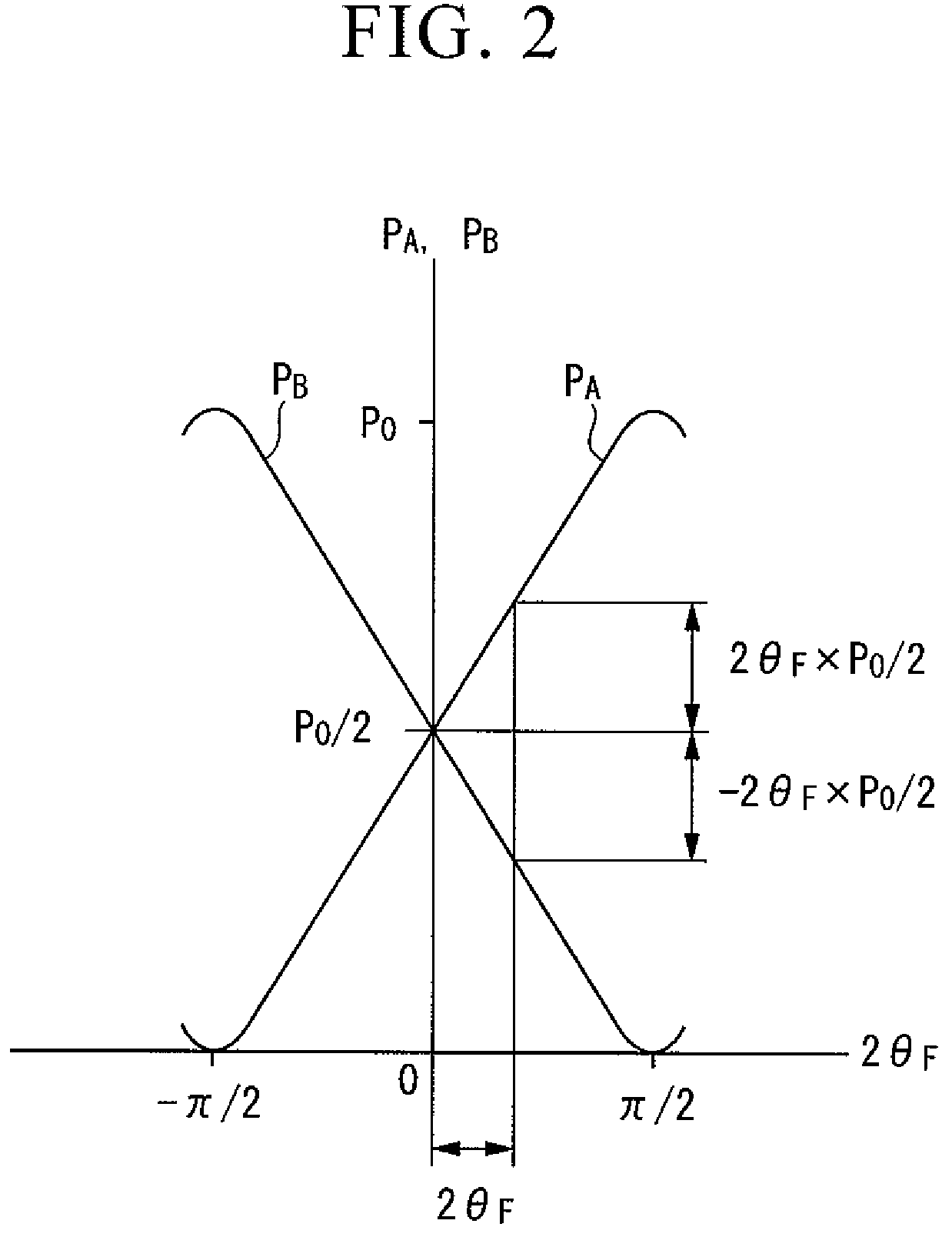

A simple constitution together with an easy calibration of output by realizing a fast light intensity detection method is realized without using the carrier signal.An optical sensor, including: a sensor to which light from a light source is lead, and by which light intensity of the light is modulated based on a physical value; light receiving elements 61 and 62 receiving two elements of divided light PA and PB having polarized waves which are orthogonally crossing each other; a variable optical attenuator operating light which is received by the light receiving elements 61 and 62; and a variable amplifier operating output signals from the light receiving elements 61 and 62, wherein both a zero point of a sensor output and sensitivity are calibrated based on a light attenuation factor or an amplification factor which is adjusted when a physical value is detected by calculating a ratio between a sum and a difference of outputs of the light receiving elements 61 and 62.

Owner:THE TOKYO ELECTRIC POWER CO INC

Method for diagnosing degradation in aircraft wiring

InactiveUS20030105598A1Resistance/reactance/impedenceEmergency protective arrangement detailsOn boardCurrent sensor

Wiring in new and older aircraft use bundled insulated conductors that are subject to deterioration over time that can result in on-board fires, loss of in-flight control and eventual crashes of the aircraft. The present invention provides a diagnostic method which permits the on-line and non-destructive diagnosis of the insulation degradation in a portion of the wiring comprising: a) measuring the current flow at locations of the aircraft wiring utilizing an optical current sensor with a bandwidth of dc to 50 kHz; b) determining the current flow within a high frequency bandwidth; and c) analysing the results of the current flow differential determination and initiate the following: i) detect and locate the point of cable failure; ii) initiate an alarm annunciation; and iii) initiate an on-board sectionalized fire suppression system.

Owner:ORTON HARRY E

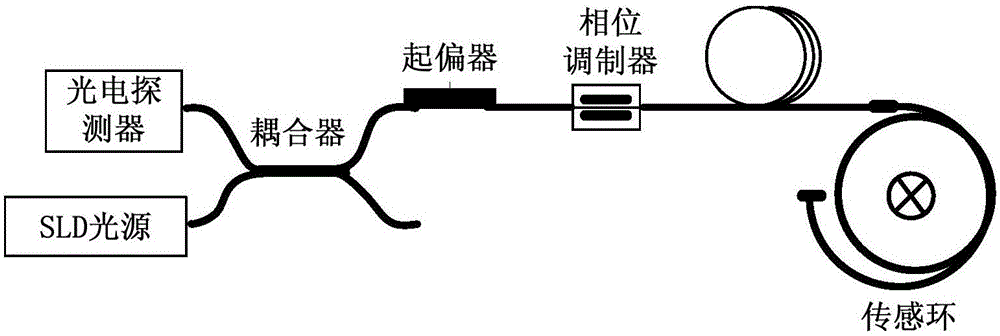

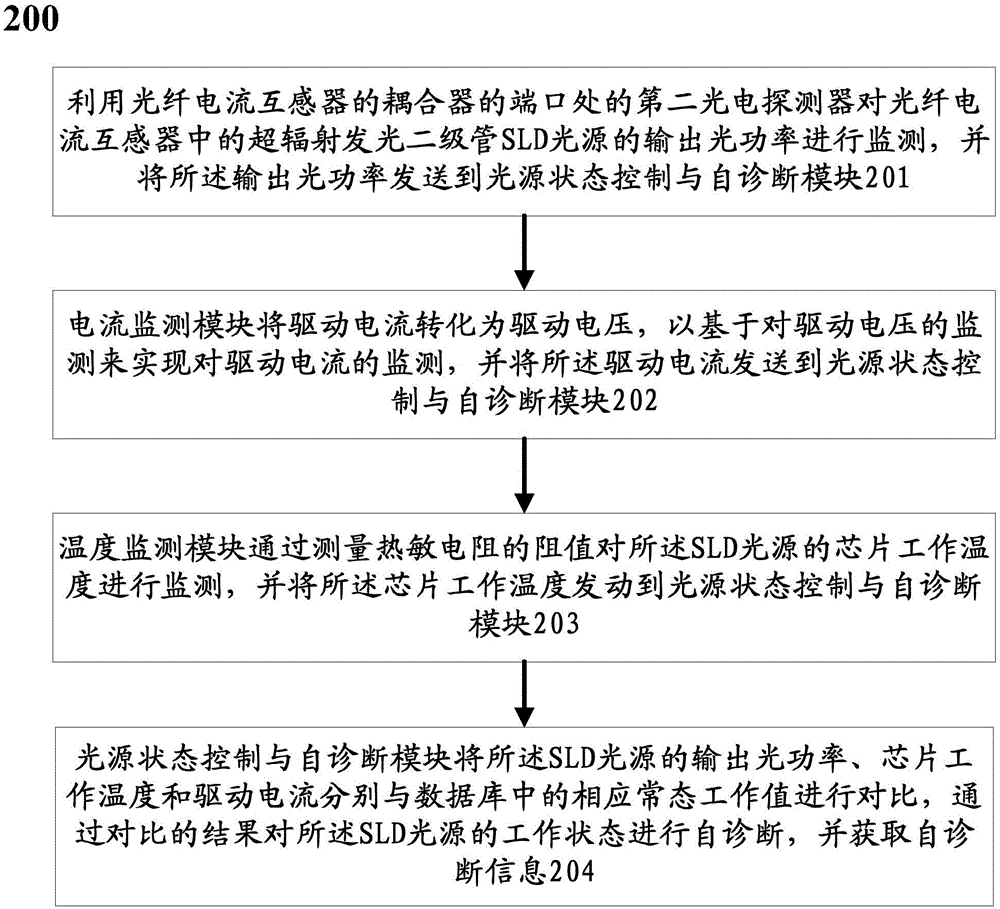

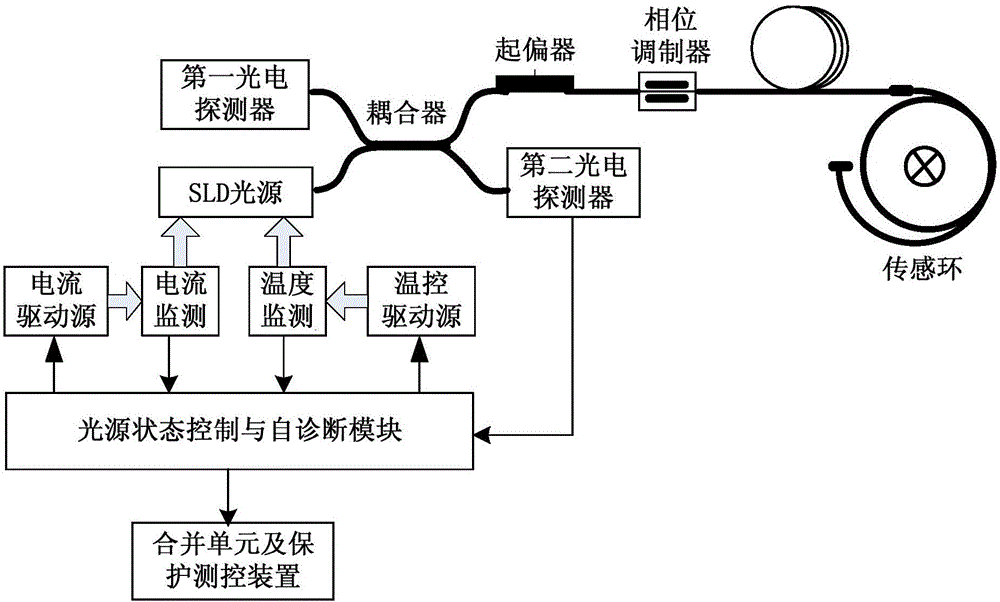

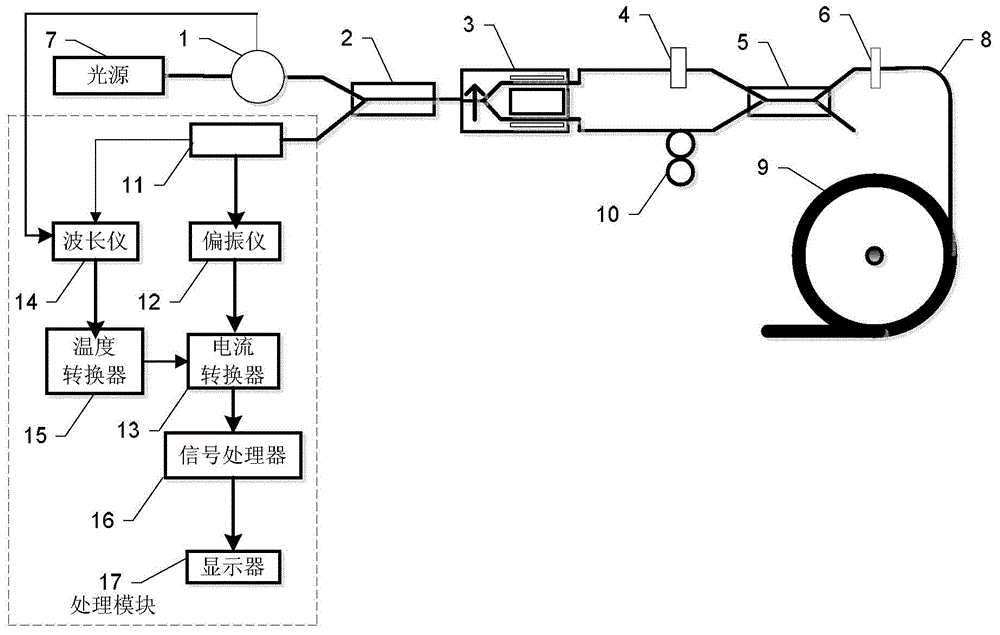

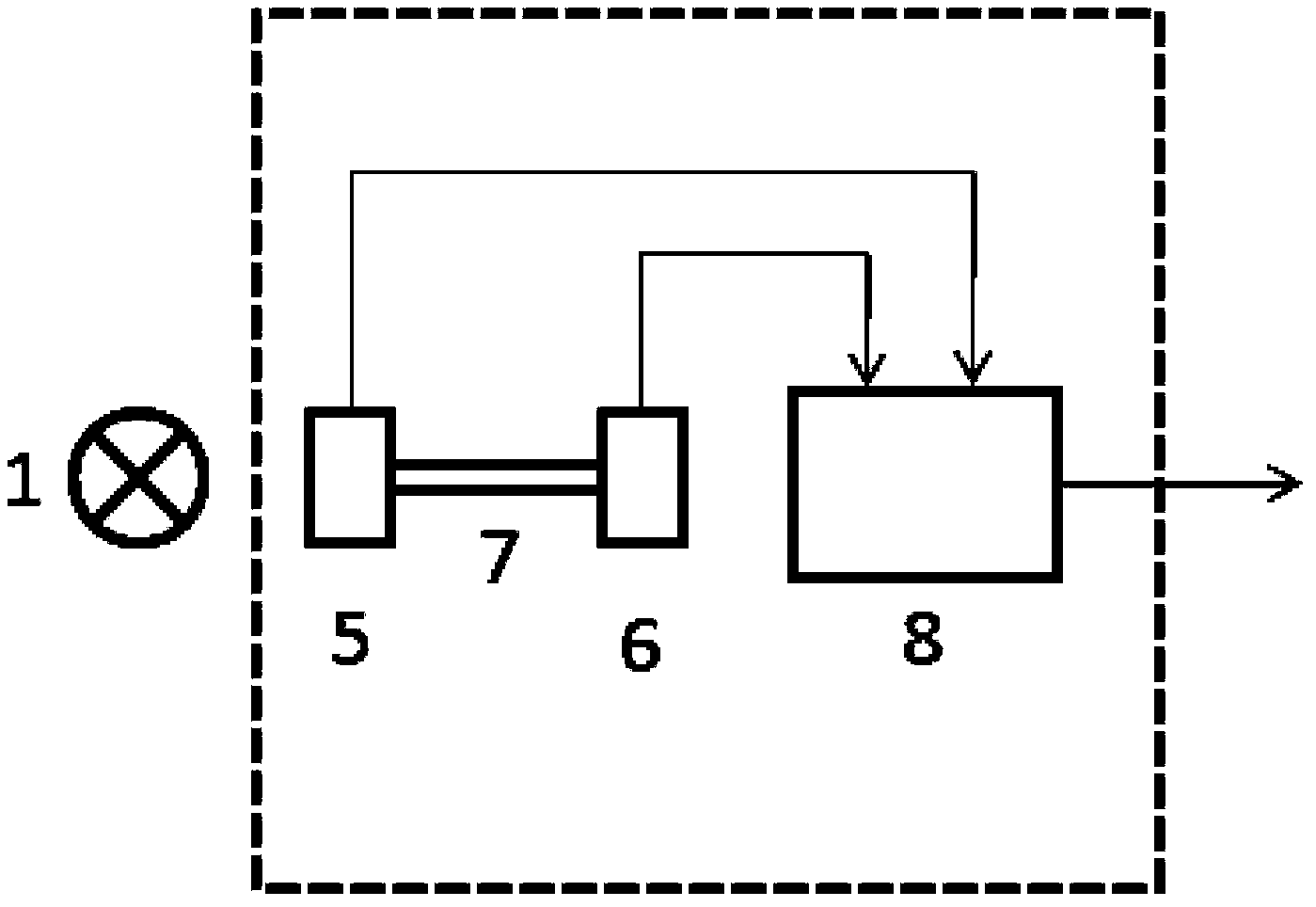

Method and system for online monitoring state of fiber-optical current transducer and self-diagnosis

InactiveCN106597347AMonitor optical powerMonitor spectral center wavelength changesElectrical measurementsFiberWorking temperature

The invention discloses a method for online monitoring the state of a fiber-optical current transducer and conducting self-diagnosis. The method includes the following steps: using a second photoelectronic detector which is arranged at a port of a coupler of the fiber-optical current transducer to monitor the output light power of a superluminescent light-emitting diode (SLD) light source in the fiber-optical current transducer and transmit the output light power to a light source state control and self-diagnosis module; a current monitoring module monitoring drive current and transmitting the drive current to the light source state control and self-diagnosis module; a temperature monitoring module monitoring the working temperature of a chip of the SLD light source by measuring the resistance of a thermistor and transmitting the working temperature of the chip to the light source state control and self-diagnosis module; the light source state control and self-diagnosis module separately comparing the output light power of the SLD light source, the working temperature of the chip and the drive current with corresponding normal state working values in a database, and conducting self-diagnosis on the working state of the SLD light source on the basis of the result of the comparison, and acquiring self-diagnosis information.

Owner:CHINA ELECTRIC POWER RES INST +3

Method for measuring current in an electric power distribution system

ActiveUS8395372B2Increase rangeHigh sensitivityMeasurement using dc-ac conversionDynamo-electric motor metersFiberCurrent sensor

Owner:MICATU

Fiber-optic current sensor

InactiveUS7075286B2Improve long-term stabilityRadiation pyrometryCurrent/voltage measurementFiberPhase shifted

