Patents

Literature

49results about How to "Improve efficiency levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

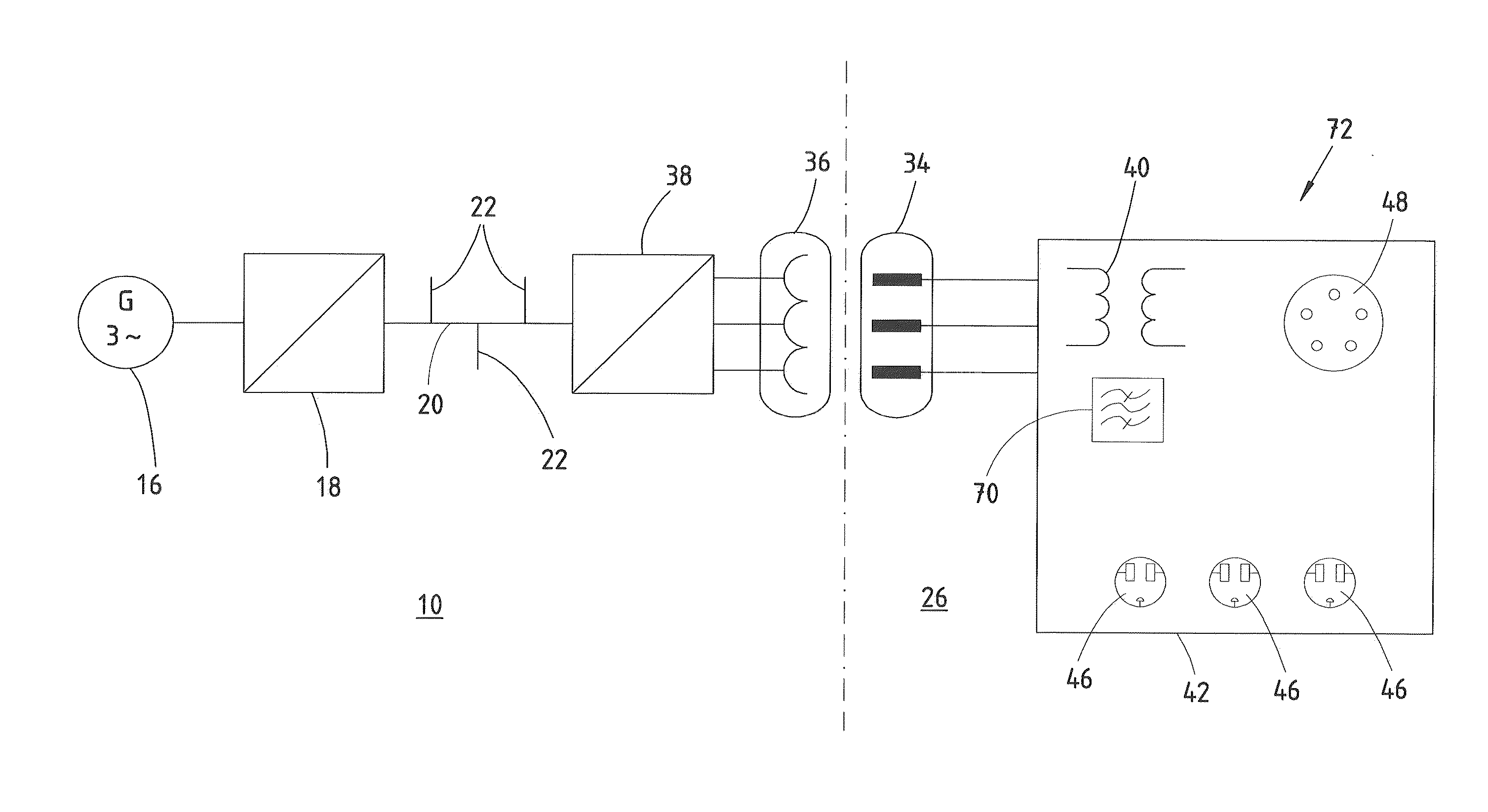

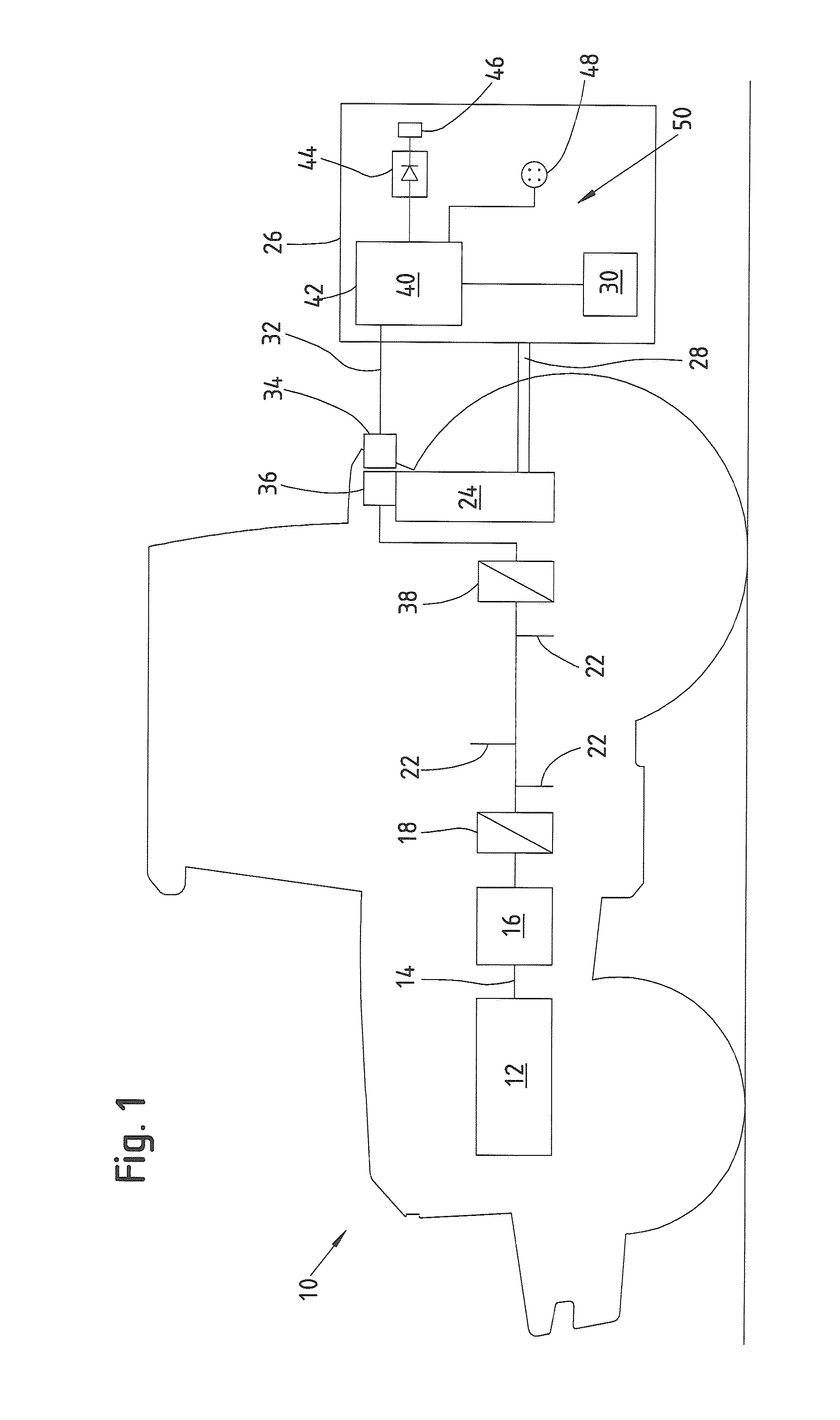

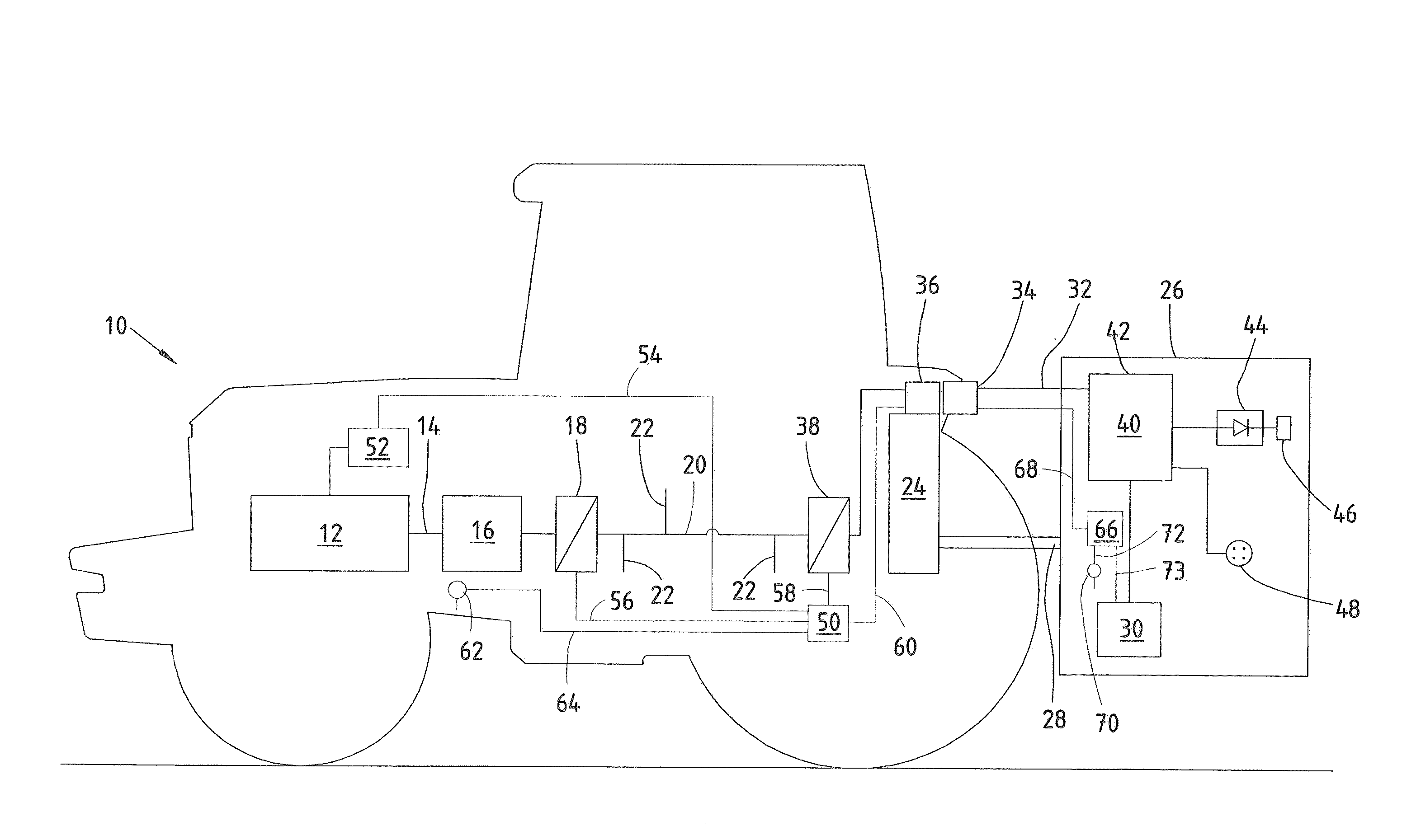

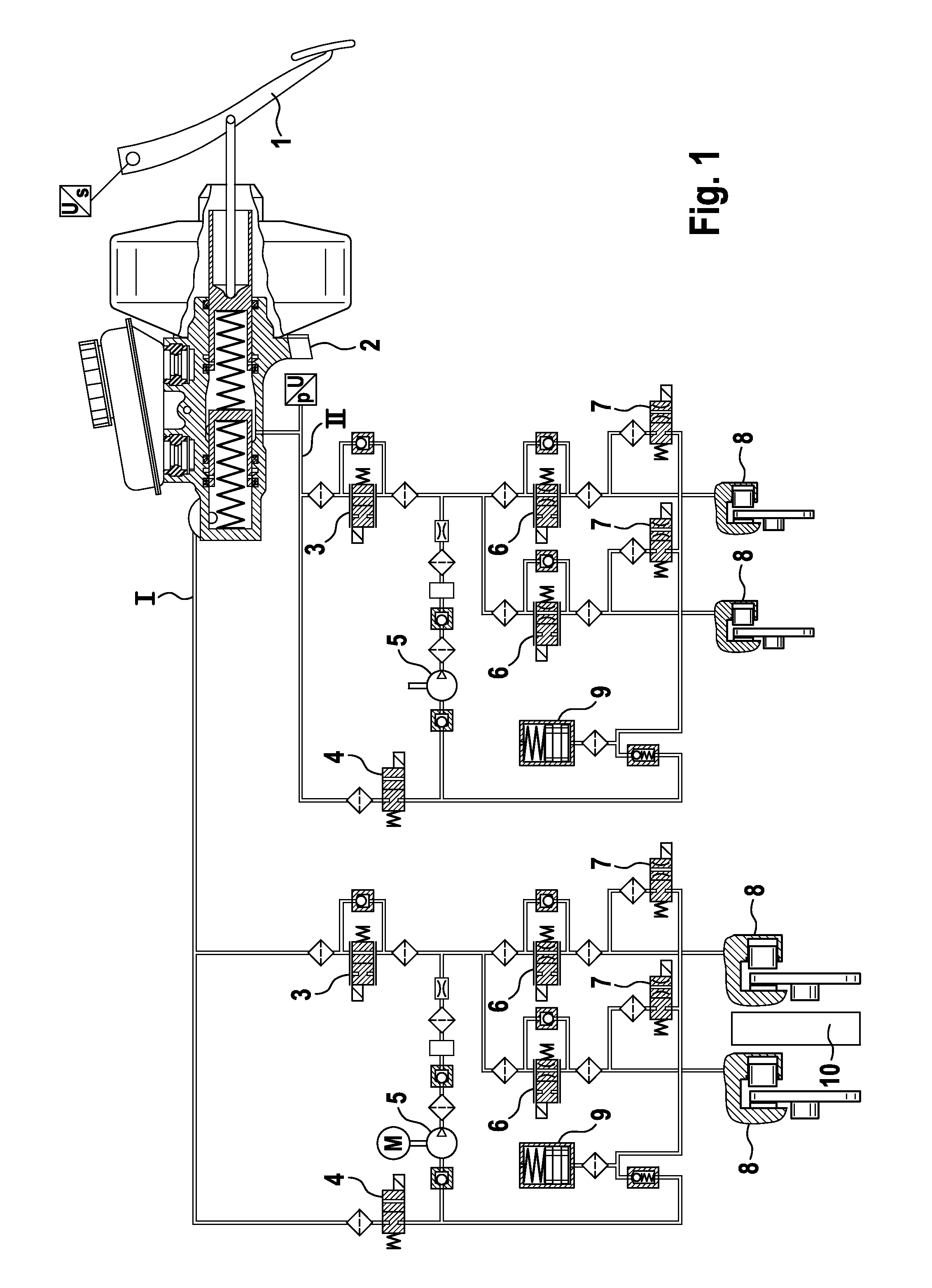

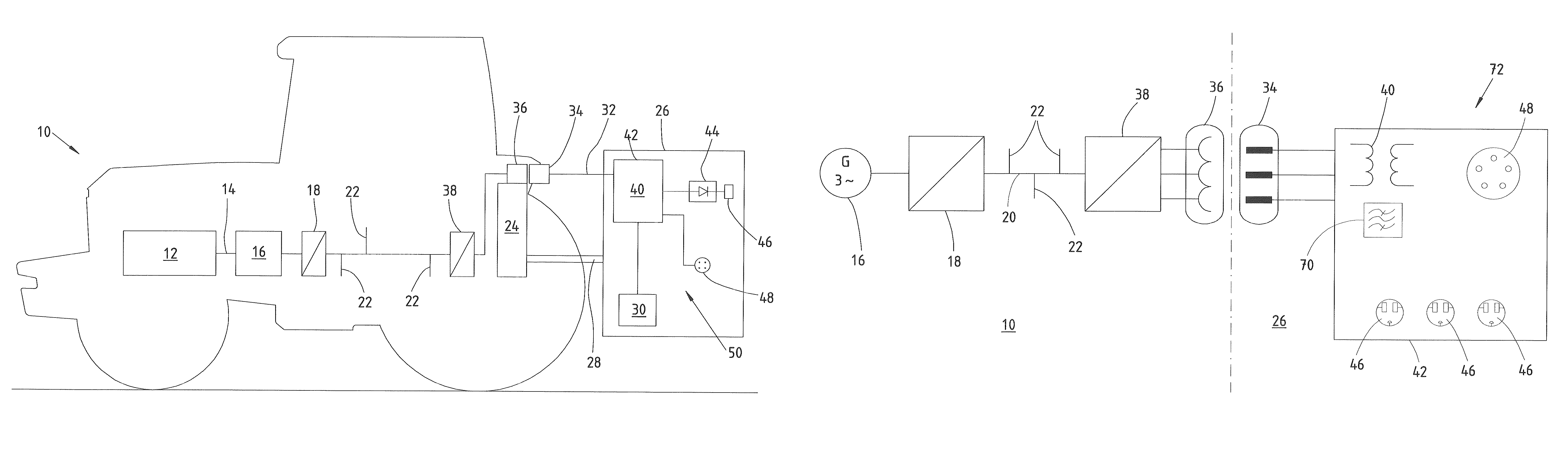

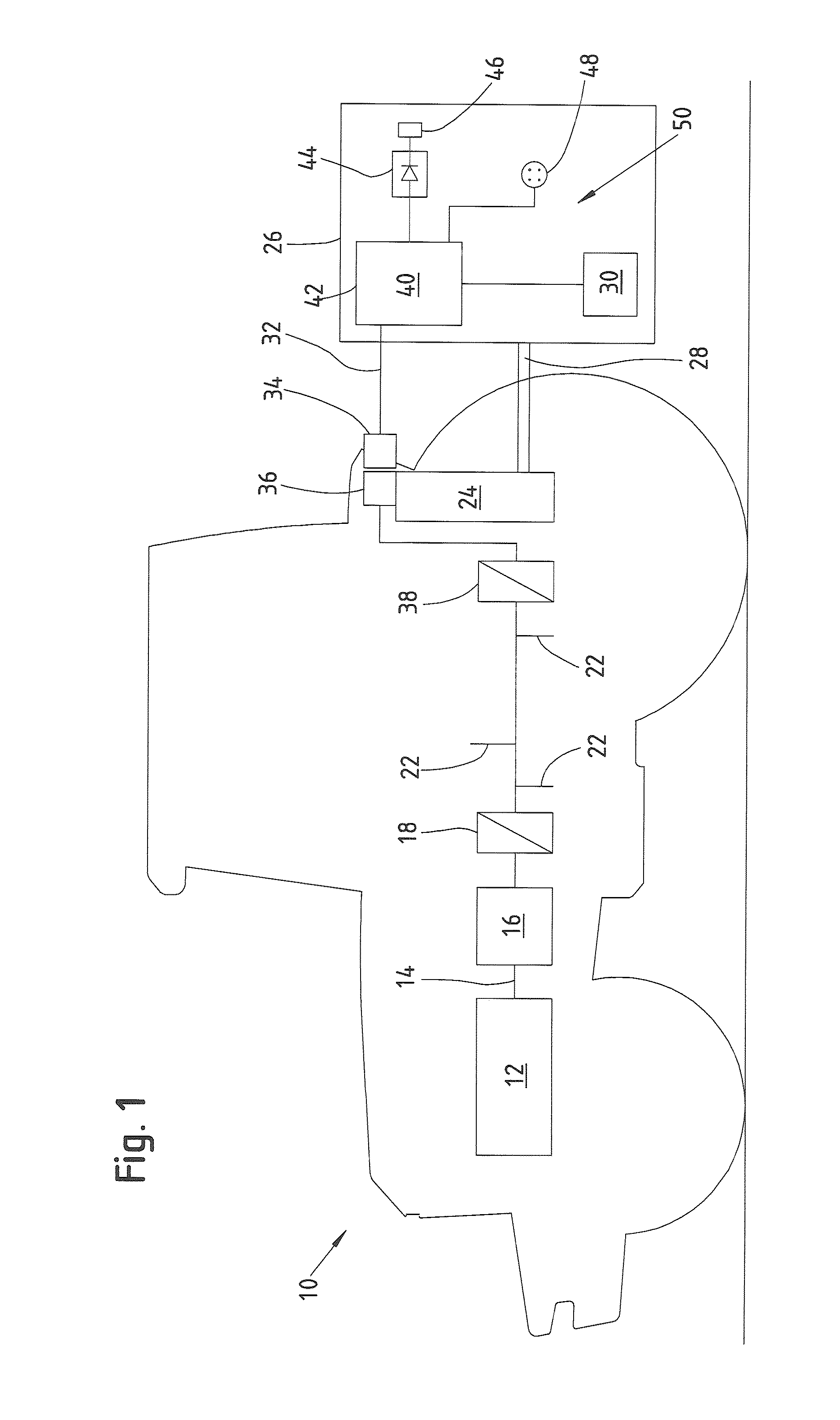

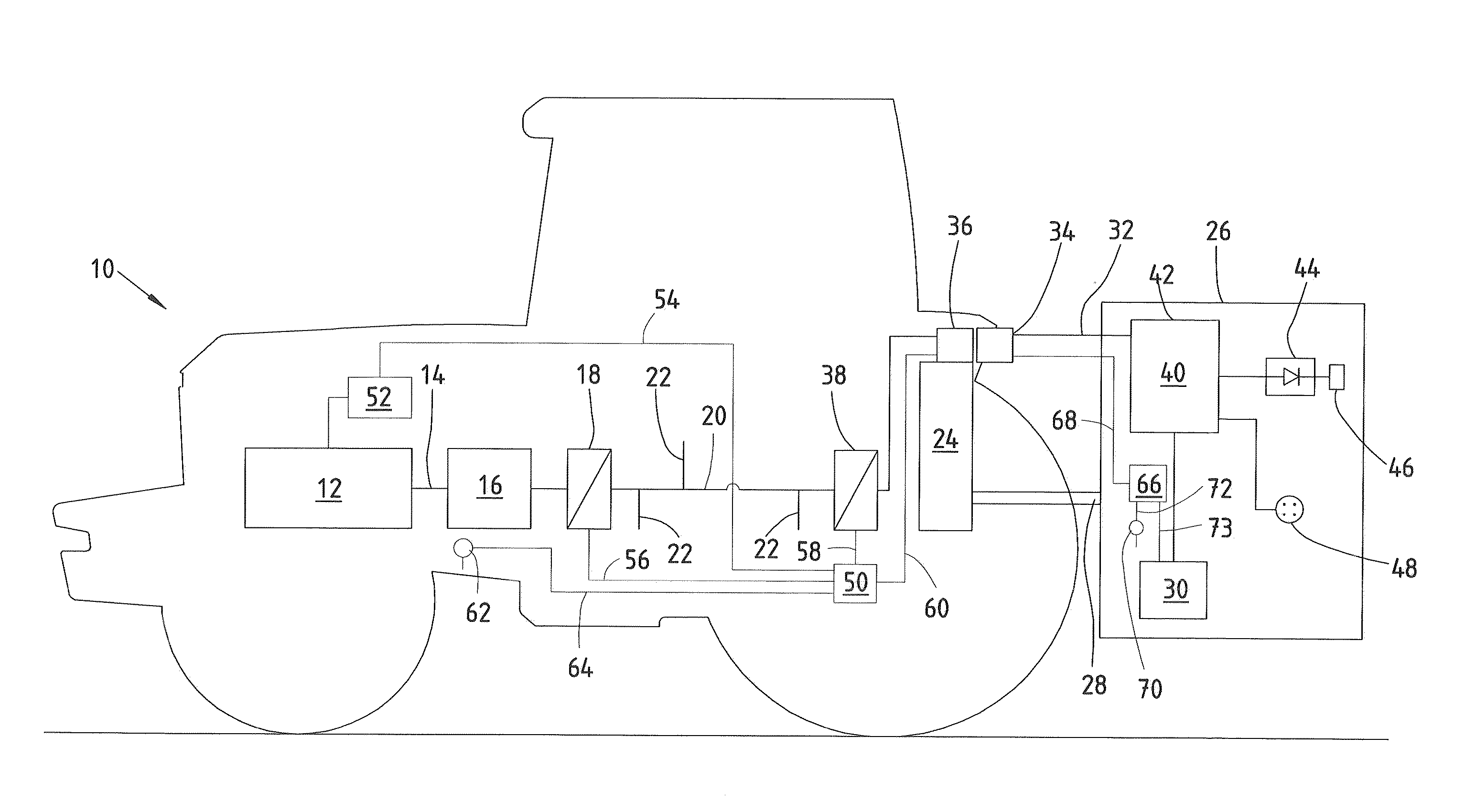

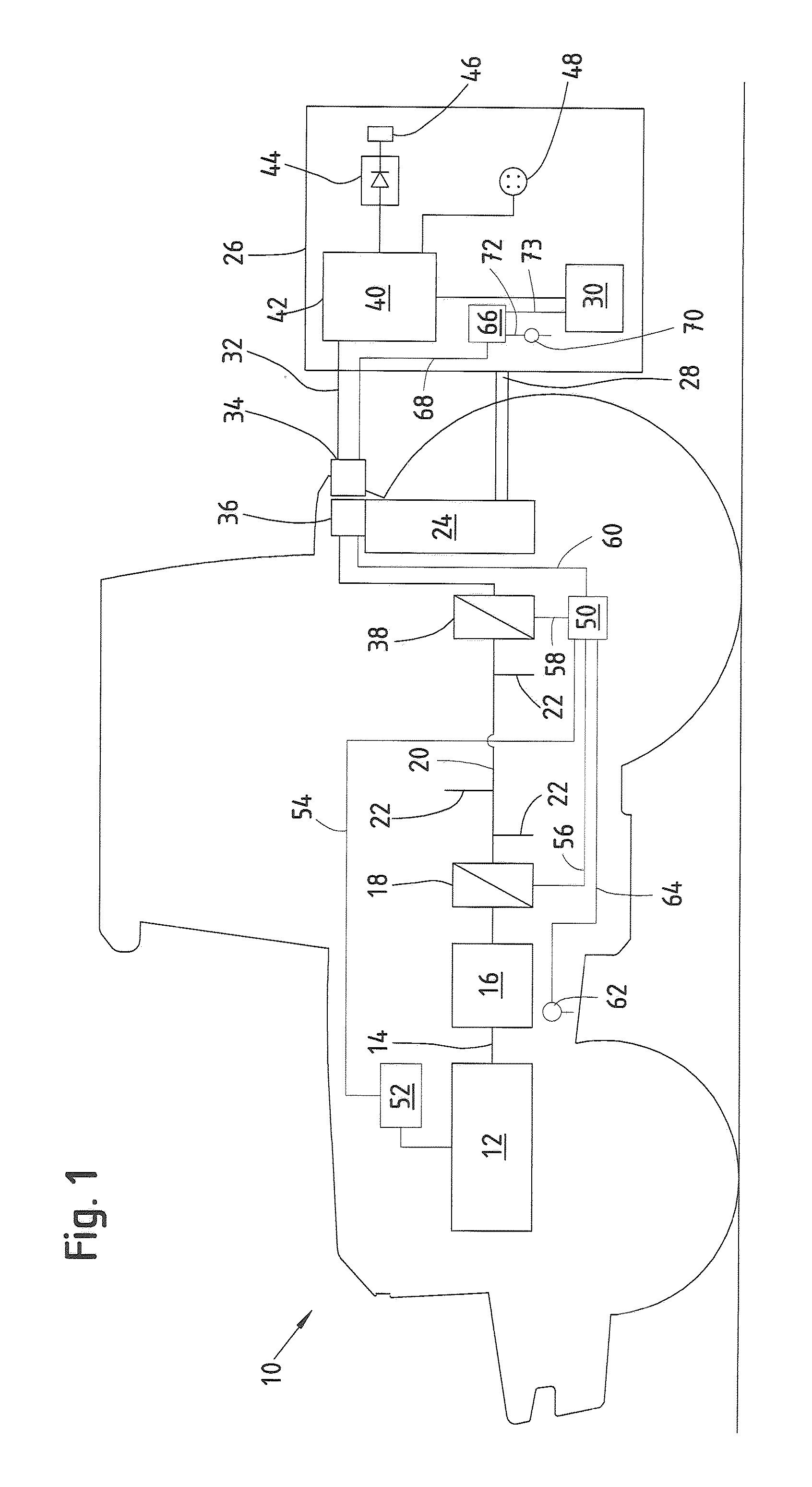

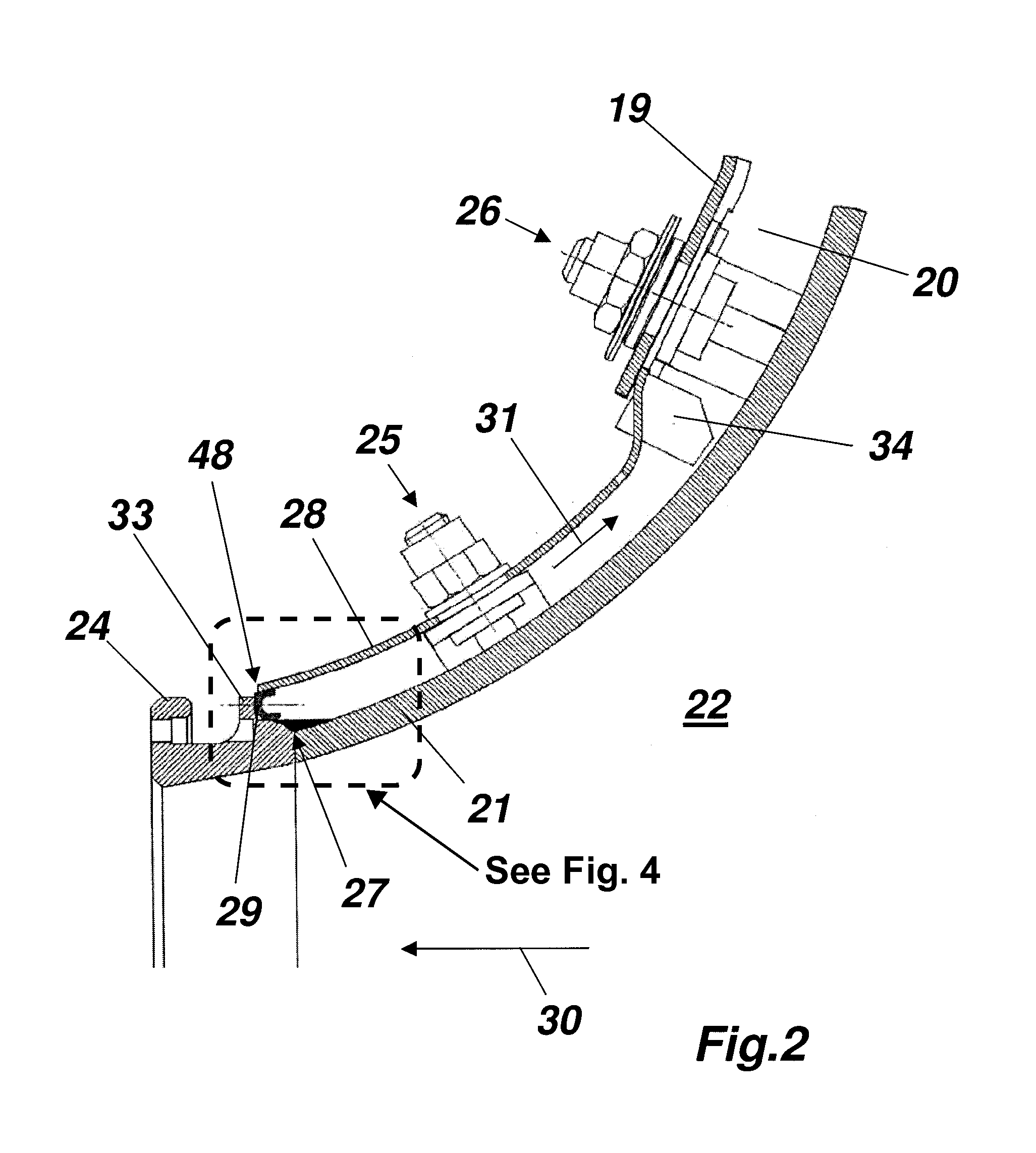

Electric System For Providing Electrical Power For A Vehicle And An Implement

ActiveUS20100308559A1Improve efficiency levelsIncrease power levelAuxillary drivesAgricultural machinesElectricityElectric power system

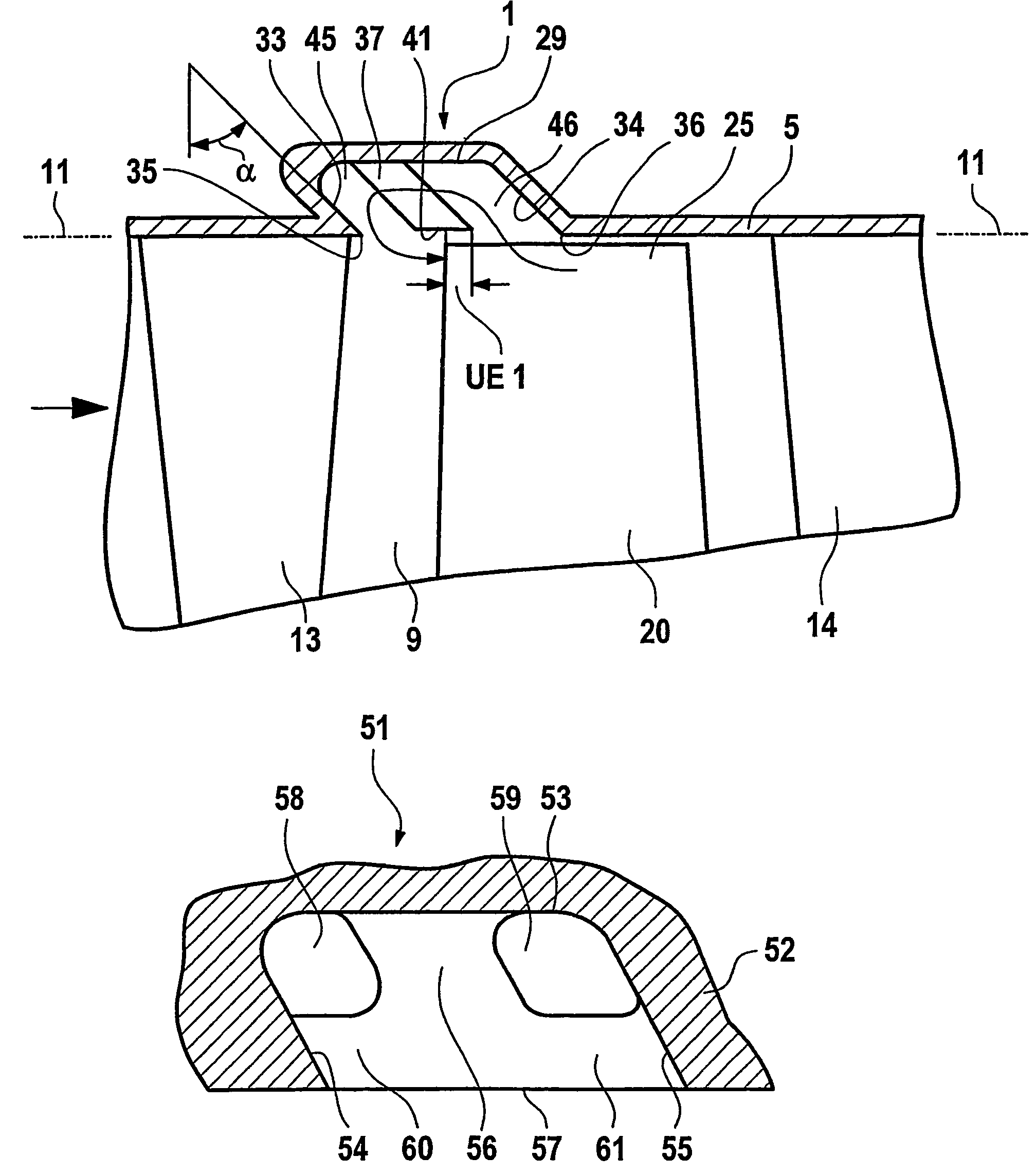

The invention relates to a device for supplying electricity to an agricultural utility vehicle (10) and / or an attachment (26) which can be coupled to the utility vehicle (10). The utility vehicle (10) comprises a generator (16) and an attachment interface (24). Electrical energy can be generated by means of the generator (16). At the attachment interface (24) an attachment (26) can be reversibly coupled to the utility vehicle (10). The attachment (26) has at least one electrical load by means of which an agricultural working function can be carried out. So that the attachment (26) can be controlled more flexibly or better when it is operating, the device according to the invention is defined by a transmission device and at least one transformer (40). By means of the transmission device the electrical energy which is generated by the generator (16) of the utility vehicle (10) can be transmitted in the form of alternating voltage to the attachment (26). The transformer (40) is provided on the attachment (26). By means of the transformer (40) the transmitted alternating voltage can be converted in order to be made available to the electrical load.

