Thin film type all-fiber current transformer with temperature compensation

A technology of current transformer and temperature compensation, applied in voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems of low measurement accuracy, achieve high measurement accuracy, eliminate errors, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

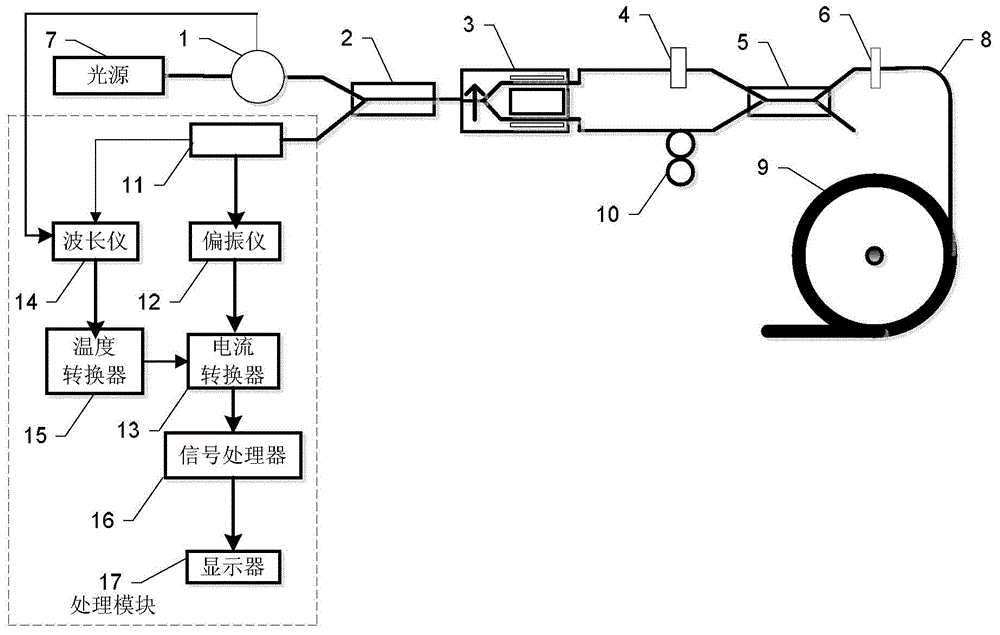

[0020] Specific implementation mode one: combine figure 1 Describe this embodiment, the thin-film all-fiber current transformer with temperature compensation described in this embodiment, the all-fiber current transformer includes a light source, an optical circulator 1, a first polarization-maintaining fiber coupler 2, and a Y waveguide Phase modulator 3, fusion branch 4, second polarization maintaining fiber coupler 5, 1 / 4 wave plate 6, transmission fiber 8, sensing fiber 9 and compensation coil 10;