Owner:ABB RES LTD

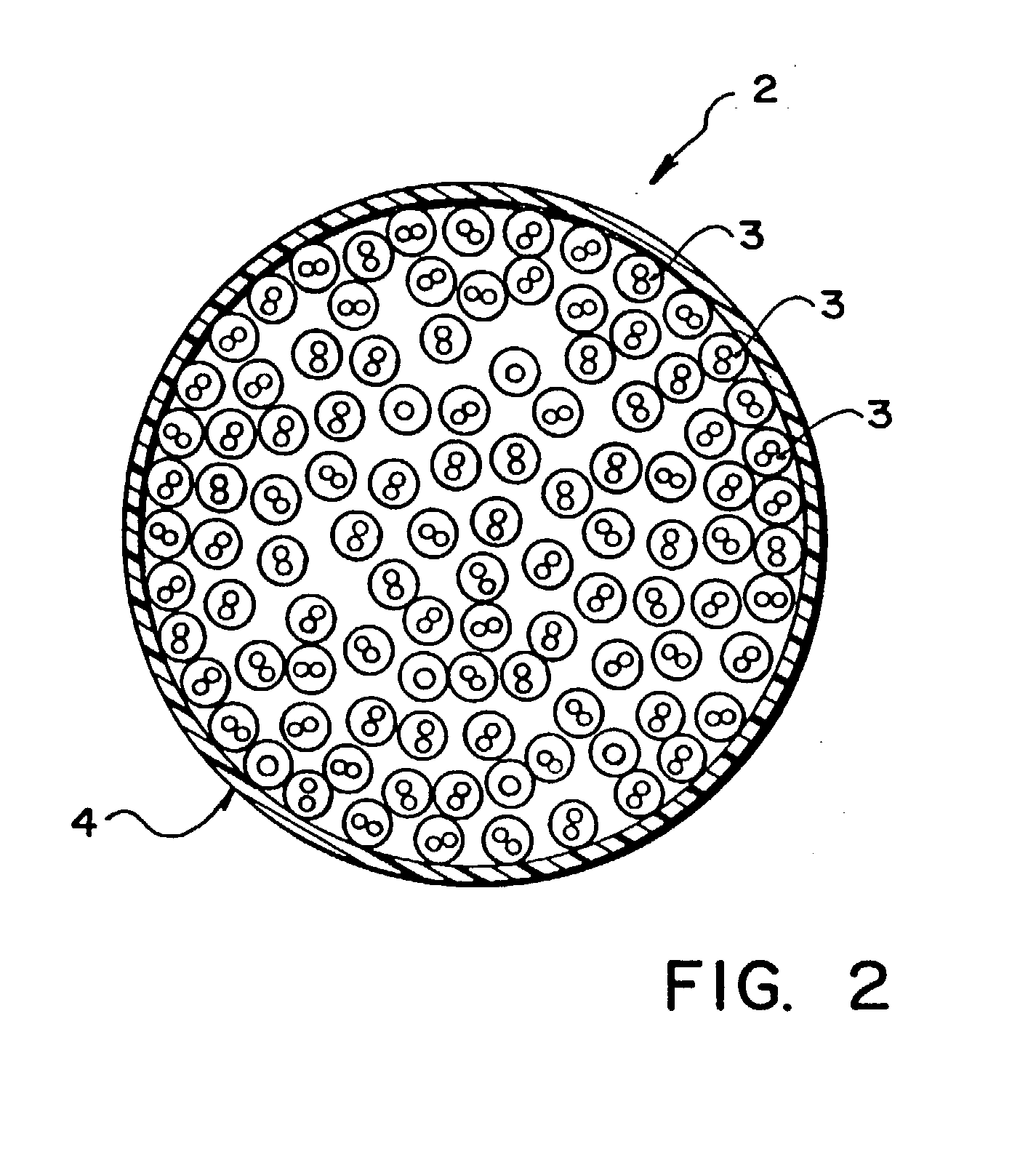

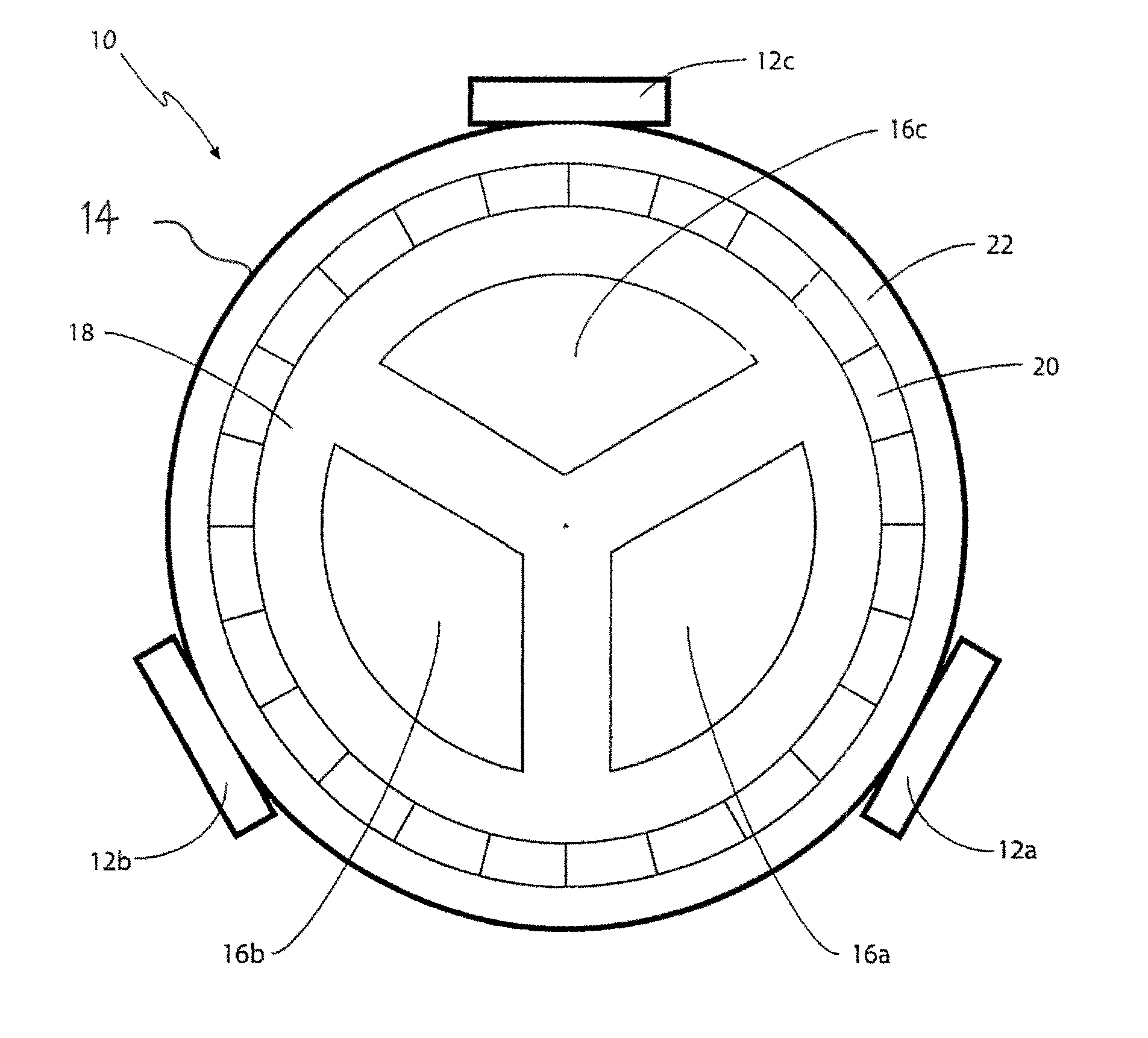

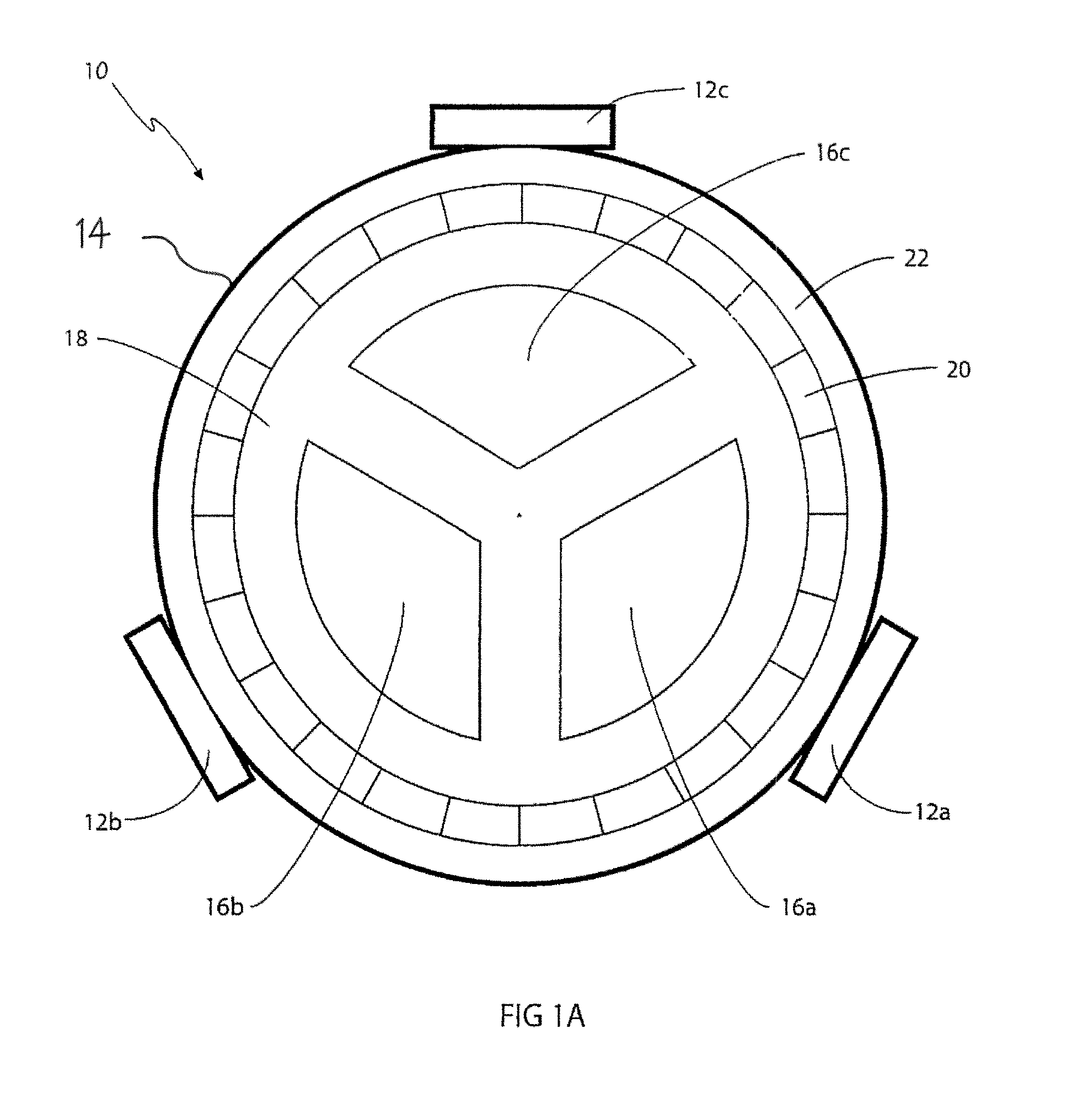

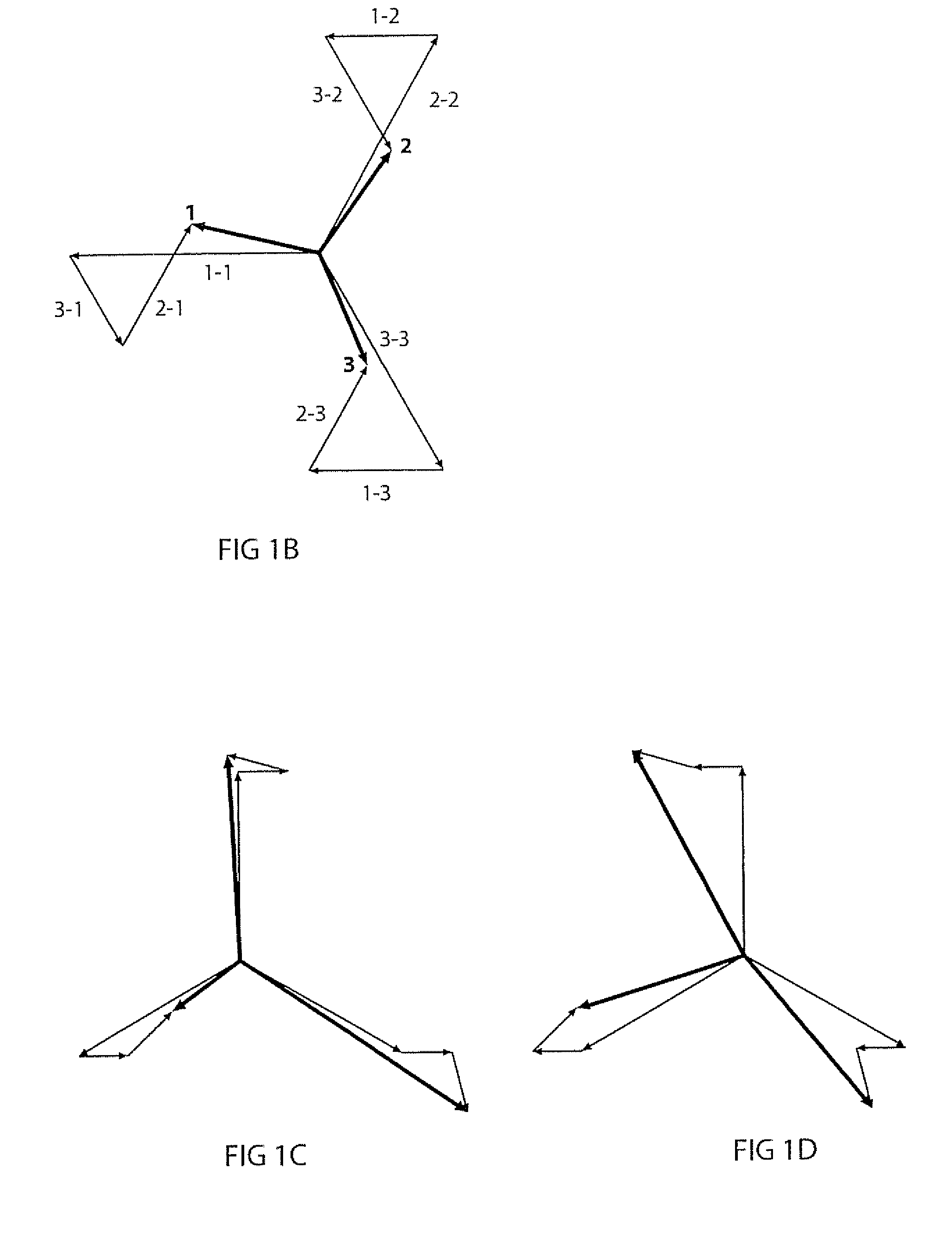

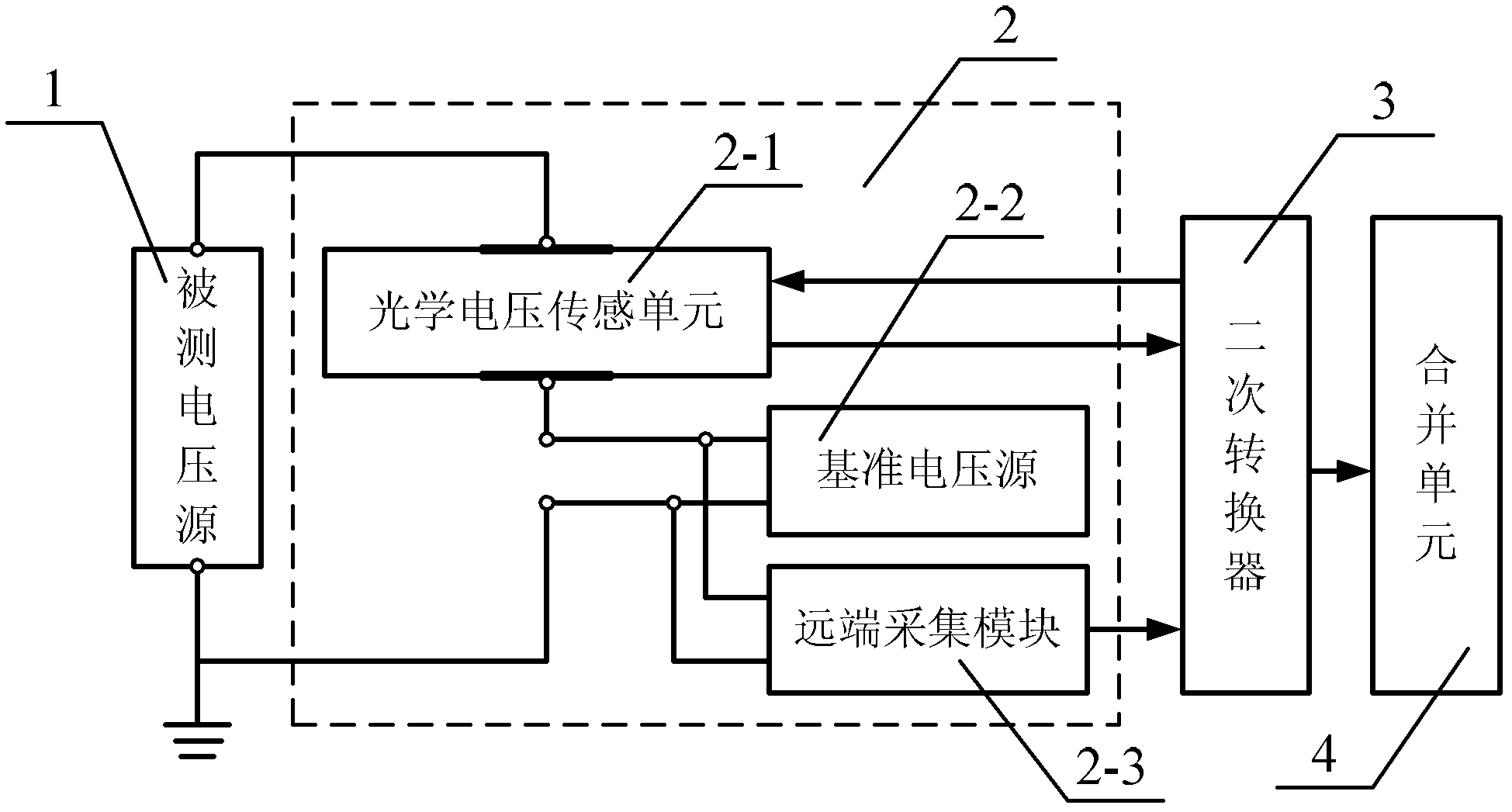

3-phase faraday optical current sensor assembly

The object of the invention is to provide a method and a system for fixating a Faraday optical current sensor (12a, 12b, 12c) in a suitable measurement position for measuring the current in a 3-phase cable (14). The 3-phase cable (14) comprises 3 individual section-shaped phase conductors (16a, 16b, 16c) insulated in relation to one another and encapsulated inside an insulator (18). The method comprises the provision of a Faraday optical current sensor arrangement comprising 3 Faraday optical current sensors (12a, 12b, 12c), each Faraday optical current sensor being fixated in a specific position outside the section-shaped phase conductors (16a, 16b, 16c), and the provision of a processing unit for calculating a current value from a magnetic field value. The method is performed by measuring 3 magnetic field values by using each of the 3 Faraday optical current sensors (12a, 12b, 12c) and calculating the current in each of the section-shaped phase conductors (16a, 16b, 16c) by using the processing unit and the 3 magnetic field values.

Owner:LANDIS & GYR OY

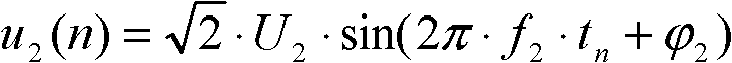

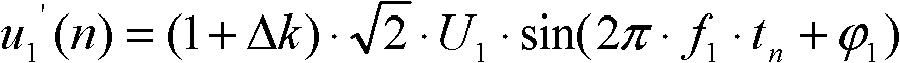

Optical voltage sensor and self-calibration method for realizing sensor

InactiveCN102435829ARealize self-calibration functionSolve the problem of poor temperature stability of measurement accuracyVoltage/current isolationMeasurement using digital techniquesTransformerVoltage source

The invention relates to a self-calibration method for realizing an optical voltage sensor, which relates to a self-calibration method for a sensor. A reference voltage source is designed to realize a self-calibration function of the optical voltage sensor. By using the current optical voltage sensor, measurement precision and temperature stability are low. By using the optical voltage sensor of the invention, the above problem can be solved. In the invention, a discrete Fourier algorithm is used to acquire an effective value of a voltage signal. Through adding a calculation sample number and windowing processing, influence of frequency fluctuation on effective value calculation can be reduced and the stability of a self-calibration coefficient can be increased. An optical voltage sensor measurement result is affected by a temperature. By using an optical current sensor in the invention, the above problem can be solved. Through testing, the measurement precision reaches an IEC 0.2 grade measuring requirement in a temperature scope of minus 40-60 DEG C. The sensor and the method are suitable for designing a voltage transformer.

