Vertical frequency adjustment mass damper for model test and design method of vertical frequency adjustment mass damper

A frequency modulation mass damping, model test technology, applied in instruments, measuring devices, vibration testing, etc., can solve the problems of damper friction sensitivity, small mass, change of damper dynamic characteristics, etc., to achieve easy installation, simple design, and reduce motion energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

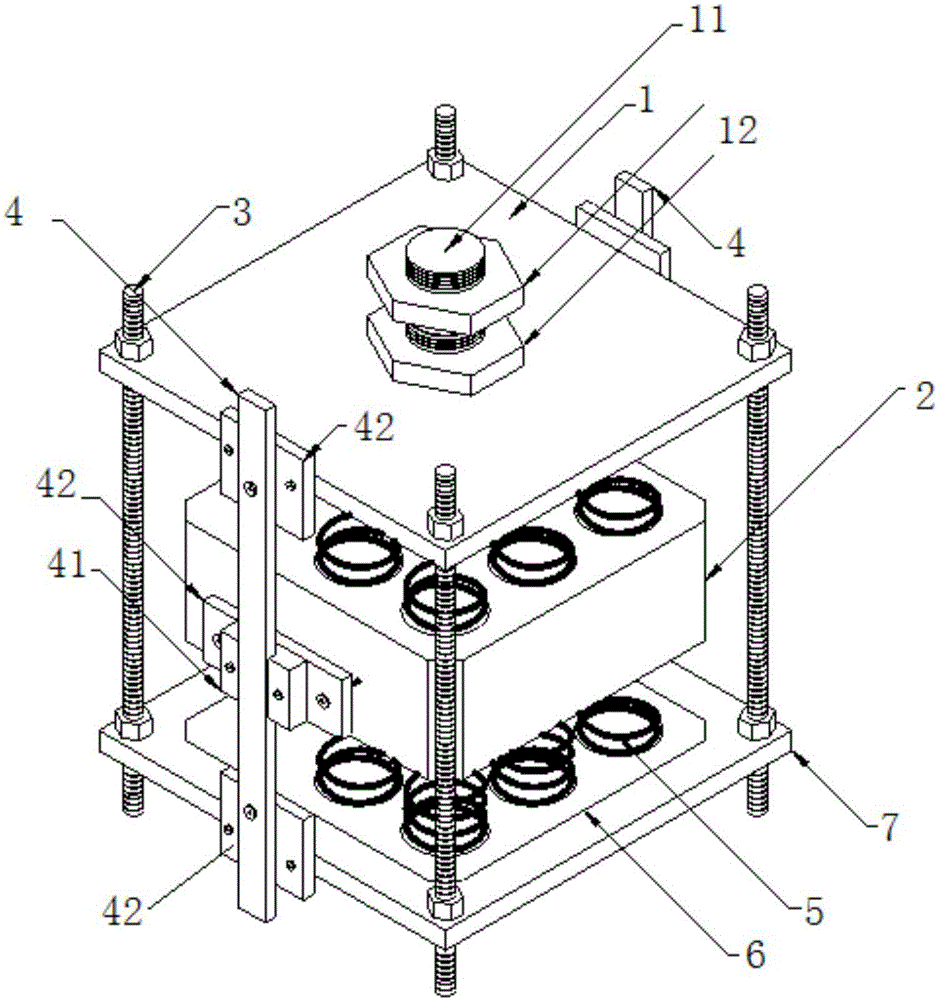

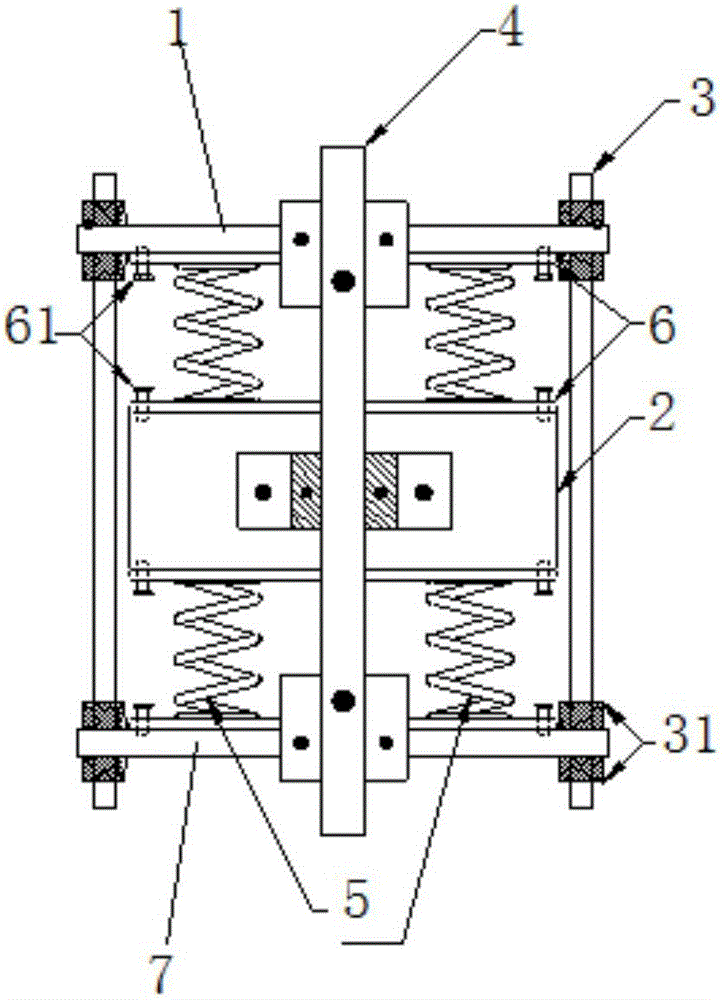

[0030] A vertically tuned mass damper for model testing, such as Figure 1-5 As shown, it includes the upper top plate 1, the lower bottom plate 7 and the mass block 2 between the top plate 1 and the bottom plate 7. The upper end of the top plate 1 is provided with a bolt 11 connected with the large-span structural model. The bolt 11 is equipped with two 12 nuts, the mass block 2 is a square, made of solid iron, the top plate 1 and the bottom plate 7 are connected by four connecting screw rods 3 arranged between them, and the connecting screw rod 3 is a cylindrical long rod provided with external threads. There are corresponding nuts, and the distance between the top plate 1 and the bottom plate 7 is adjusted by connecting the screw rod 3 and the