Liquid-ring vacuum pump, and impeller for a liquid-ring vacuum pump

A liquid ring vacuum pump and impeller technology, applied in the direction of pumps, rotary piston pumps, mechanical equipment, etc., can solve problems such as unfiltered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

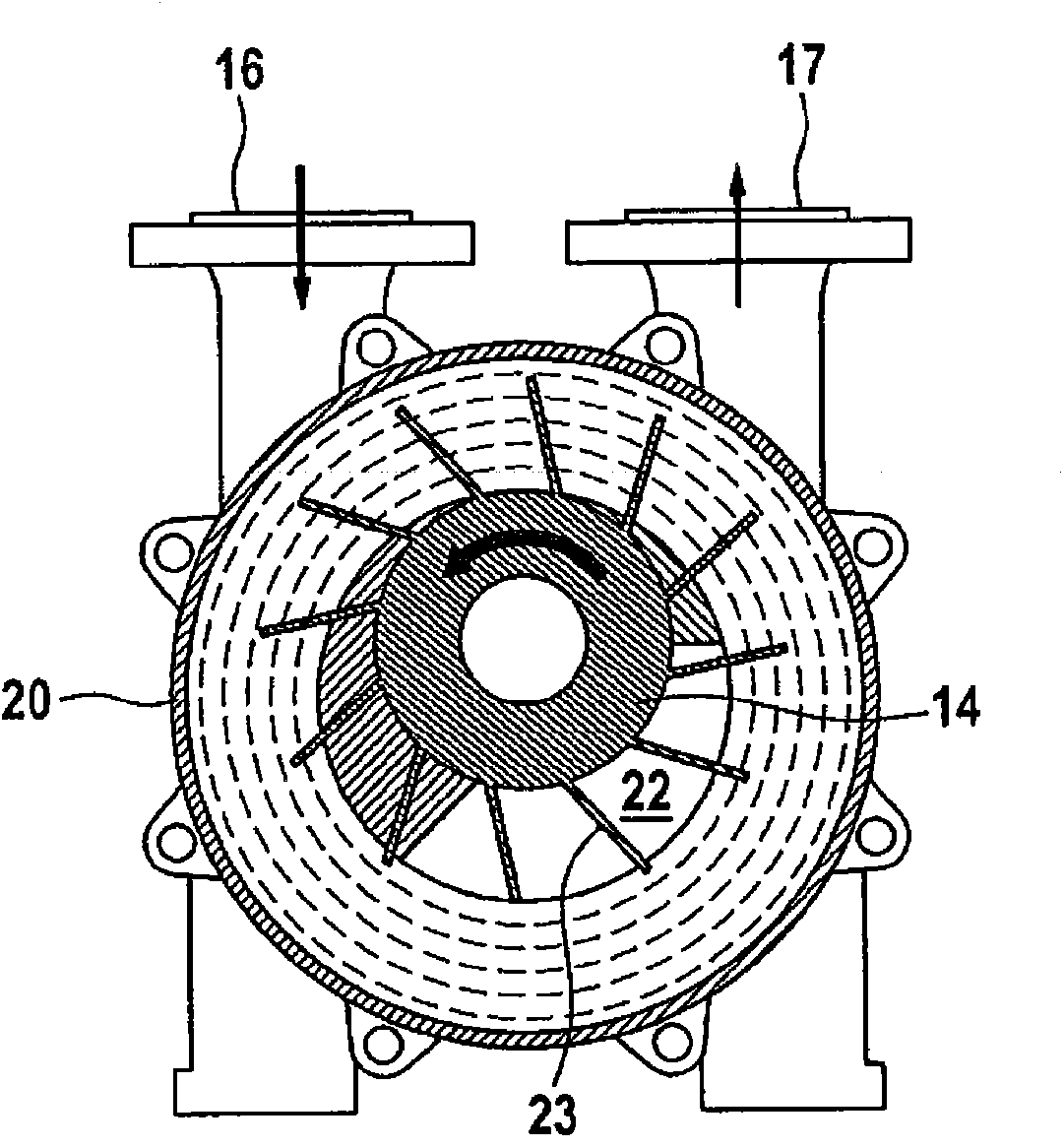

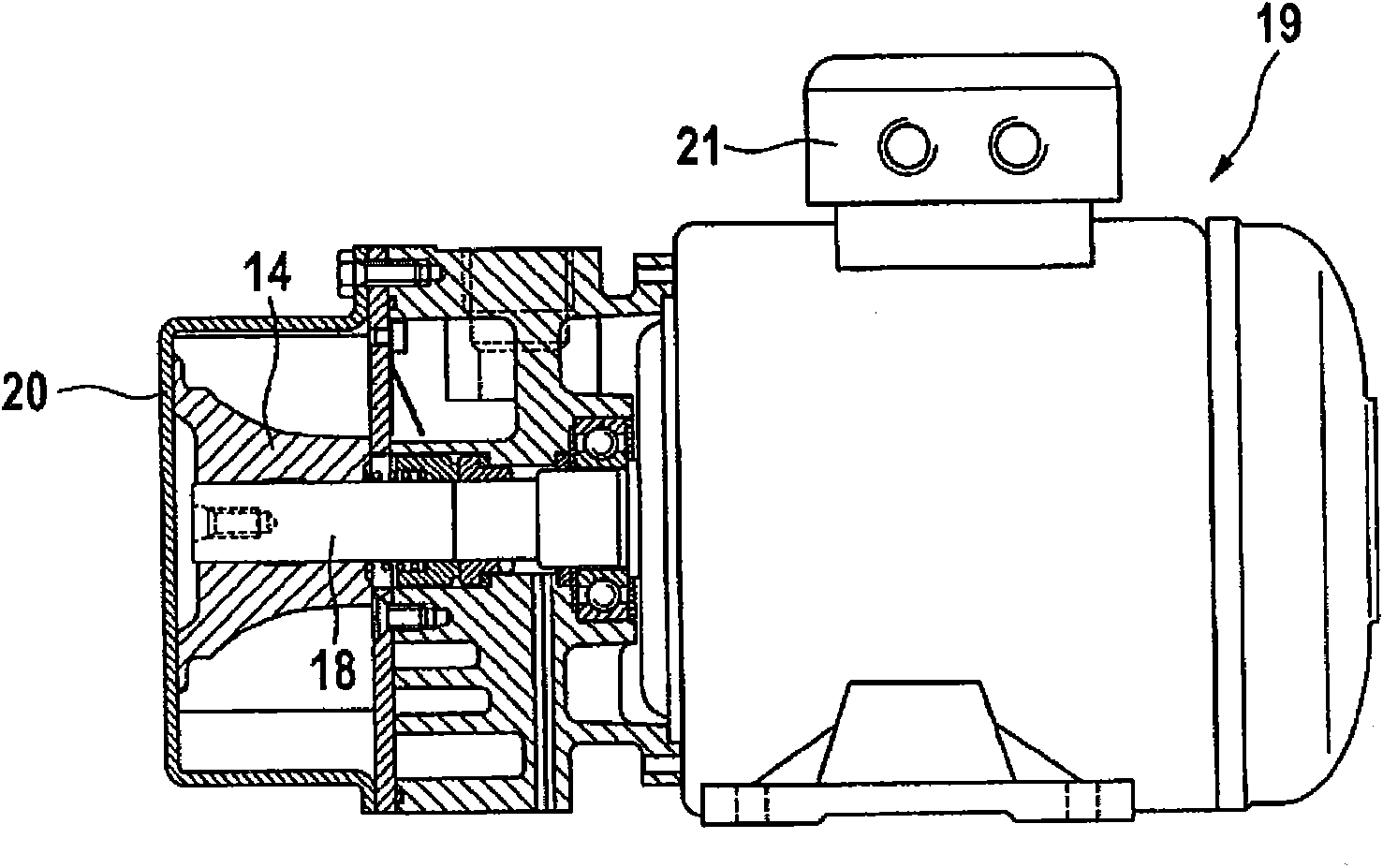

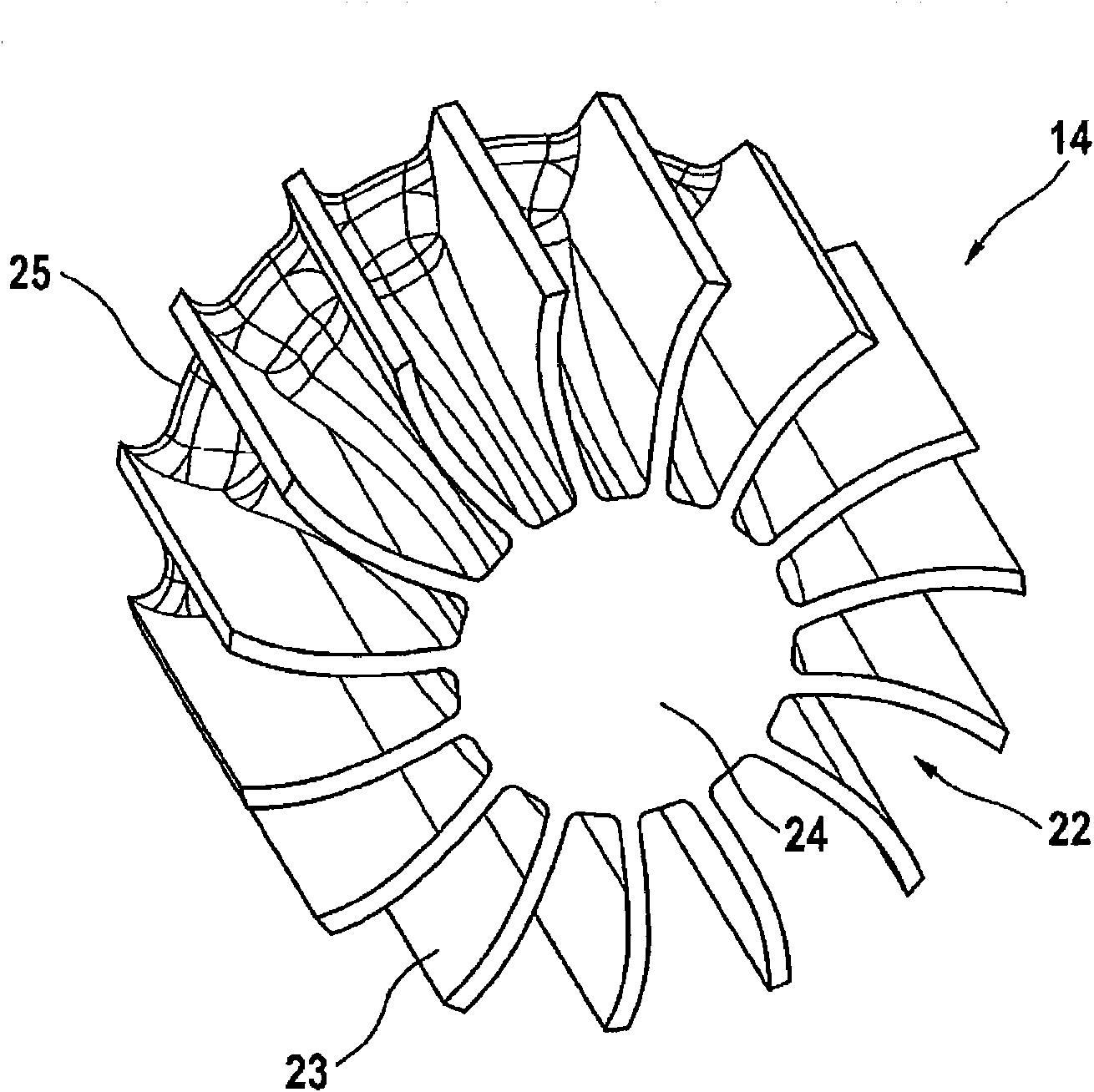

[0021] exist figure 1 In the liquid ring vacuum pump shown, the impeller 14 is mounted eccentrically in the pump housing 20 . The liquid inside the pump is driven by the rotating impeller 14 and forms a liquid ring extending radially inward from the outer wall of the pump casing 20 . Due to the eccentric mounting, the blades of the impeller 14 protrude into the liquid ring to different depths depending on the angular position. The volume of the chamber 22 enclosed between the two vanes thus changes. The liquid ring thus acts as a piston which moves up and down in the chamber during the revolution of the impeller 14 .

[0022] From the inlet 16 a tube leads into the interior of the pump in which the impeller 14 rotates. The tubes open in the region where the blades of the impeller 14 emerge from the liquid ring, in which region the chamber enclosed between the two blades thereby widens. Due to the enlarged chamber, gas is sucked into the chamber through the inlet 16 . Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com