Owner:HARBIN INST OF TECH

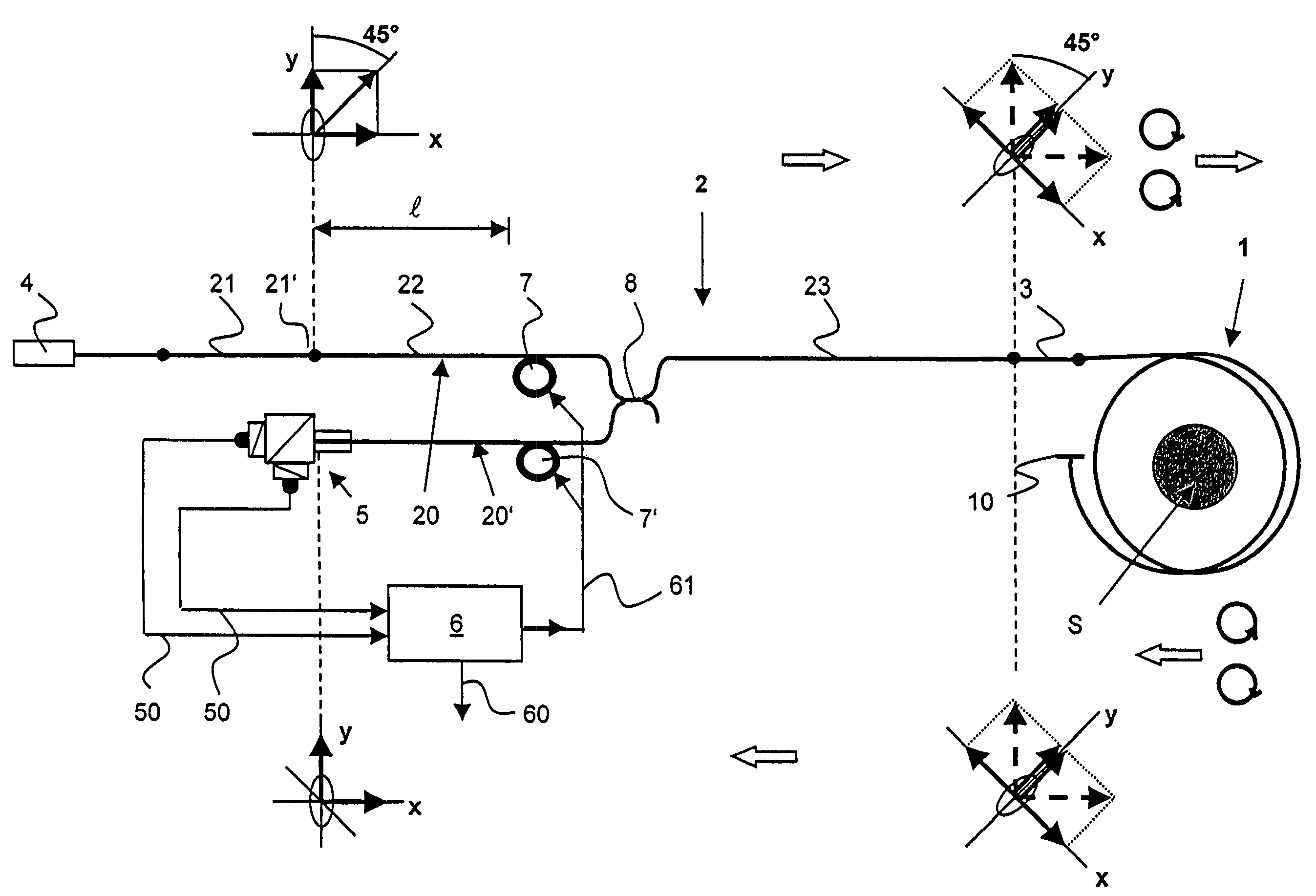

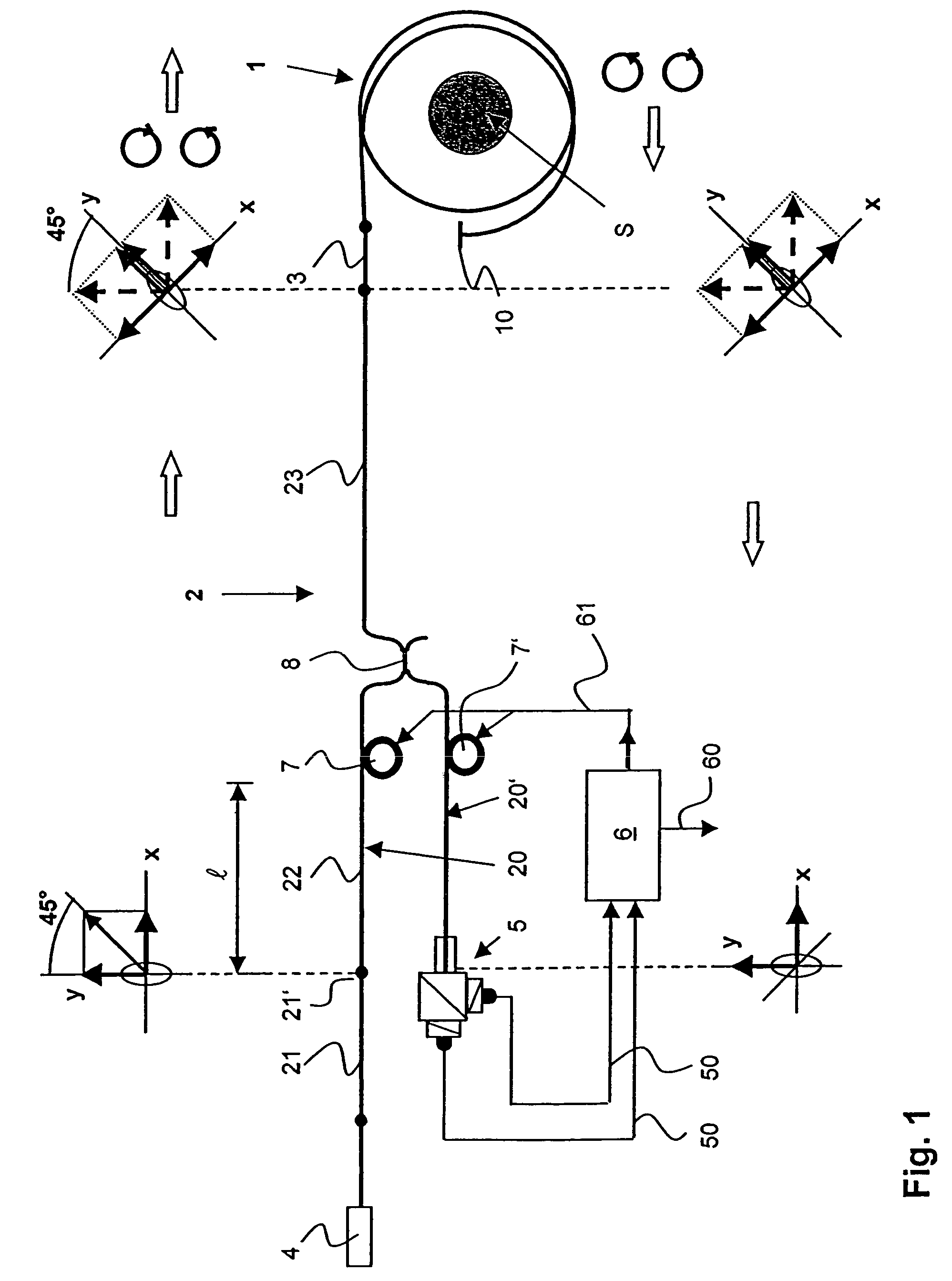

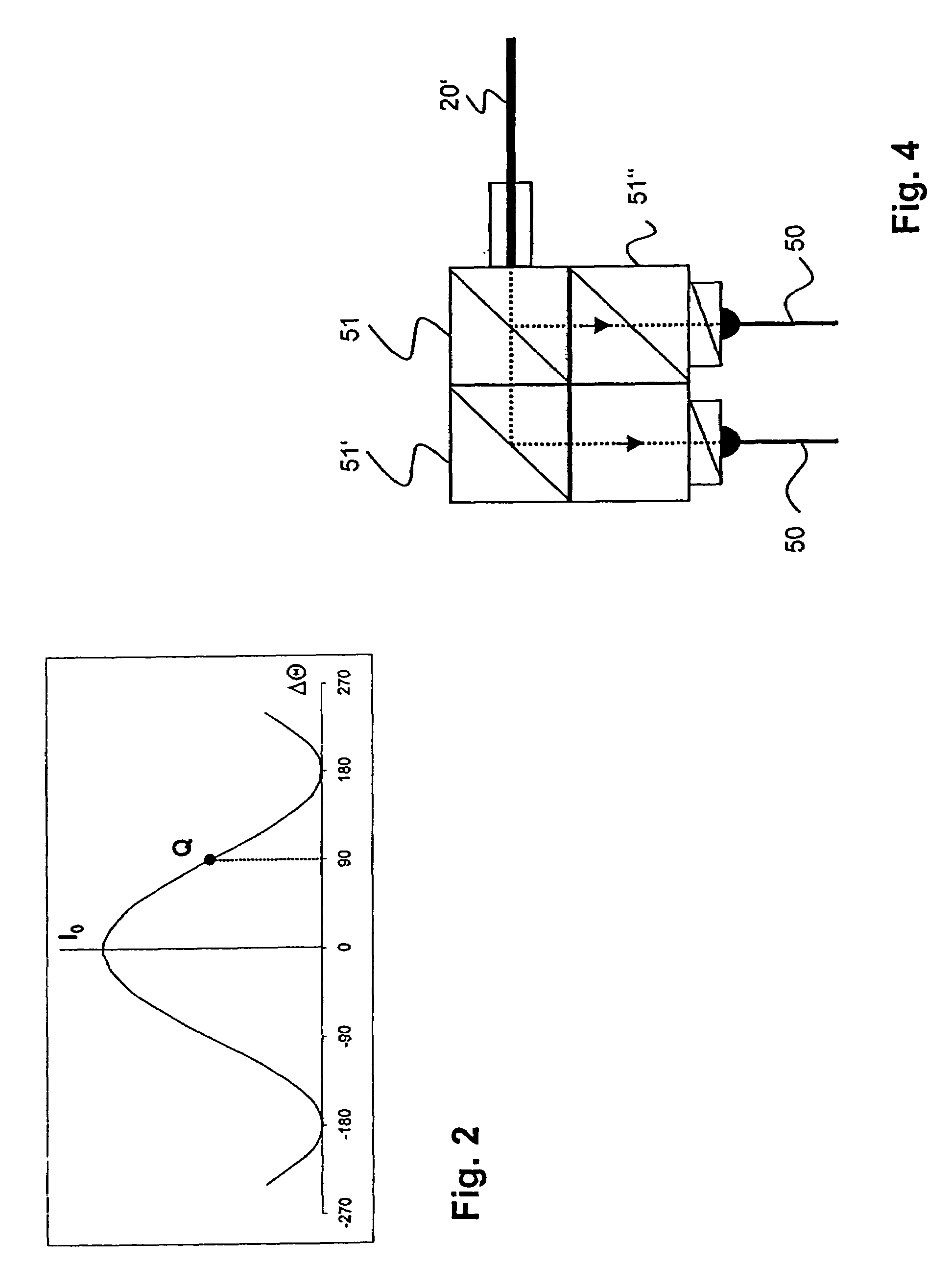

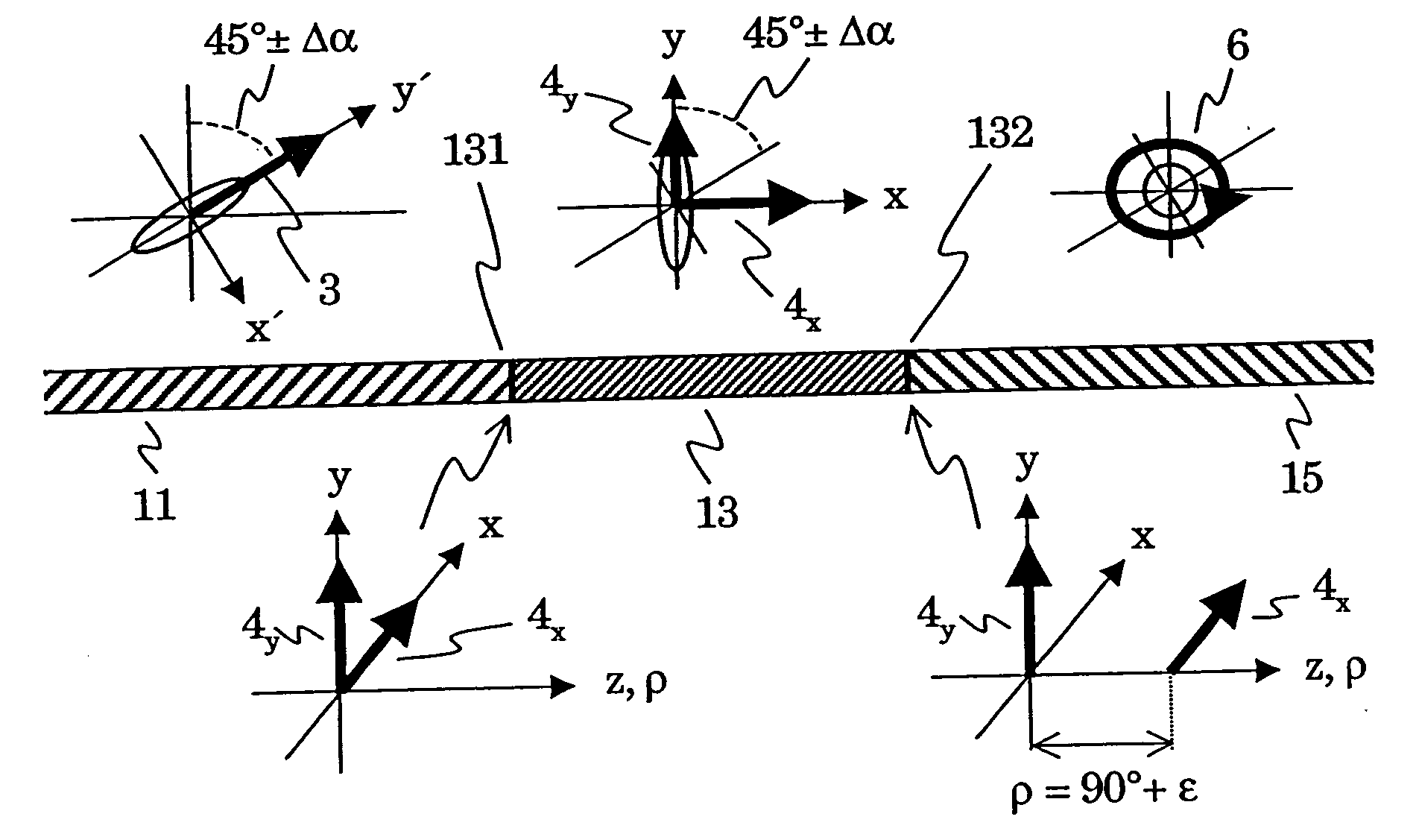

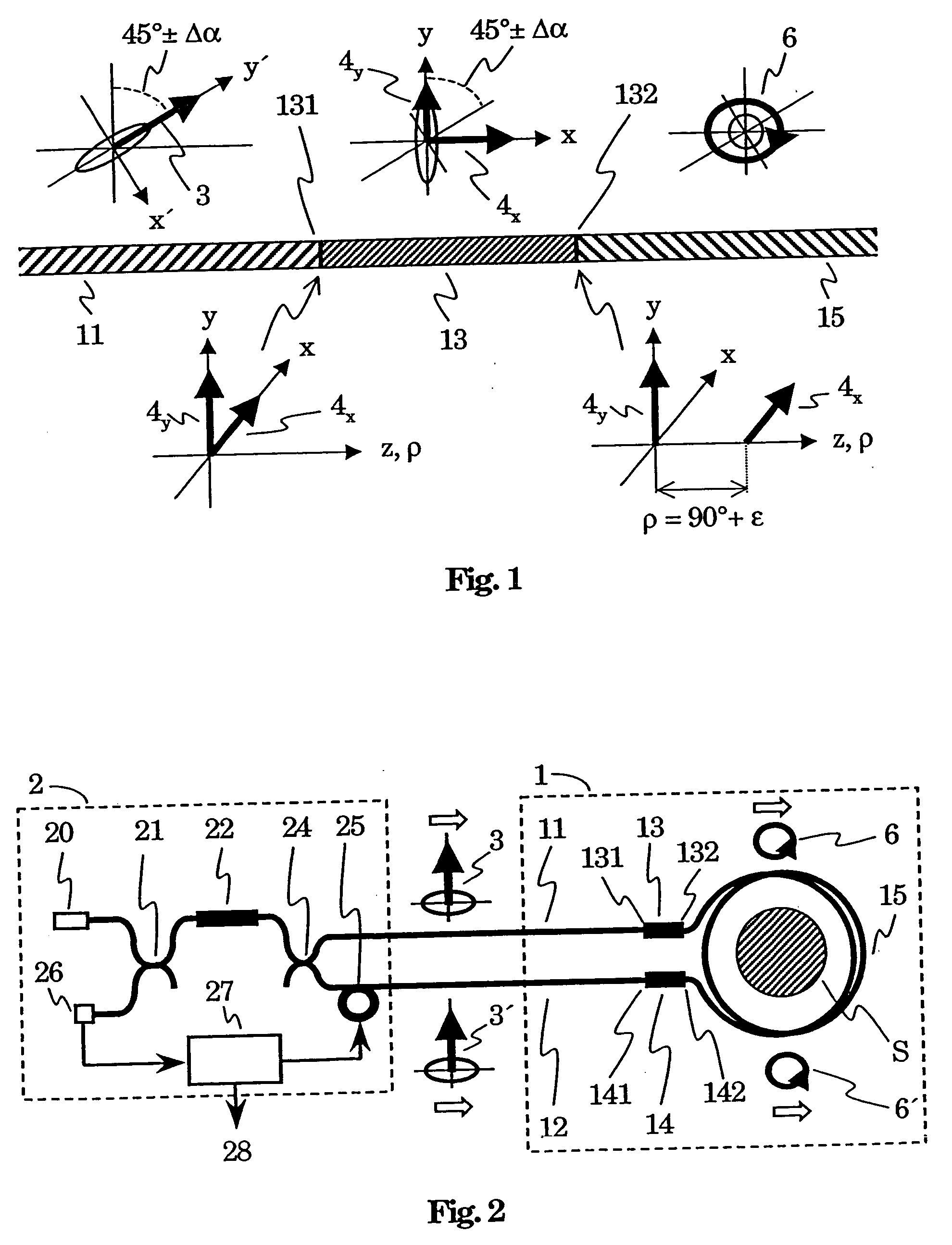

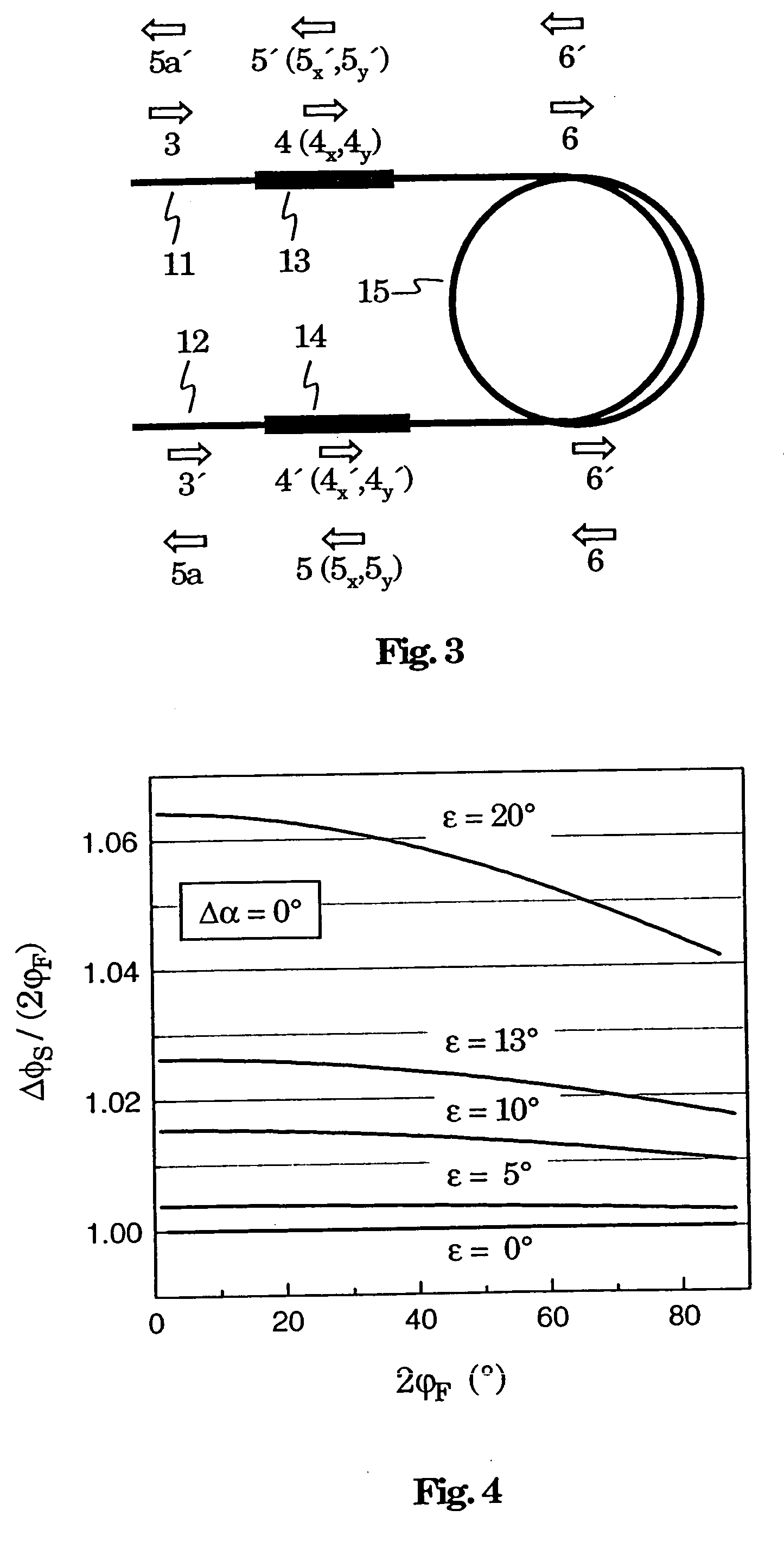

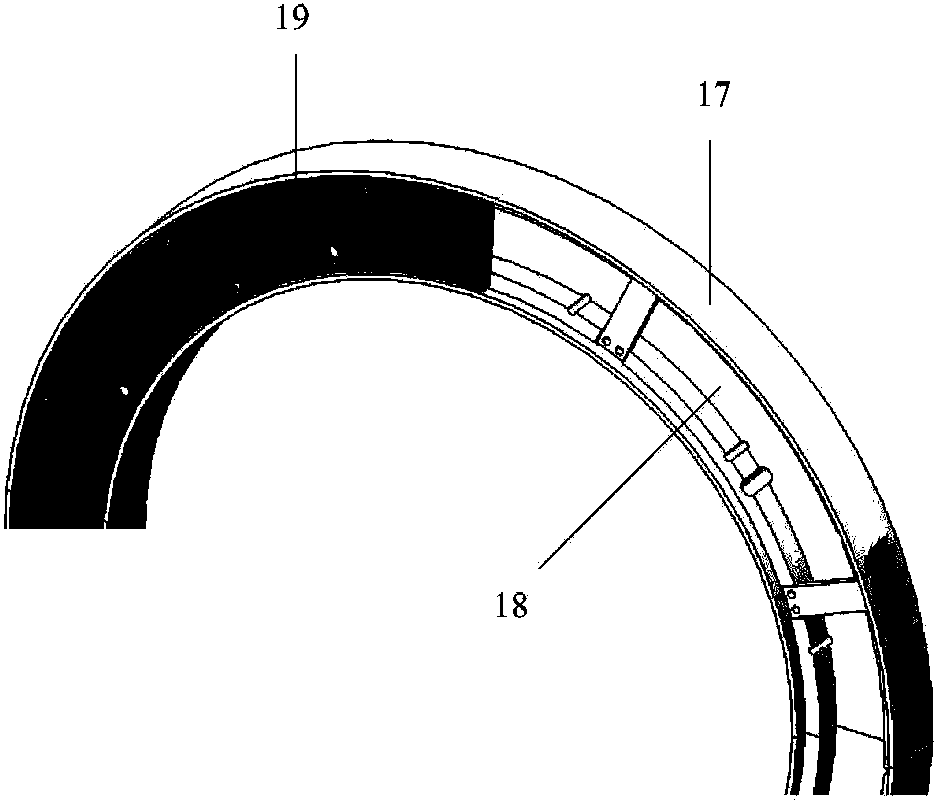

Production method for a sensor head for optical current sensors

InactiveUS20040246467A1Intuitive evaluationHigh measurement accuracyAngle measurementManufacture of electrical instrumentsFiberPhase retardation

An optical current or magnetic field sensor has a sensor head which has a first phase delay element (13), a second phase delay element and a sensor fiber (15) The two phase delay elements (13) are optically connected to opposite ends of the sensor element (15), and the phase delay angle rho on at least one of the phase delay elements (13) deviates by an angle epsilon, with epsilon<>0°, from 90°. Linearly polarized light waves (3) are injected into the first phase delay element (13), with a polarization axis (y') of these linearly polarized light waves (3) including an angle which deviates from 45° by an angle Deltaalpha, with Deltaalpha<>0°, with a principal axis (y) of the first phase delay element (13). The angle Deltaalpha is selected as a function of at least the angle epsilon. This choice of the angle Deltaalpha makes it possible to compensate for non-linearities between a direct measurement signal and an electrical current or magnetic field to be measured which occur because of the angle epsilon<>0°.

Owner:ABB RES LTD

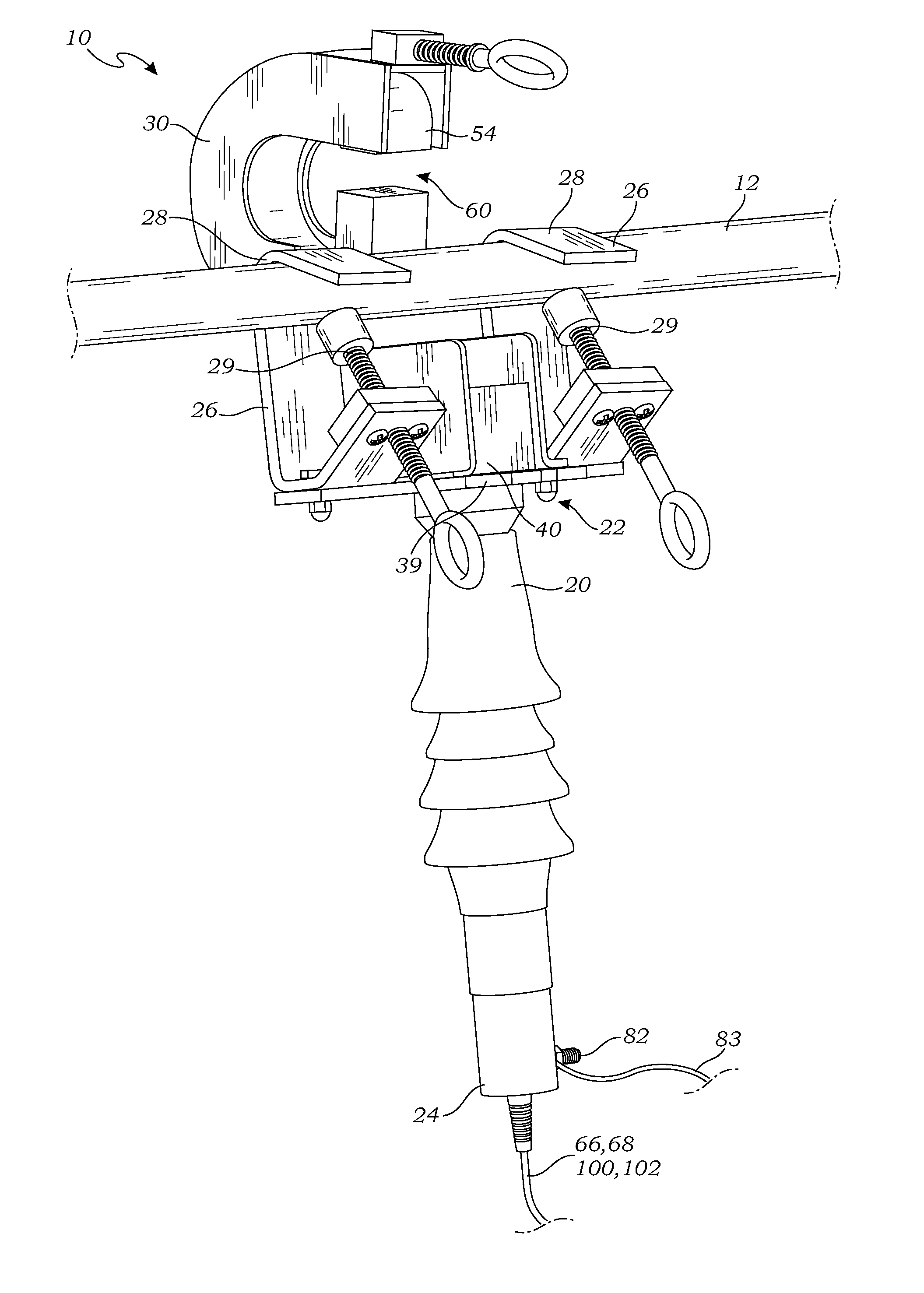

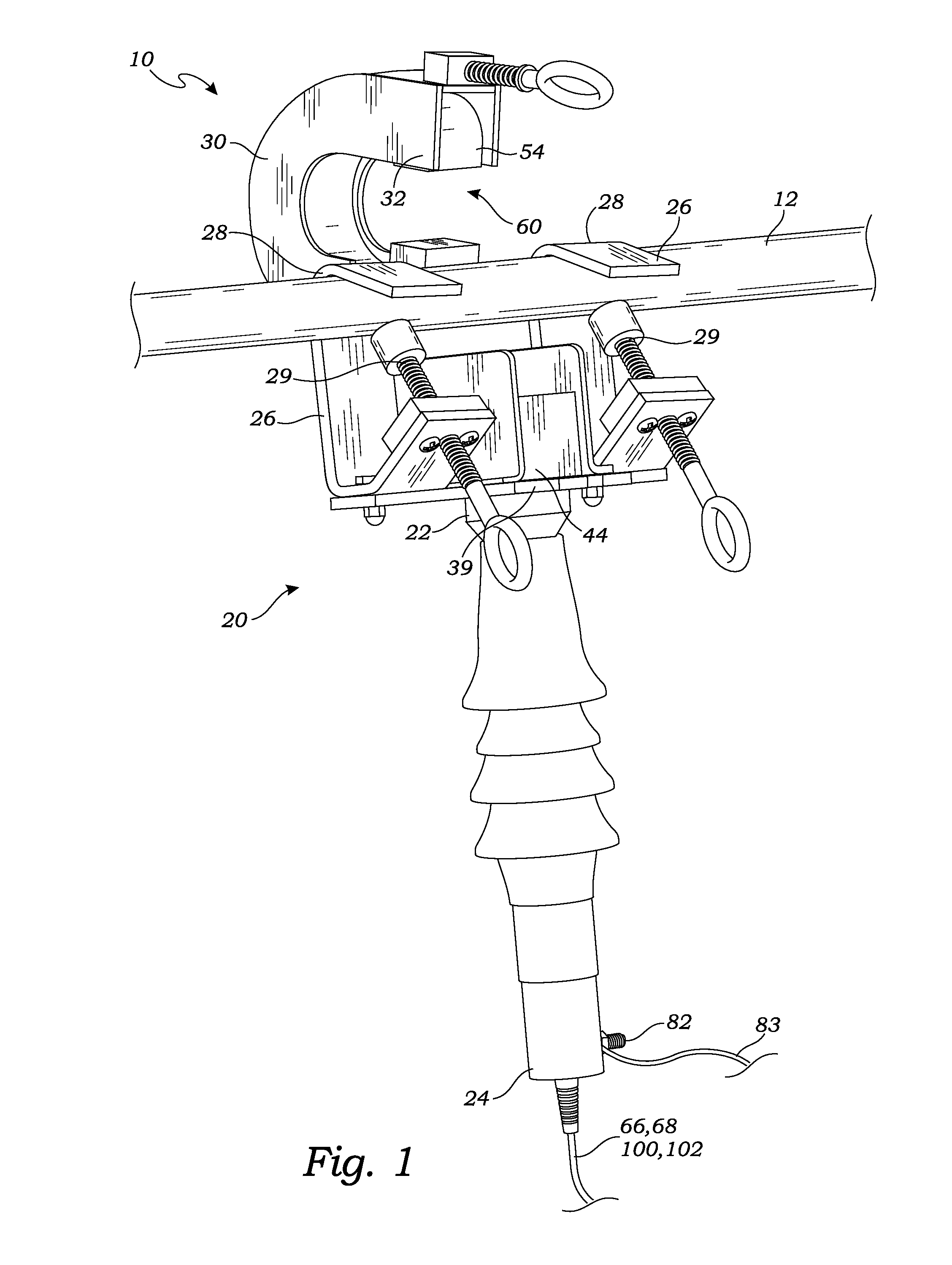

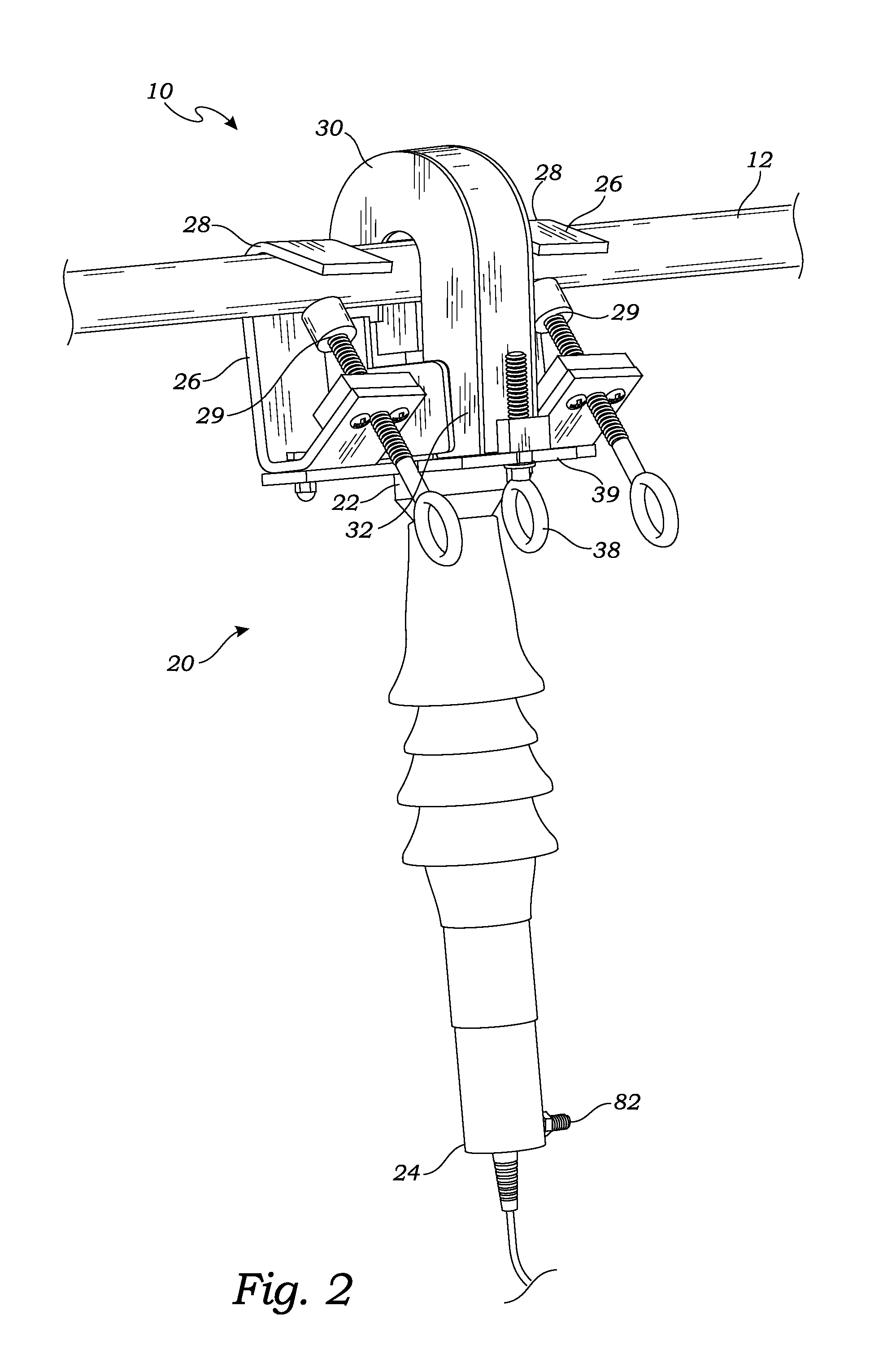

Method for measuring current in an electric power distribution system

ActiveUS20110095750A1Reduce riskIncrease rangeCurrent/voltage measurementAnalysis by electrical excitationFiberCurrent sensor

