Water seal protection sleeve of remote-transmission temperature sensing bulb

A technology of temperature sensing and temperature sensing package, which is applied in the direction of thermal switch parts, etc., can solve the problems of pressure vessel leakage and inability to guarantee the internal pressure of the vessel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

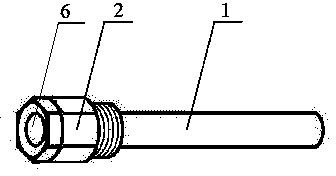

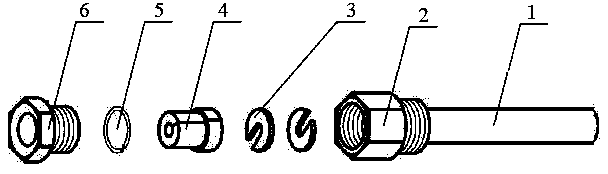

[0009] Such as figure 1 and figure 2 As shown, the present invention is a water-sealed sheath of a remote sensing temperature bulb, which includes a heat pipe 1, a threaded joint 2, a hollow compression plug 6 that matches the threaded joint 2, and a temperature sensing package. One end of the heat pipe 1 is closed, and the other end is connected to the threaded joint 2; the main body end of the temperature-sensing package is inserted into the heat-conducting tube 1, and the capillary end of the temperature-sensing package is located in the threaded joint 2, on the capillary end in the threaded joint 2 A U-shaped card 3 and a round convex table-shaped tensioning sleeve 4 are placed sequentially from the inside to the outside. The axial direction of the tensioning sleeve 4 is provided with a unilateral cut corresponding to the end of the capillary; the compression screw plug 6 will tighten the The sleeve 4 is compressed in the threaded joint 2; an elastic washer 5 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com