Owner:DEERE & CO

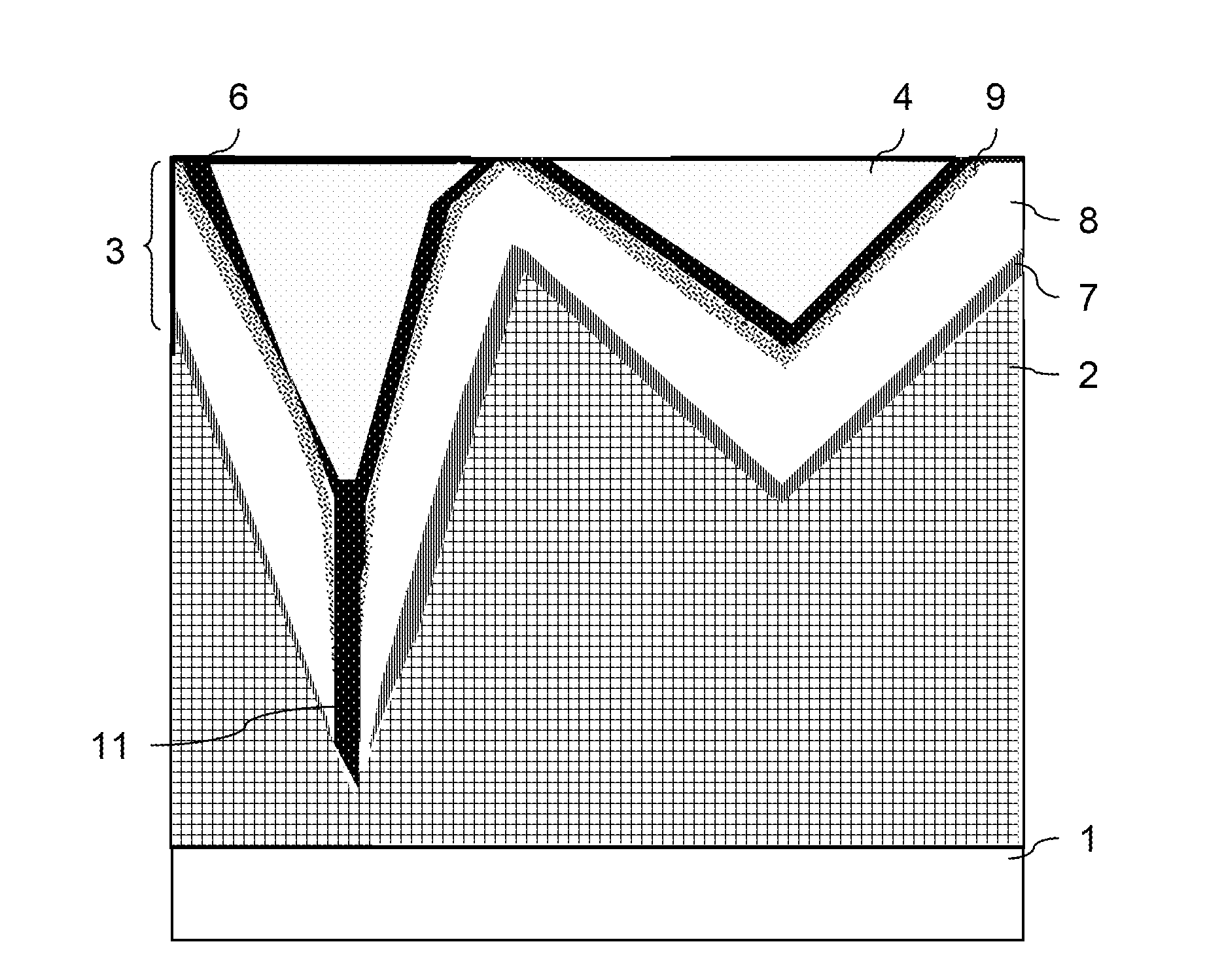

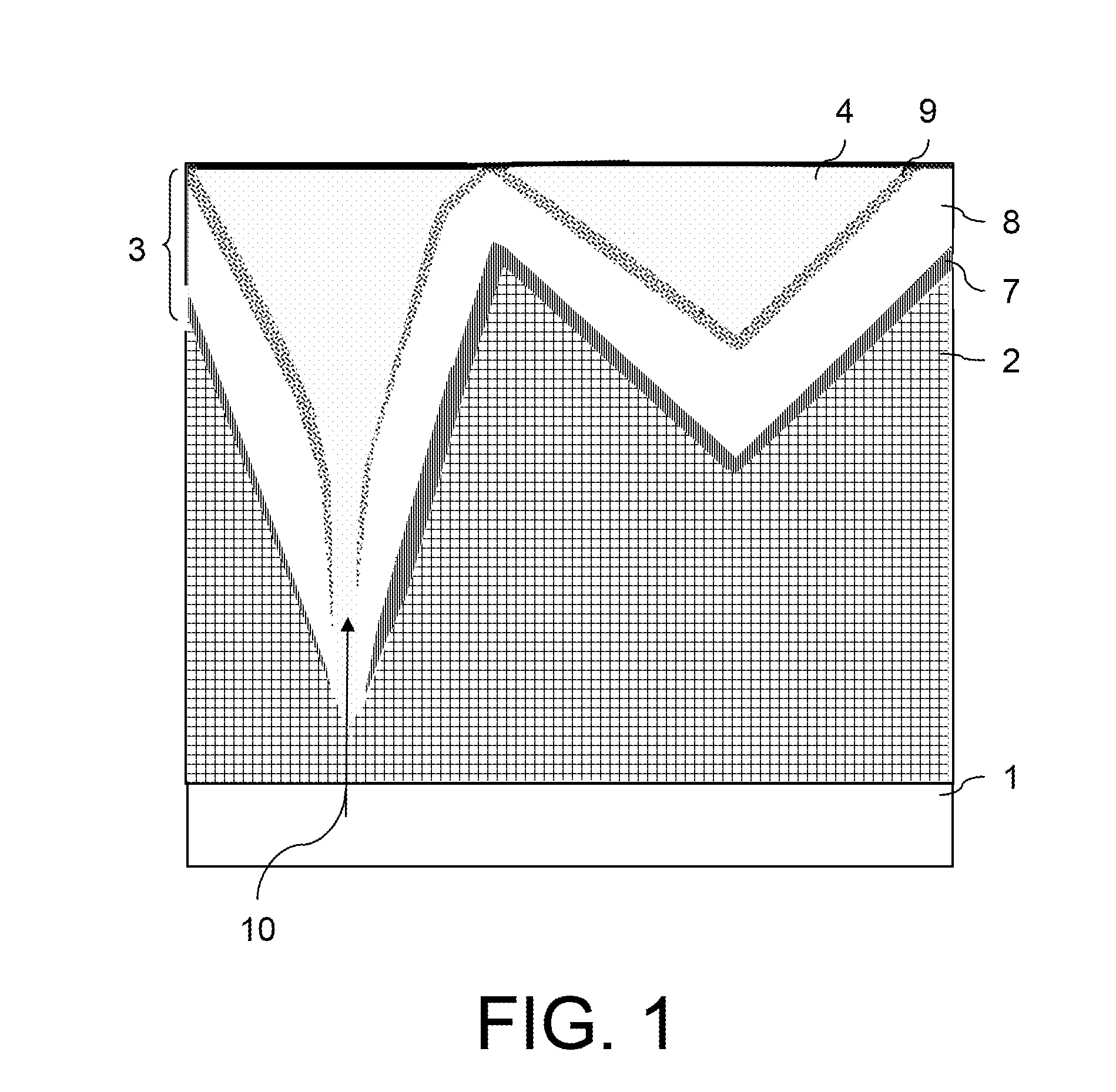

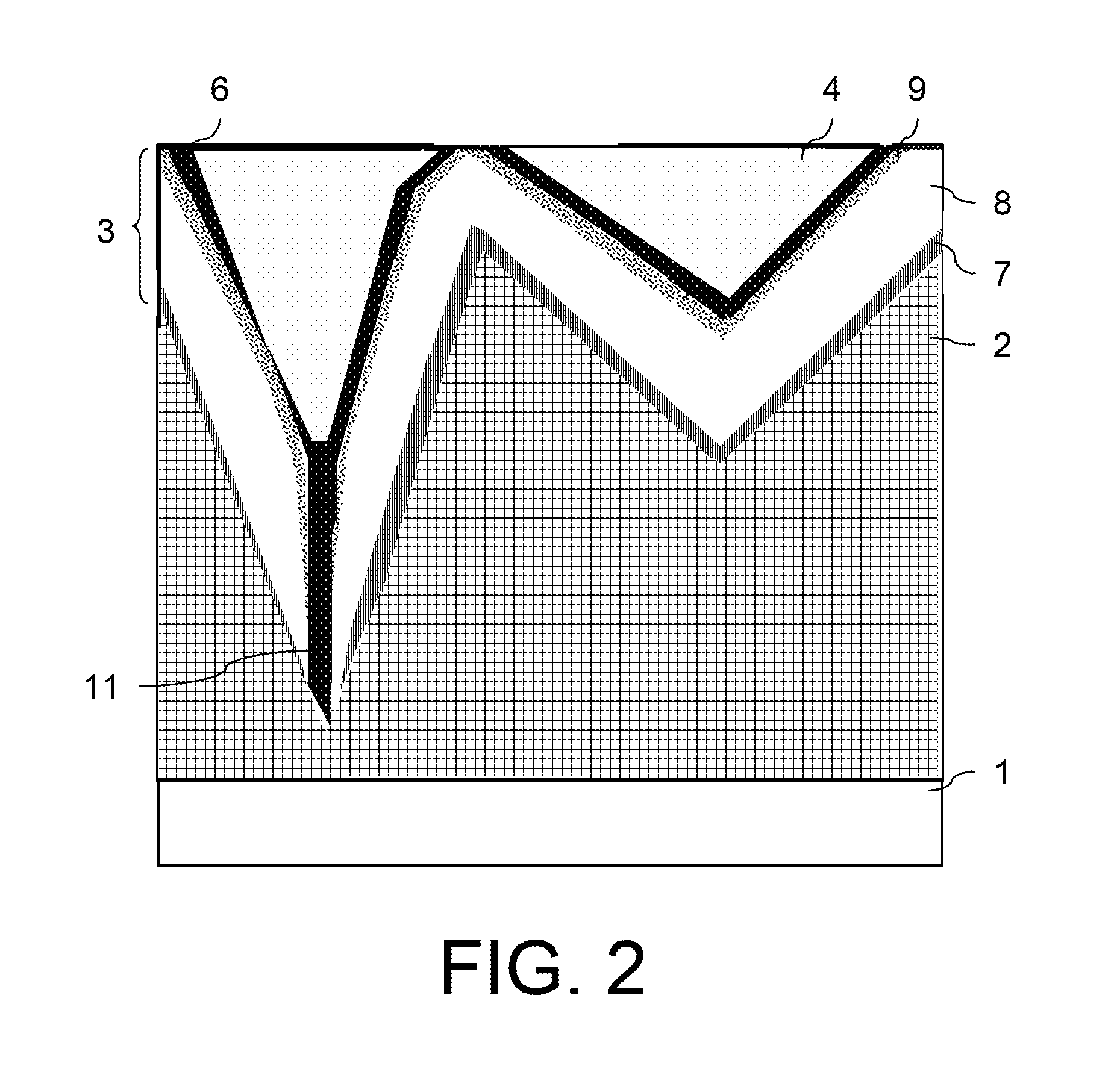

Method for obtaining high performance thin film devices deposited on highly textured substrates

InactiveUS20100313932A1Improve efficiency levelsCurrent is decreased and eliminatedPV power plantsCoatingsEngineeringThin film solar cell

The present invention provides an improved thin film solar cell, wherein at least one additional resistive transparent conductive oxide (TCO) layer is incorporated into the solar cell. The additional resistive TCO electrically separates the conductive TCO layers acting as electrodes of such a cell and thus decreases or prevents performance losses. Furthermore, methods for the production of such solar cells are disclosed.

Owner:OERLIKON SOLAR AG (TRUEBBACH)