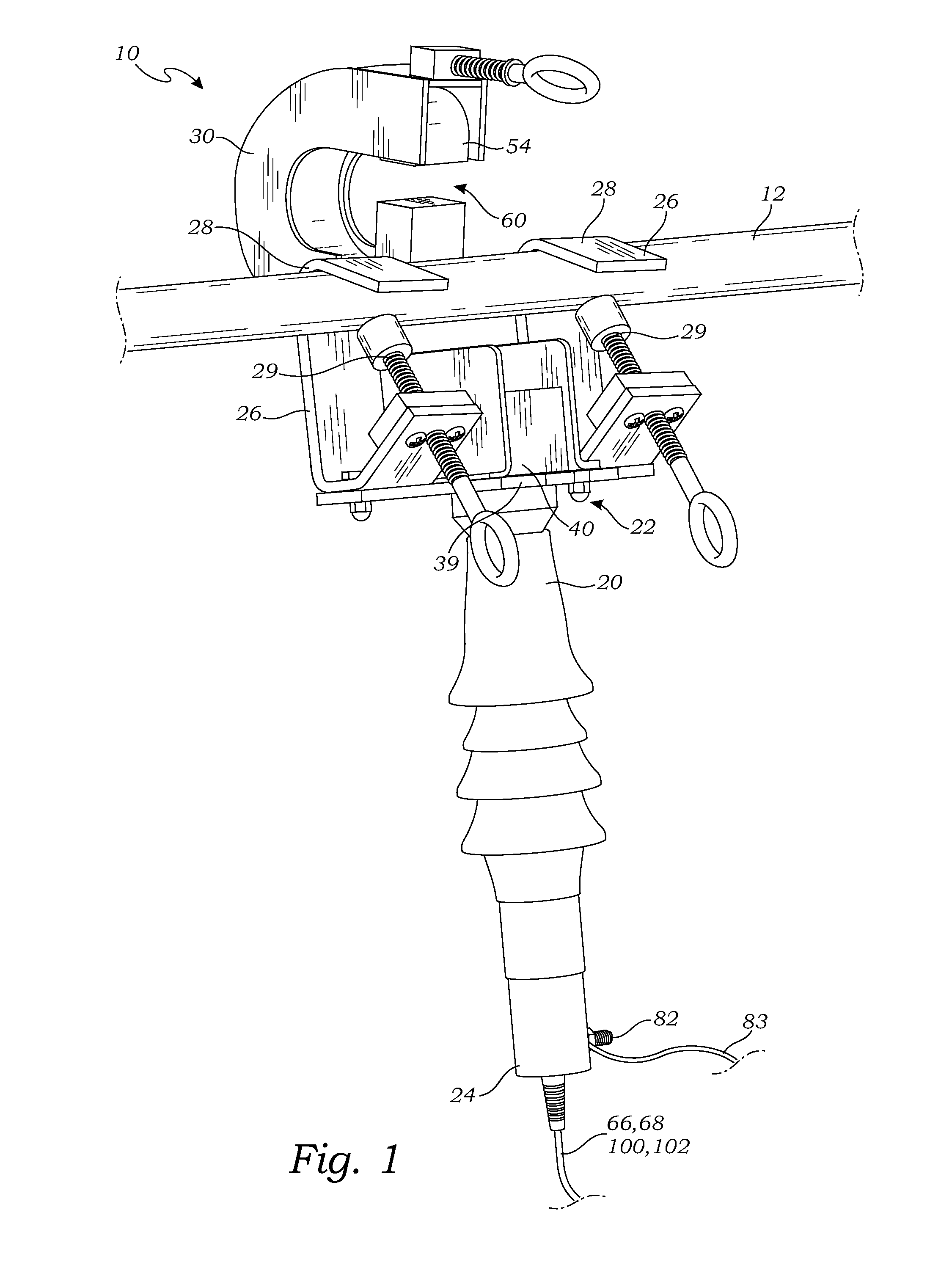

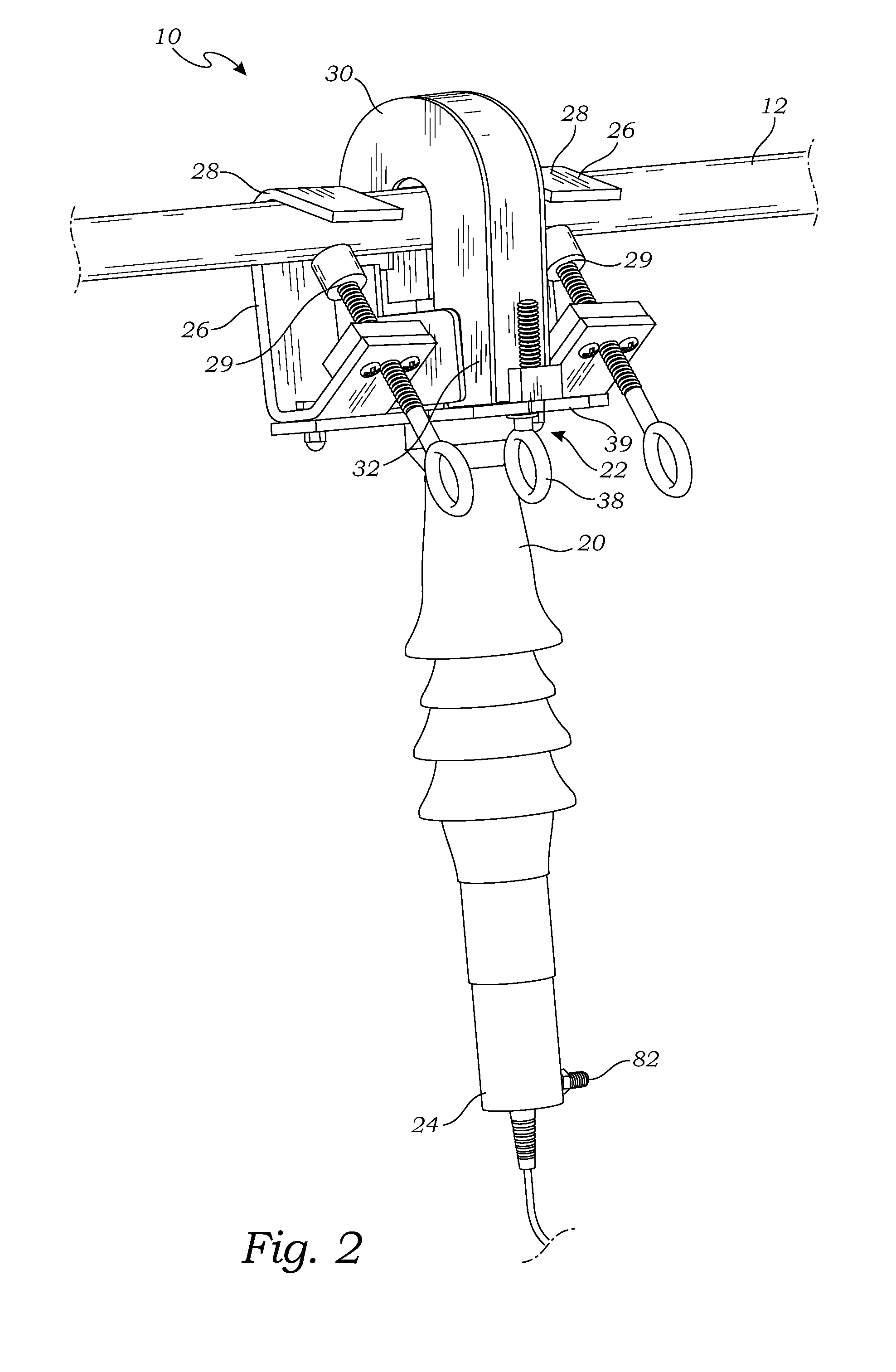

A method of measuring a current of a current carrying cable teaches the first step of providing an optical sensor assembly comprising a base unit, and an optical current sensor mounted on the base unit for transmitting a beam of polarized electromagnetic radiation to an optical fiber. A light detector is also provided having a first channel that operably connecting the light detector to an analog to digital converter through a programmable gain amplifier, a second channel that operably connects the light detector directly to the analog to digital converter, and a processor operably connected to the analog to digital converter. The optical sensor assembly is mounted adjacent the current carrying cable, and the fiber optic is operably connected to a light detector. A plurality of factors are then evaluated from rotation information from the light detector, by using the first and second channels for analog to digital conversion operably connected with the processor.

Owner:MICATU

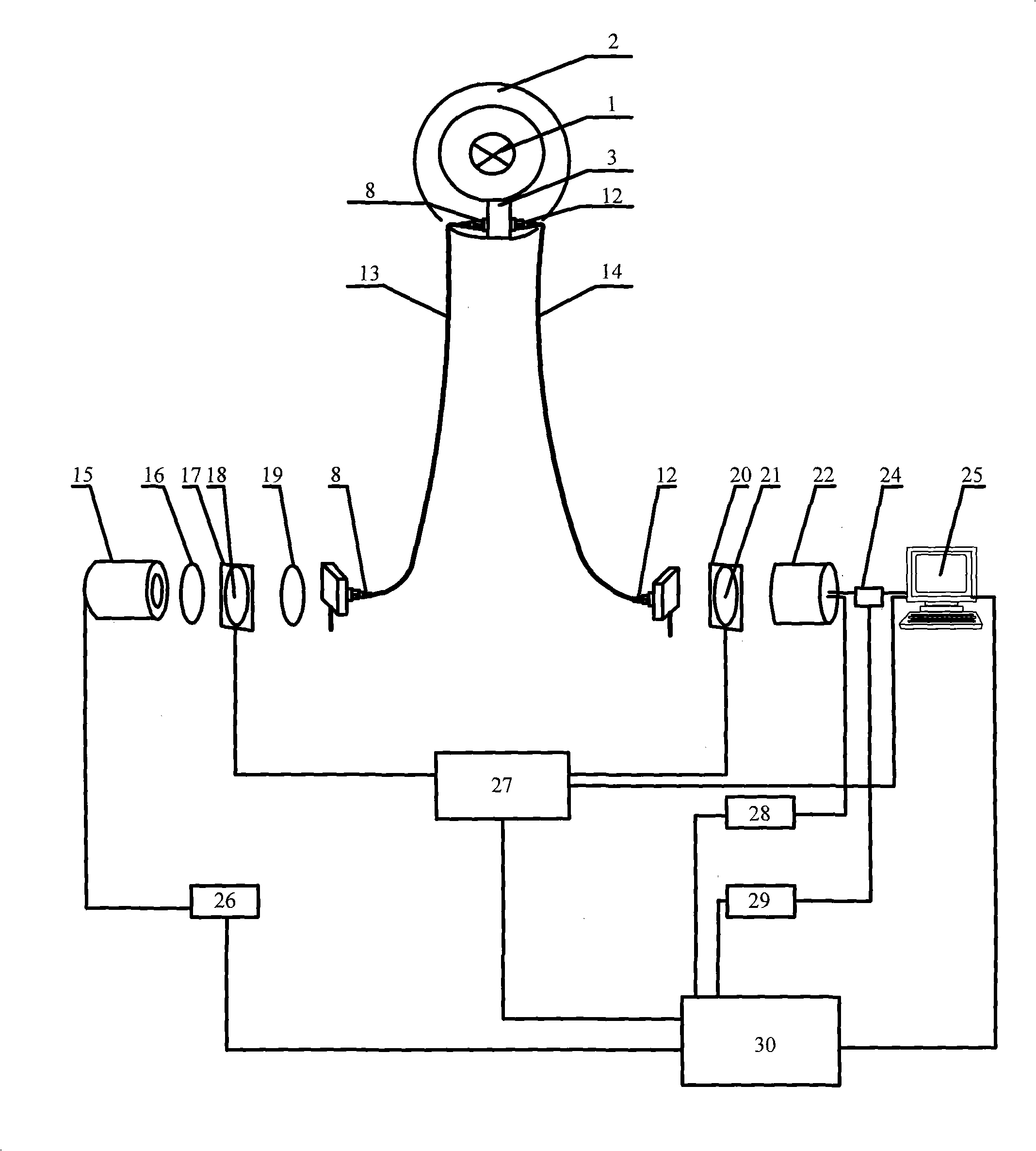

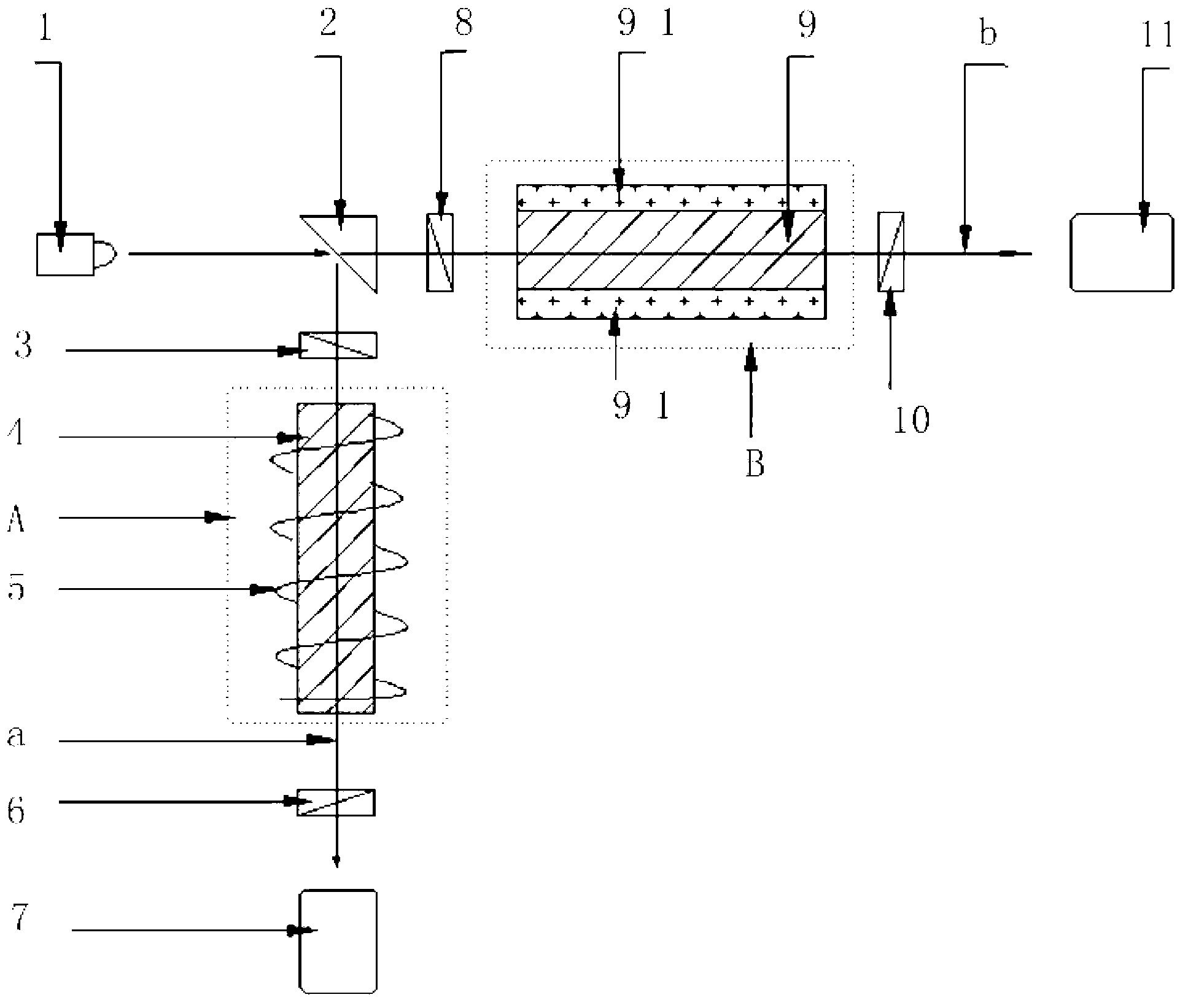

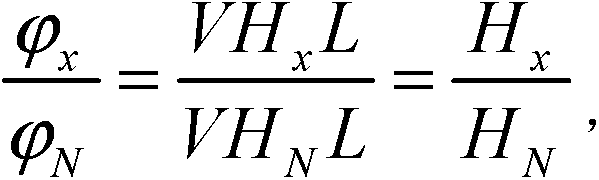

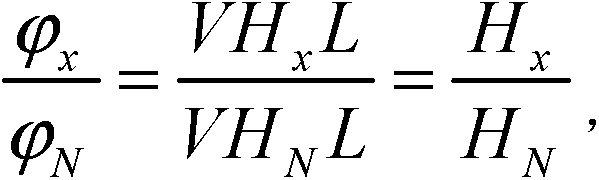

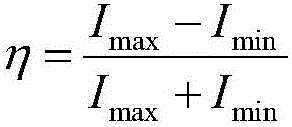

Optical current sensor and current measurement method based on comparative measurement structure

InactiveCN103163360AAvoid interactionAvoid errorsCurrent/voltage measurementCurrent sensorOptoelectronics

The invention belongs to the technical field of optical current sensors, discloses an optical current sensor and a current measurement method based on a comparative measurement structure and aims to solve the problem that a measurement result of a lead current is inaccurate because the Verdet constant of a magneto-optical material in the conventional optical current sensor is influenced by temperature change. A laser beam emitted by a laser generator of the sensor is subjected to light splitting by a light splitter to form a measurement light beam and a reference light beam, wherein the measurement light beam is transmitted to first magneto-optical glass, a first polarization analyzer and a first photoelectric detector sequentially after being polarized by a first polarizer; and the reference light beam is transmitted to second magneto-optical glass, a second polarization analyzer and a second photoelectric detector after being polarized by a second polarizer. By the method, the magnetic field intensity of the first magneto-optical glass is acquired according to Faraday deflection angles of the first magneto-optical glass and the second magneto-optical glass and the magnetic field intensity of the second magneto-optical glass, so that a value of current in an electrified coil is obtained. The sensor is applied to measurement of the current in the electrified coil.

Owner:HARBIN INST OF TECH

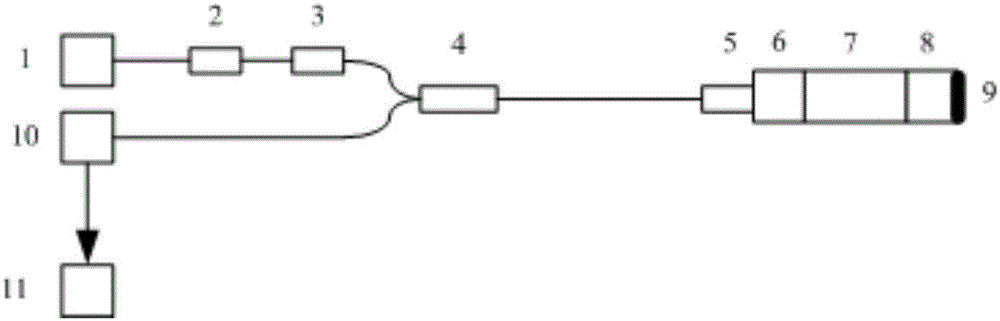

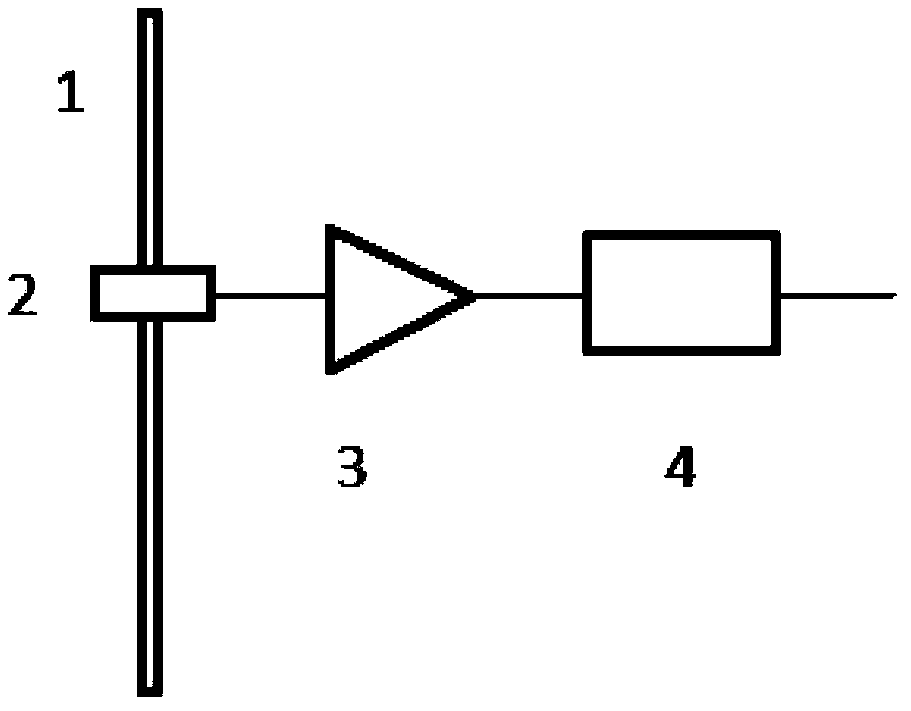

Novel optical path sensing unit for low-voltage optical current sensor

ActiveCN106526277AImprove reliabilityReduce in quantityVoltage/current isolationElectrical conductorLow voltage

The present invention discloses a novel optical path sensing unit for a low-voltage optical current sensor. The unit comprises a light source, an optical fiber isolator, an optical fiber depolarizer, an optical fiber coupler, a photoelectric detector and a second unit. The light source, the optical fiber isolator, the optical fiber depolarizer, the optical fiber coupler and the second unit are connected with each other through the optical fiber. The photoelectric detector is connected with the optical fiber coupler, the second unit is connected with a conductor, the optical axis direction of the second unit is perpendicular to the current direction of the conductor, and the second unit includes an optical fiber collimator, a polarizer, a magneto-optical crystal, a Faraday rotator and a reflector. The novel optical path sensing unit for the low-voltage optical current sensor solves the problems that the optical path structure of the current optical current sensor is complex, many kinds of optical devices are required the technology realization difficulty is big, the engineering installation difficulty is big and the product cost is high. In addition, the measurement sensitivity is ensured.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

