Two-way transmission optical current sensor

A technology of a current sensor and an optical sensor, applied in the field of sensors, can solve the problems such as the optical path structure is not easy to encapsulate the environmental tolerance, and the system performance is adversely affected, and achieves the effect of simplifying the optical path structure, facilitating the packaging, and improving the tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

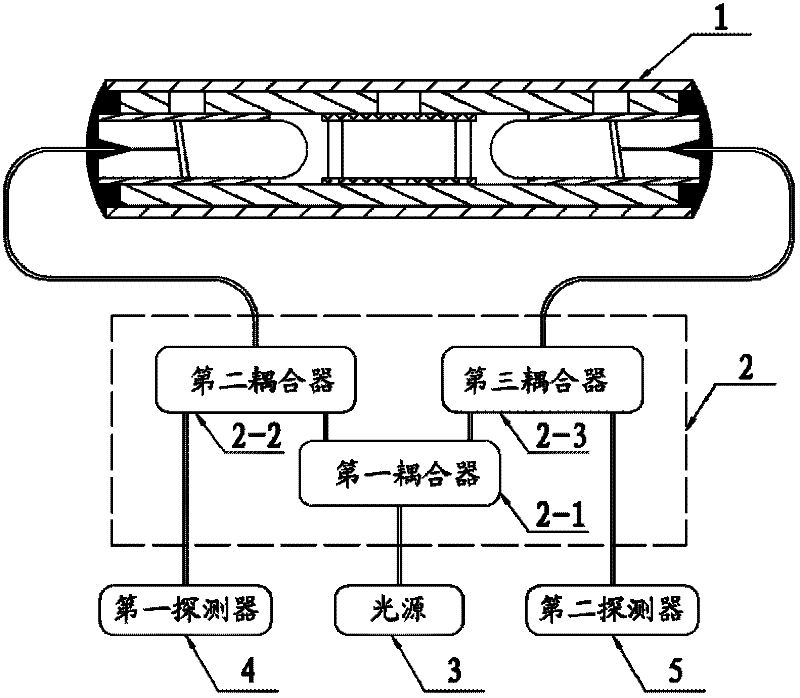

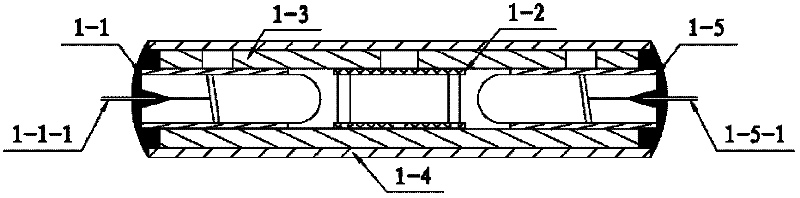

[0015] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment mode, the optical current sensor of bidirectional transmission of the present invention is characterized in that it comprises optical sensor 1, coupler module 2, light source 3, first detector 4 and second detector 5; Coupler module 2 comprises the first A coupler 2-1, a second coupler 2-2, a third coupler 2-3; the input end of the first port of the first coupler 2-1 is connected to the output end of the light source 3, and the first coupler 2- The output of the second port of 1 is connected to the input of the second port of the second coupler 2-2, and the output of the third port of the first coupler 2-1 is connected to the second port of the third coupler 2-3 The input end of the first port of the second coupler 2-2 is connected with an input and output end of the optical sensor 1, and the input and output end of the first port of the third coupler 2-3 is connected with the opt...

specific Embodiment approach 2

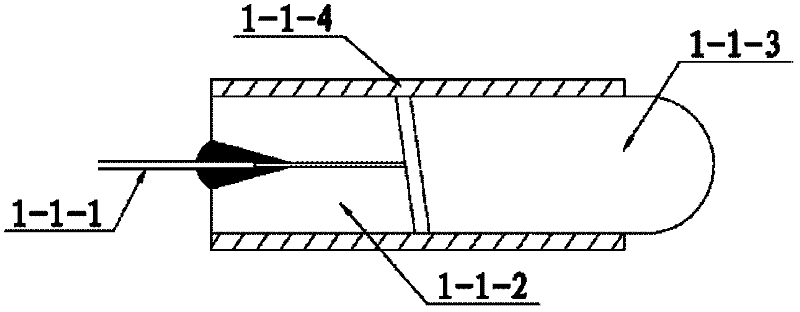

[0018] Specific implementation mode two: combination image 3 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that its first fiber collimator 1-1 includes a first optical fiber pigtail 1-1-1, a pin 1-1-2, a lens 1- 1-3 and collimator sleeve 1-1-4, the collimator sleeve 1-1-4 is hollow, and the first optical fiber pigtail 1-1-1 is fixed inside the pin 1-1-2 In the hole, the pin 1-1-2 of the first optical fiber pigtail 1-1-1 is adjacent to the lens 1-1-3 and is set and fixed in the collimator sleeve 1-1-4, the pin There is a gap between 1-1-2 and the lens 1-1-3, and the end face of the first optical fiber pigtail 1-1-1 is ground to be inclined to the side wall of the collimator sleeve 1-1-4 by 8 degree angle, and anti-reflection coating is coated on the fiber outlet end face of the first optical fiber pigtail 1-1-1; the connection end of the first optical fiber pigtail 1-1-1 is connected to the first port of the second coupler 2-2 ...

specific Embodiment approach 3

[0022] Specific implementation mode three: combination Figure 4 and Figure 5 This embodiment is described. The difference between this embodiment and the second embodiment is that its magneto-optical glass core 1-2 includes a magneto-optic glass column 1-2-1, a first polarizing glass 1-2-2, a second polarizing glass 1-2-4 and glass core sleeve 1-2-3; first polarizing glass 1-2-2, magneto-optical glass column 1-2-1 and second polarizing glass 1-2-4 from left to right The arrangement set is fixed in the glass core casing 1-2-3, and the polarization directions of the first polarizing glass 1-2-2 and the second polarizing glass 1-2-4 form an included angle of 45 degrees.

[0023] The glass core sleeve 1-2-3 is a hollow glass sleeve, and the inner diameter of the sleeve is slightly larger than the outer diameters of the magneto-optical glass column 1-2-1, the polarizing glass 1-2-2 and the polarizing glass 1-2-4, The magneto-optical glass column 1-2-1, the polarizing glass 1-2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com