Optical current sensor based on microelectronic mechanical system, making and detecting method thereof

A current sensor and micro-electronic machinery technology, applied in the field of current sensor, can solve problems such as susceptibility to strong magnetic interference, difficulty in practical application, and affecting system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

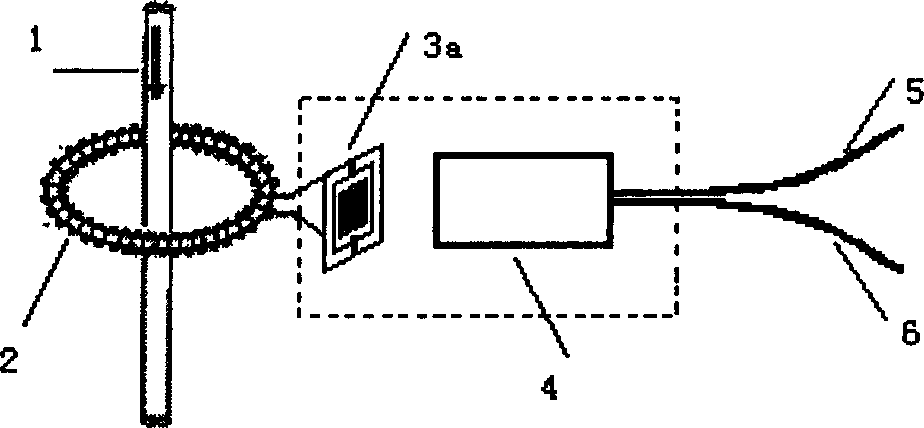

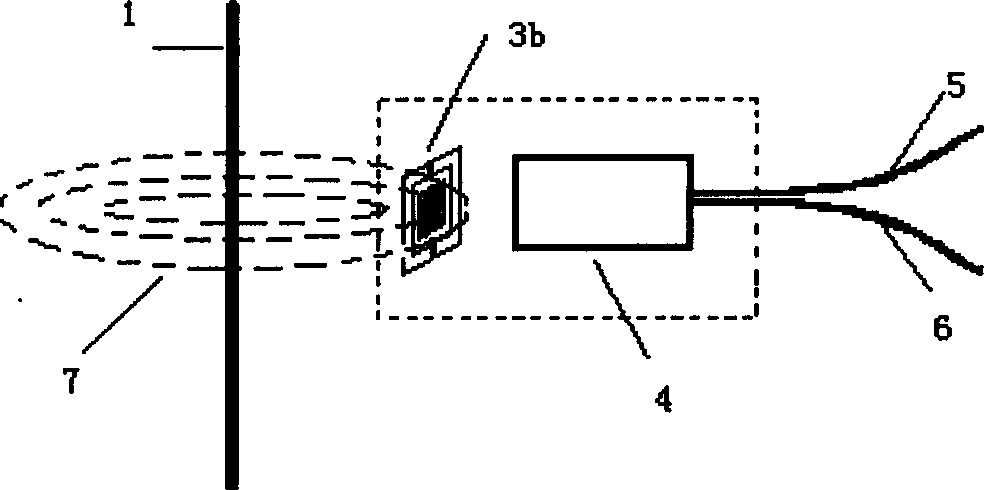

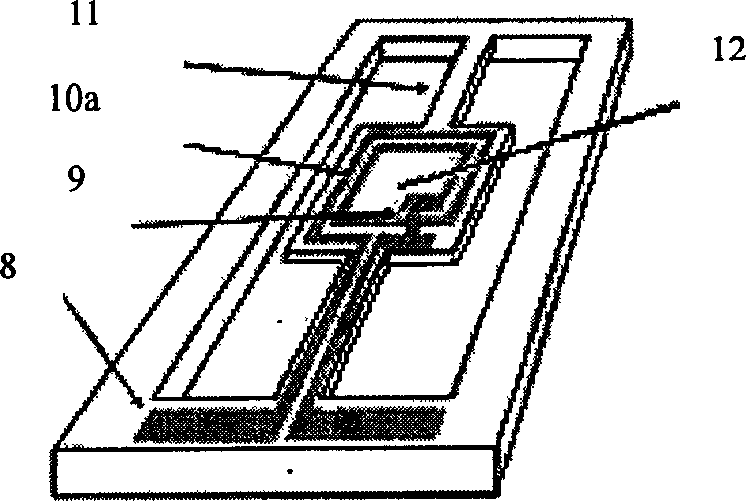

[0040] Taking Rogowski coils in series with helical coil MEMS torsion micromirrors and permanent magnets (NdFeB) to generate magnetic fields as an example to illustrate the implementation steps, in which silicon is used as the substrate material, gold is used as the MEMS coil material, the torsion plane, the metal coil, the torsion The beams are all rectangular:

[0041] 1. Design of parameters

[0042] A. Calculate its resistance, mutual inductance, and self-inductance according to the adjustable Rogowski coil parameters (number of turns, ring diameter, mandrel diameter, wire diameter, etc.).

[0043] B. Calculate the moment of inertia and damping according to the initial parameters (length, width, height) of the rotating film.

[0044] C. Calculate the resistance, mutual inductance, and self-inductance of the coil according to the structural parameters of the metal coil (turns, length, width, height, single-turn coil width, and coil spacing) and position parameters (the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com