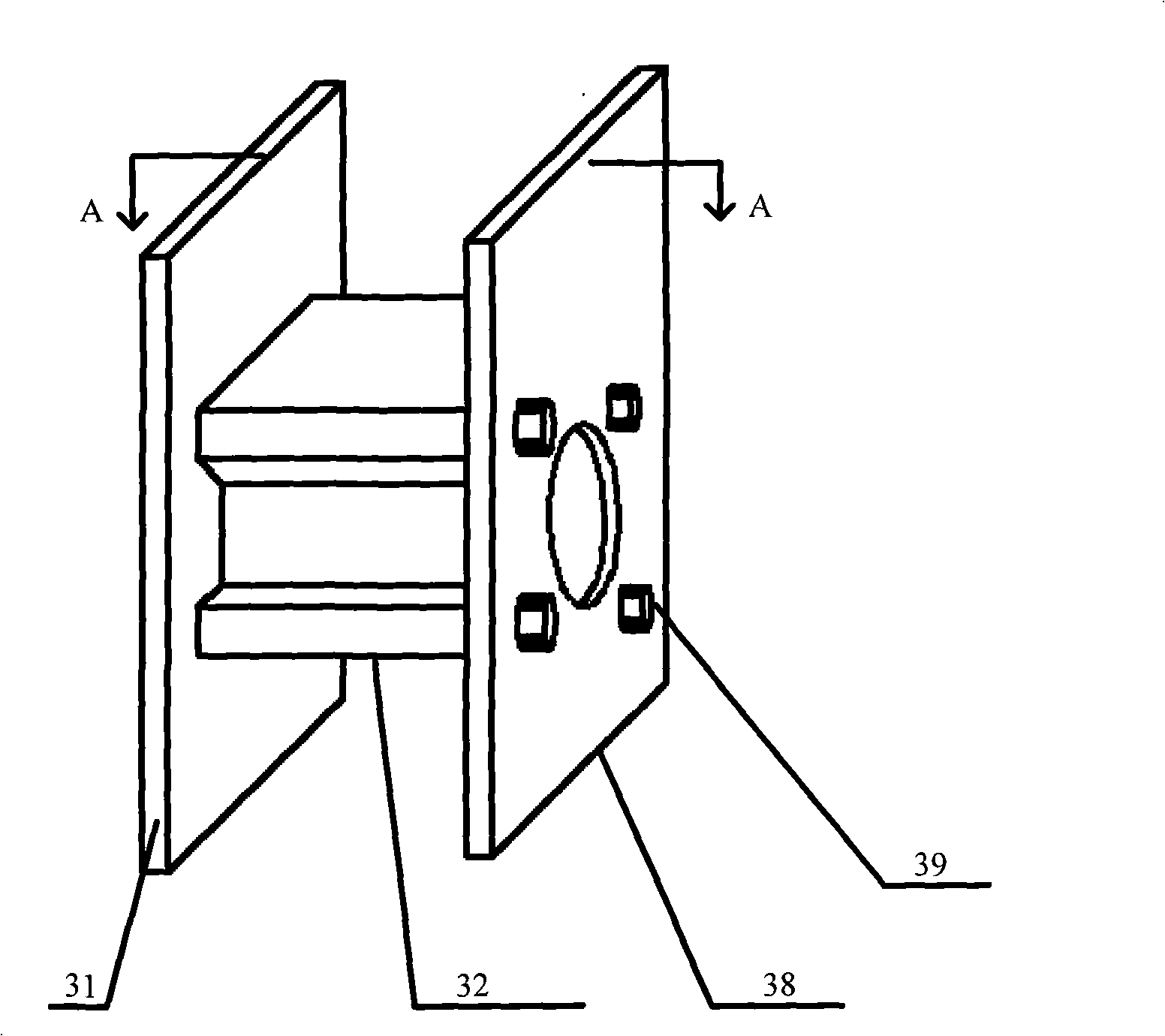

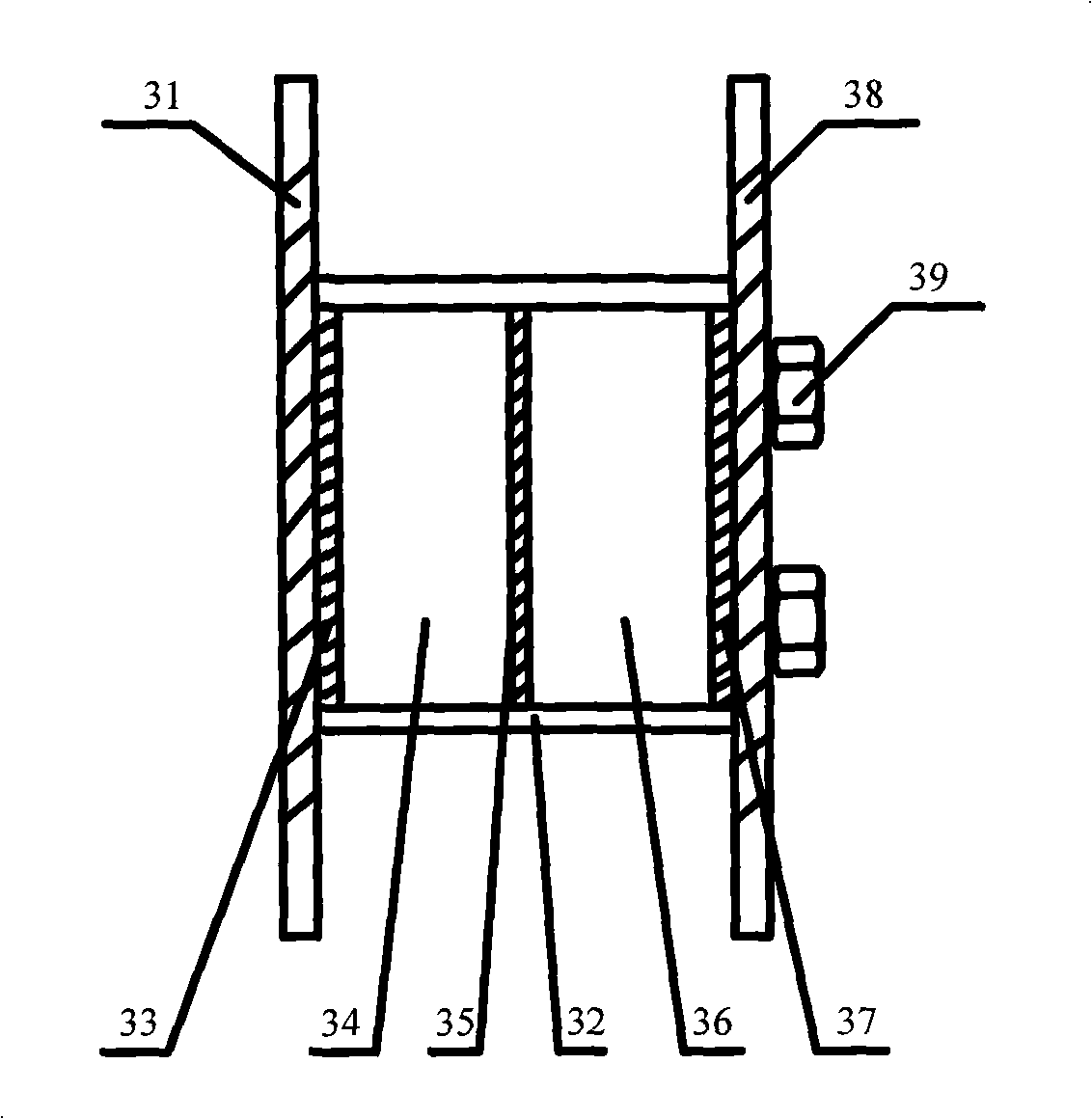

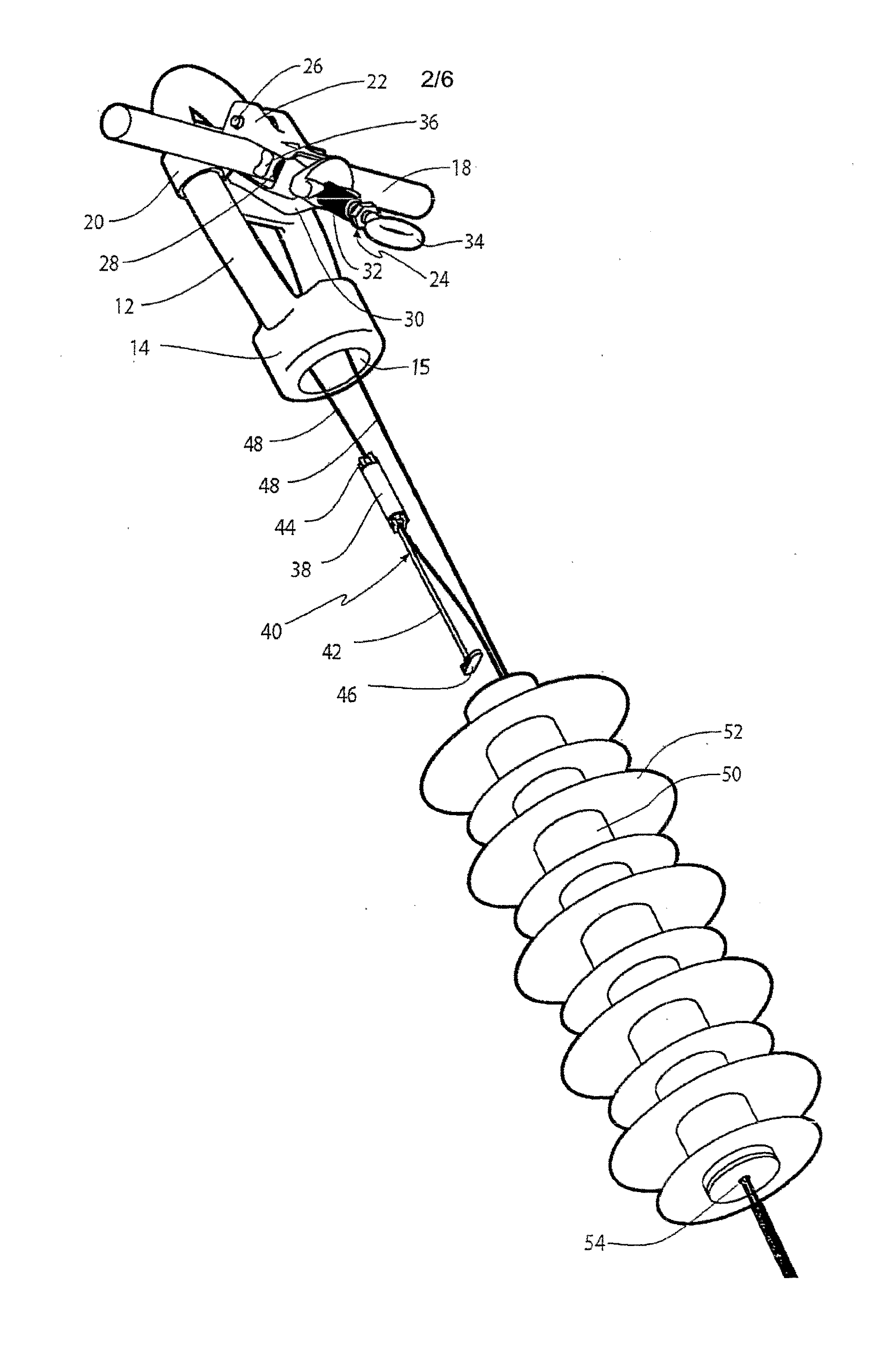

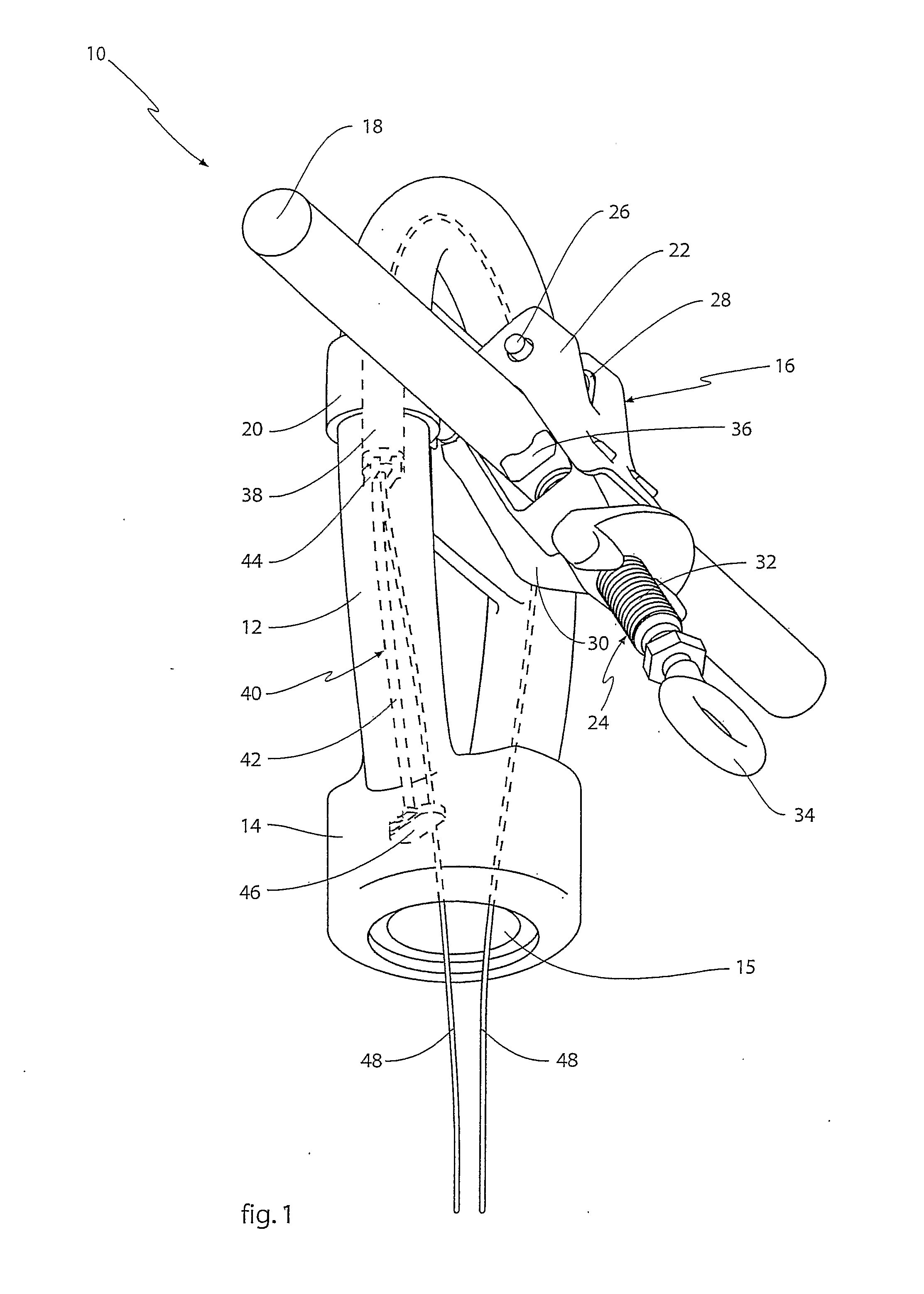

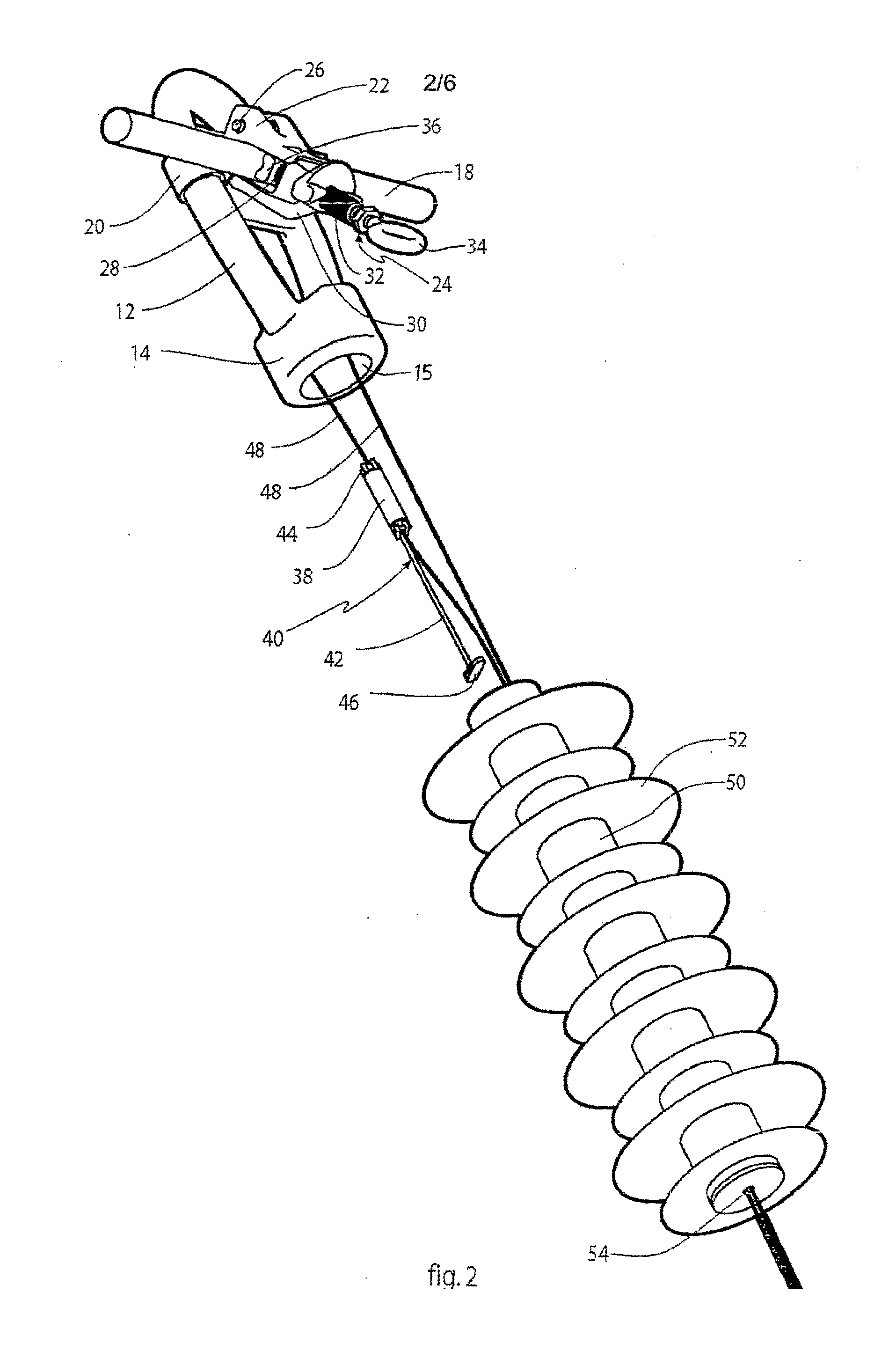

Faraday optical current sensor arrangement

InactiveUS20110062944A1Improve protectionEliminate riskBase element modificationsElectrical testingCurrent sensorEngineering

A Faraday optical current sensor arrangement for measuring the current through a power line comprises a Faraday optical current sensor (38) having an elongated and substantially cylindrical shape defining a first end and a second end opposite the first end. The Faraday optical current sensor has a first optical conduit (48) extending from the first end and a second optical conduit (48) extending from the second end. Furthermore, the Faraday optical current sensor arrangement comprises a hollow housing (12,14) enveloping the Faraday optical current sensor and fixating the Faraday optical current sensor in a specific measurement position relative to the hollow housing. The hollow housing defines a channel for accommodating the Faraday optical current sensor and the first and second optical conduits and an opening (15) for communicating with the channel. The hollow housing includes a holder (16) for fixating the power line and the hollow housing relative to one another in a juxtaposed position and positioning the Faraday optical current sensor in a specific measuring position relative to the power line.

Owner:POWERSENSE AS

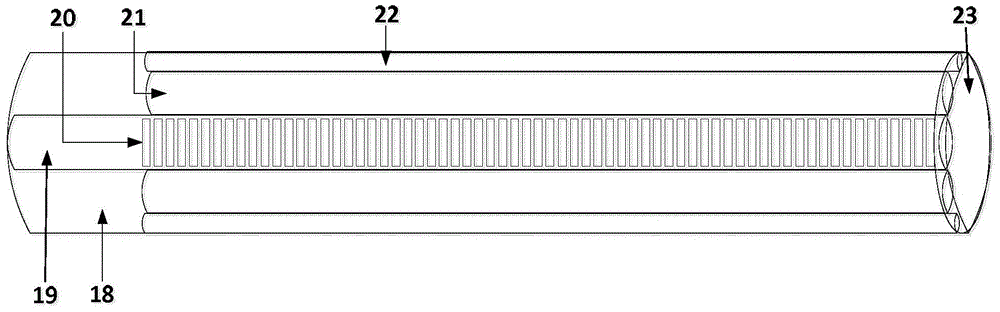

Thin film type all-fiber current transformer with temperature compensation

InactiveCN104459267AEliminate errorsHigh measurement accuracyCurrent/voltage measurementVoltage/current isolationFiberFiber coupler

The invention discloses a thin film type all-fiber current transformer with temperature compensation, and belongs to the technical field of optical current sensors. The problem that a fiber current transformer is likely to be influenced by temperature and vibration, and measurement accuracy is low is solved. According to the thin film type all-fiber current transformer, light emitted by a light source passes through a circulator, a first polarization-maintaining fiber coupler and a Y-waveguide in sequence, the Y-waveguide outputs two paths of light, one path of light passes through a welding branch, rotates by 90 degrees and enters a second polarization-maintaining fiber coupler, the other path of light passes through a compensating coil and enters the second polarization-maintaining fiber coupler, the two paths of light are coupled into one path to be input into a 1 / 4 wave plate by the second polarization-maintaining fiber coupler, the 1 / 4 wave plate outputs left rotating light and right rotating light, a Faraday effect happens in a sensor fiber, and then the left rotating light and the right rotating light return to the first polarization-maintaining fiber coupler. In the return process, the original light returned through the welding branch is input into the compensating coil, the other path of light is input into a processing module through the welding branch and the first polarization-maintaining fiber coupler, and the processing module processes the input light to obtain a current value to be measured. The thin film type all-fiber current transformer is used for measuring the current value.

Owner:HARBIN UNIV OF SCI & TECH

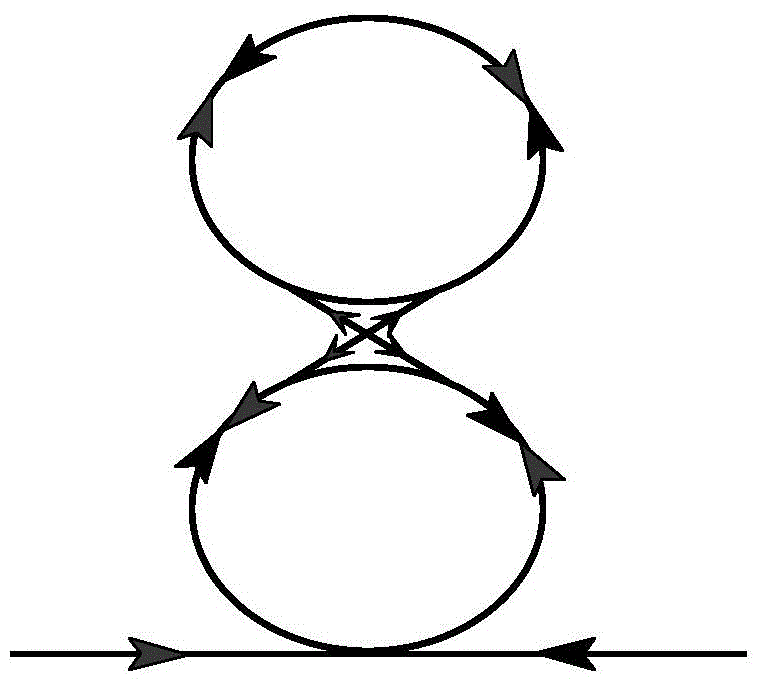

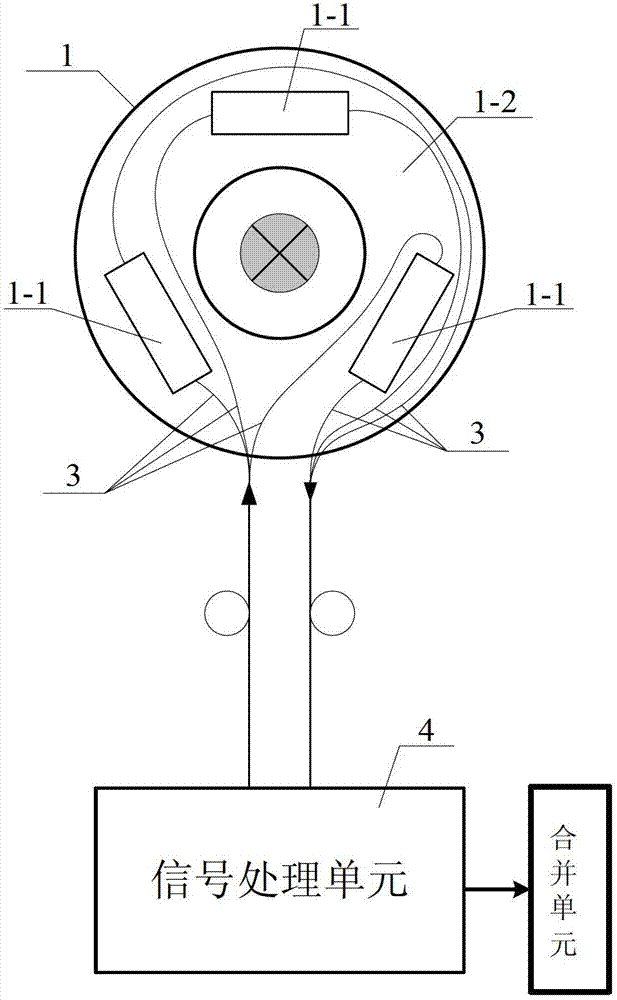

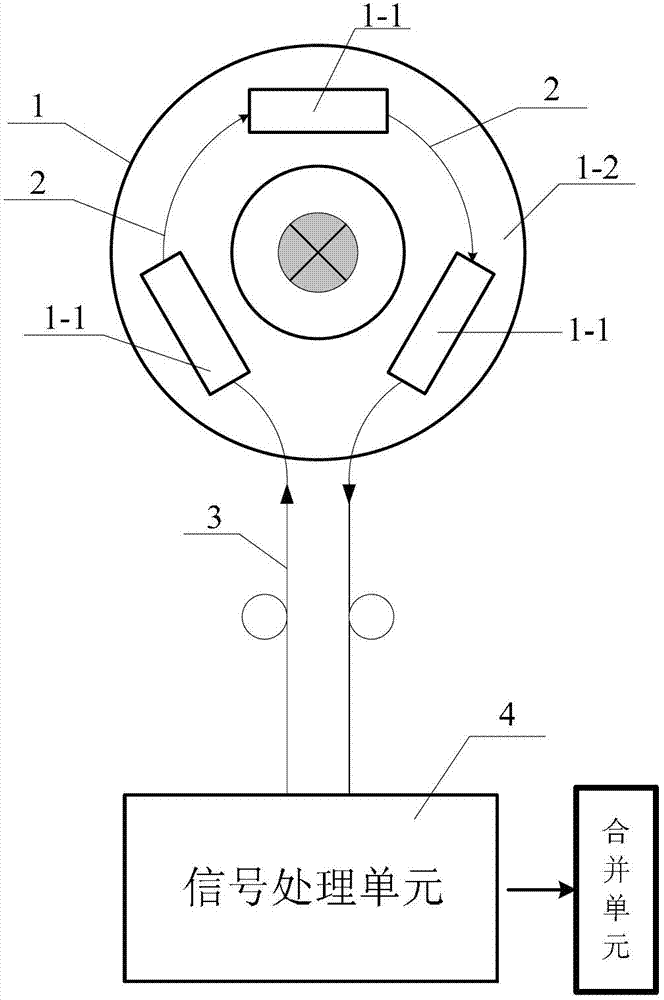

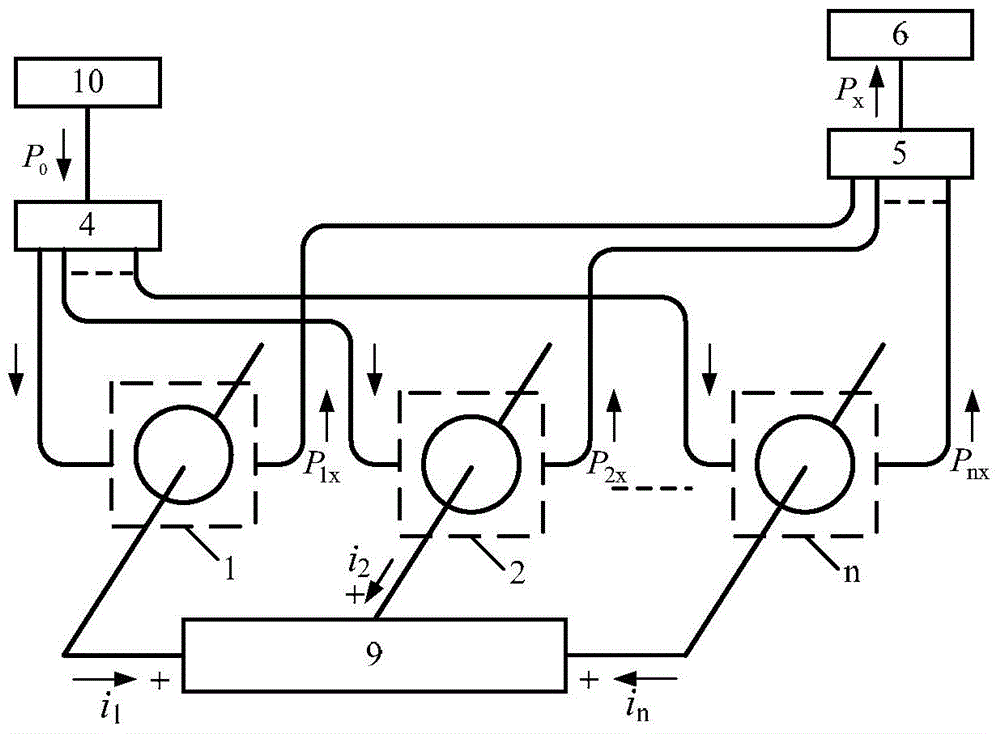

Optical current transformer and method for resisting external magnetic field interference

ActiveCN102818919AHigh measurement accuracyFully anti-interference ability of external magnetic fieldCurrent/voltage measurementVoltage/current isolationCurrent sensorEngineering

The invention relates an optical current transformer and a method for resisting external magnetic field interference, and aims to solve the problems of limited shielding effects, complex structure, complexity in insulation, large size and great weight of the conventional optical current transformer. The optical current transformer comprises m through light path type optical current sensors. The length of magneto-optic glass of each optical current sensor along an incidence direction is 1. The optical current sensors are fixedly arranged on an insulating tray to form a zero-sum magnetic resistance structure S<m>. The optical current transformer comprises the m optical current sensors in a series-connected topological relationship, and the optical current sensors form the zero-sum magnetic resistance structure S<m>. The method for resisting the external magnetic field interference by using the optical current transformer comprises the following steps that a tested bus penetrates through the central position of the optical current transformer, interference current igr is positioned on a point P outside the plane loop of the S<m>, and the m optical current sensors are arranged according to the zero-sum magnetic resistance structure S<m>. The optical current transformer and the method for resisting the external magnetic field interference are applied to the field of current transformers of power systems.

