Optical current transformer and method for resisting external magnetic field interference

A current transformer and current sensor technology, applied in the direction of voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems of large volume and weight, limited shielding effect, complex insulation, etc., and achieve small size, low cost, Insulation and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

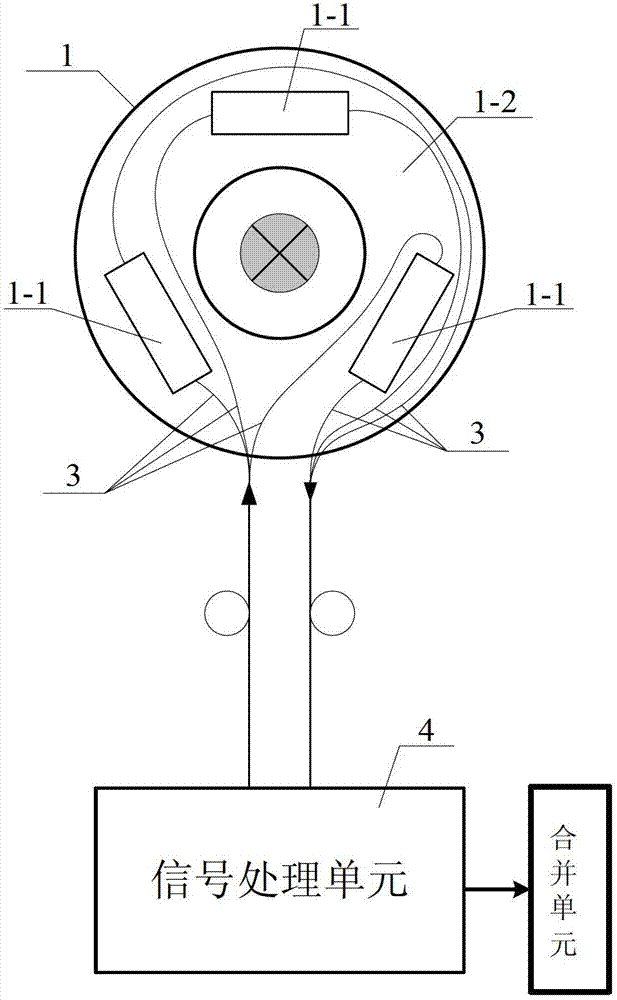

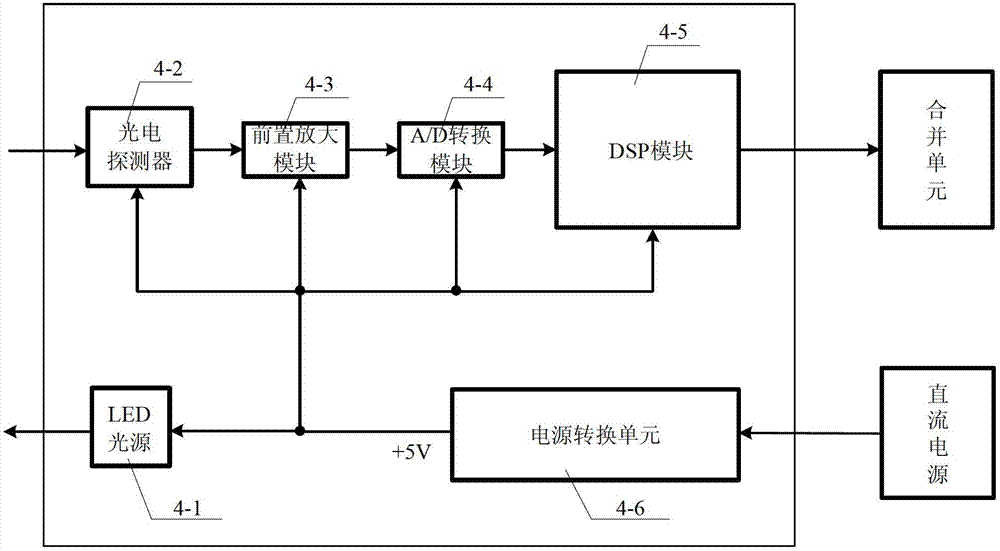

[0036] Specific implementation mode one: combine figure 1 and image 3 Describe this embodiment, the optical current transformer described in this embodiment includes an optical sensing unit 1, a signal processing unit 4 and a multimode optical fiber 3, and the optical sensing unit 1 includes m optical current sensors 1-1 and An insulating tray 1-2, m≥2; the m sets of optical current sensors 1-1 are the same straight-through optical current sensors 1-1, and the magneto-optical glass of the m sets of optical current sensors 1-1 passes along the The length of the light direction is l, and the m optical current sensors 1-1 are fixed on the insulating tray 1-2, and the m optical current sensors 1-1 independently output to the signal processing unit 4 through the multimode optical fiber 3; The m sets of optical current sensors 1-1 of the sensing unit 1 form a zero sum magnetic structure S m The optical signal input end of the optical sensing unit 1 communicates with the optical s...