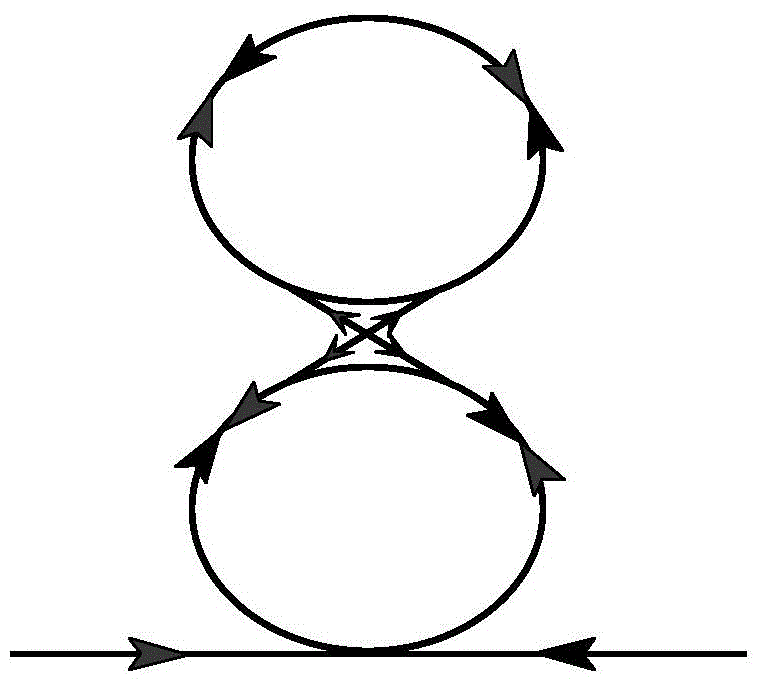

[0021] The light emitted by the light source enters the first polarization-maintaining fiber coupler 2 through the circulator 1, and the light emitted by the first polarization-maintaining fiber coupler 2 enters the Y-waveguide phase modulator 3, and the Y-waveguide phase modulator 3 first converts the incident light The polarized light is converted into linearly polarized light, and then the linearly polarized light is divided into two parallel linearly polarized light outputs...

specific Embodiment approach 2

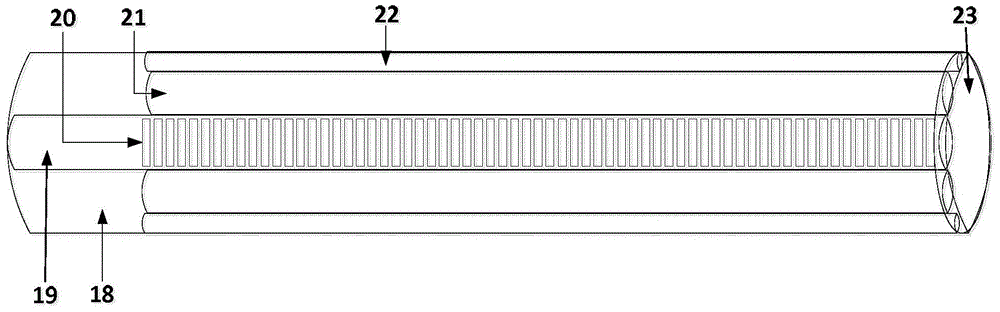

[0044] Specific implementation mode two: combination image 3 Describe this embodiment, this embodiment is a further limitation of the thin-film all-fiber-optic current transformer with temperature compensation described in the first embodiment,

[0045] The sensing fiber 9 includes a fiber cladding 18, a fiber core 19, a FBG grating 20, a magneto-optical material 21, a reflective gold film 22 and a reflective silver film 23;

[0046] The head end of the fiber core 19 is provided with a cladding 18, and the end of the fiber core 19 is provided with a reflective silver film 23. The fiber core 19 is provided with a FBG grating 20, and the outer surface of the fiber core 19 is covered with a magneto-optical material 21. There is a reflective gold film 22 on the outer surface.

[0047] Such as image 3 Shown is a schematic diagram of the structure of the sensing fiber 9, wherein the FBG grating 20 is used for temperature measurement, the magneto-optical material 21 is used for m...

specific Embodiment approach 3

[0056] Embodiment 3: This embodiment is a further limitation of the thin-film all-fiber current transformer with temperature compensation described in Embodiment 1 or 2. The processing module includes a third polarization-maintaining fiber coupler 11, a polarimeter 12. Current converter 13, wavelength meter 14, temperature converter 15, signal processor 16 and display 17;

[0057] The light after interference in the Y-waveguide phase modulator 3 is input to the third polarization-maintaining fiber coupler 11 through the first polarization-maintaining fiber coupler 2, and the third polarization-maintaining fiber coupler 11 divides the input light into two beams,

[0058] One of them is input to the wavelength meter 14 and is compared with the light in the circulator 1 to output a wavelength shift signal, the wavelength shift signal is input to the temperature converter 15, and the temperature converter 15 outputs a temperature change signal to be input to the current converter 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com