Owner:HARBIN INST OF TECH

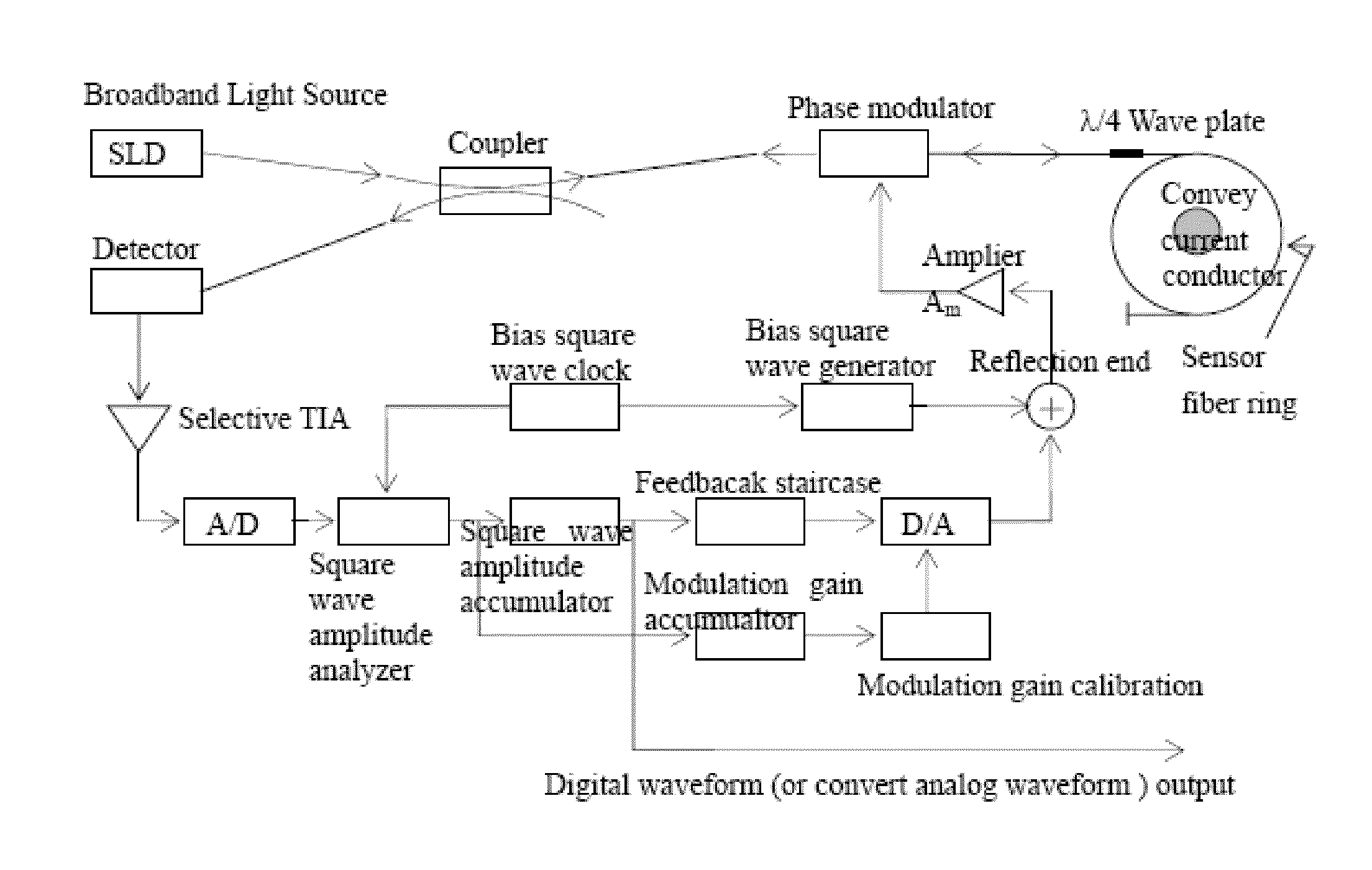

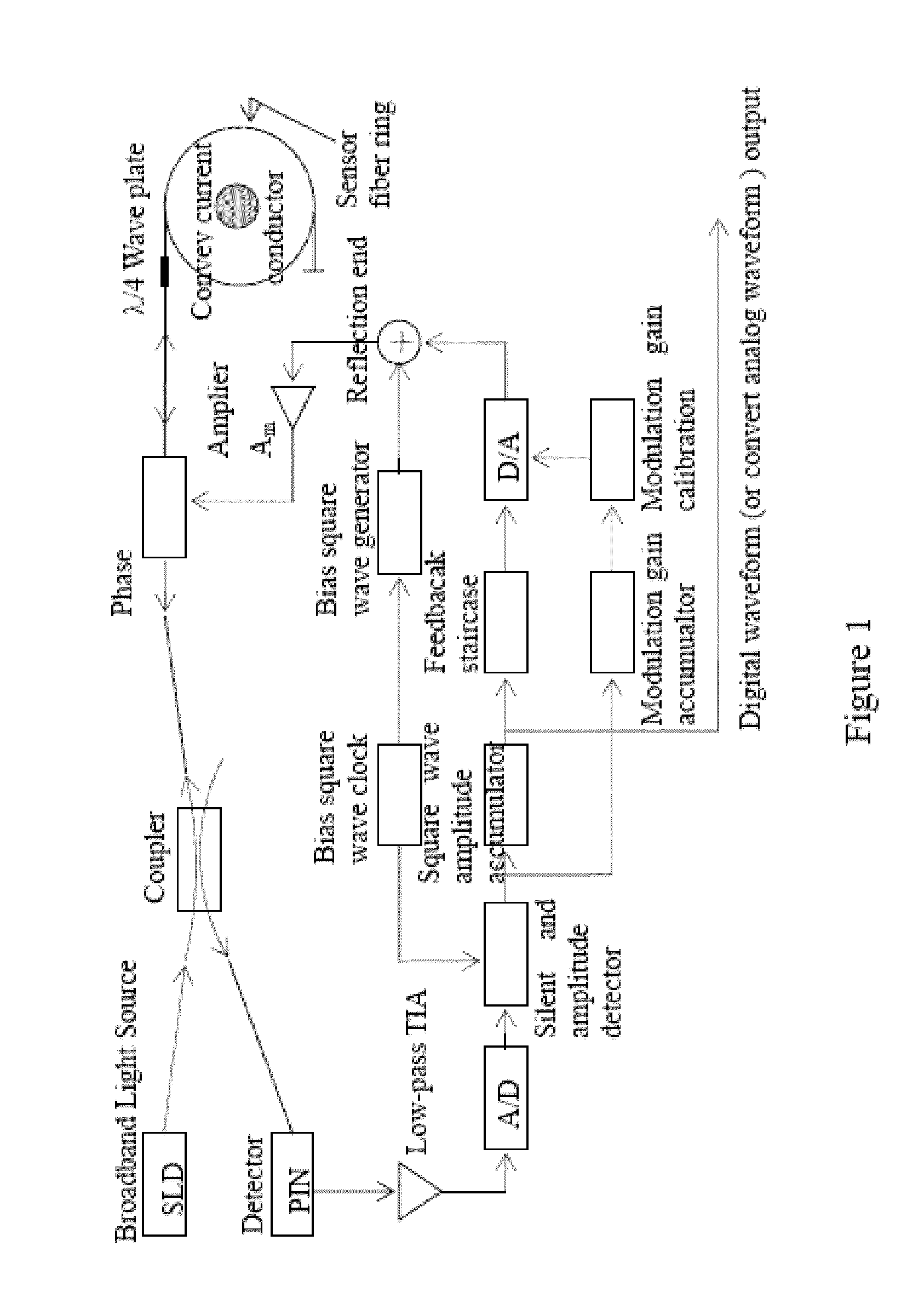

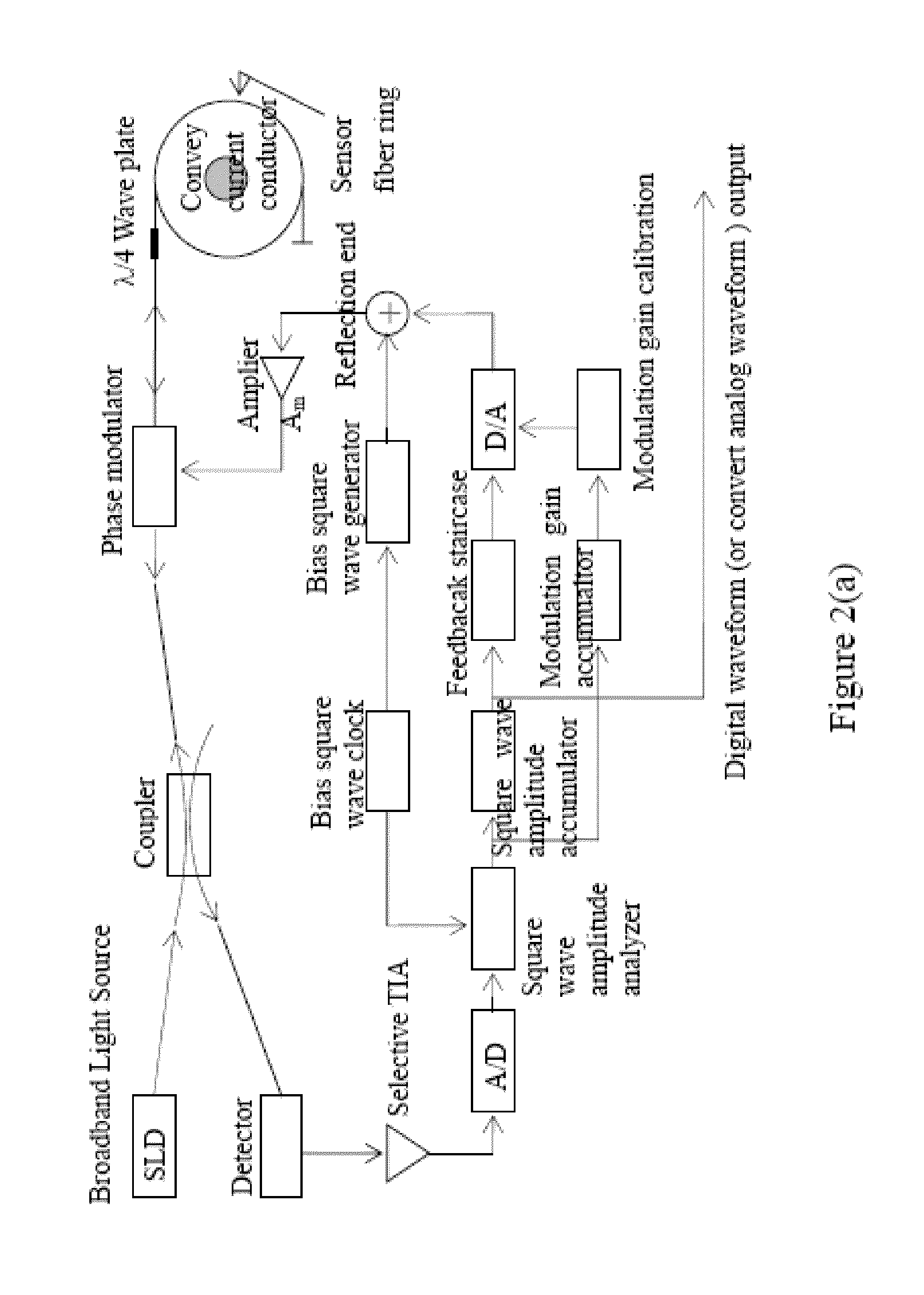

Digital closed-loop fiber optical current sensor

InactiveUS20130278241A1Reduce noise power level of closed-loopHigh bandwidthResistance/reactance/impedenceVoltage-current phase angleFiberClosed loop

This present inversion provides a digital closed-loop fiber optical current sensor. The modulation signal of the optical wave “phase modulator” of the fiber optical current sensor system is modulation square wave, signal processing system extracts any harmonic wave of the photoelectric converter output modulation square waves, and extracts the measured current information from it. The preamplifier of signal processing system is transimpedance amplifier TIA, the bandwidth is extracted 1 / 650 instantaneous amplitude square wave directly from the modulation square wave (existing), thus the thermal noise of the preamplifier output and shot noise level is reduced to the existing technology of below 1 / 650; the current-voltage gain of transimpedance amplifier TIA does not depend on the feedback network resistance, thus it can have high current-voltage conversion gain and use low resistance in the feedback network TIA at the same time. So it can reduce resistance thermal noise to negligible that is accounted for a large proportion of TIA output noise.

Owner:CHINA ELECTRIC POWER RES INST

Polarization insensitive current and magnetic sensors with active temperature compensation

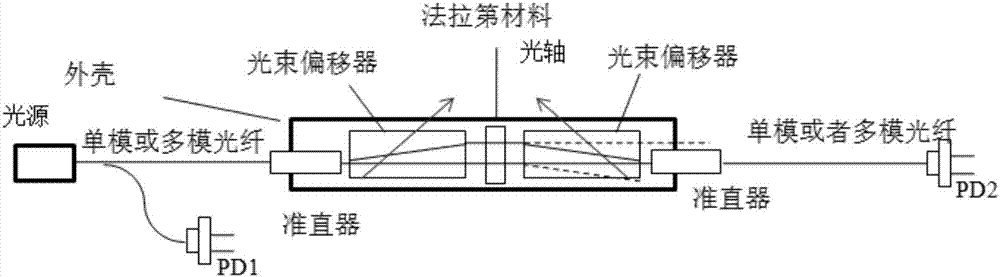

ActiveCN107085130ADetection advantageAvoid electromagnetic interferenceCurrent/voltage measurementThermometers using physical/chemical changesCurrent sensorLight beam

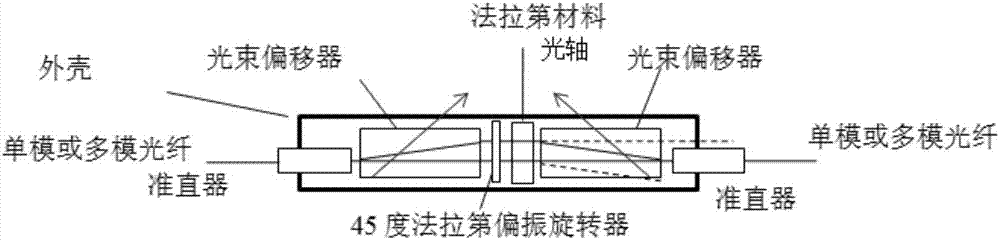

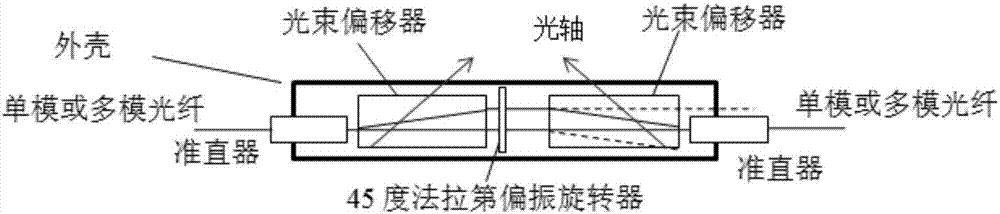

The ivnention discloses a current sensor based on optical sensing and a corresponding temperature sensor. The current sensor comprises: a light source, a first transmission fiber, an optical current sensor probe comprising a beam shifter, a Faraday material, an output beam shifter, a second transmission fiber, an optical detection unit and a measurement module. According to the invention, a polarization insensitive current and magnetic sensor and a system thereof adopting active temperature compensation can ensure sensing precision, measurement range and stability of the optical fiber current sensor when sensing the circuit.

Owner:姚晓天 +1

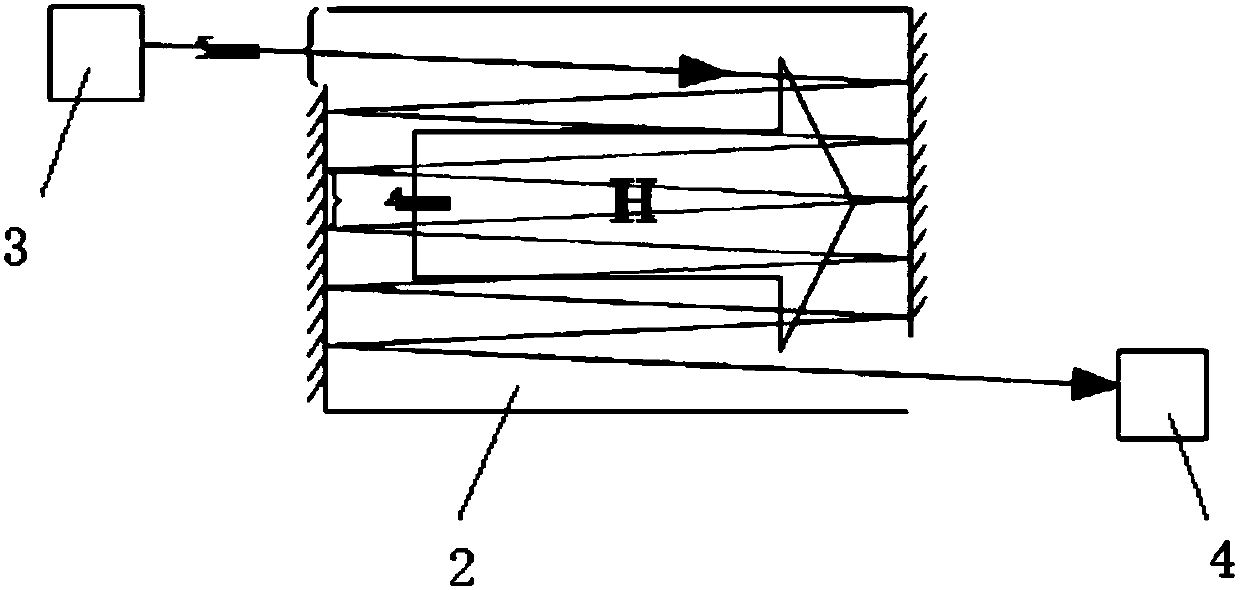

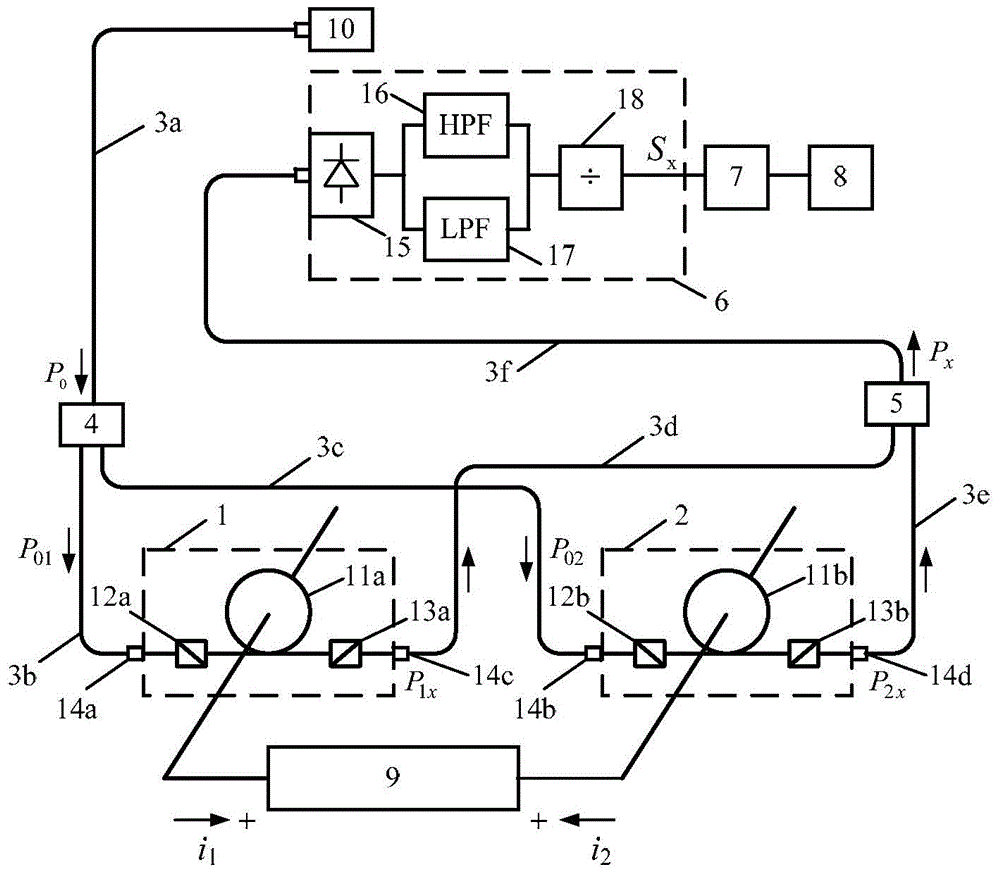

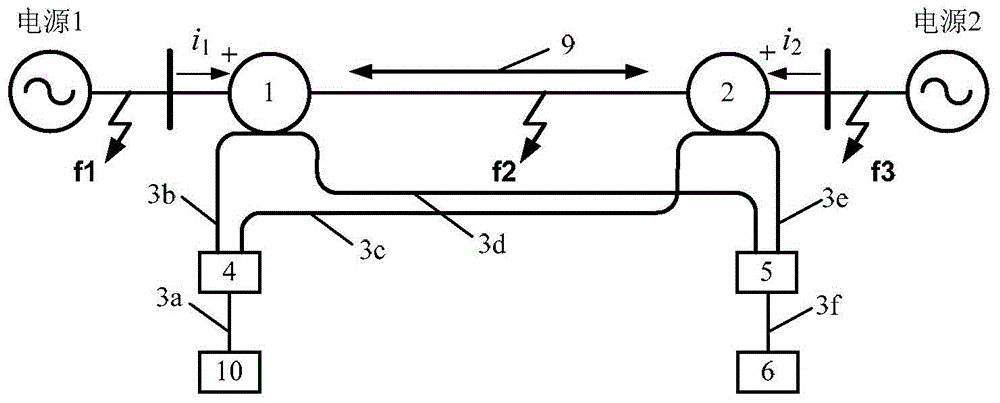

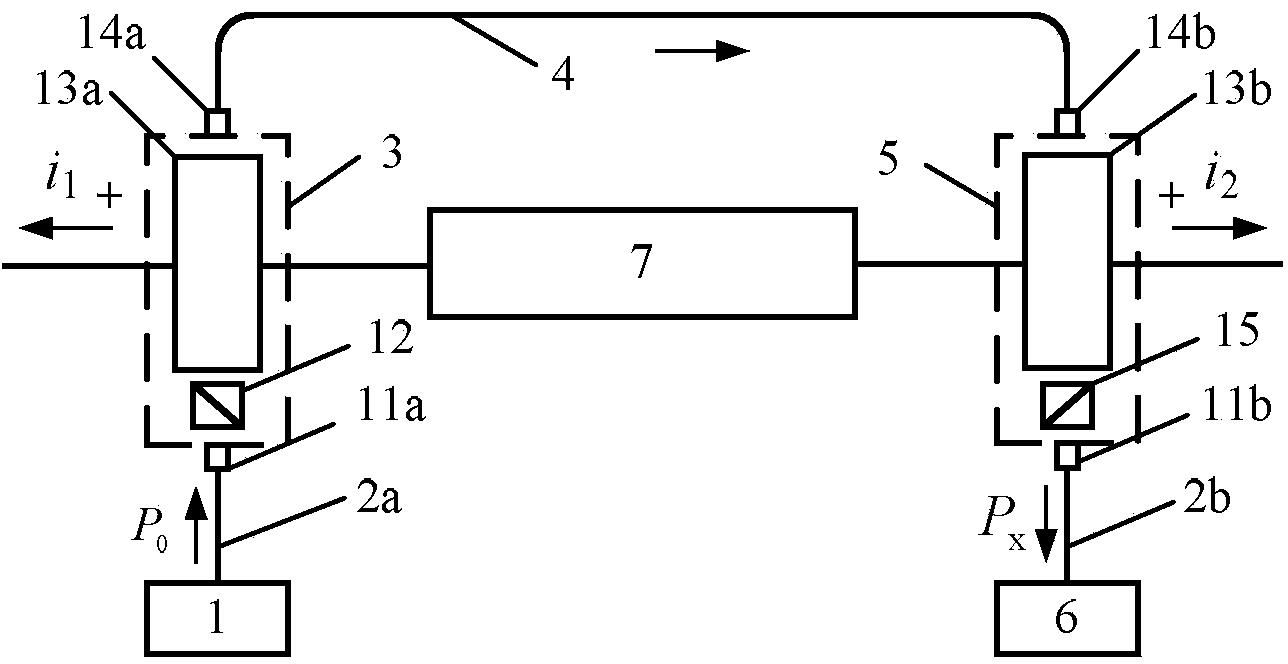

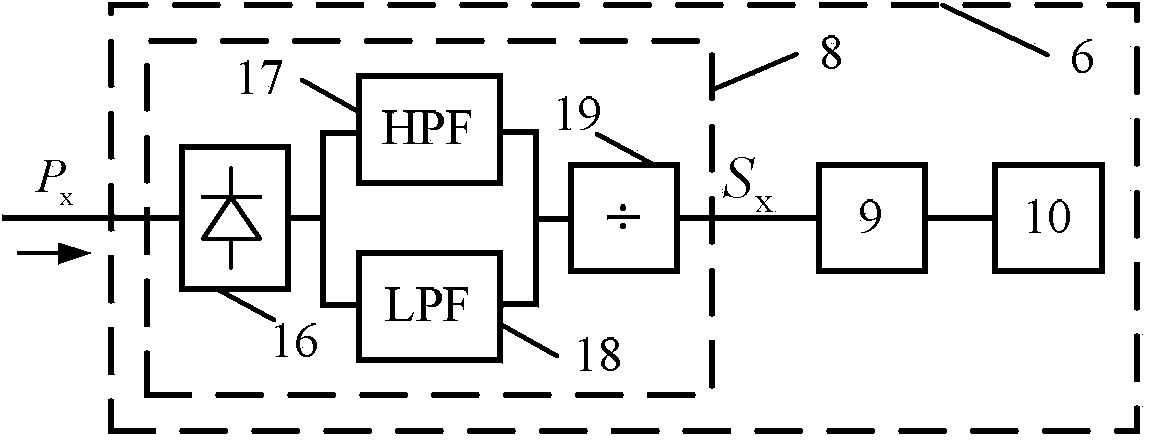

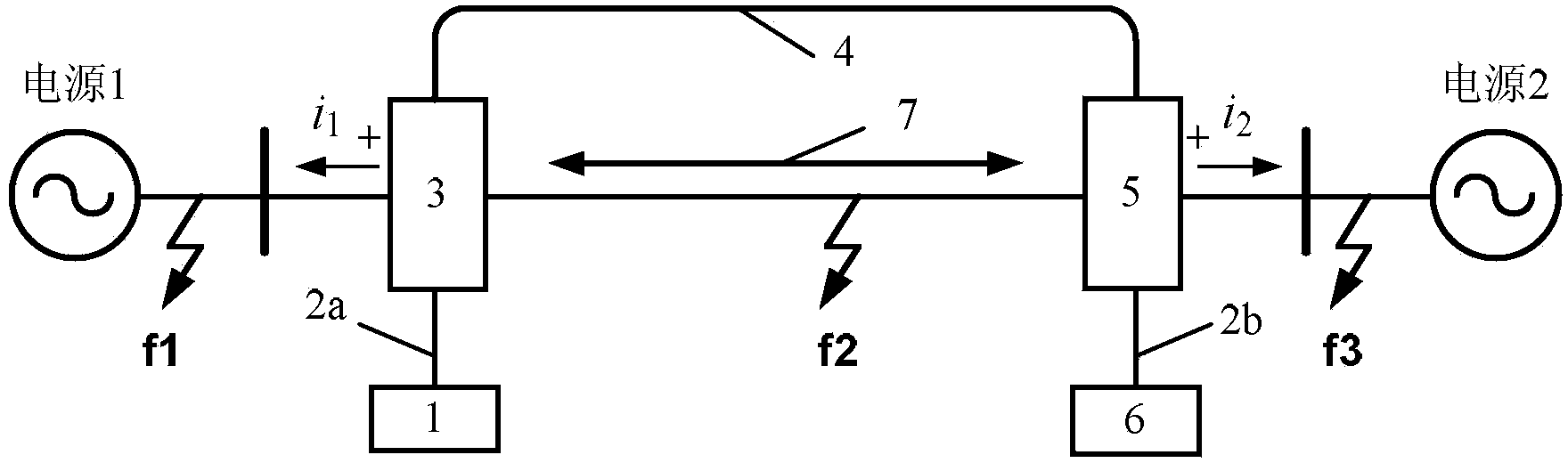

Differential protection device based on optics current sensors

ActiveCN104158161ALower requirementReduce optical power lossCurrent/voltage measurementEmergency protective circuit arrangementsBeam splitterElectric power system

The invention relates to a power system relay protection device, in particular to a differential protection device based on optics current sensors to solve the problem that the power loss of a carrier optical signal output by the optics current sensor in cascading is serious. The first optics current sensor and the second optics current sensor are arranged at the two ends of a protection section, a light source is connected with the incidence end of a multimode optical fiber beam splitter through multimode optical fiber, the output end of the multimode optical fiber beam splitter is connected with the incidence end of the first optics current sensor and the incidence end of the second optics current sensor through multimode optical fiber, the emitting end of the first optics current sensor and the emitting end of the second optics current sensor are respectively connected with the incidence end of the multimode optical fiber beam splitter through multimode optical fiber, and the emitting end of the multimode optical fiber beam splitter is connected with the input end of an optical signal processing unit through multimode optical fiber.

Owner:HARBIN INST OF TECH +3

Dual probe-based calibration-free optical current sensor and method

InactiveCN104076180AEasy to hang the netImprove anti-interference abilityCurrent/voltage measurementVoltage/current isolationCurrent sensorOptical current transducer

The invention discloses a dual probe-based calibration-free optical current sensor and a method. The sensor is composed of two magneto optical current sensing heads, a sensing head fixing support and a measuring unit. According to the method, as the sensing head fixing support is adopted, the relative distance of the two sensing head can be ensured to be fixed and is not influenced by temperature, stress and other environmental disturbance. The measuring unit receives output light intensity of the two magneto optical current sensing heads and the output light intensity is converted into electrical signals and an output measurement current value is calculated. Through demodulating the measurement values of the sensing heads, influences of the distance in relative to a cable lead on the measuring result in the case of installation can be directly eliminated, and the difficulty that power needs to be on for calibration in the case of onsite installation of the sensor can be avoided.