specific Embodiment approach 2

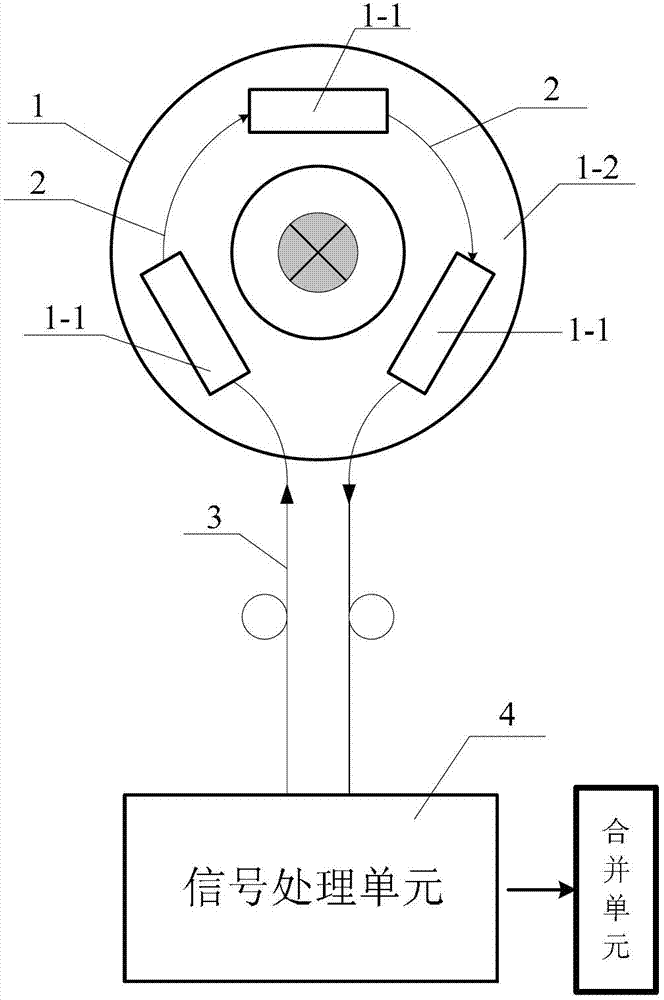

[0039] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment, the optical current transformer described in this embodiment includes an optical sensing unit 1, a signal processing unit 4, a polarization-maintaining optical fiber 2 and a multimode optical fiber 3, and the optical sensing unit 1 includes m optical current transformers A sensor 1-1 and an insulating tray 1-2, the m optical current sensors 1-1 are the same straight-through optical current sensors 1-1, the magneto-optical current sensors 1-1 of the m optical current sensors 1-1 The length of the glass along the light-passing direction is l, and m optical current sensors 1-1 are fixed on insulating trays 1-2 to form a series topology relationship, and polarization-maintaining optical fibers 2 are used between the m optical current sensors 1-1 connection; m sets of optical current sensors 1-1 of the optical sensing unit 1 form a zero sum magnetic structure S m The optical sign...

specific Embodiment approach 3

[0041] Specific Embodiment Three: This embodiment is a further limitation of the optical current transformer described in Embodiment 1 or Embodiment 2. The zero-sum magnetic structure S m are m directed straight line segments l k The m-order symmetric polygonal discrete loop formed, k=1, 2,..., m; the directed straight line segment l k is a short side, and the length of each short side is l, and the side between two adjacent short sides is a long side (or a directed straight line segment l k is the long side, this embodiment uses the short side as an example for illustration); the discrete loop satisfies the following two conditions:

[0042] 1. m long sides and m short sides constitute a symmetrical 2m polygon, and the symmetrical 2m polygon is a symmetrical 2m polygon inscribed in a circle;

[0043] 2. m directed line segments l k Take the opposite direction or the clockwise direction as the positive direction;

[0044] Take the zero and imperial magnetic structure S m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com