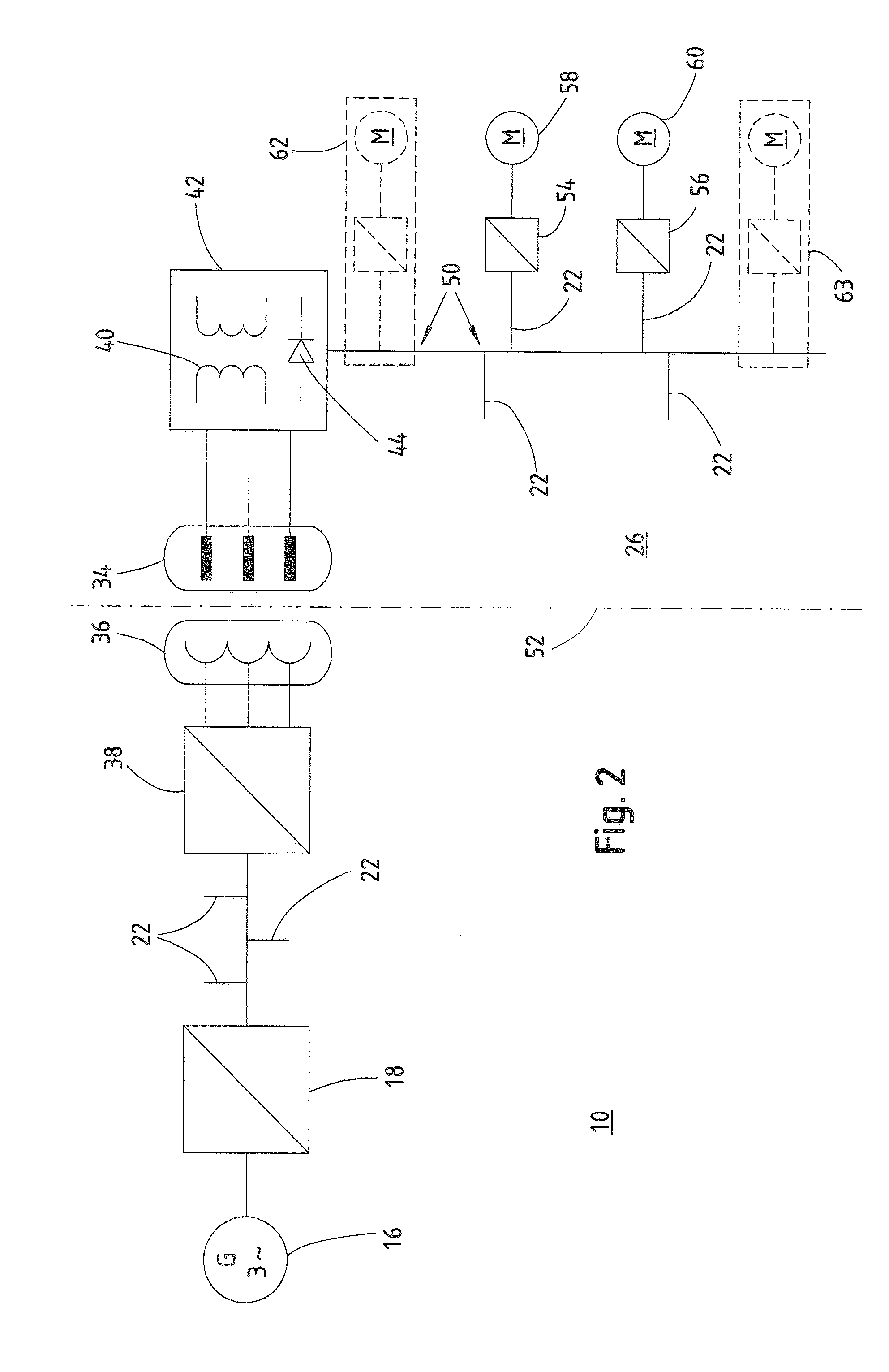

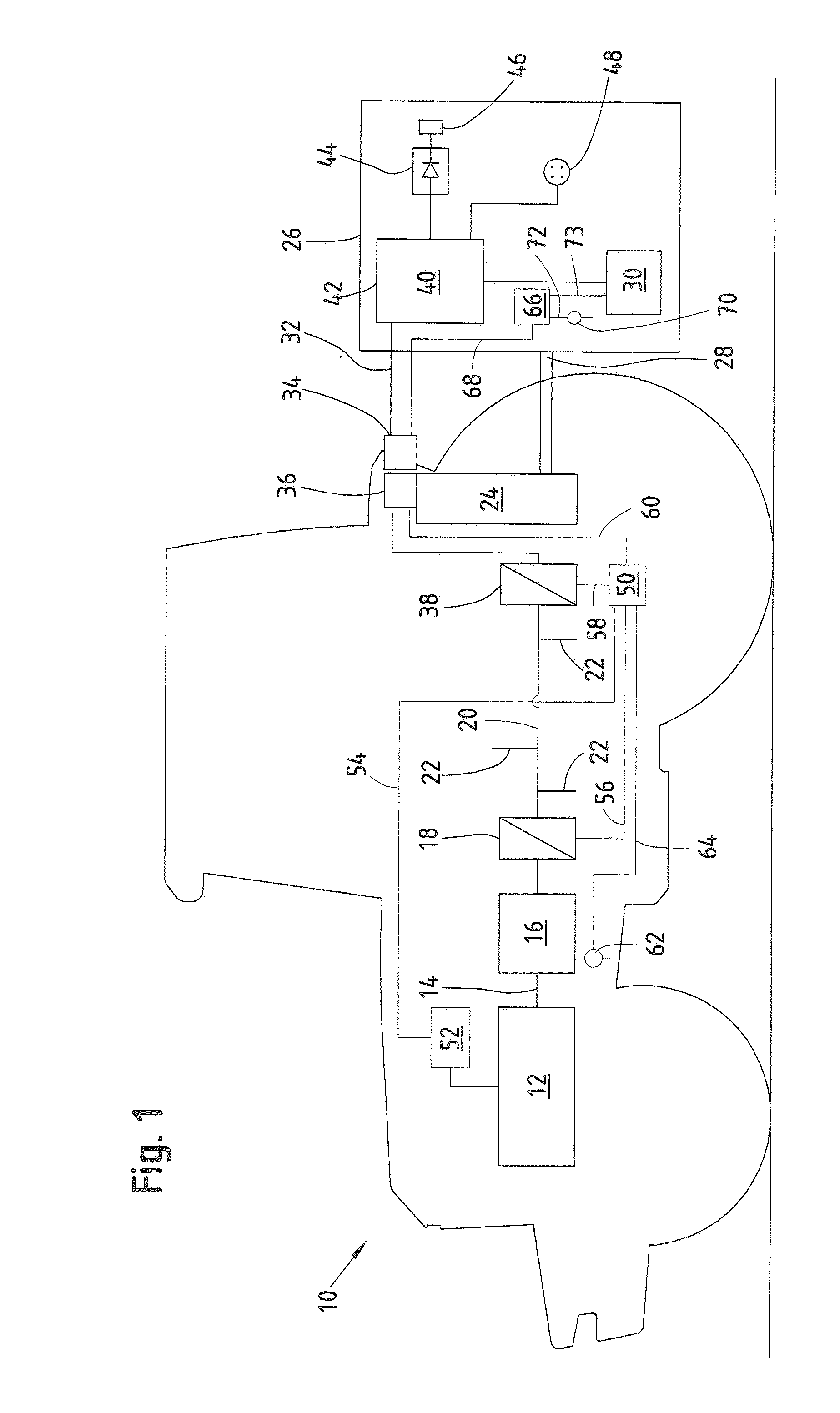

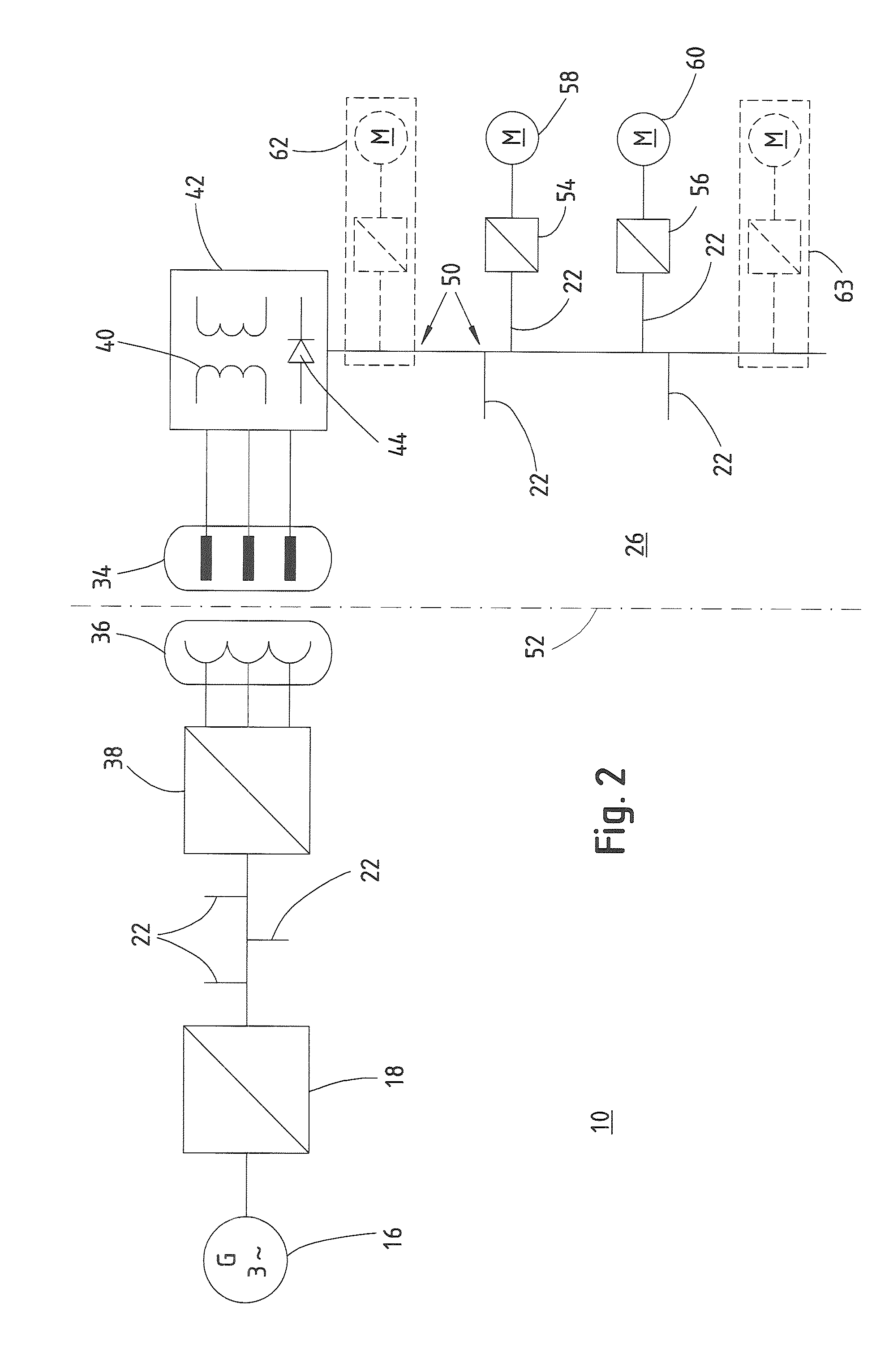

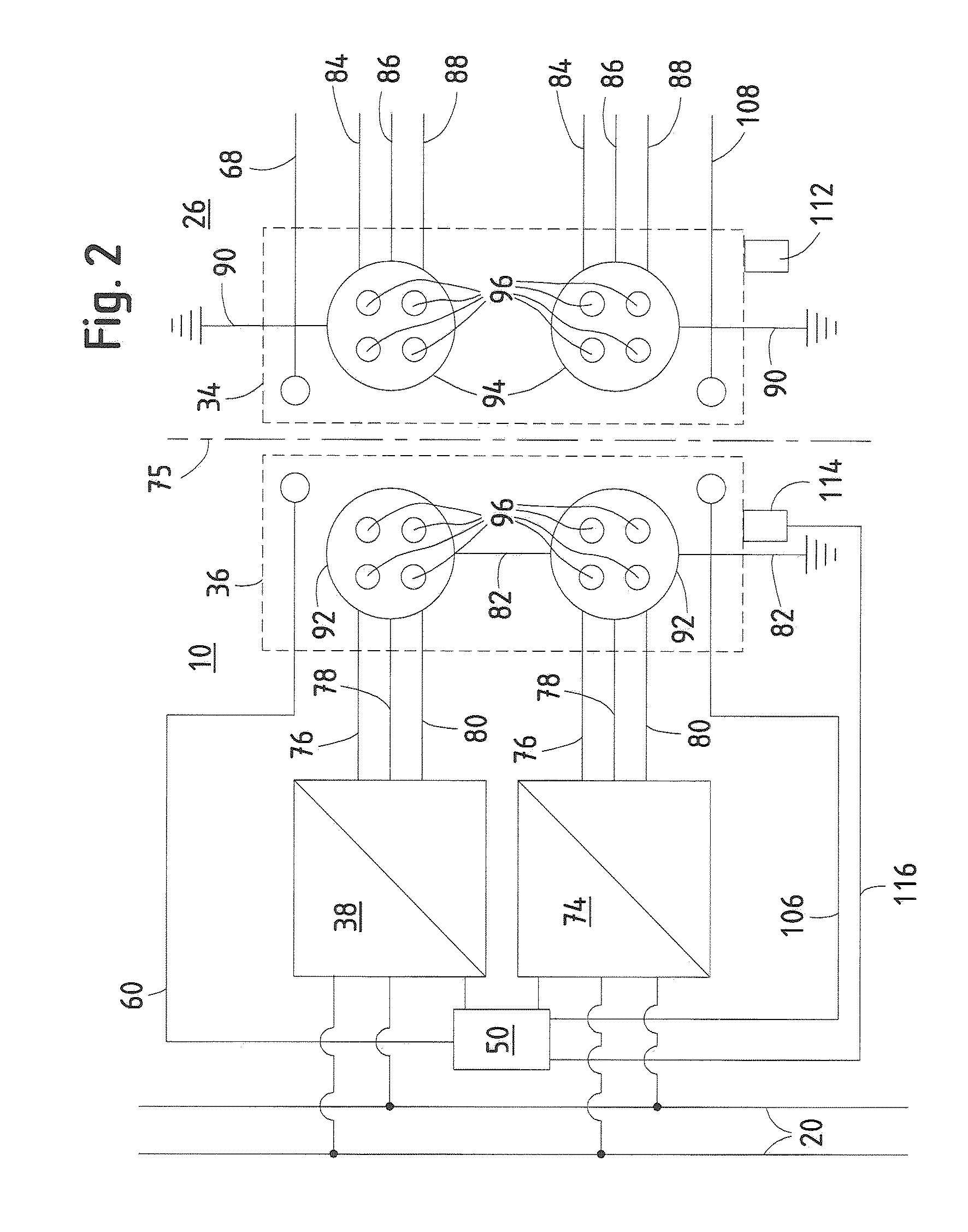

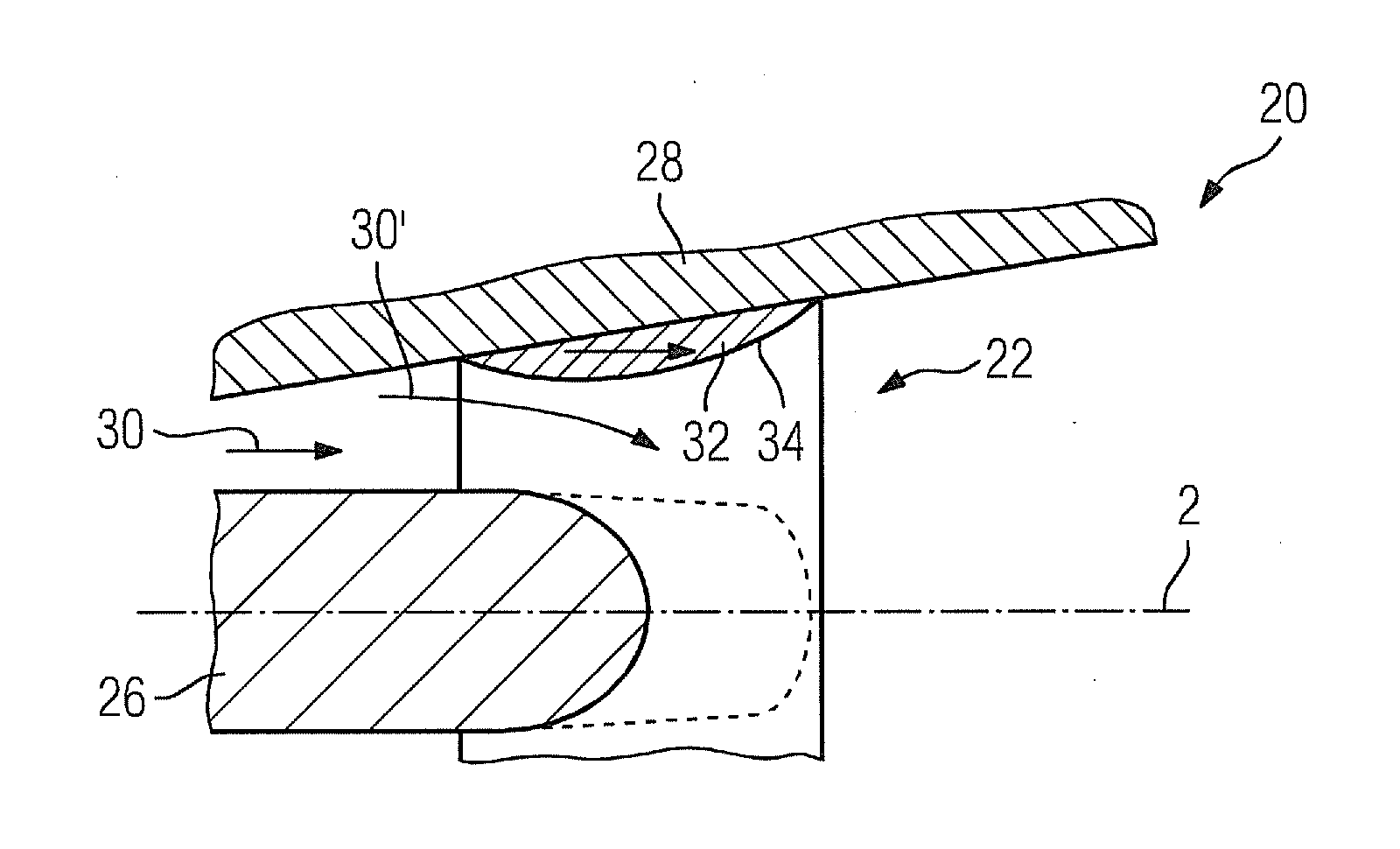

Electric Connection System

ActiveUS20110204712A1Improve efficiencySimple designAgricultural machinesElectric devicesElectricityElectronic systems

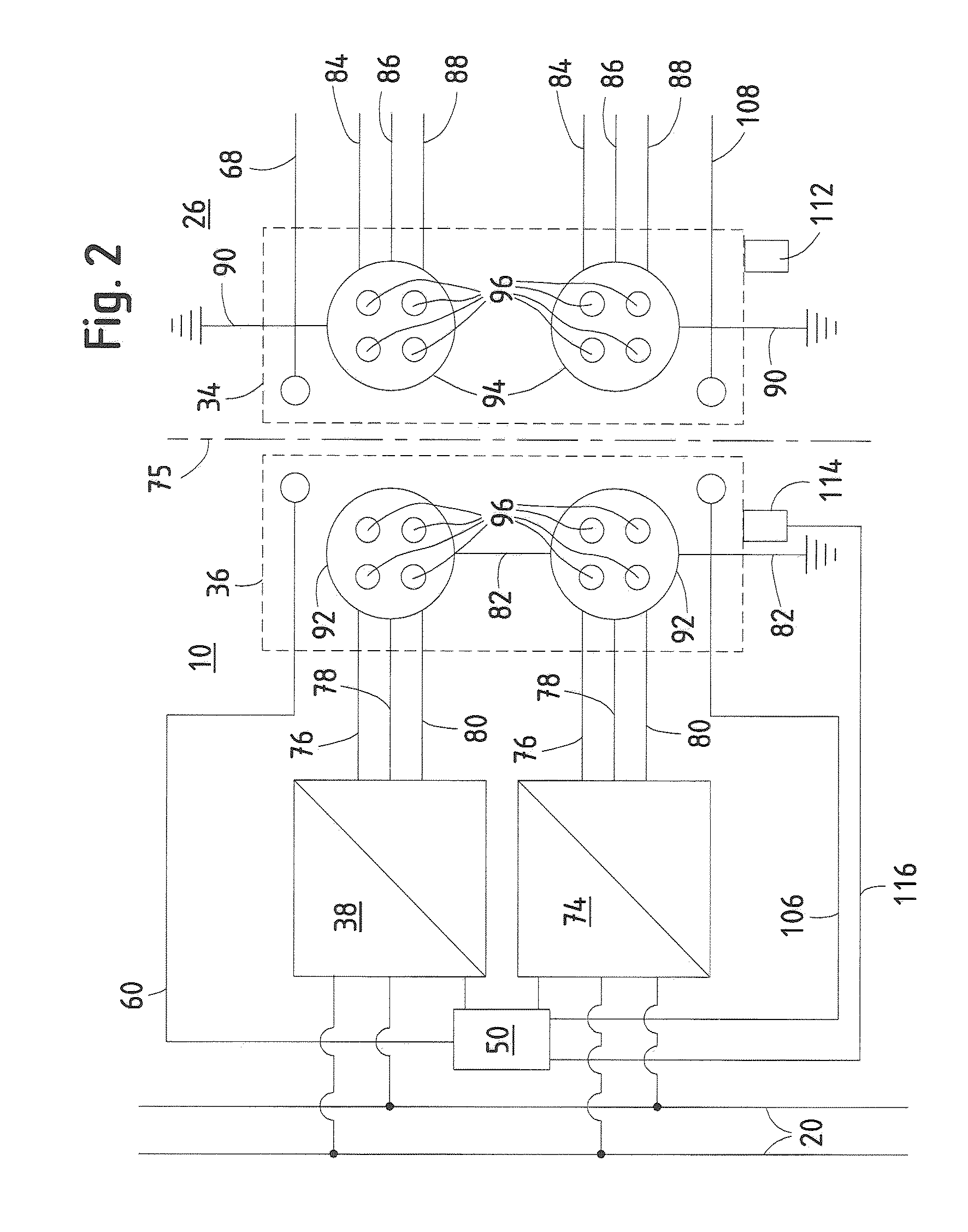

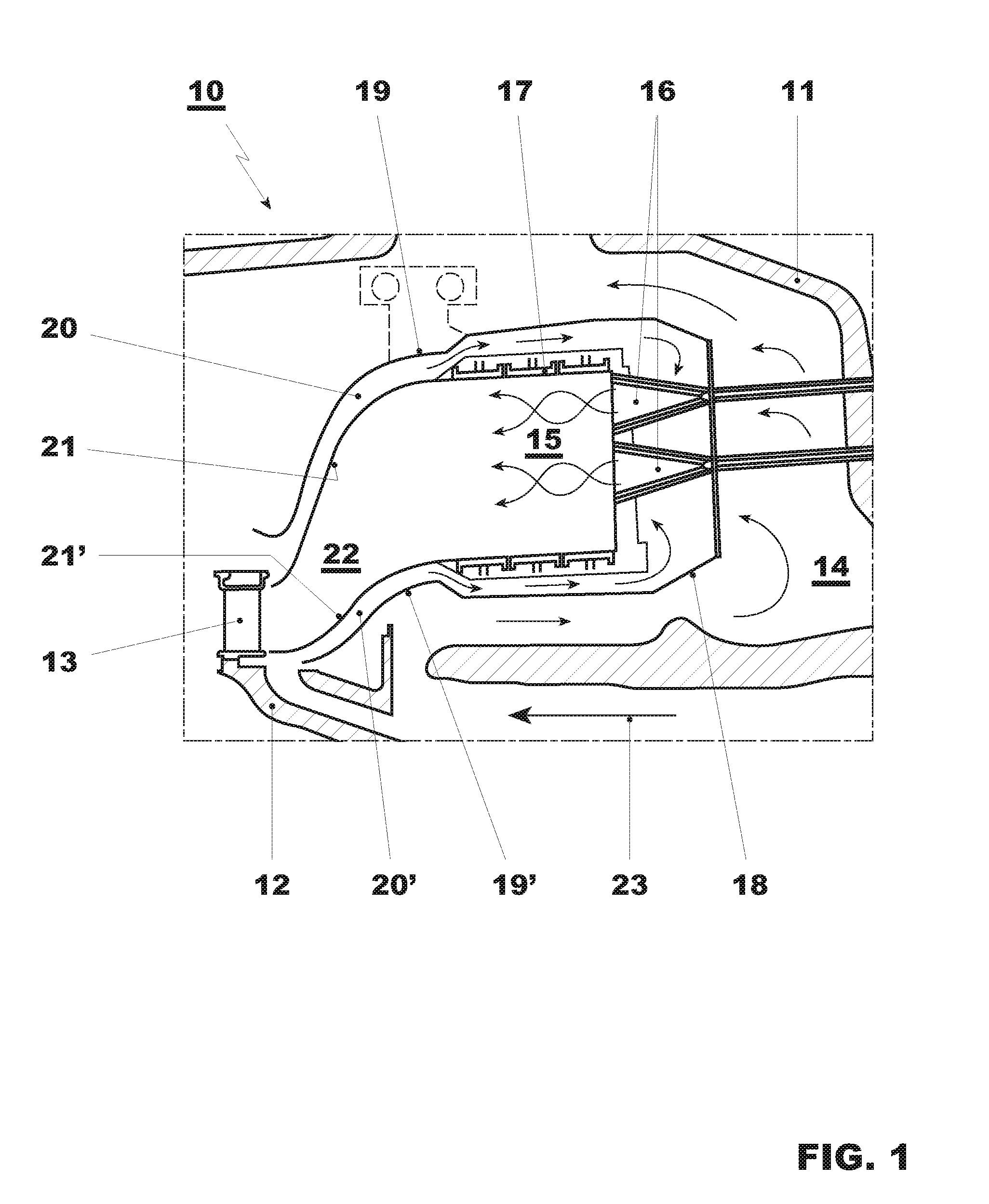

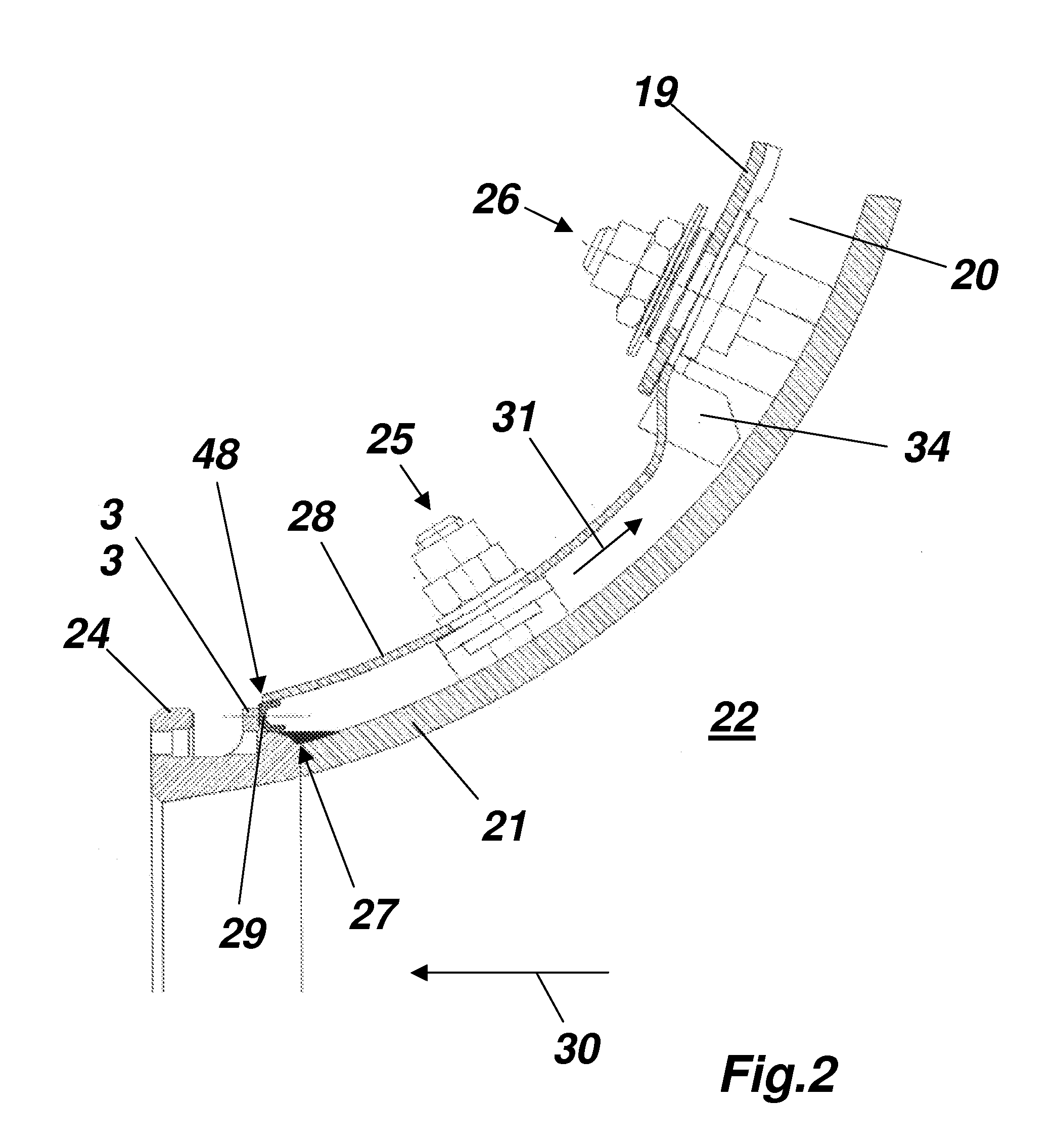

The invention relates to a device for transmitting electrical energy from an agricultural utility vehicle (10) to an attachment (26) which can be reversibly coupled to the utility vehicle (10). The device comprises at least one power electronics system (38, 74) which is arranged on the utility vehicle side, at least one electrical utility vehicle interface (36) and at least one electrical attachment interface (34). The power electronics system (38, 74) can be supplied with electrical energy which can be generated by a generator (16) of the utility vehicle (10). The power electronics system (38, 74) can be connected electrically to the generator (16) and to the utility vehicle interface (36). The attachment (26) has at least one attachment interface (34) and at least one electrical load (30, 102, 104). An agricultural working function can be carried out with the electrical load (30, 102, 104) of the attachment (26). At least one utility vehicle interface (36) can be coupled to at least one attachment interface (34), and in this way at least some of the electrical energy which is generated by the generator (16) of the utility vehicle (10) can be transmitted to the attachment (26) via the utility vehicle interface (36).