Owner:陈 国梁 +2

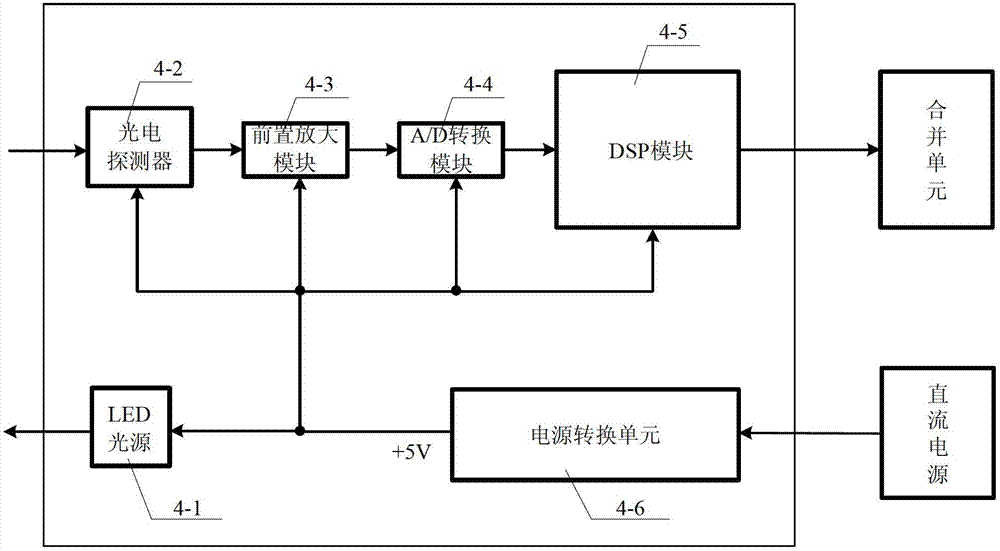

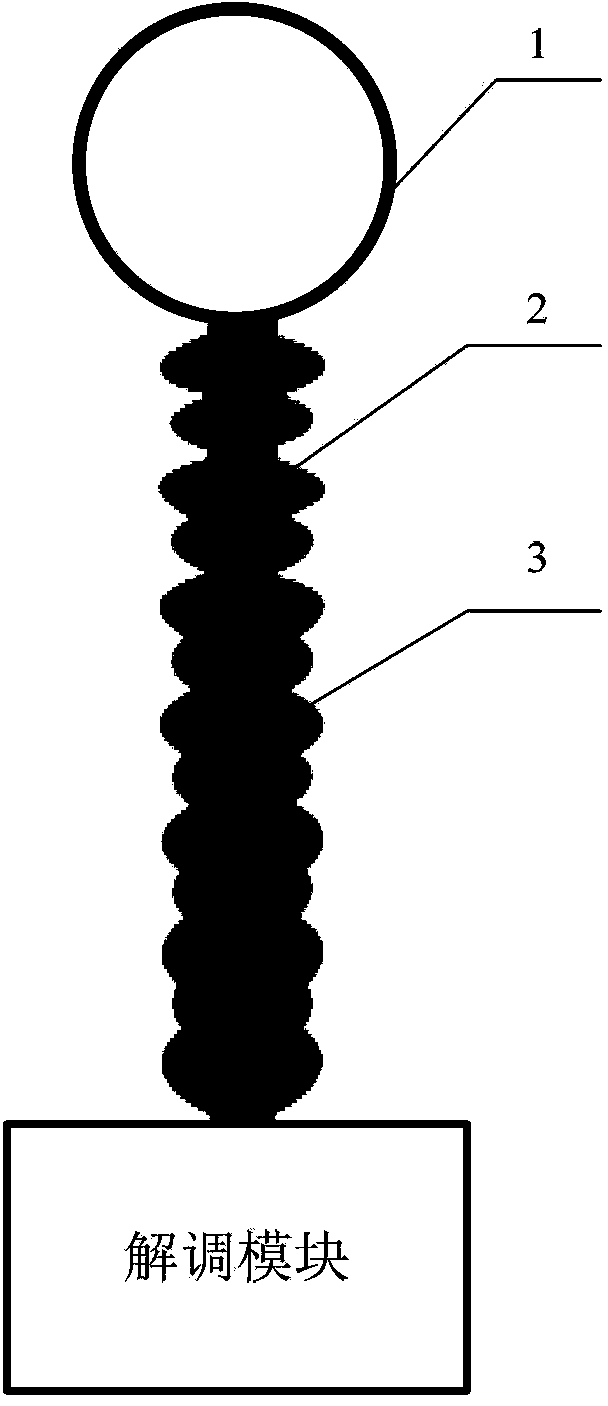

Optical current sensor and high-frequency signal measurement system

ActiveCN103424607AImprove insulation performanceImprove interferenceVoltage/current isolationMeasurement using digital techniquesMetallic materialsCurrent sensor

The invention relates to an optical current sensor and a high-frequency signal measurement system. The optical current sensor comprises an optical sensing part, a polarization maintaining fiber, an insulator and a demodulation module. The optical sensing part, the polarization maintaining fiber and the demodulation module are connected in sequence. The optical sensing part is supported by the insulator. The polarization maintaining fiber locates in an inner cavity of the insulator. The optical sensing part comprises a first sensing fiber ring, a second sensing fiber ring, a first wave plate, a first reflector, a second wave plate, a second reflector and a support, wherein the first wave plate, the first reflector, the second wave plate, the second reflector and the support are all made of nonmetal material. The first sensing fiber ring and the second sensing fiber ring are opposite in current direction. The demodulation module outputs two linearly-polarized beams passing the polarization maintaining fiber and the optical sensing part, the linearly-polarized beams carrying measured current information are returned and received by the polarization maintaining fiber, the beams are operated on the basis of differential induction, and measured current is obtained. The optical current sensor is capable of measuring high-frequency signals, and measurement is higher in accuracy and reliability.

Owner:山东曜德电气有限公司

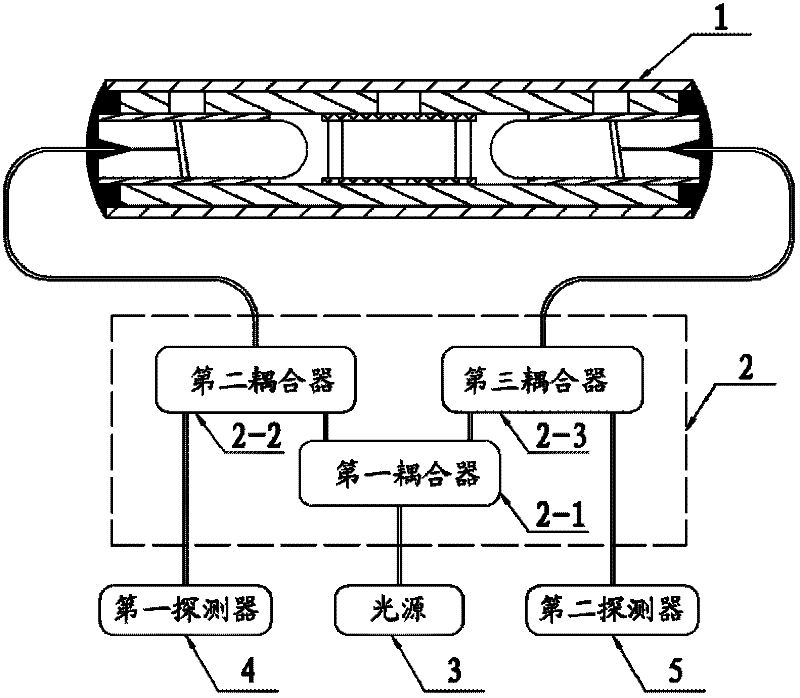

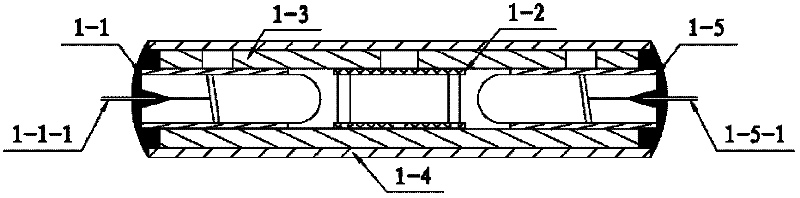

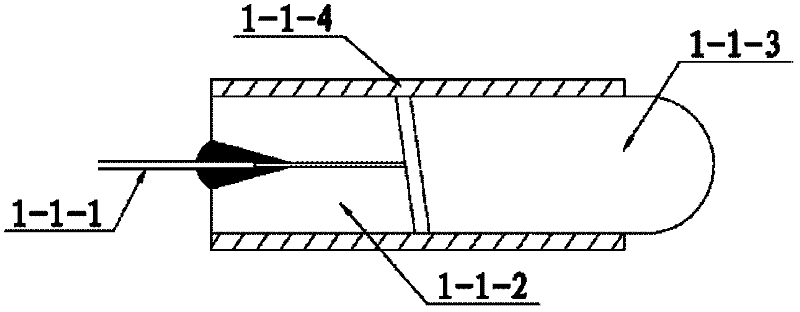

Two-way transmission optical current sensor

InactiveCN102565496ARealize two-way transmissionImprove toleranceCurrent/voltage measurementVoltage/current isolationBidirectional transmissionCurrent sensor

A two-way transmission optical current sensor relates to a sensor, for solving the problems of difficult packaging and weak environmental tolerance of one in and two out optical path structure of the prior optical current sensor. The optical current sensor comprises an optical sensor, three couplers, a light source, a first detector and a second detector. The first coupler has a first port connected with an output end of the light source, a second port connected with a second port of the second coupler, and a third port connected with a second port of the third coupler. The second coupler has a first port connected with one input / output end of the optical sensor, and the third coupler has a first port connected with the other input / output end of the optical sensor. The second coupler has a third port connected with an input end of the first detector, and the third coupler has a third port connected with an input end of the second detector. The invention is used for measuring currents, can bidirectionally transmit optical signals, is easy to package, and has strong tolerance to environmental change.

Owner:HARBIN INST OF TECH +1

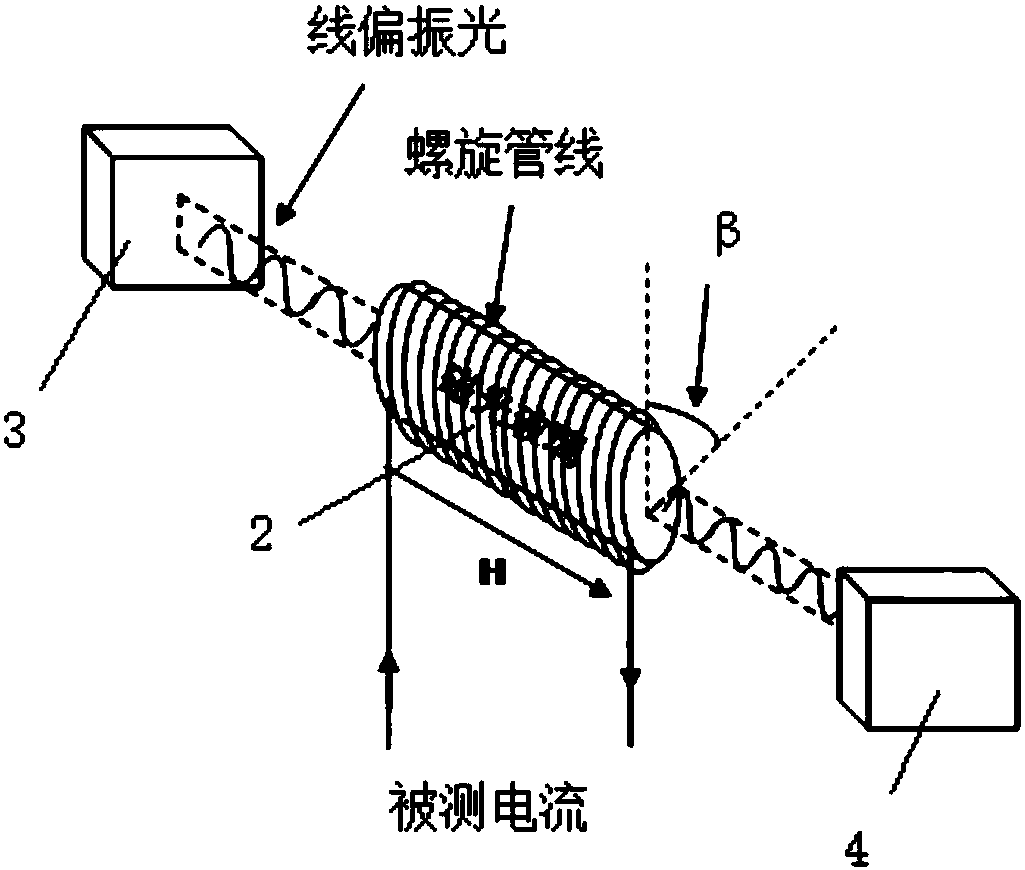

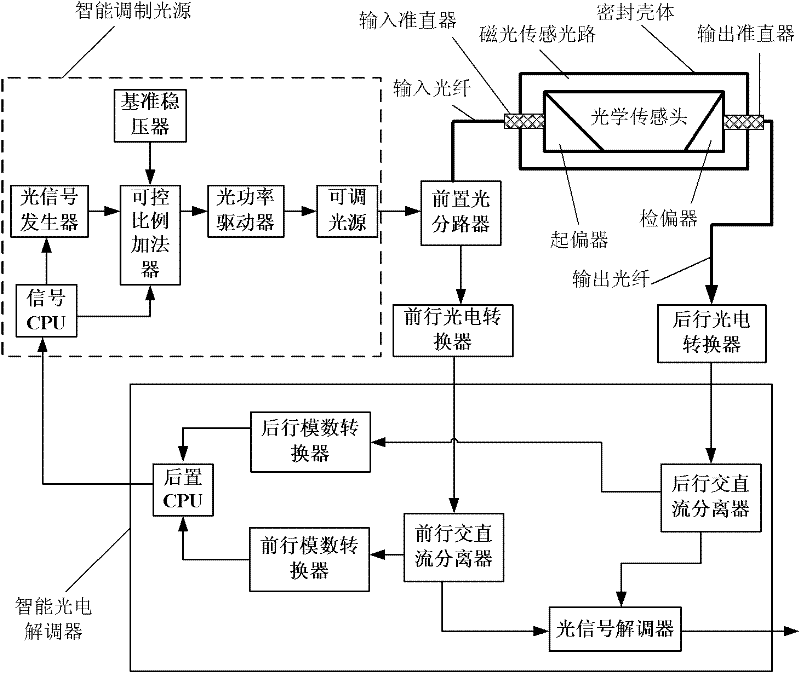

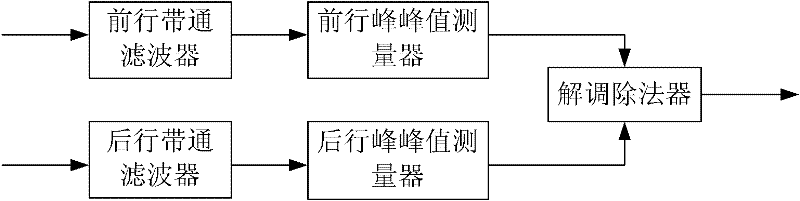

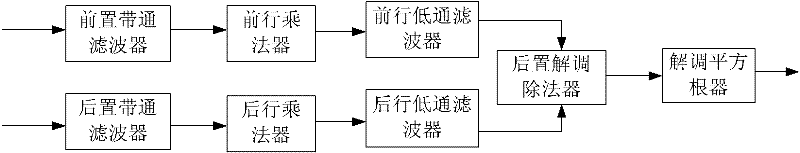

Modulation type optical current transducer and method thereof for measuring alternating current and direct current

ActiveCN102243258AReduced measurement accuracyEliminate distractionsCurrent/voltage measurementVoltage/current isolationCurrent transducerDc current

The invention discloses a modulation type optical current transducer and a method thereof for measuring alternating and direct current in the technical field of high-voltage circuit current measurement of electric power systems. The current transducer comprises an intelligent modulation light source, a front light splitter, a forward photoelectric converter, a magneto-optical sensing circuit, a backward photoelectric converter and an intelligent photoelectric demodulator, wherein light emitted by the intelligent modulation light source is divided into two beams of light through the front light splitter, one beam of light passes through the magneto-optical sensing circuit and is introduced into the backward photoelectric converter, while the other beam of light is connected to the forward photoelectric converter; electric signals of the backward photoelectric converter and the forward photoelectric converter are input into the intelligent photoelectric demodulator; and a feedback photoelectric signal can be input into the intelligent modulation light source by the intelligent photoelectric demodulator. By utilizing the modulation type optical current transducer, the influences of environmental temperature, unstable light source output and other factors are overcome, and the measurement accuracy of the optical current transducer is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

