Optical current sensor based on Faraday magneto-optic effect and current measurement method thereof

A Faraday magneto-optical and current sensor technology, applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., can solve the problems of difficult to adapt to the power system, complex insulation structure, magnetic hysteresis, etc., to achieve insulation performance without affecting , The effect of good transient performance and large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

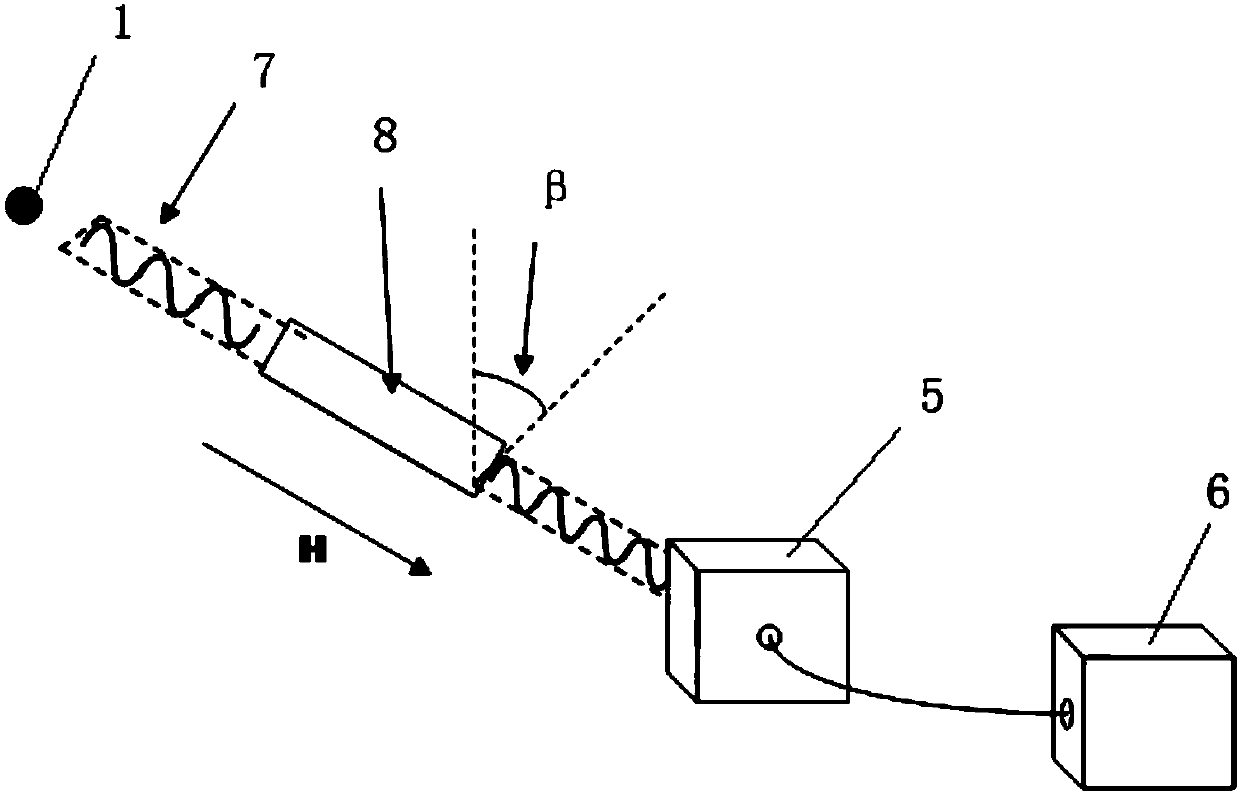

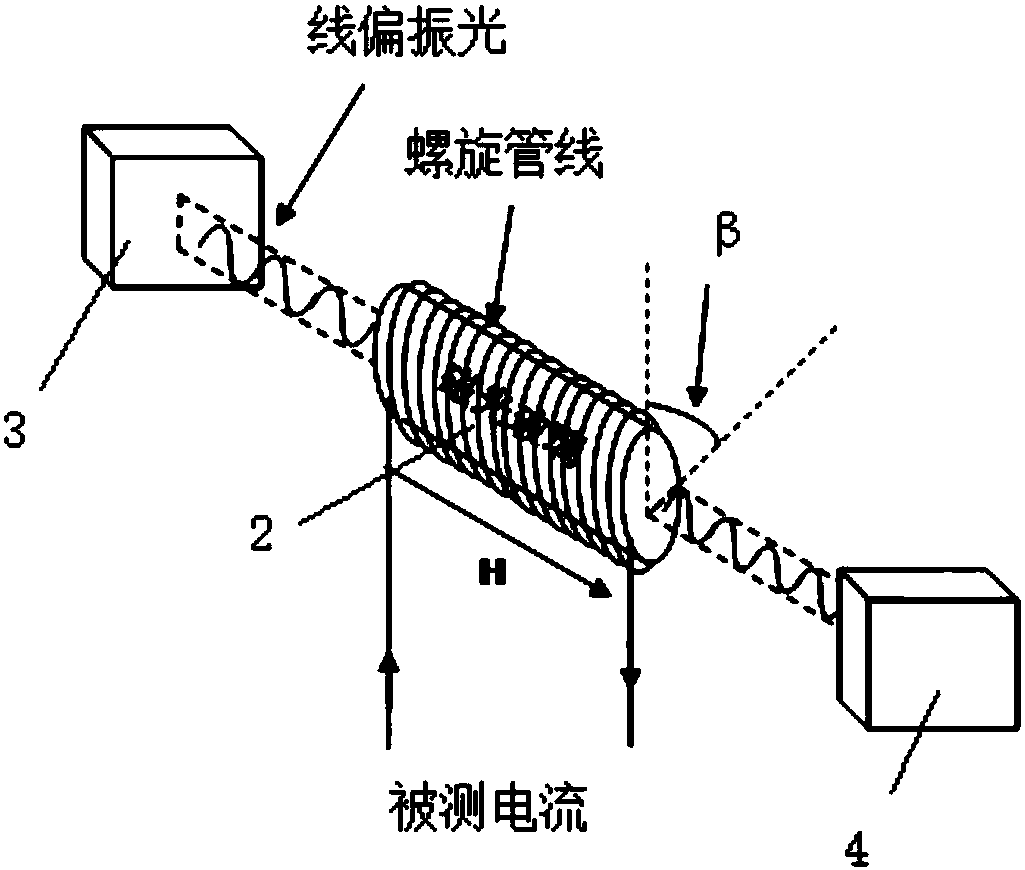

[0046] Such as figure 1 and figure 2 Shown is a schematic structural diagram of Embodiment 1 of the optical current sensor based on the Faraday magneto-optical effect of the present invention. This embodiment is based on the optical current sensor of the Faraday magneto-optical effect, including:

[0047] The laser generator 1 is used to generate polarized laser light with a predetermined wavelength. The laser generator 1 in this embodiment generates polarized laser light with a wavelength of 632.8nm. At this wavelength, the Verdet constant of the selected magneto-optical glass is the largest;