nuts. The vertical frequency modulation mass damper is provided with a vertical linear track 4, the linear track 4 is fixedly connected with the top plate 1 and the bottom plate 7, and a plurality of springs are respectively arranged ...

Embodiment 2

[0032] The design of the mass block and the spring in the vertical frequency modulation mass damper adopts the following methods:

[0033] (a) According to the expected damping effect and the local pressure capacity of the suspension of the large-span structural model, determine the mass m of a single damper mass block TMD , and then determine the size of the mass block and the size of the damper;

[0034] (b) Determine the frequency f of the long-span structural model to be controlled TMD ;

[0035] (c) According to the formula k TMD = m TMD (2·π·f TMD ) 2 / N determines the stiffness coefficient of each spring, where N is the number of spring elements, which is determined according to the actual situation, and N is taken as an even number to make the spring arrangement symmetrical;

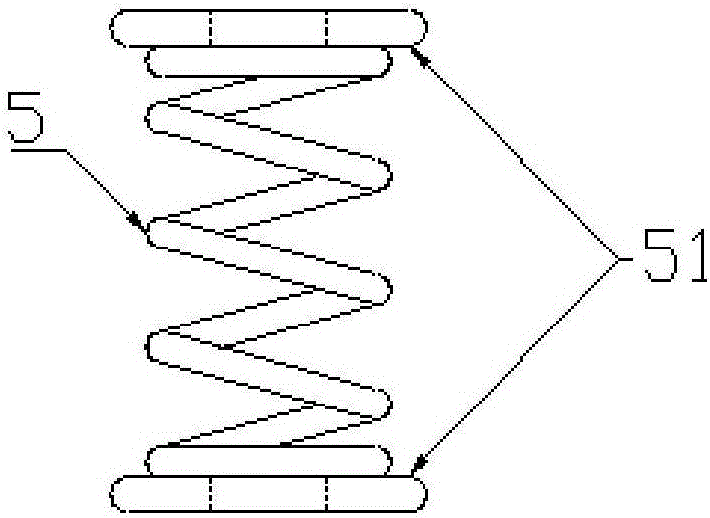

[0036] (d) According to the formula k TMD =Gd 4 / (8D 3n), choose a spring that meets the stiffness, size and other requirements, where G is the shear modulus of the spring, d is the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com