An electronic transformer with anti-corrosion function

An electronic transformer and anti-corrosion technology, which is applied in the direction of transformer/inductor casing, transformer/inductor parts, inductors, etc., to achieve the effect of improving the voltage conversion rate and high reliability and fidelity of large current transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

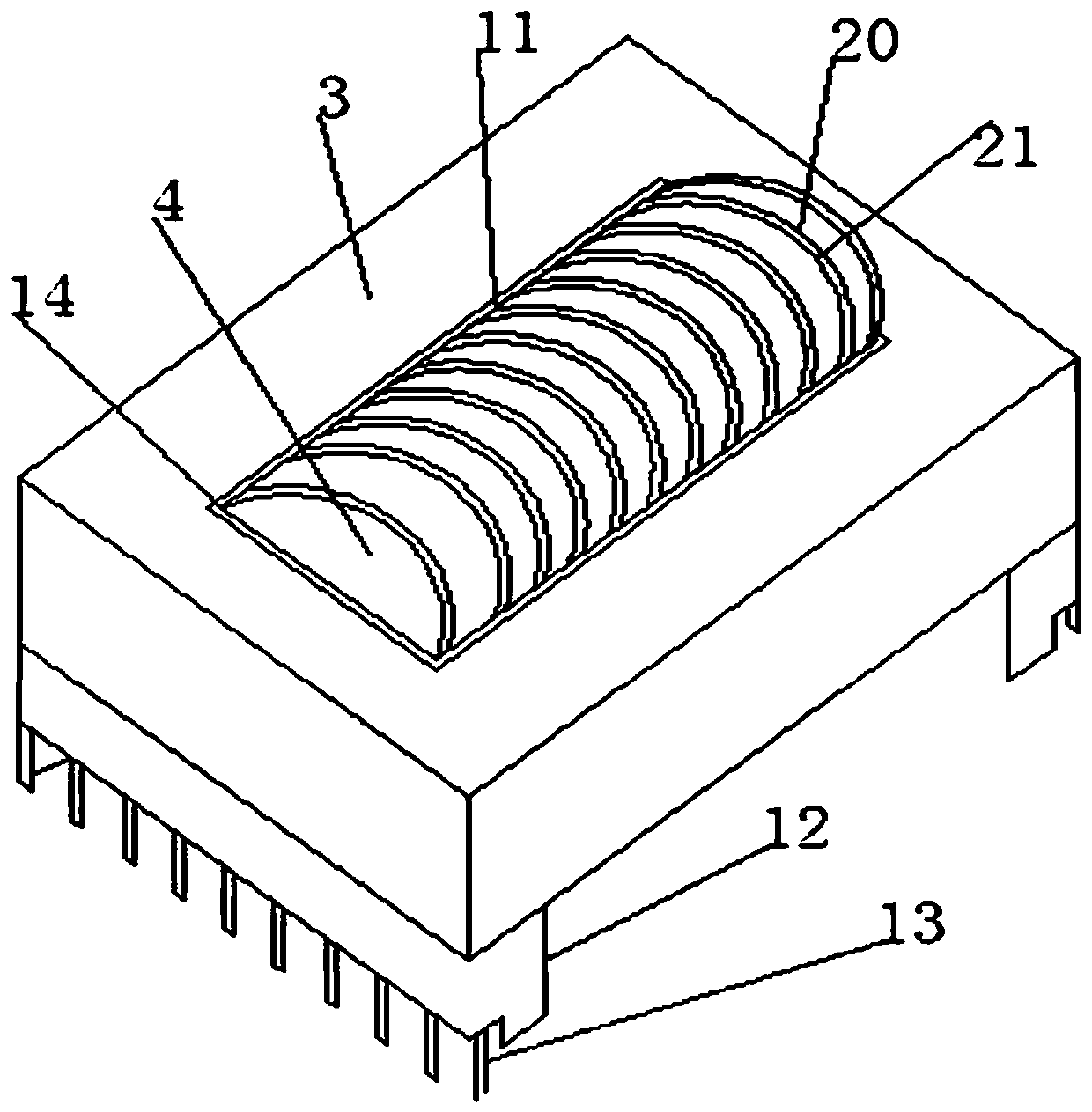

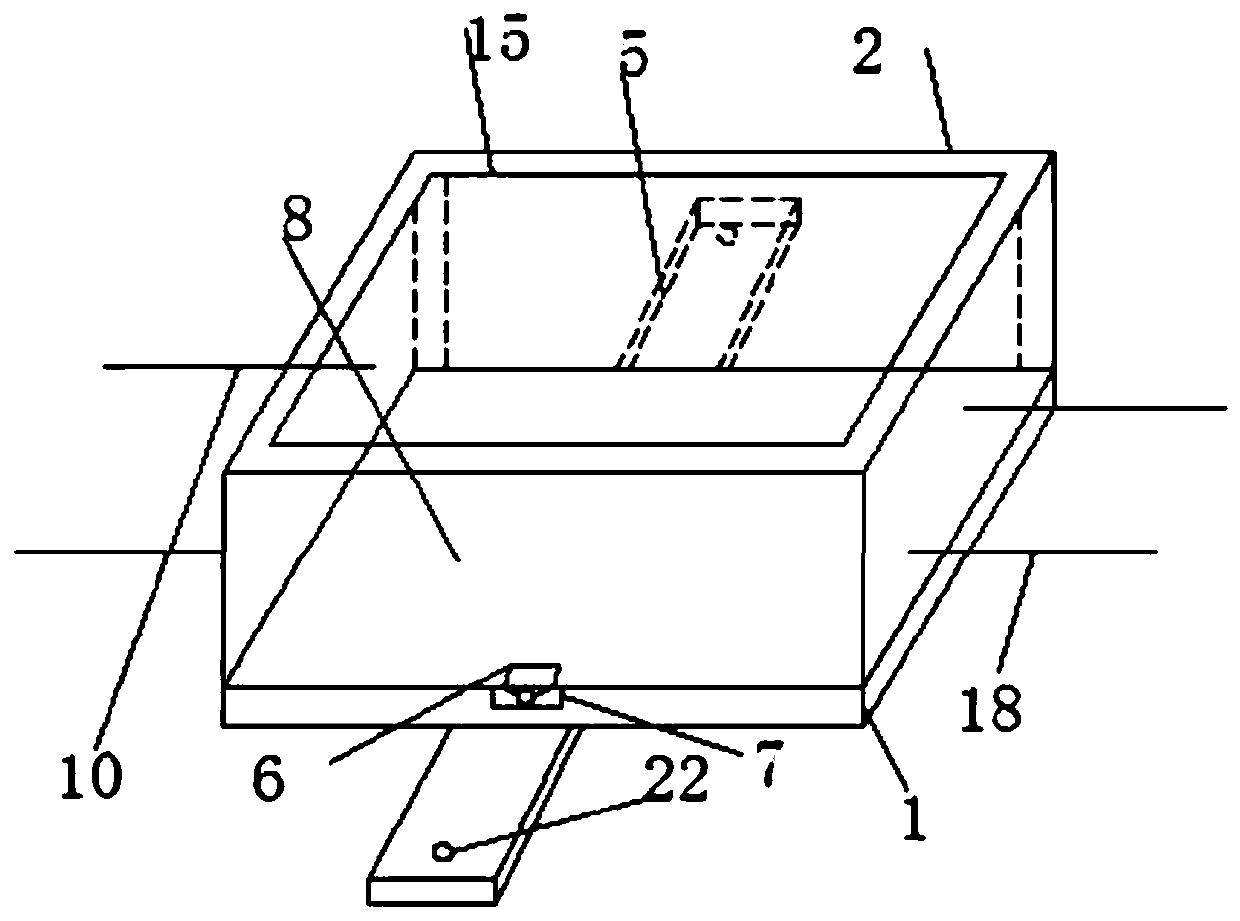

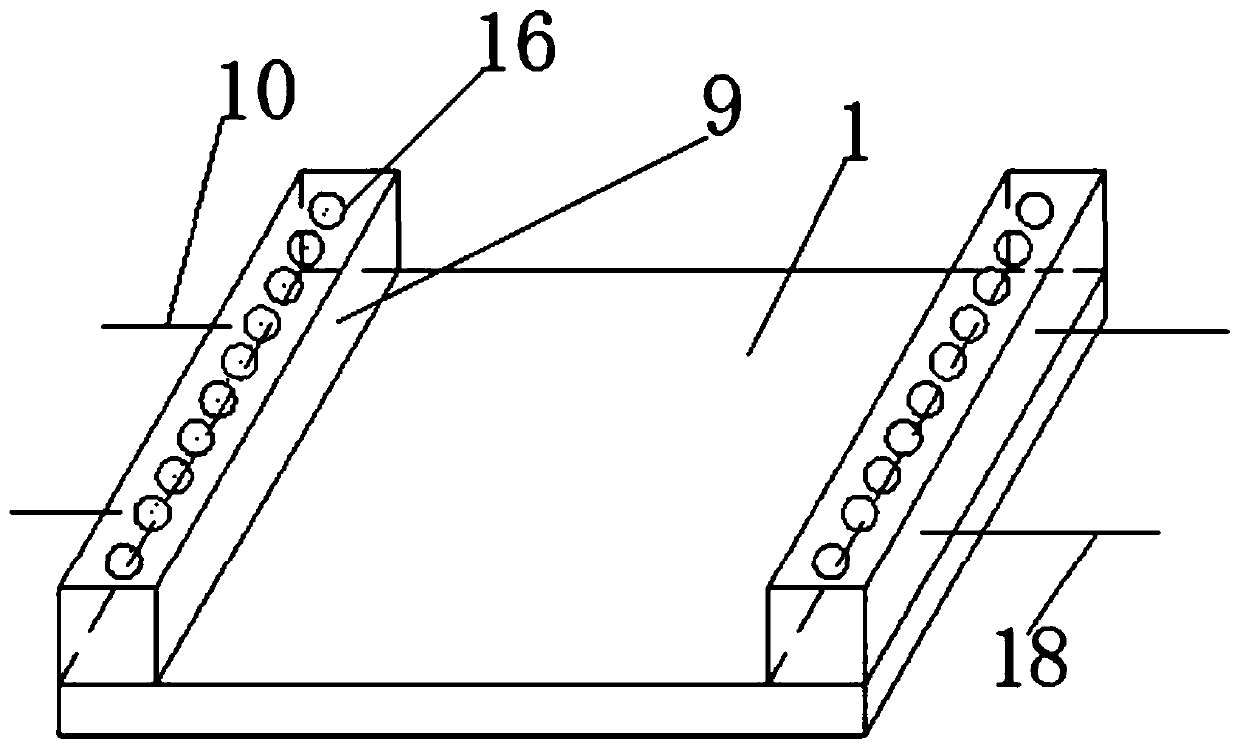

[0024] Embodiment 1 refers to Figure 1-4 , an electronic transformer with anti-corrosion function, including a base 1, a cover shell 2, a winding frame 3, a magnetic core 4, and a fixed connector 5, the edge of the base 1 is provided with a buckle 6; the edge of the cover shell 2 is a There is a card slot 7 on the side, and the cover shell 2 is engaged with the buckle 6 of the base 1 through the card slot 7. After the cover shell 2 is engaged with the base 1, the interior is hollow, which is called the first cavity 8, and the second A cavity 8 is provided with a slot 9, the slot 9 is closely connected with the bottom of both sides when the base 1 and the cover shell 2 are closed, a lead wire is provided at the joint between the slot 9 and the cover shell 2, and the outer surface of the cover shell 2 is coated with Cover one deck anti-corrosion film; Described bobbin 3 is cuboid, and its bobbin 3 center is provided with through hole, and this through hole forms cavity, is call...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com