Owner:DEERE & CO

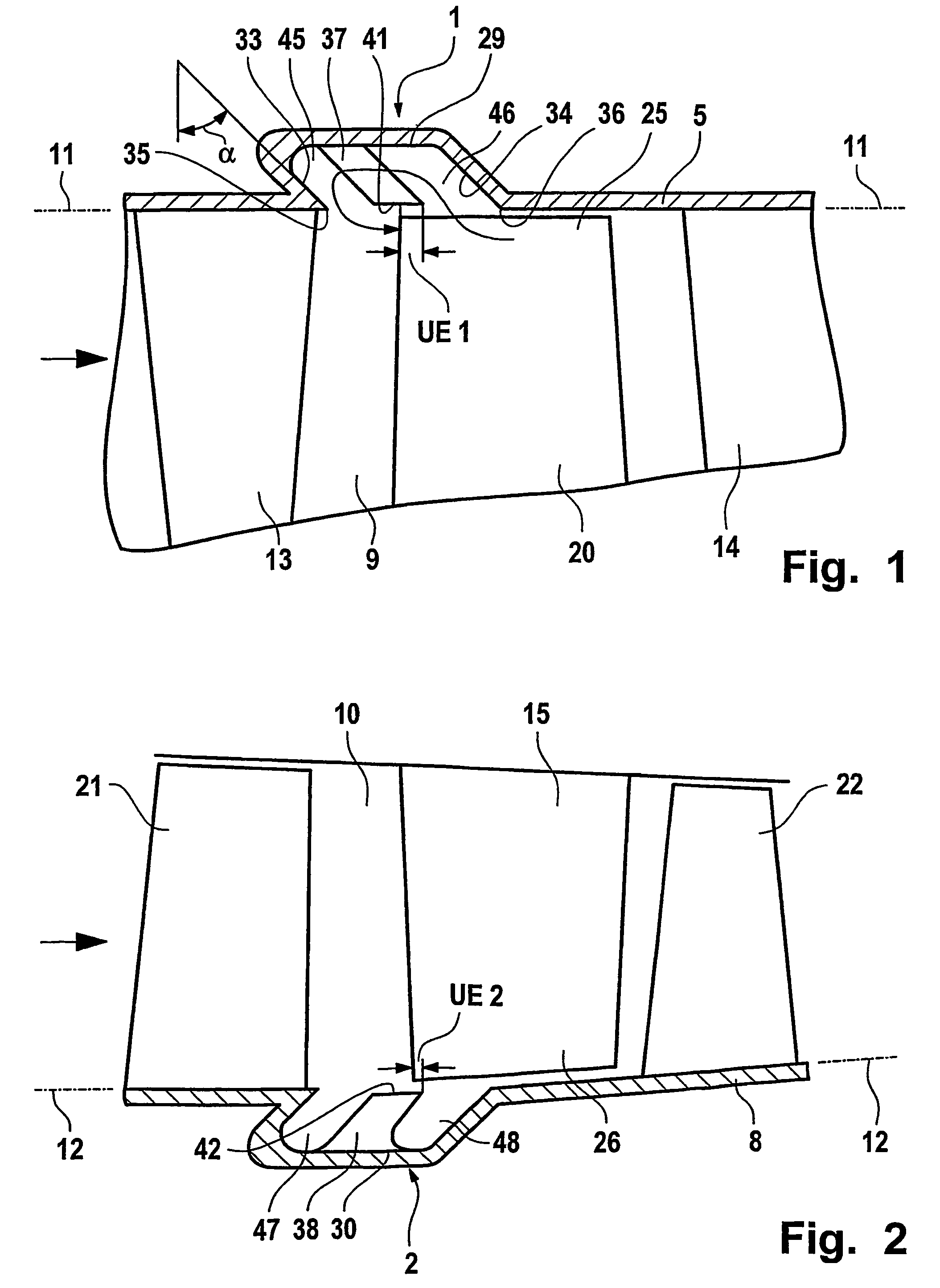

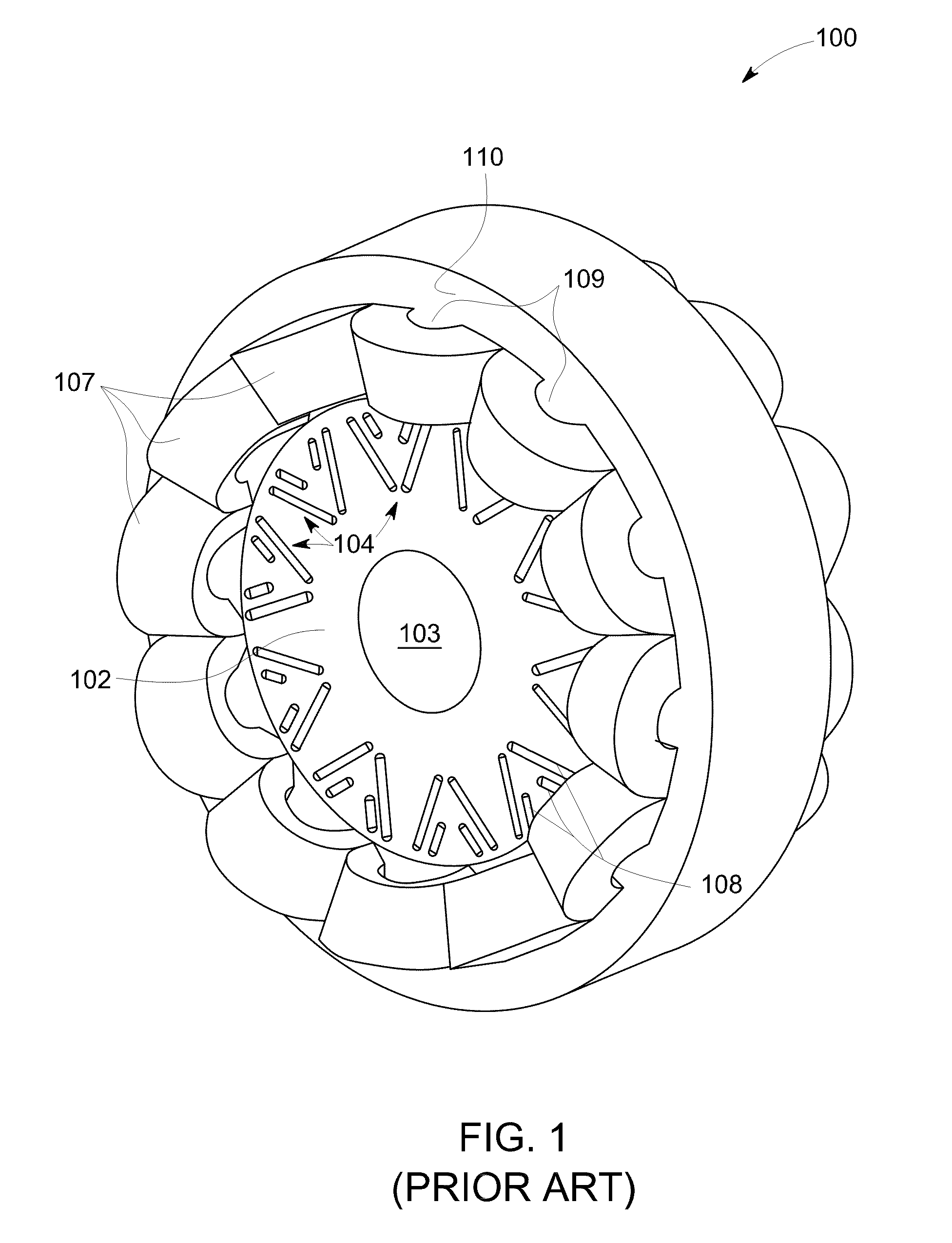

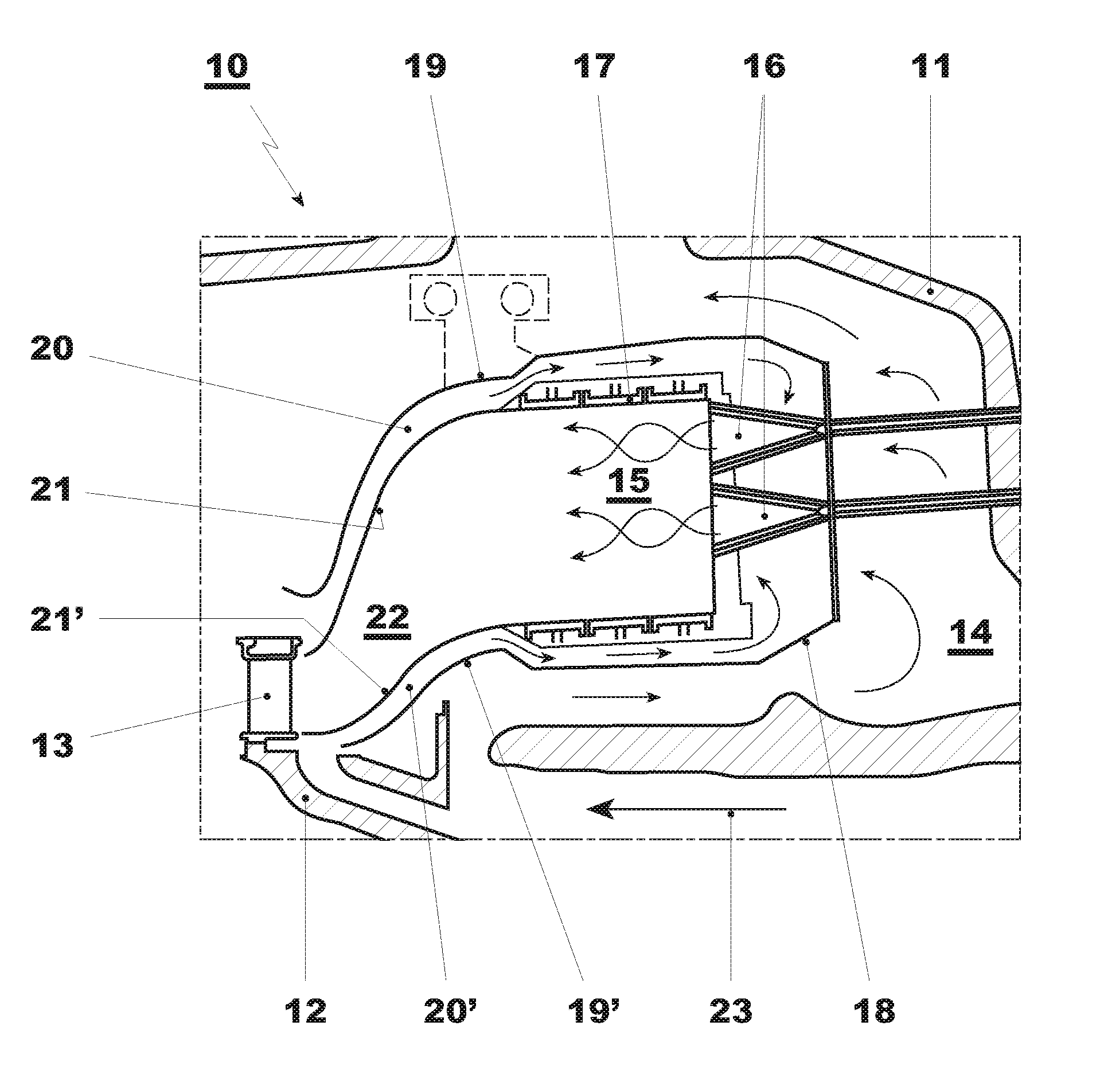

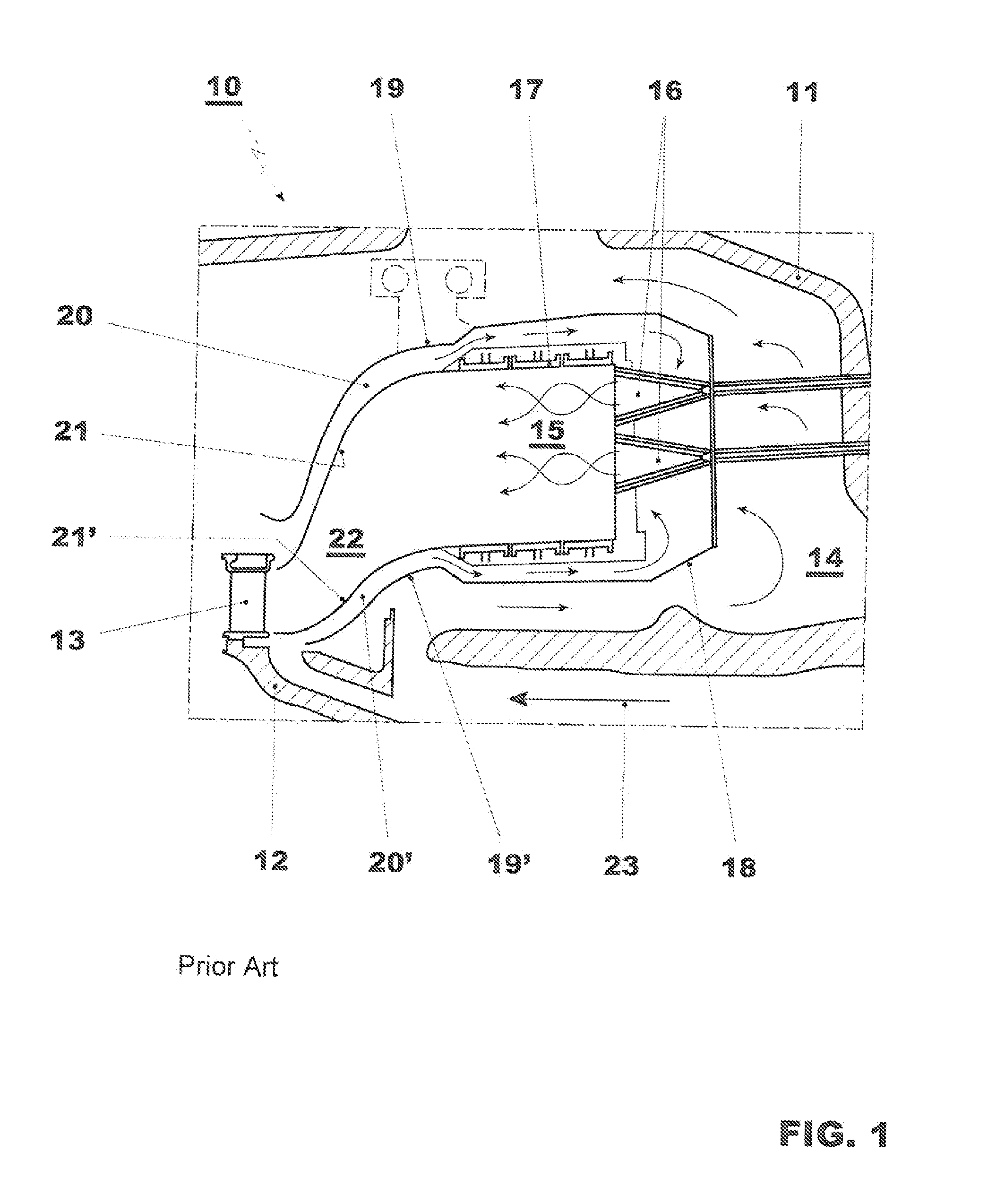

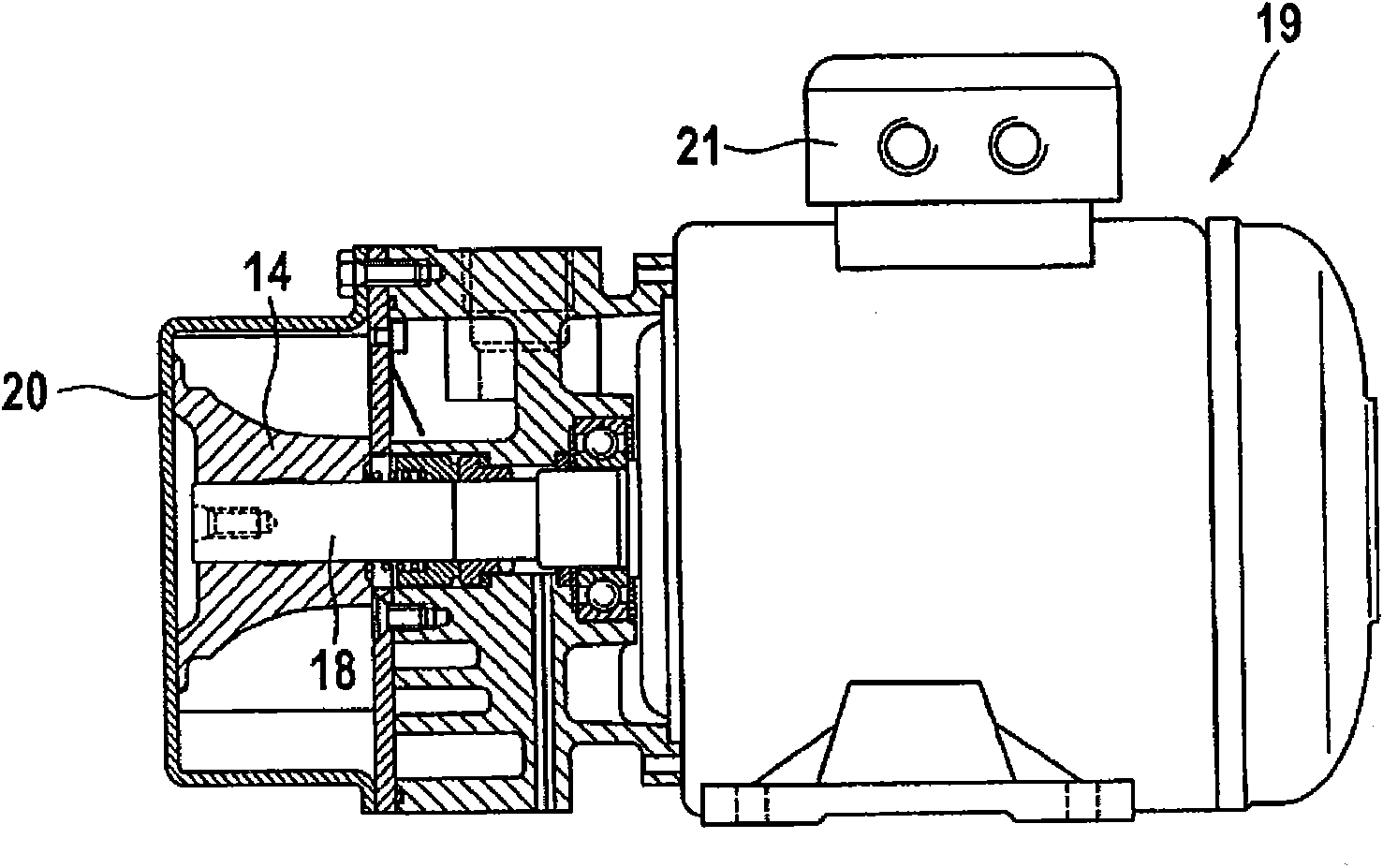

Recirculation structure for a turbocompressor

InactiveUS7186072B2Low efficiencyEnhancement of the surge marginPump componentsReaction enginesEngineeringMechanical engineering

Owner:MTU AERO ENGINES GMBH

Methods and apparatus for controlling the output voltage of a switched-mode power supply

ActiveUS7157963B1Long pulse widthReadily balanceNegative-feedback-circuit arrangementsAmplifier modifications to raise efficiencySwitched-mode power supplyControl switch