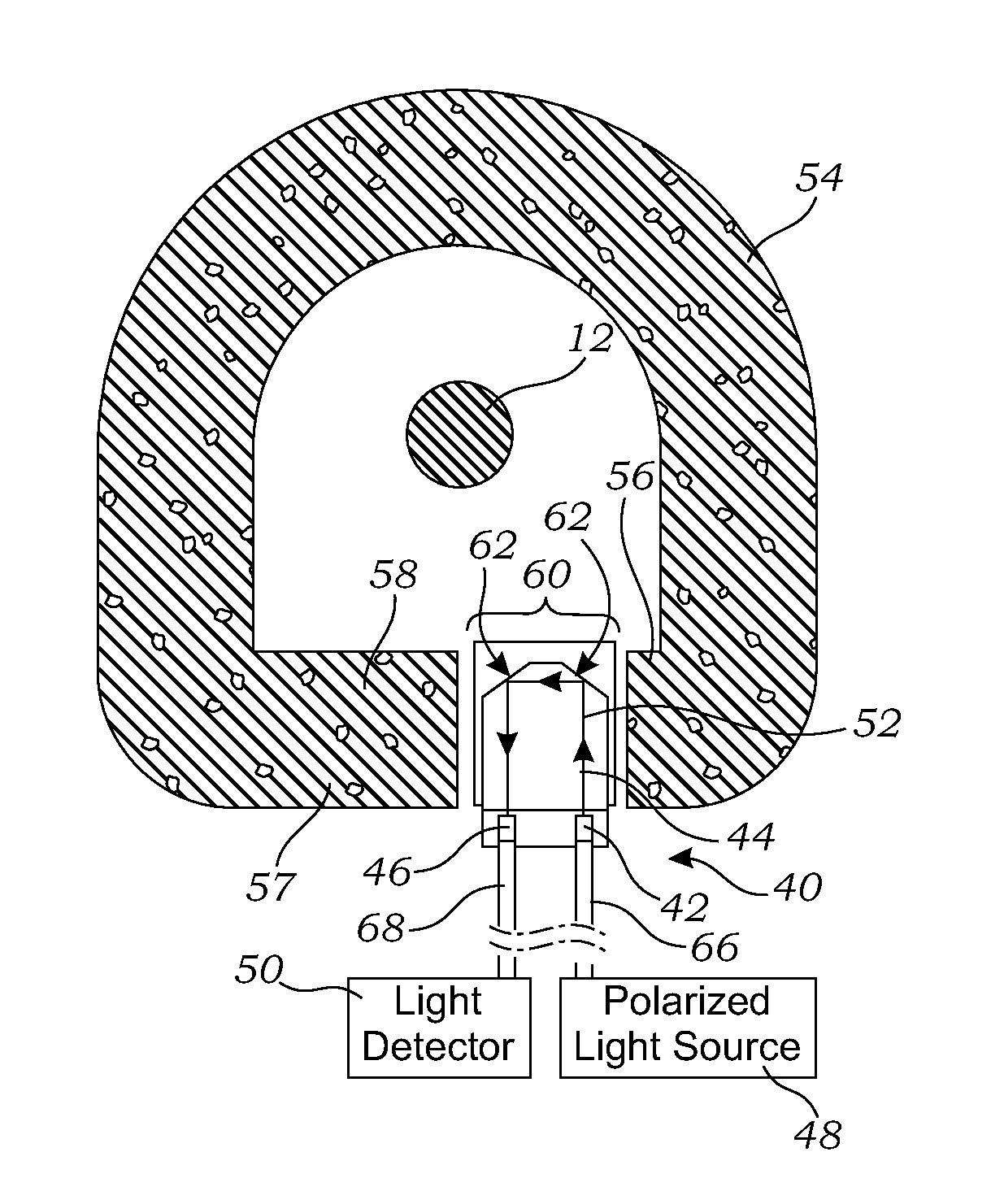

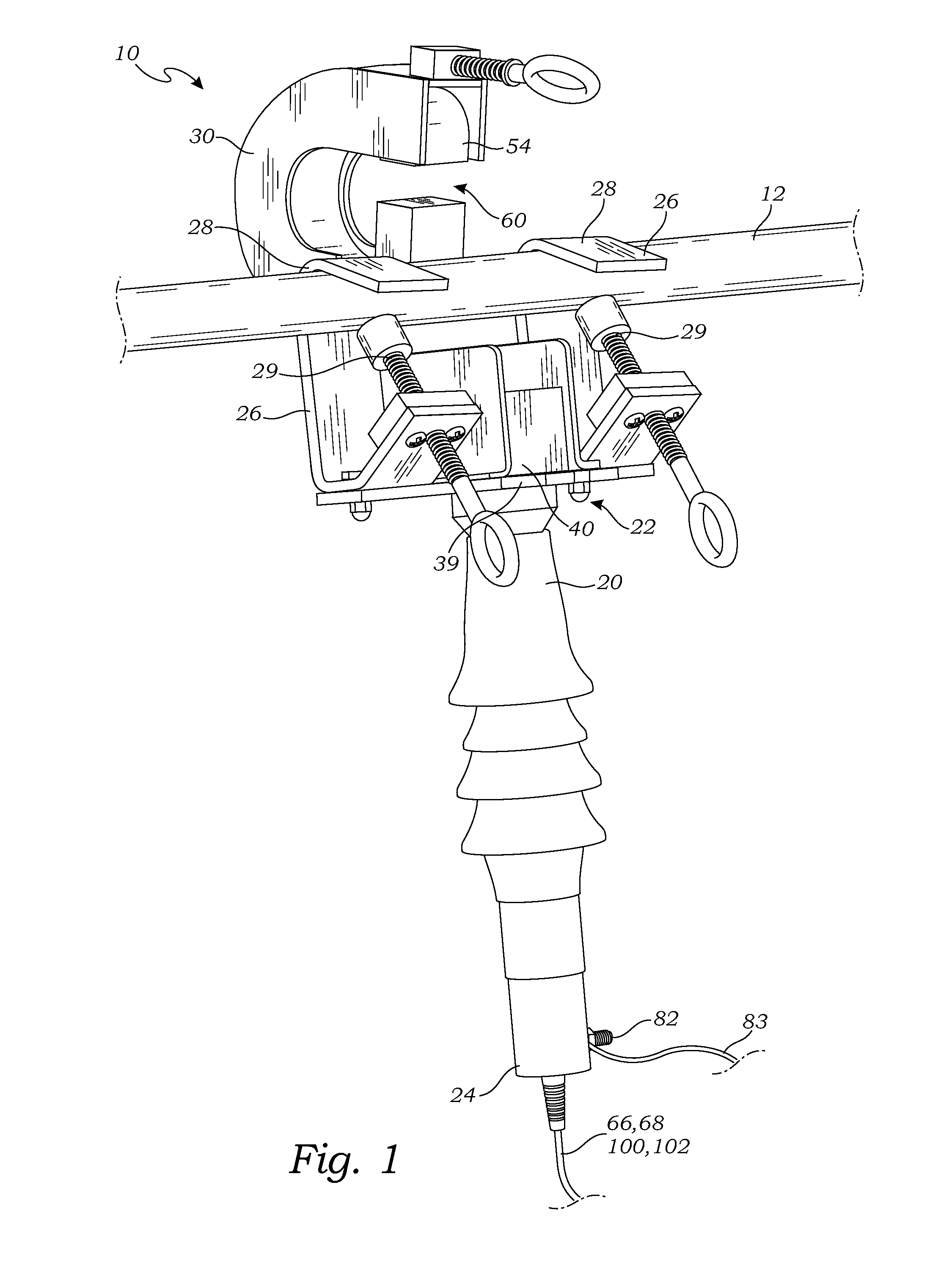

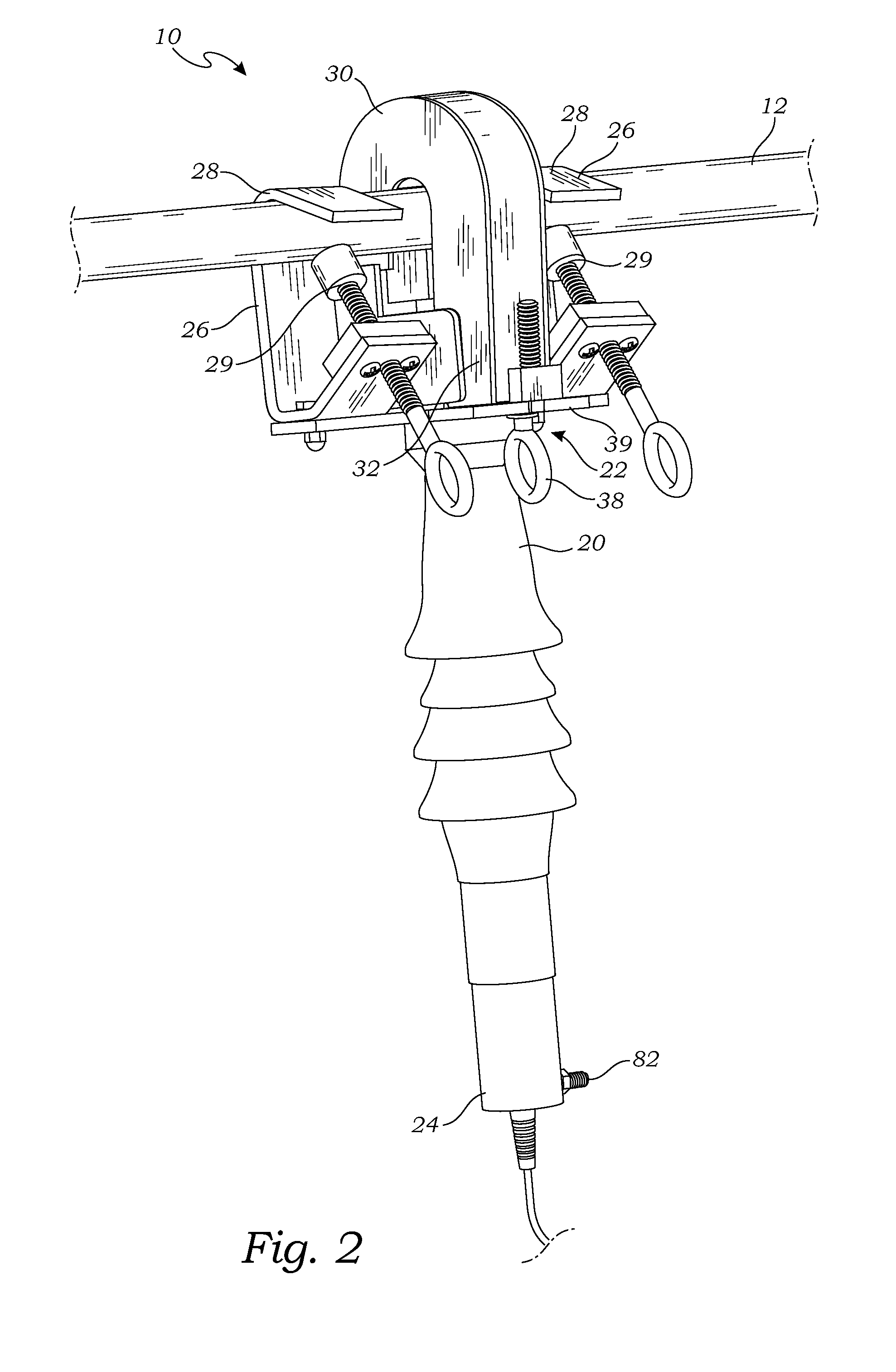

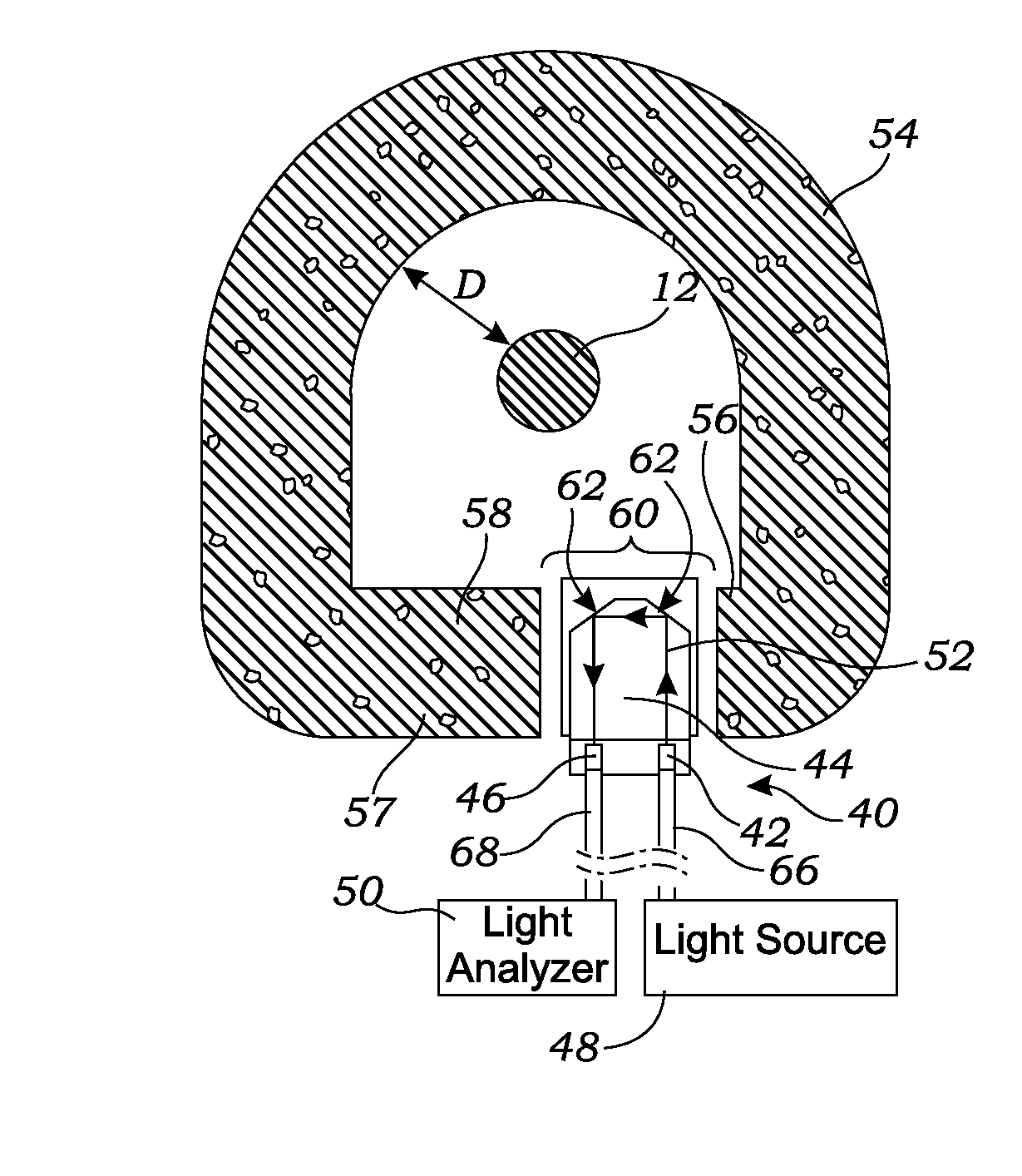

Optical sensor assembly for installation on a current carrying cable

ActiveUS20130033267A1Electrical measurement instrument detailsDigital variable/waveform displayElectricityCurrent sensor

An optical sensor assembly, for installation on a current carrying cable, senses the current in the cable and provides an electrical output indicating the current. To sense the current, a magnetic concentrator is placed in close proximity to the cable and creates a magnetic field representing current in the cable. An optical current sensor, within the created magnetic field, exposes a beam of polarized light to the magnetic field. The beam of polarized light is rotated thereby, by Faraday effect, according to the current in the cable. The amount of rotation is analyzed and converted to electrical signals to portray the current in the cable. The electrical signals may be processed, evaluated and analyzed to provide one or more of several elements of quality of the current in the cable.

Owner:MICATU

Differential protection device based on Faraday magneto-optical effect

ActiveCN103715650ANo error componentAvoiding Misidentified Internal Fault SituationsCurrent/voltage measurementEmergency protective arrangements for automatic disconnectionElectric power systemCurrent sensor

The invention discloses a differential protection device based on a Faraday magneto-optical effect, relating to a differential protection device, belonging to the field of relay protection of a power system. According to the differential protection device, the problems that large error components can be generated in differential operation and an internal fault and an external fault inside a section can not be accurately judged in an existing differential protection device. The differential protection device comprises a light source, a first multimode fiber, a second multimode fiber, a first optical current sensor, a polarization maintaining optical fiber, a second optical current sensor and an electronic processing unit; the first optical current sensor comprises a first multimode optical fiber collimator, a polarizer, a first Faraday magnetic-optical element and a first polarization maintaining collimator; and the second optical current sensor comprises a second polarization maintaining optical fiber collimator, a second Faraday magnetic-optical element, a polarization analyzer and a second multimode optical fiber collimator. The differential protection device is used in relay protection of the power system.

Owner:HARBIN INST OF TECH +3

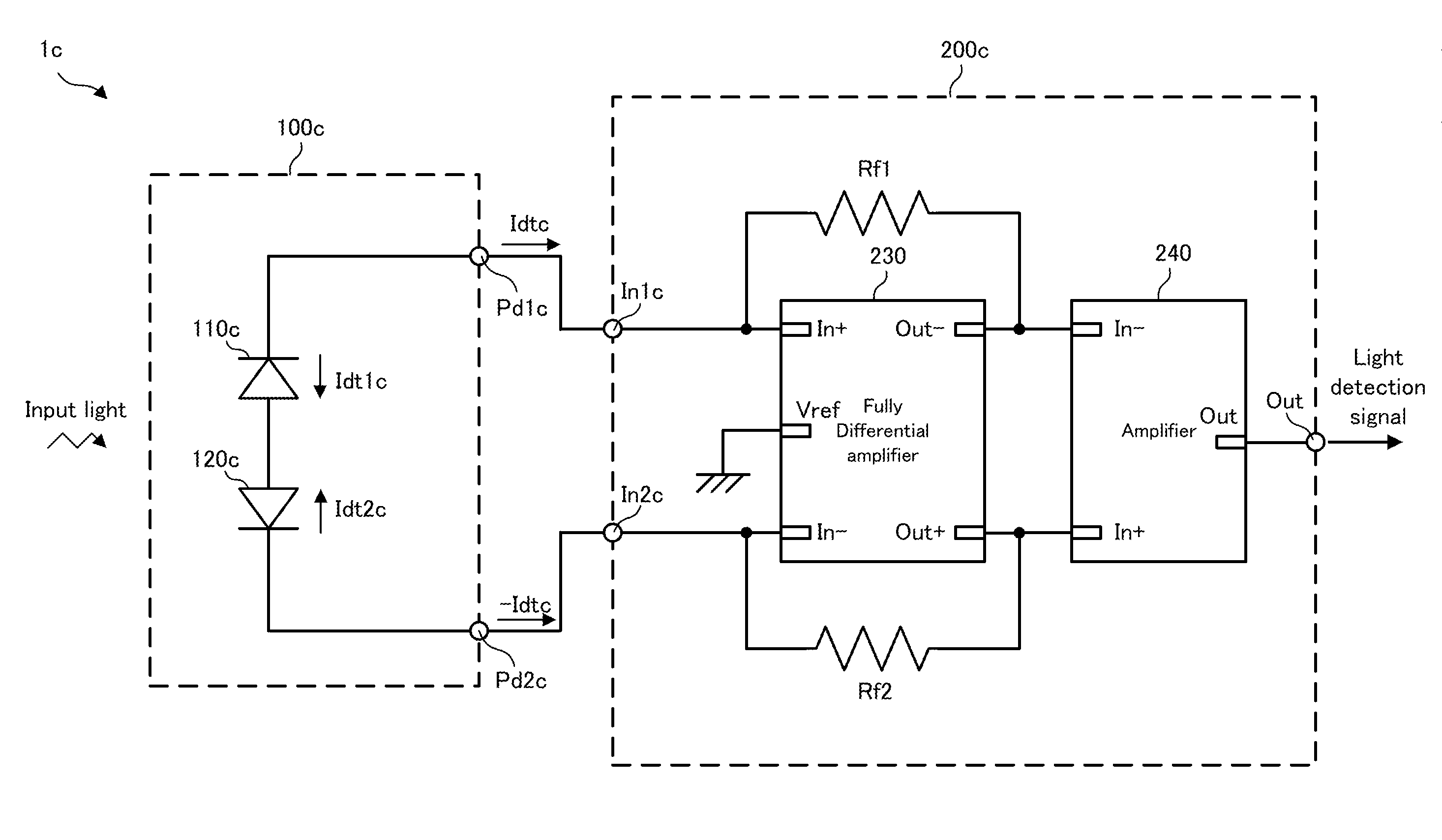

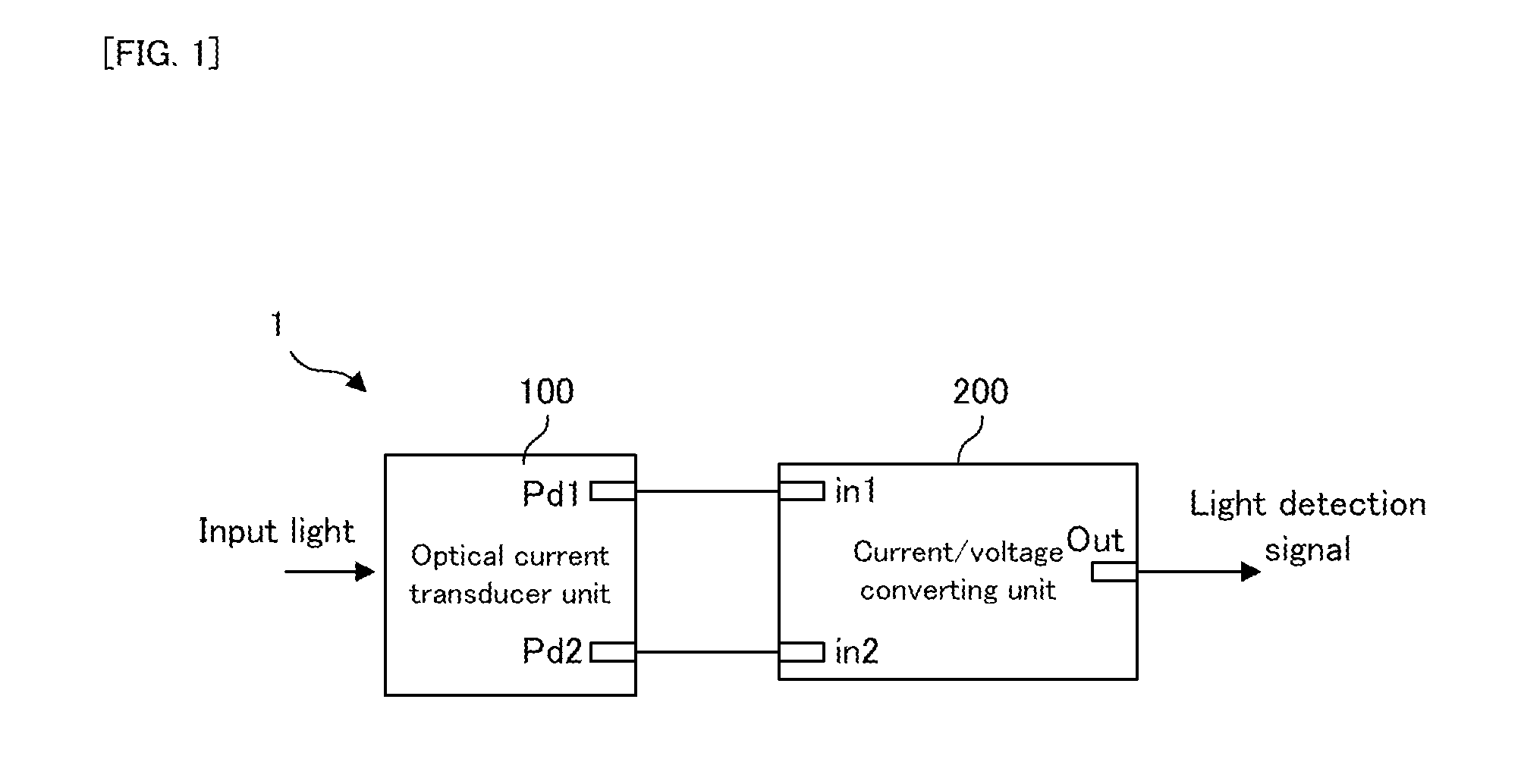

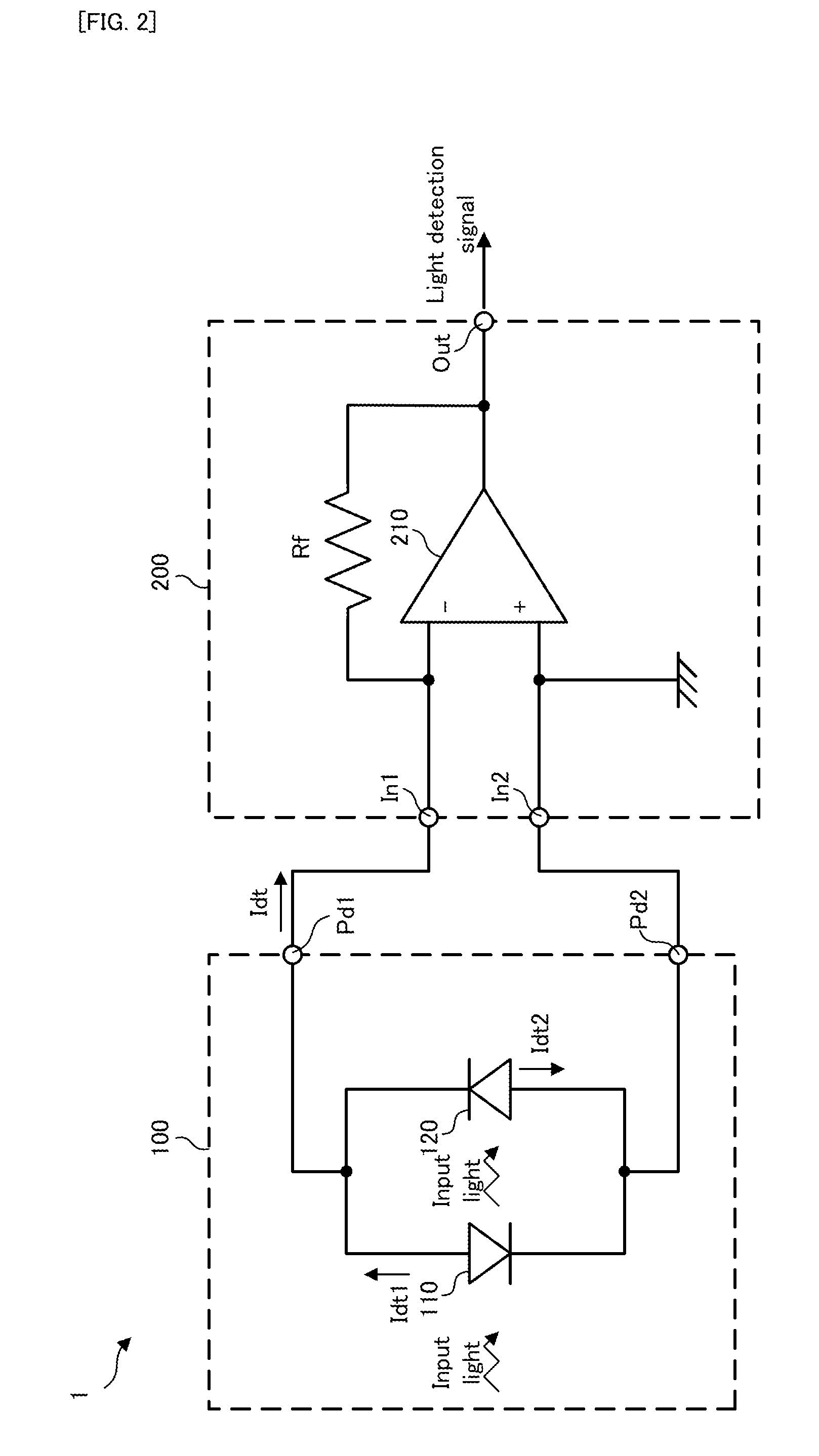

Light detecting apparatus and fluid measuring apparatus

ActiveUS20130090564A1Lighter componentThe detection signal is accurateVolume/mass flow measurementCatheterMeasurement devicePhotoelectric conversion

A light detecting apparatus includes: a first photoelectric conversion element unit (110) and a second photoelectric conversion element unit(120) each of which converts input light to an electric current and output it; an optical current transducer unit (100) for outputting, as a detected current, a differential current between an electric current outputted by the first photoelectric conversion element unit and an electric current outputted by the second photoelectric conversion element unit; and a first current / voltage converting unit (200) for amplifying the detected current outputted from the optical current transducer unit, converting it to a voltage signal, and outputting the voltage signal.

Owner:AIR WATER BIODESIGN INC

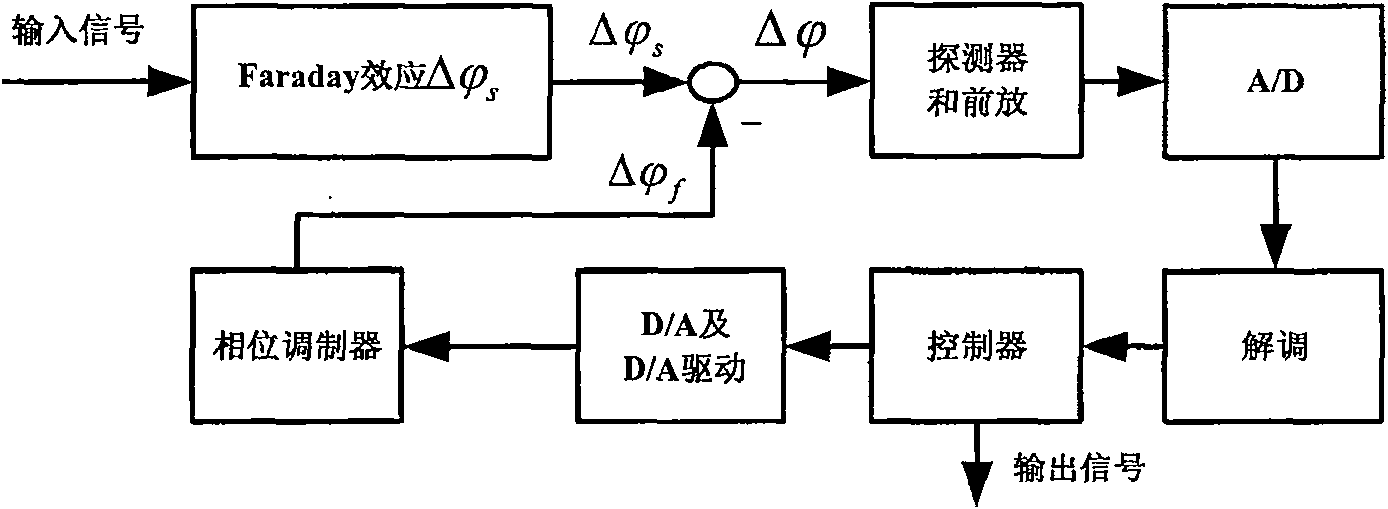

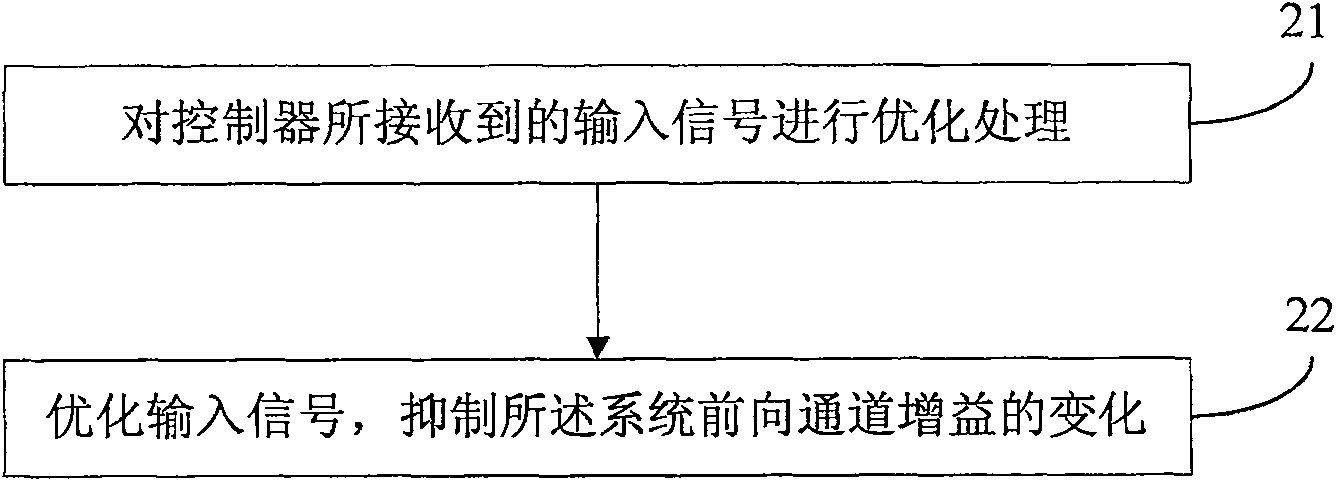

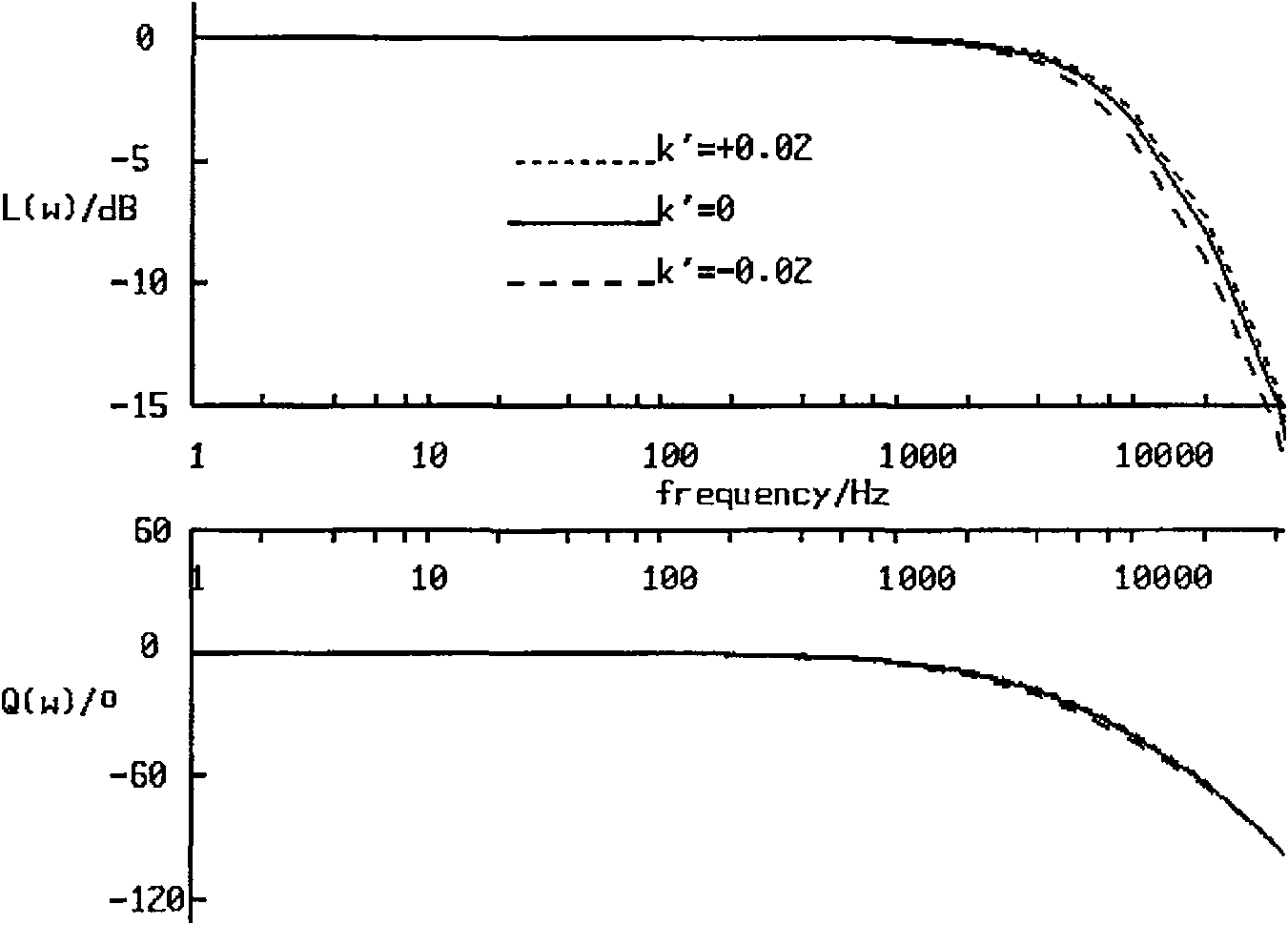

Control processing method and device for optical fiber current transformer

InactiveCN100575959COptimizing State VariablesCurrent/voltage measurementElectric controllersState variablePerformance index

The embodiment of the present invention provides a control processing method and a device for an optical current transducer. After a controller of an optical current transducer system receives an input signal, according to the parameter setting and the performance index requirement of the optical current transducer, the feedback signal of the system is controlled to be optimized so as to optimize the state equation of the system to obtain the state variable of the system after the optimization calculation. Afterwards, subsequent processing is carried out for the state variable of the optimized system so as to obtain an output signal and a feedback signal of the system. By the optimizing processing carried out for the controller, the variation of the gain in a forward channel of the system is restrained, so that the system performance is not influenced by the variation of the gain in the forward channel of the system, and the frequency characteristics of the system are improved, thereby improving the system performance of the optical current transducer.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com