[0048] The integrated probe 8 includes a magneto-optical medium 2, and the two ends of the magneto-optical medium 2 are respectively provided with a polarizer 3 and an analyzer 4, and the polarizer 3 and the analyzer 4 are respectively insulated and packaged at both ends of the magneto-optical medium 2 ; In addition, the integrated probe also includes a fixed bracket and packaging, ...

Embodiment 2

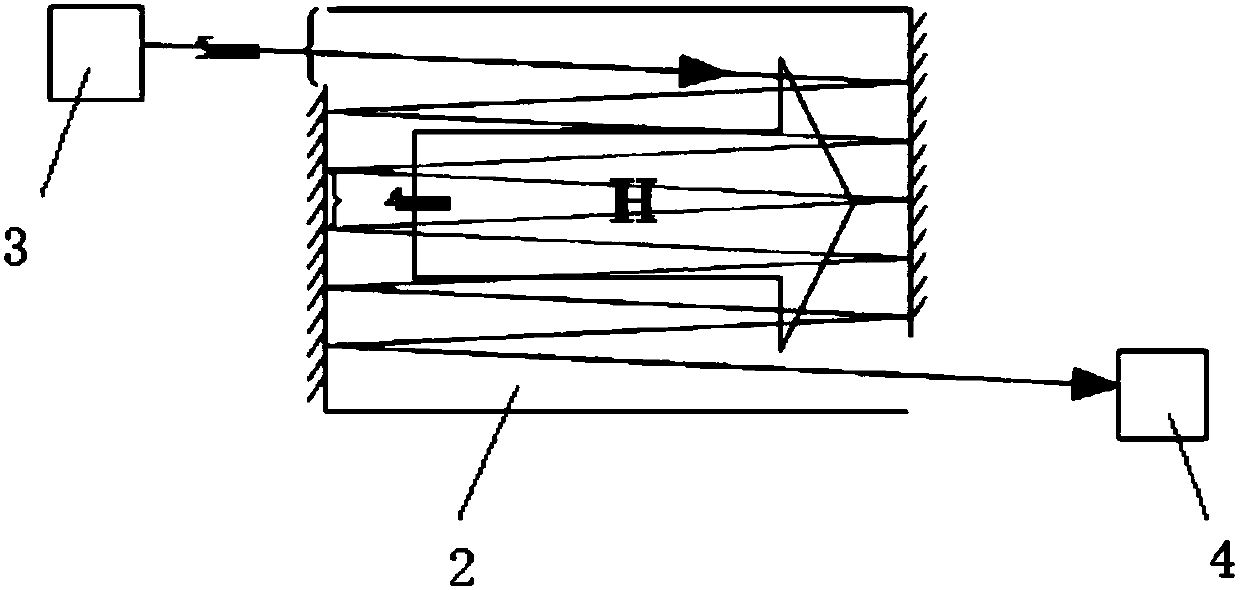

[0067] Such as image 3 As shown, it is a structural schematic diagram of the integrated probe of Embodiment 2 of the optical current sensor based on the Faraday magneto-optic effect of the present invention. This embodiment is based on the optical current sensor of the Faraday magneto-optical effect, including:

[0068] The laser generator 1 is used to generate polarized laser light with a predetermined wavelength. The laser generator 1 in this embodiment generates polarized laser light with a wavelength of 632.8nm. At this wavelength, the Verdet constant of the selected magneto-optical glass is the largest;

[0069] The integrated probe includes a magneto-optical medium 2, and the two ends of the magneto-optical medium 2 are respectively provided with a polarizer 3 and an analyzer 4, and the polarizer 3 and the analyzer 4 are respectively insulated and packaged at both ends of the magneto-optical medium 2; In addition, the integrated probe also includes a fixed bracket and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com