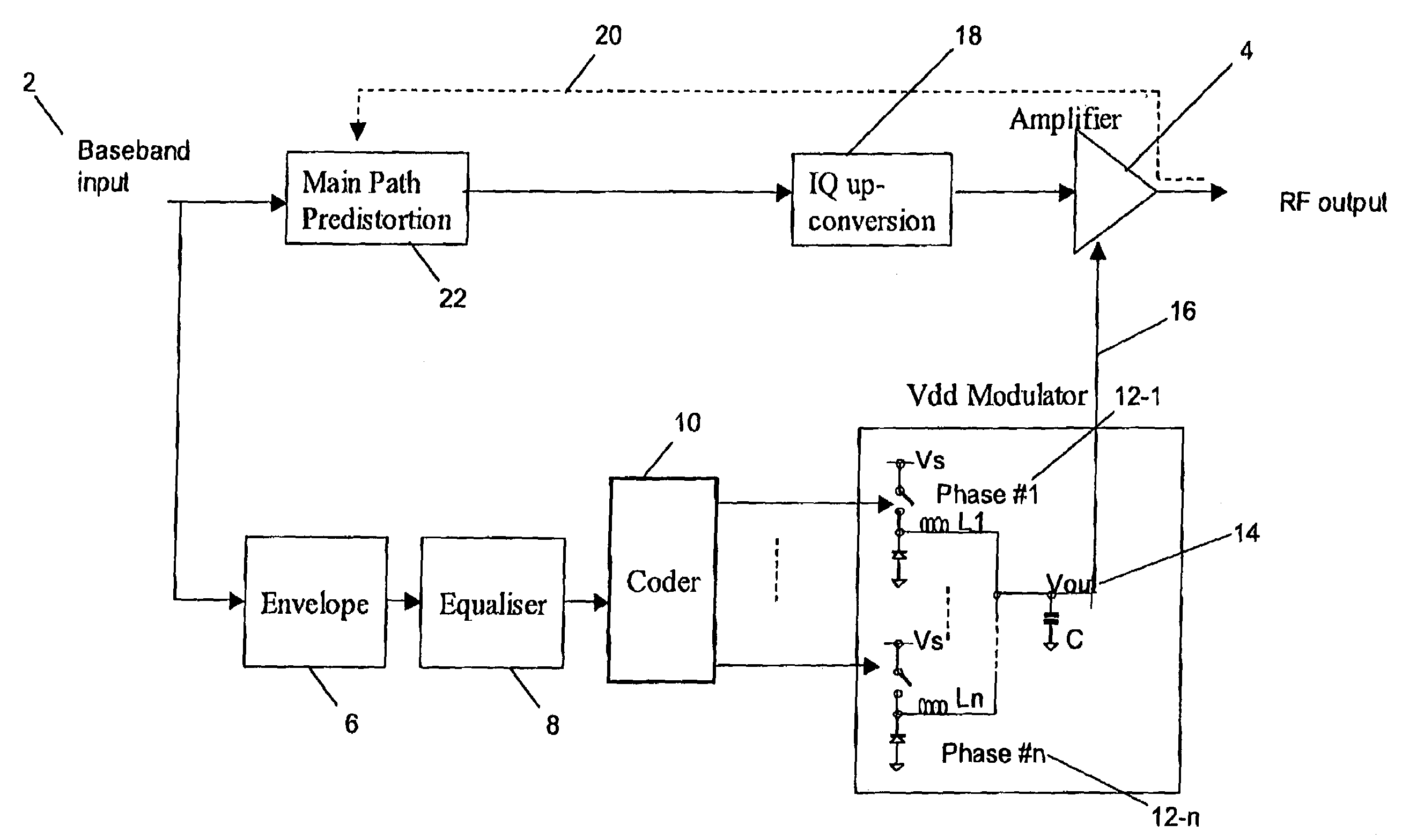

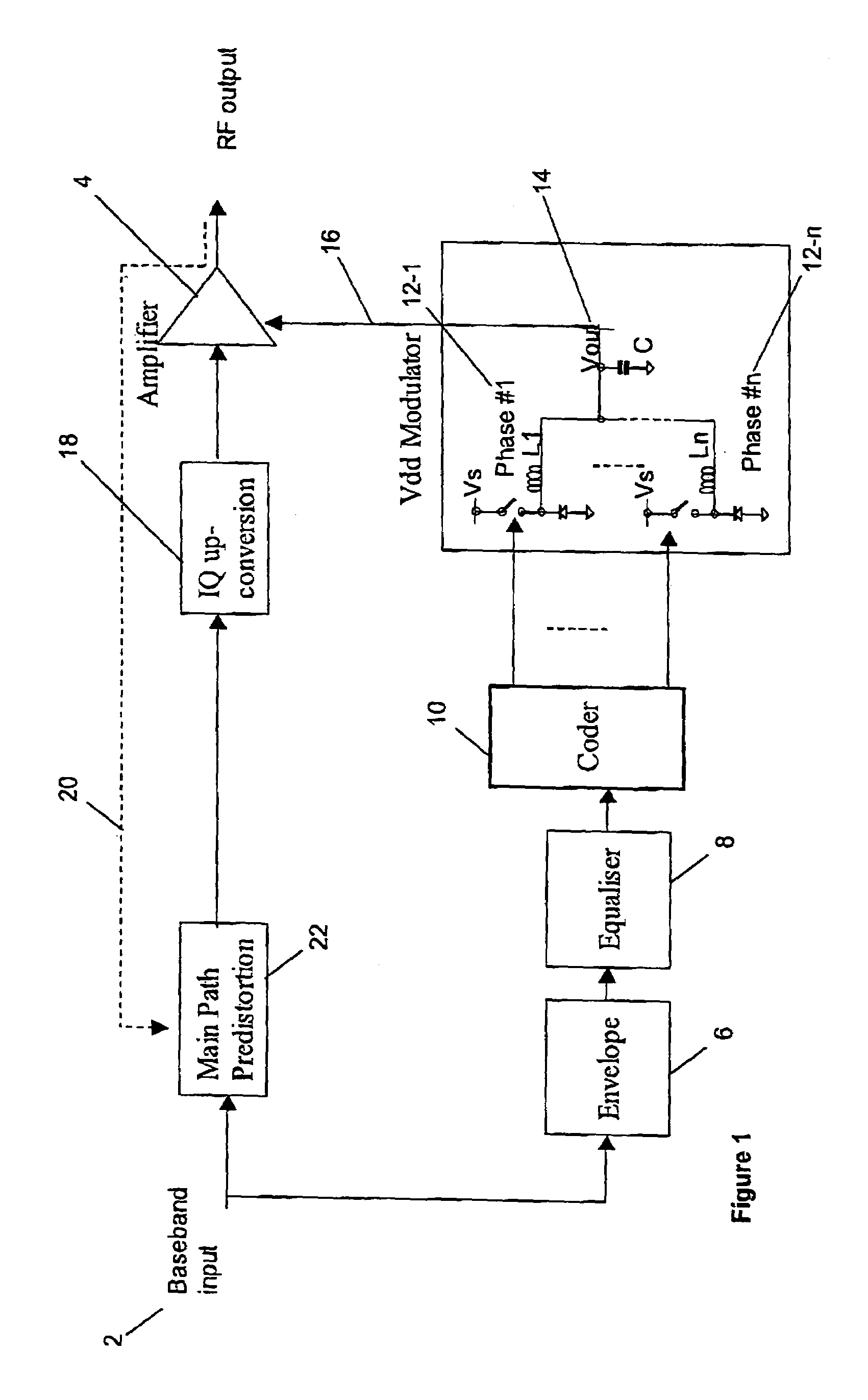

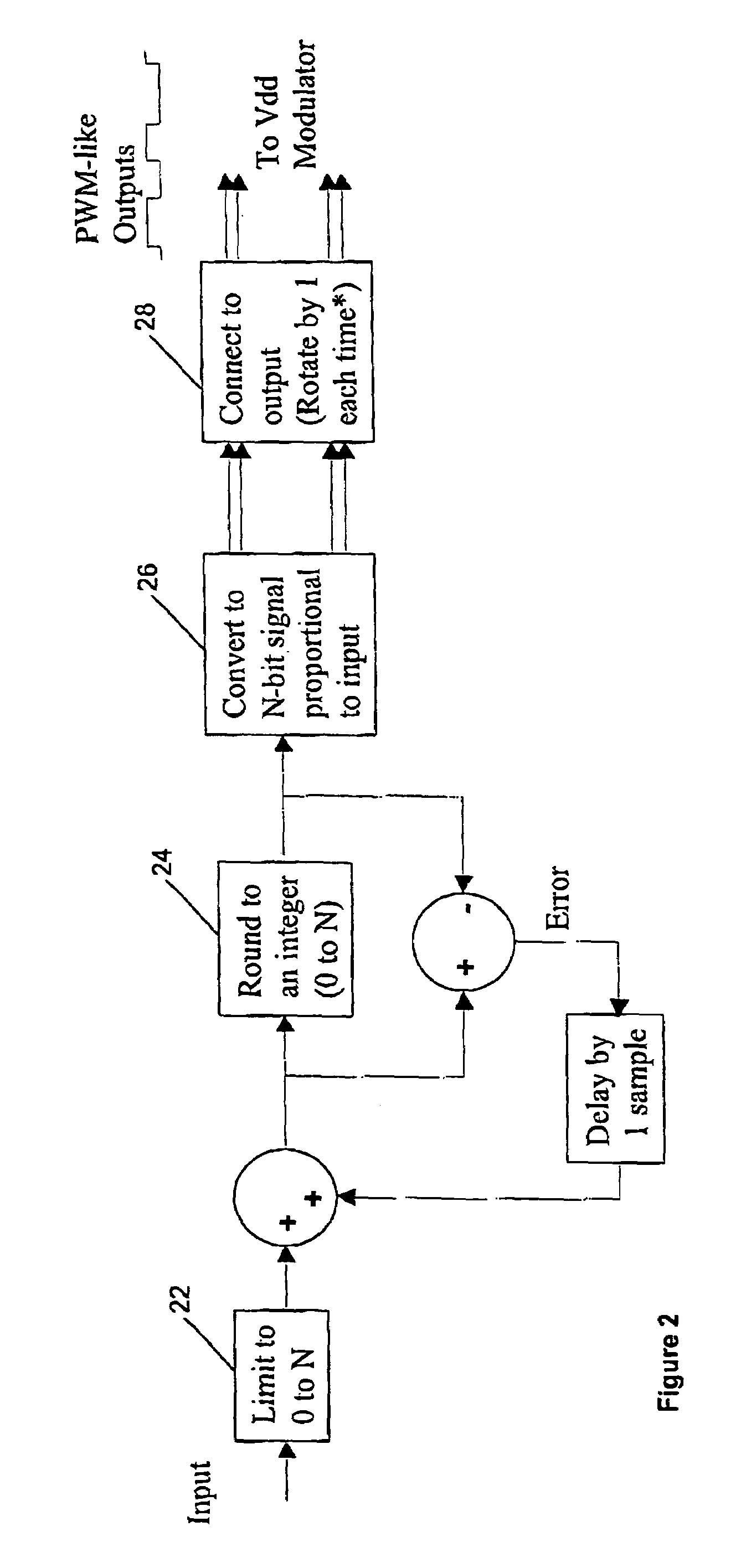

Linear power amplifiers tend to be inefficient. This is a particular problem for RF amplifiers in a cellular base station. In order to improve the efficiency of such amplifiers, attempts have been made to modulate the power supply to the amplifier proportional to the envelope of the signal to be amplified. An UMTS signal requires power supply modulation at frequencies of the order of 10 to 20 megahertz. When quantization noise is taken into account, oversampling becomes desirable. However, switching power supplies at frequencies of the order of 40 or 80 or even 160 megahertz becomes difficult. By modifying the coding of phases of the power supply to be switched so that the number of phases enabled is proportional to the desired power supply output voltage rather than the length of a pulse in a time domain on any particular phase being proportional to the output voltage, dramatic improvements are achieved in switching losses, balance between phases and accurate tracking of the input signal. Rotation of switching across the phases achieves good balance and by jittering or randomizing the rotation, switching noise may be moved out of band.

Owner:META PLATFORMS INC

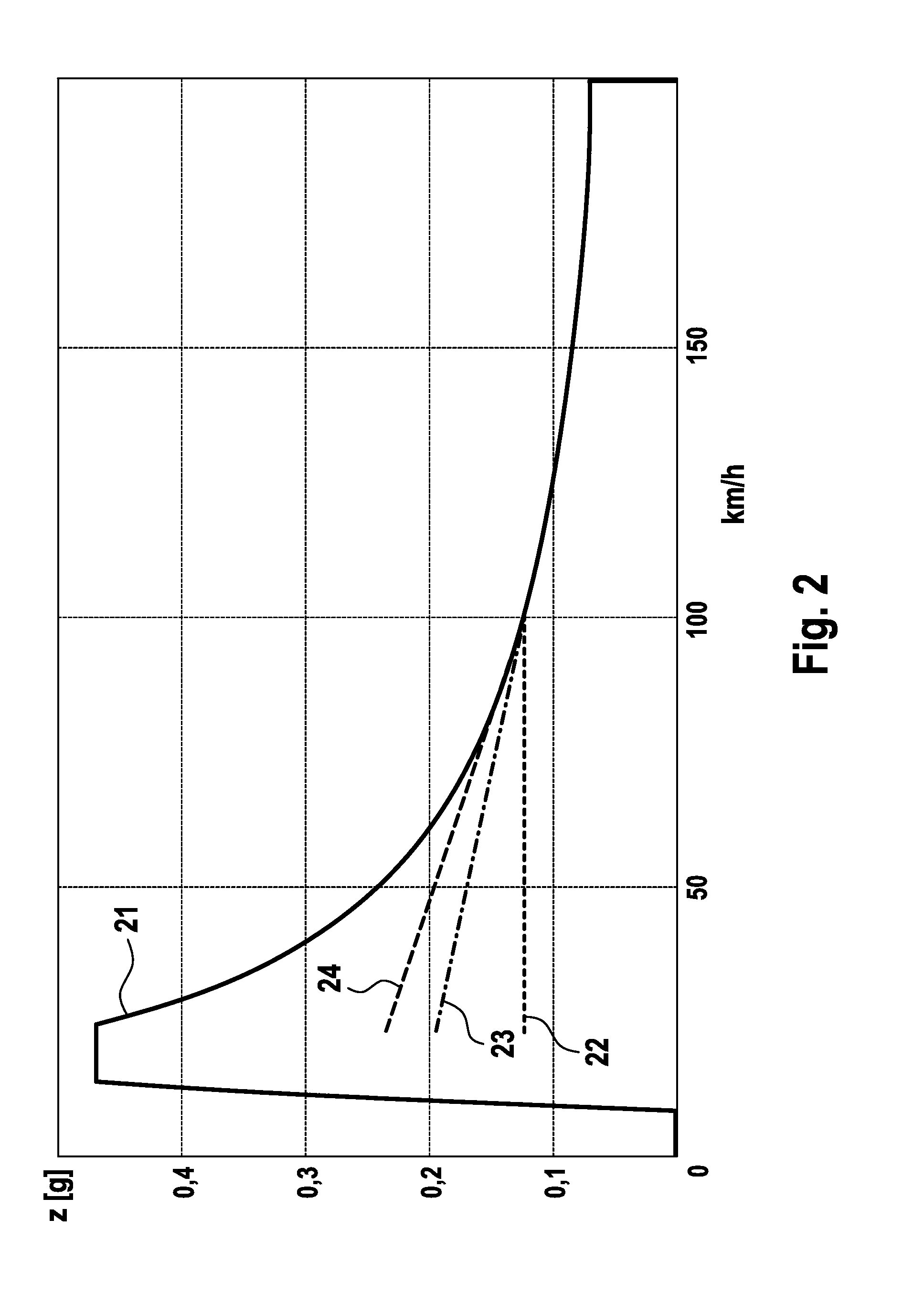

Method for Controlling a Motor Vehicle Brake System

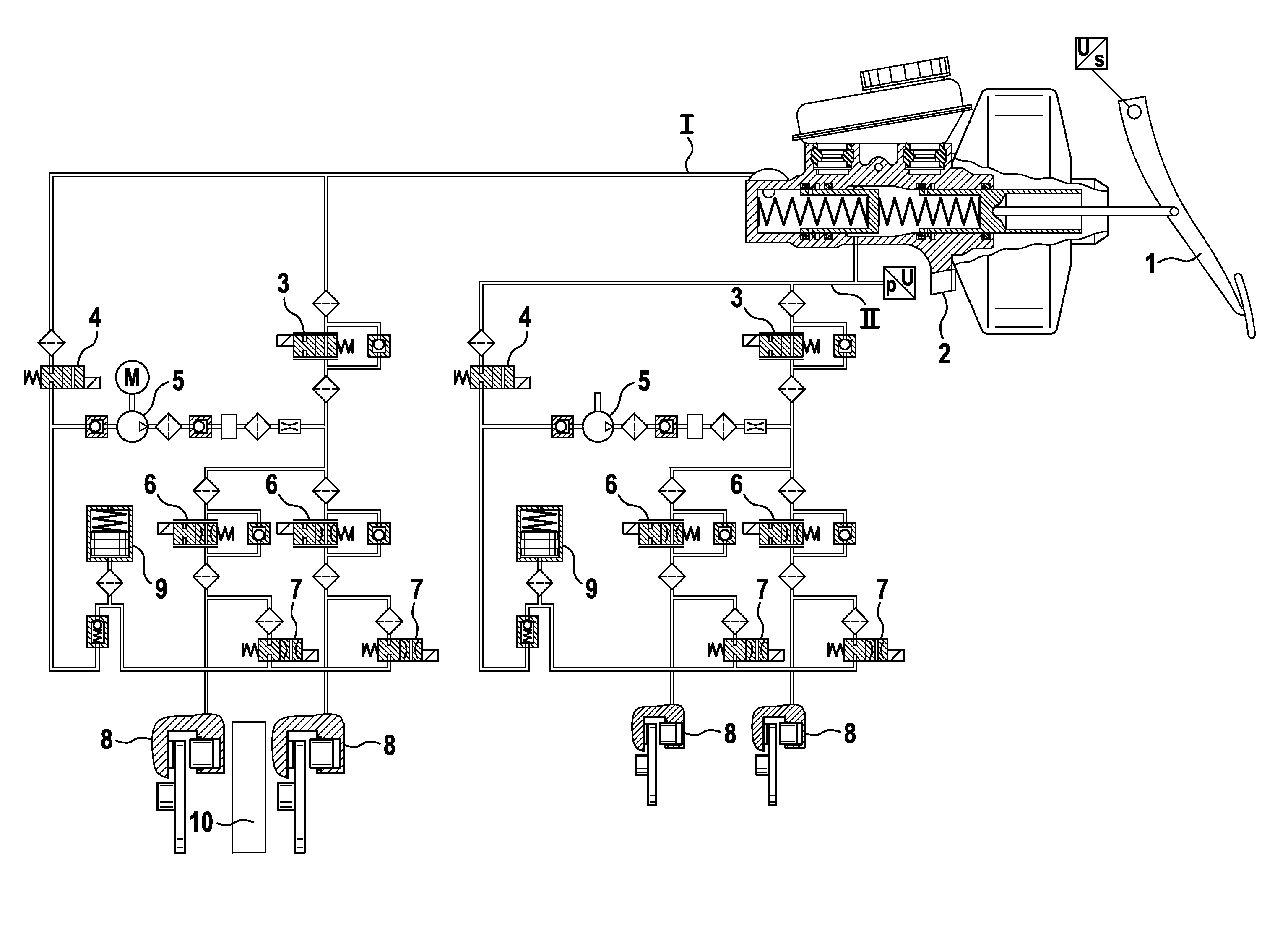

ActiveUS20130204502A1Improve efficiency levelsBraking element arrangementsInternal combustion piston enginesElectricityRegenerative brake

A method in which open- or closed-loop control of a motor vehicle brake system is carried out having friction brakes on the wheels of at least one axle, wherein the brake pressure generating means for the wheels of at least one axle are in a direct operative connection to the brake pedal, and at least one electrical machine is in an operative connection to at least one axle which can be used by applying an electrically regenerative braking torque for converting kinetic energy into electrical energy. In order to raise the efficiency level of the recuperation, the regenerative deceleration is increased even in the case of an unchanged brake pedal position and / or brake pedal force, and a motor vehicle brake system which is open-loop or closed-loop controlled.

Owner:CONTINENTAL TEVES AG & CO OHG

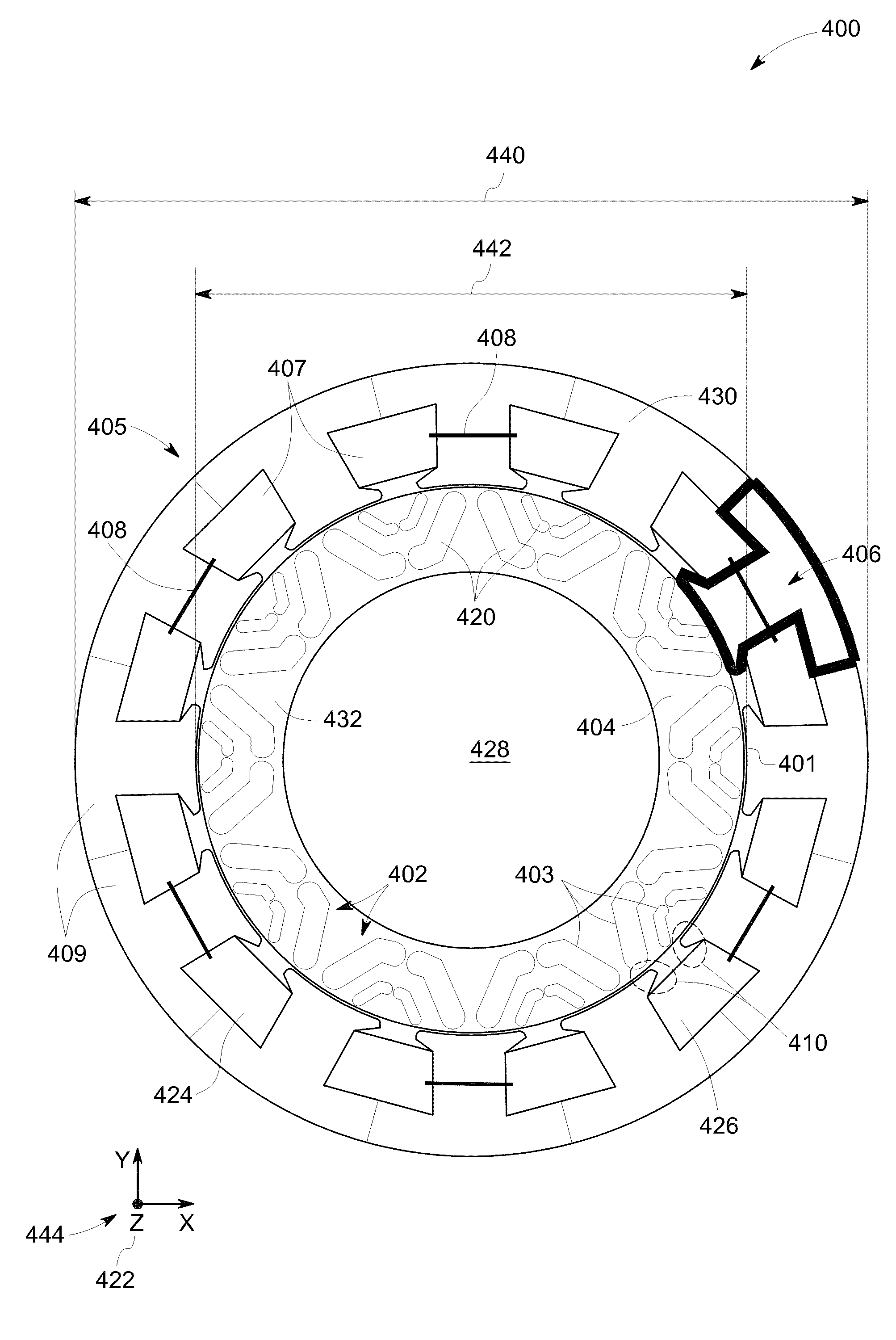

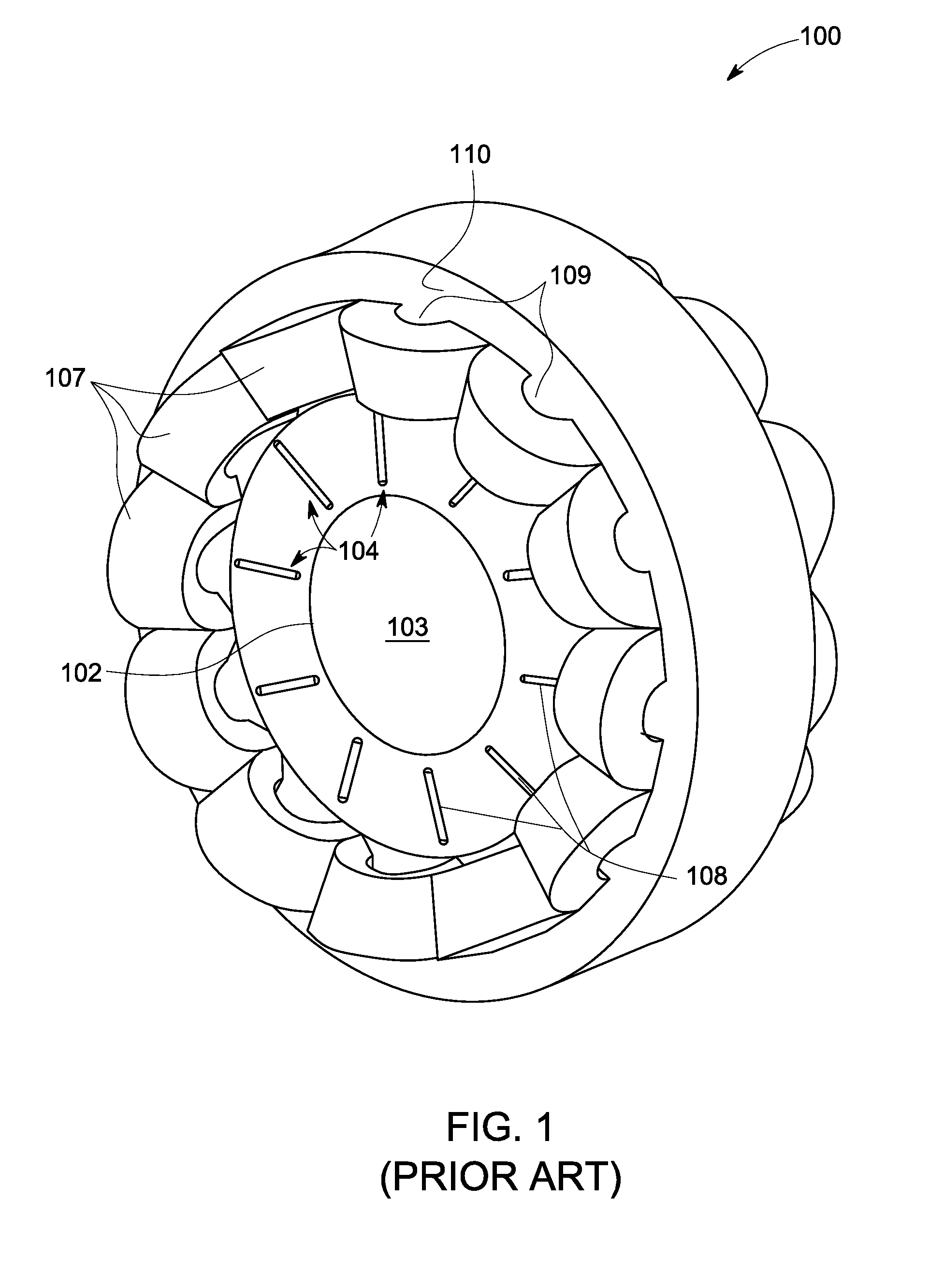

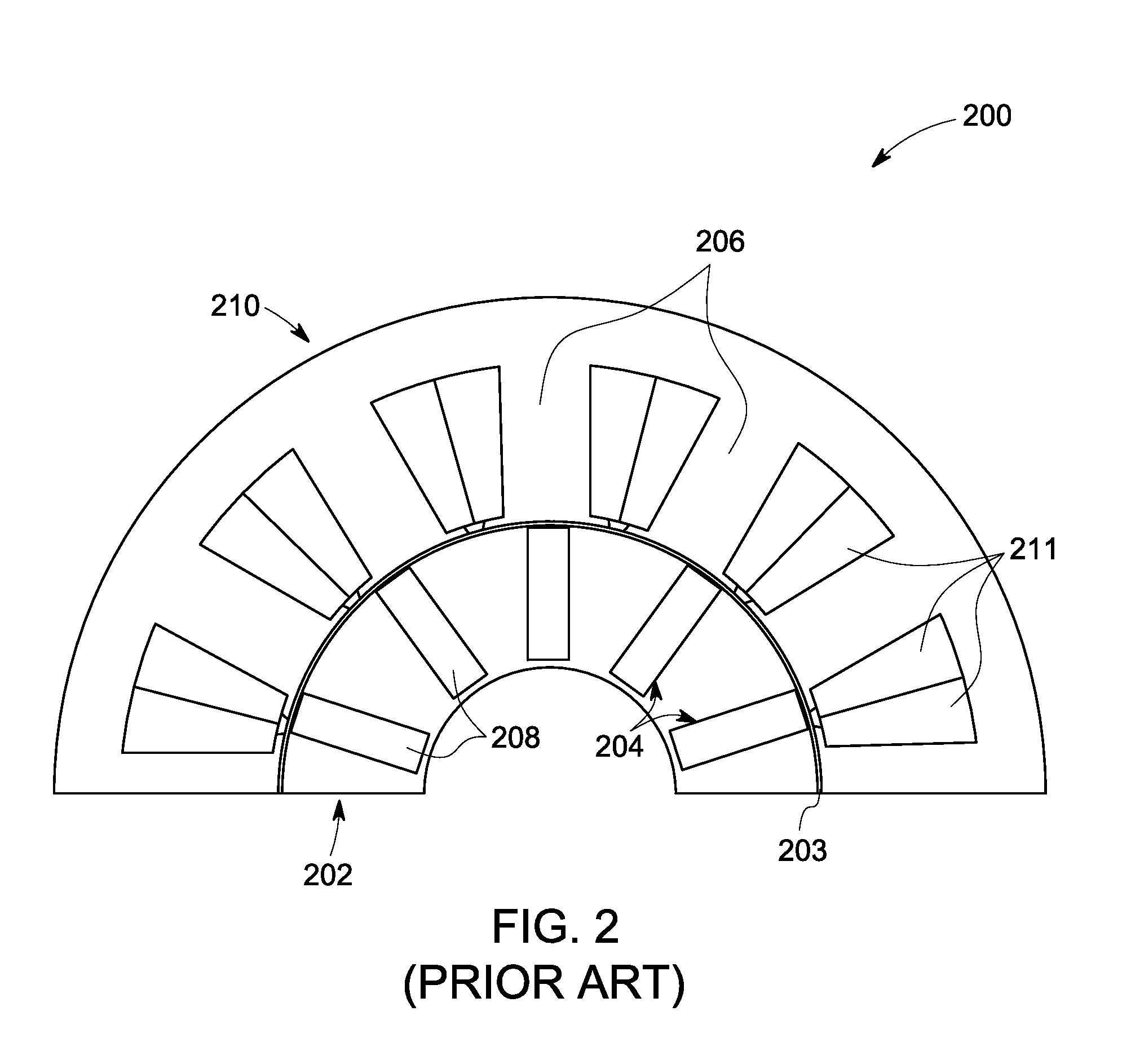

Electric machine

InactiveUS20100244603A1Level of efficiencyImprove efficiency levelsMagnetic circuitDC commutatorHigh resistivityEngineering

An electrical machine is disclosed. The electrical machine comprises a first discontinuous volume comprising a high resistivity soft magnetic material.

Owner:GENERAL ELECTRIC CO

Electric system for providing electrical power for a vehicle and an implement

ActiveUS8256544B2Improve efficiency levelsIncrease power levelAuxillary drivesAgricultural machinesElectricityTransformer

Owner:DEERE & CO

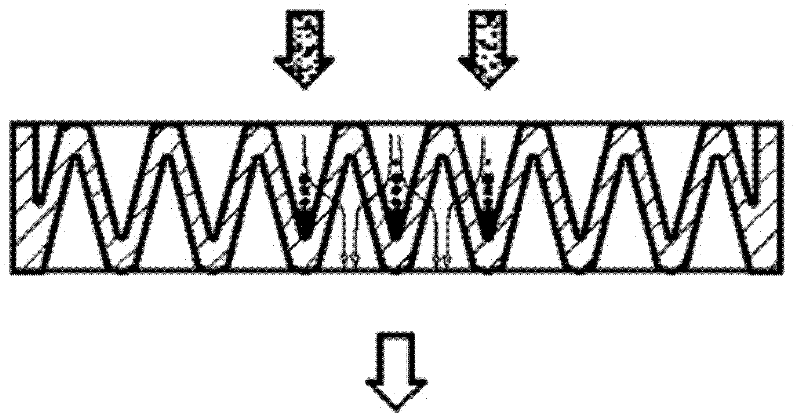

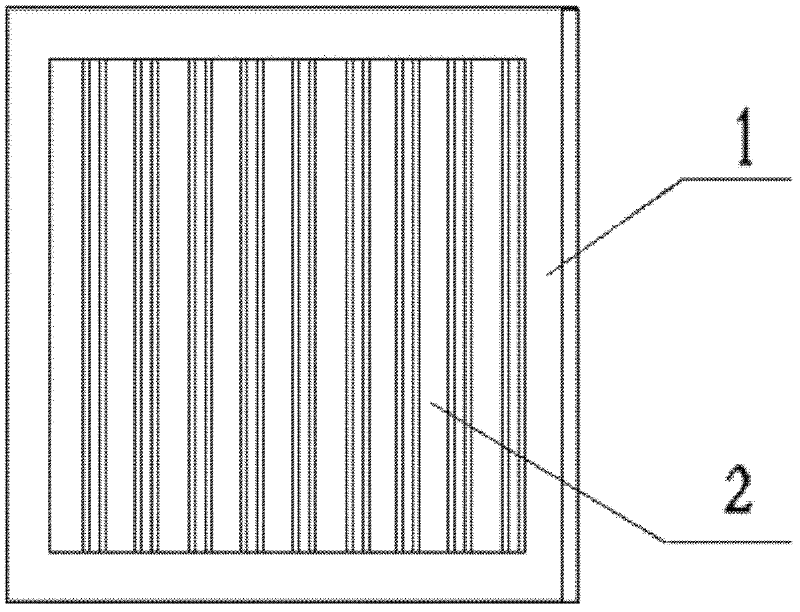

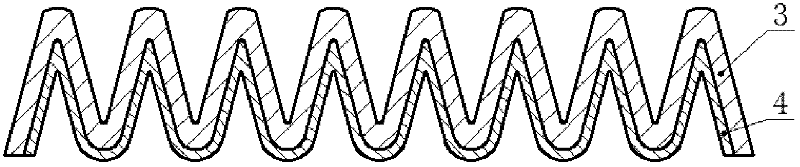

Folding air purification filter for heating and ventilating air conditioner

InactiveCN102240490AImprove efficiency levelsExtended service lifeDispersed particle filtrationLighting and heating apparatusAirflowEngineering

The invention relates to a folding air purification filter for a heating and ventilating air conditioner. The folding air purification filter comprises a frame and a composite gradient fiber filter screen, wherein the composite gradient fiber filter screen consists of a first non-woven filter material arranged on an outer layer and a second non-woven filter material arranged on an inner layer; and the first non-woven filter material and the second non-woven filter material are subjected to gradient combination to be folded and fixed in the frame. In the folding air purification filter, the conventional single-layer folding filter material is changed into a composite folding filter material with gradient, so that granules with a large size in air can enter the inside of the filter material to solve the problem of blocking in the process of forming filter cakes on the surface of the filter material, reduce the resistance of airflow and prolong the service life of the filter while the dust containing capacity is increased and the efficiency level of the filter is improved.

Owner:DONGHUA UNIV +1

Electric connection system

ActiveUS9030040B2Simple designImprove efficiency levelsAgricultural machinesElectric devicesElectronic systemsPower electronics

Owner:DEERE & CO

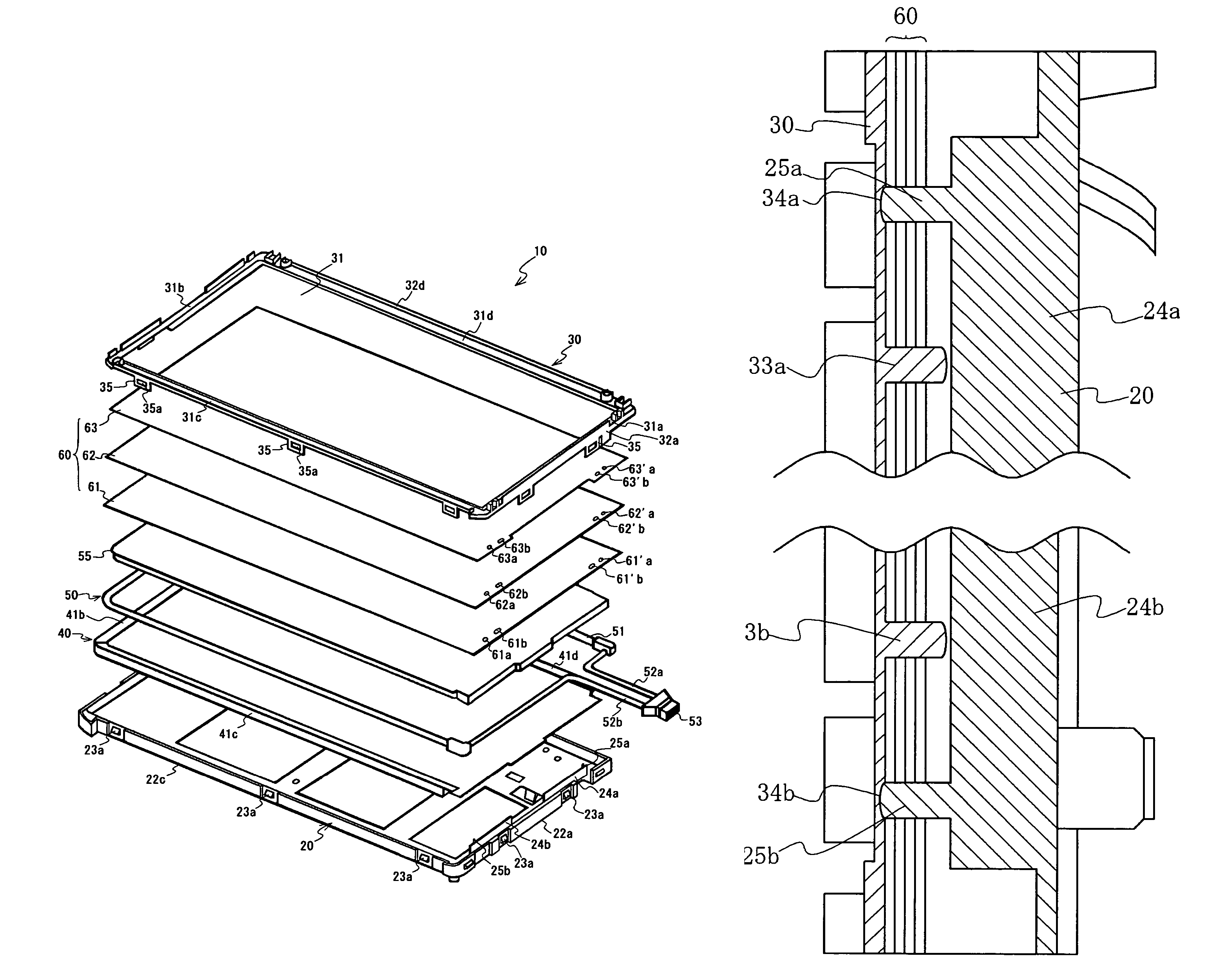

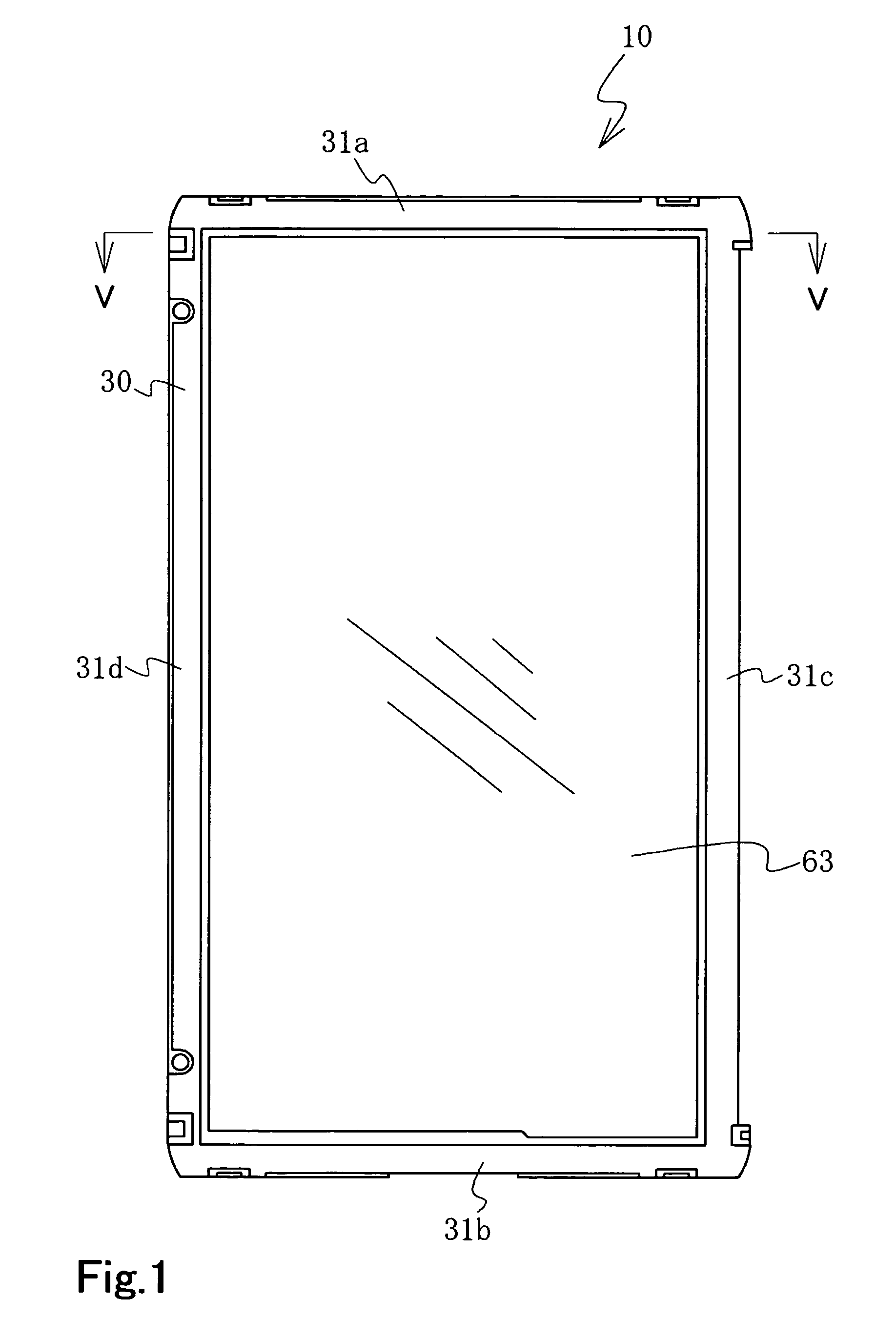

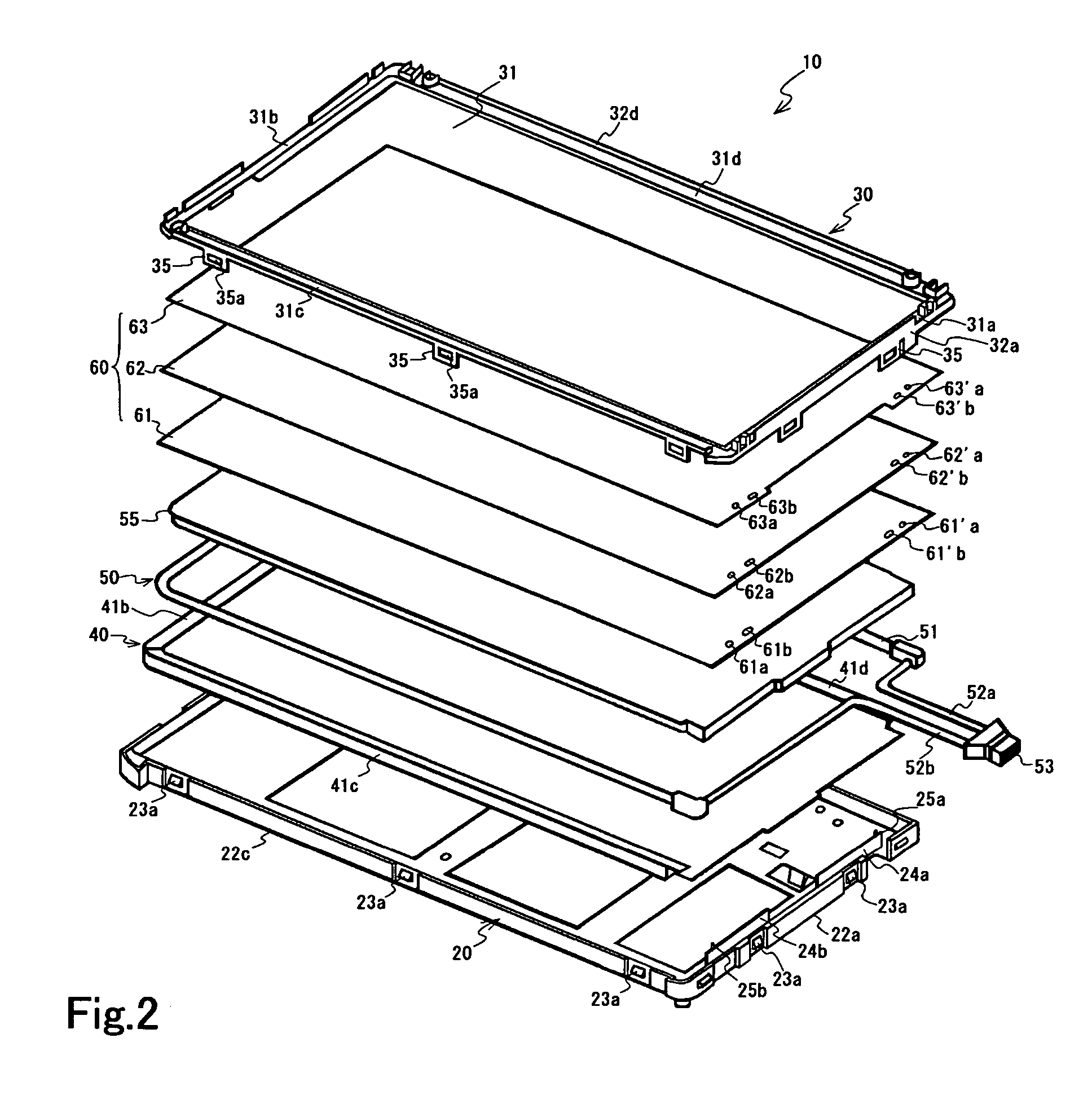

Liquid crystal display device

ActiveUS7161643B2Improving alignment and fixingLarge displayOptical light guidesNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device includes a liquid crystal panel, at least one optical sheet substantially rectangular in shape, where first and second openings are formed on the end edges of one side of the optical sheet at a predetermined interval, a main frame in which the optical sheet(s) are placed, and a sub-frame arranged above the main frame, in which the main frame is provided with first small protrusions jutting upward corresponding to the first openings at the top surface, while the rear surface of the sub-frame is provided with second small protrusions jutting downward corresponding to the second openings, thereupon the first small protrusions are inserted into the first openings of the optical sheet(s) and the second small protrusions are inserted into the second openings to connect and install the sub-frame to the main frame, and the optical sheet(s) are then aligned and fixed. Accordingly, the optical sheets are aligned better and firmly fixed to achieve larger display screens and thinner liquid crystal display devices.

Owner:JAPAN DISPLAY WEST

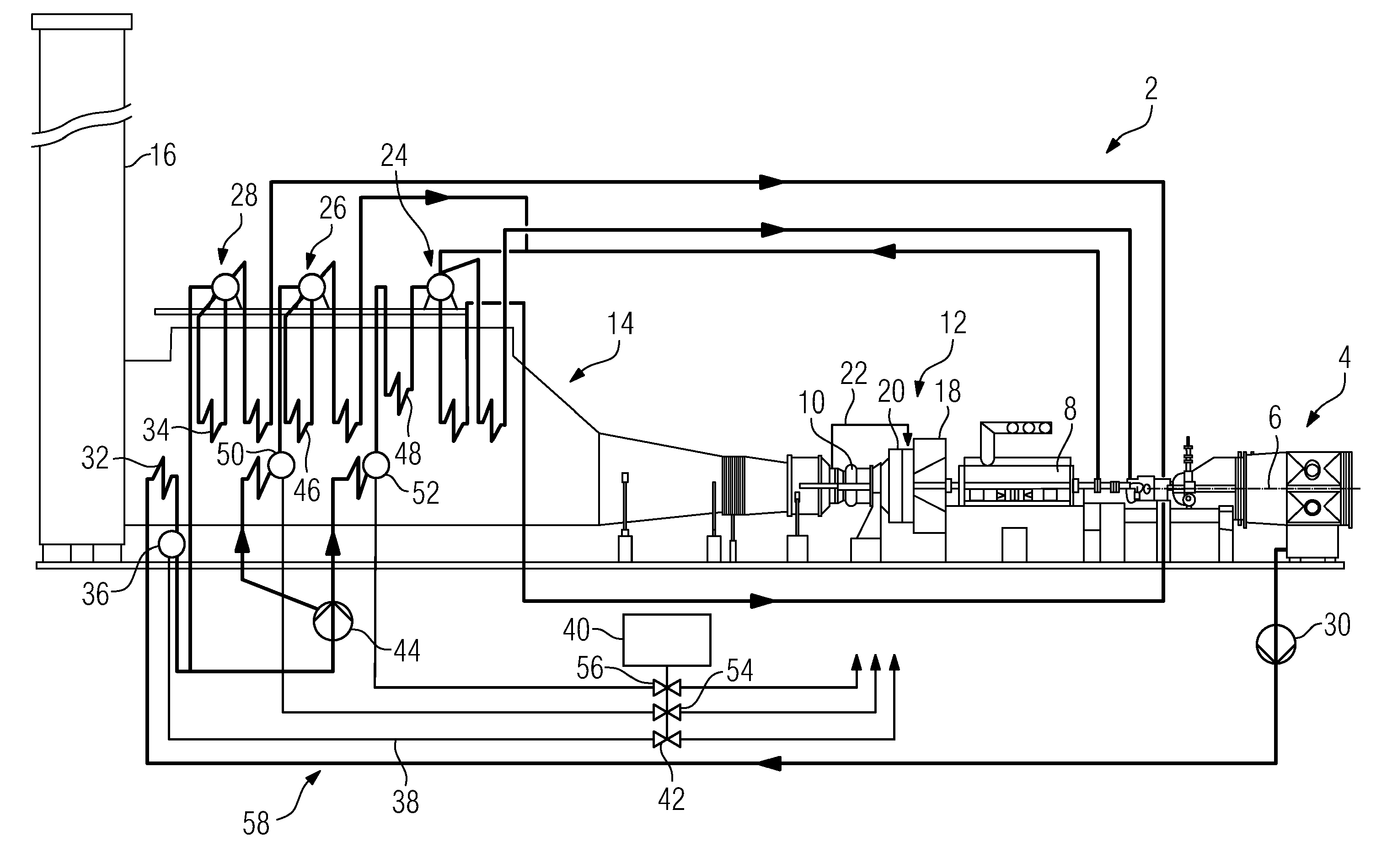

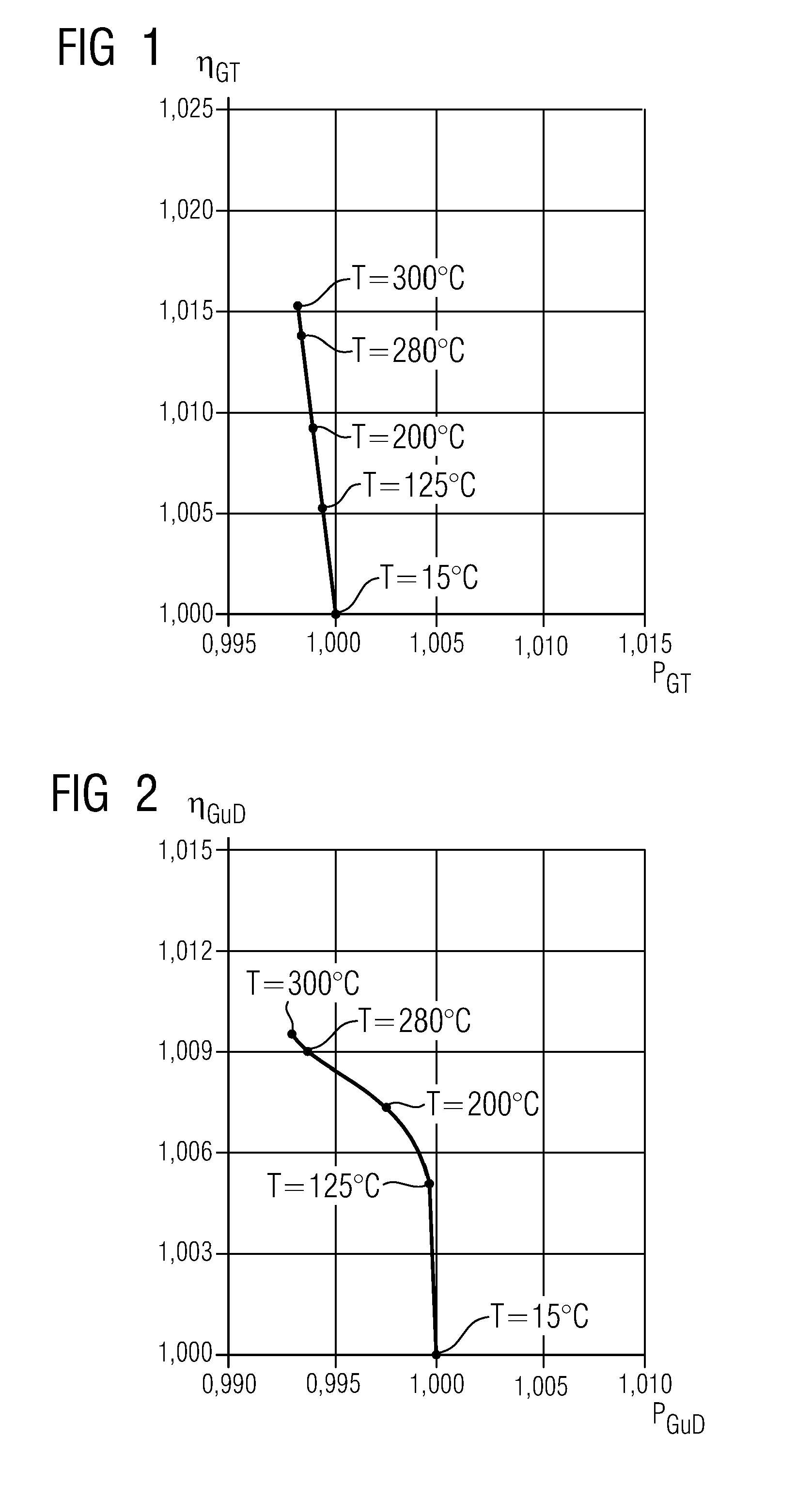

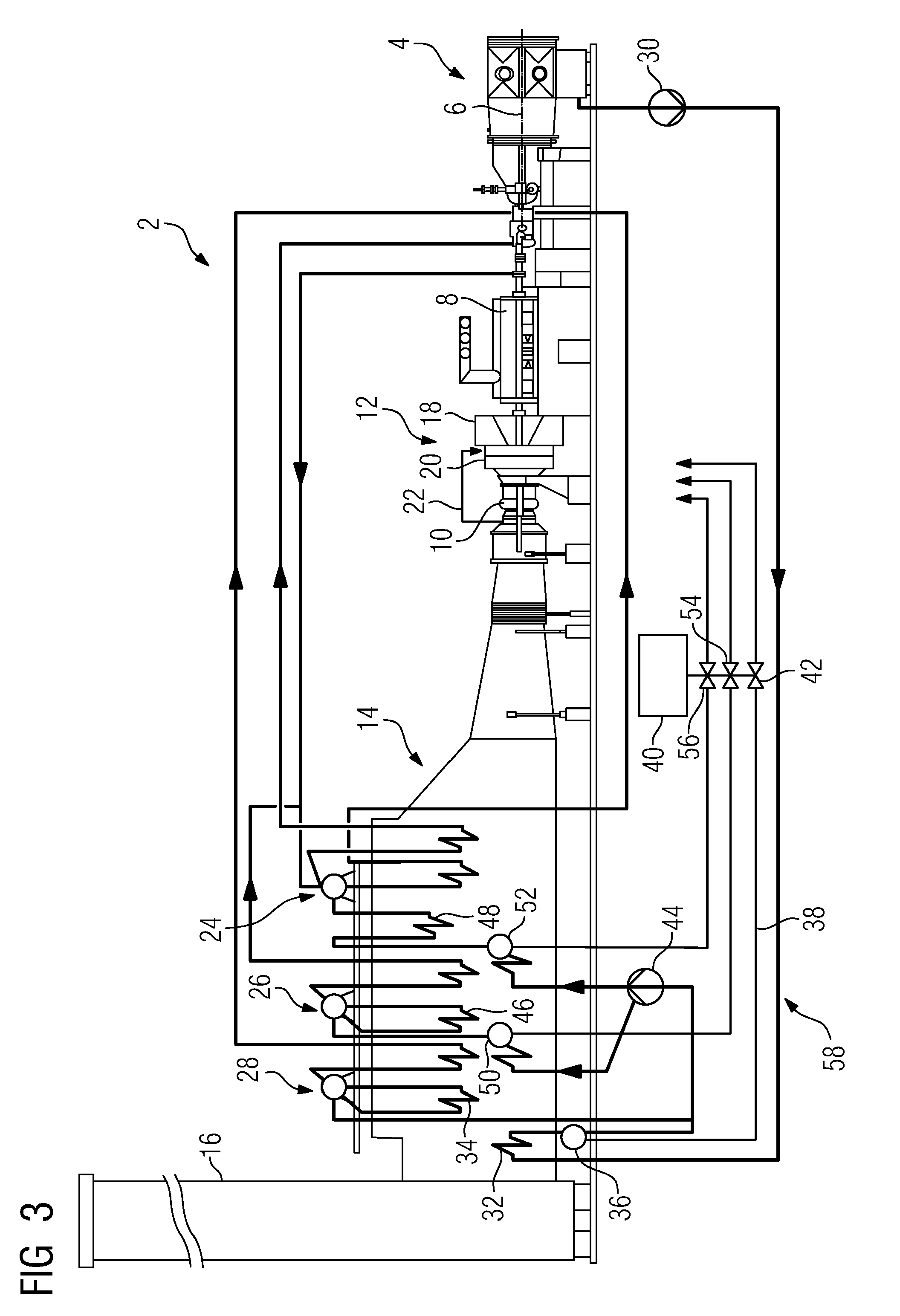

Method for operating a firing system

InactiveUS20100024430A1Easy to operateImprove efficiencyLiquid fuel feeder/distributionGas turbine plantsCombustion systemCombustion chamber

A method for operating a firing system with a combustion chamber, in which a fuel is preheated and is supplied in the preheated state for combustion in the combustion chamber. The preheated temperature of the fuel is set higher for a part load of the firing system than with a basic load. In addition, the preheated temperature of the fuel is set using a variable obtained from the combustion in particular a load of the firing system. A firing system is also provided.

Owner:SIEMENS AG

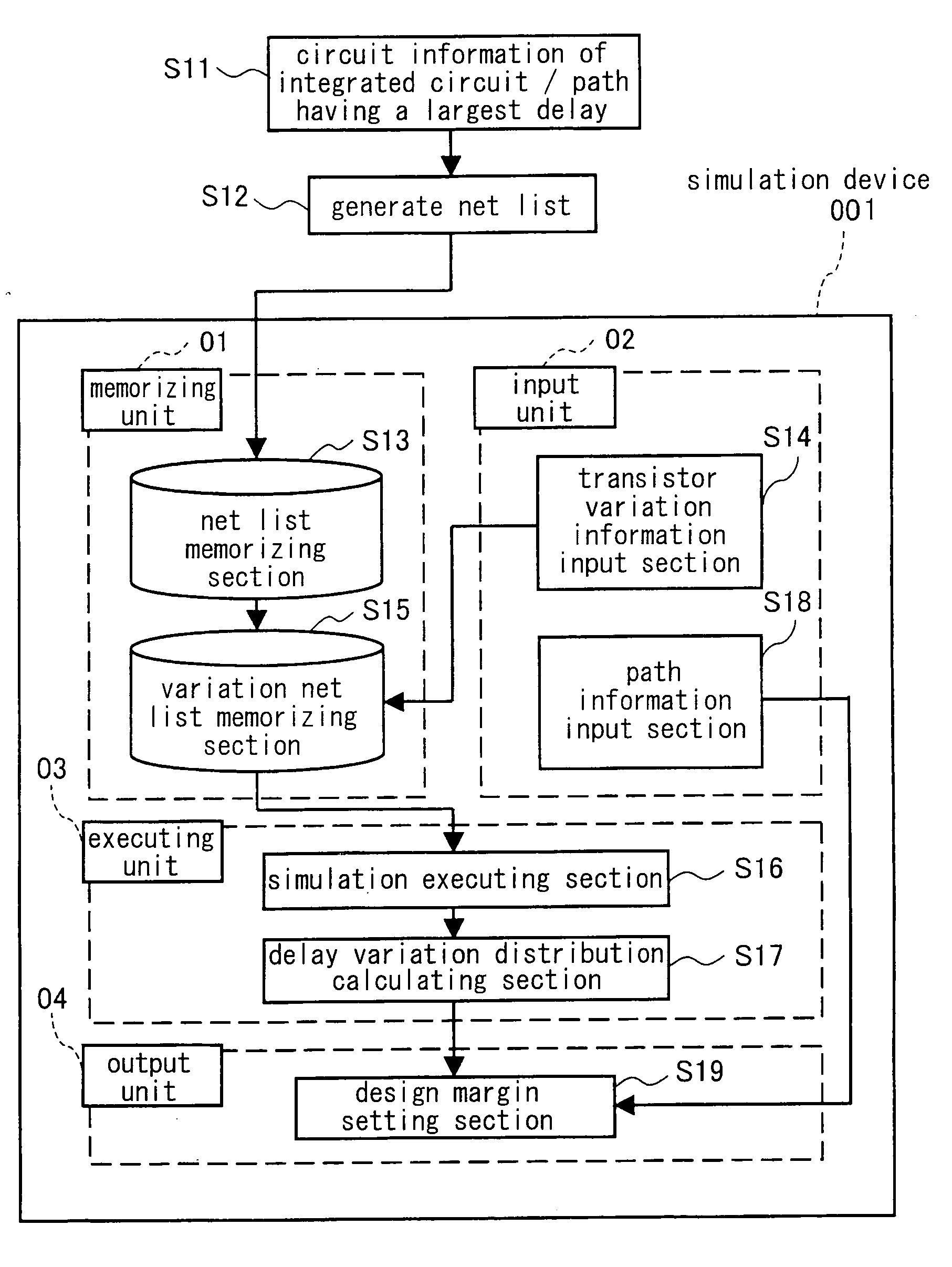

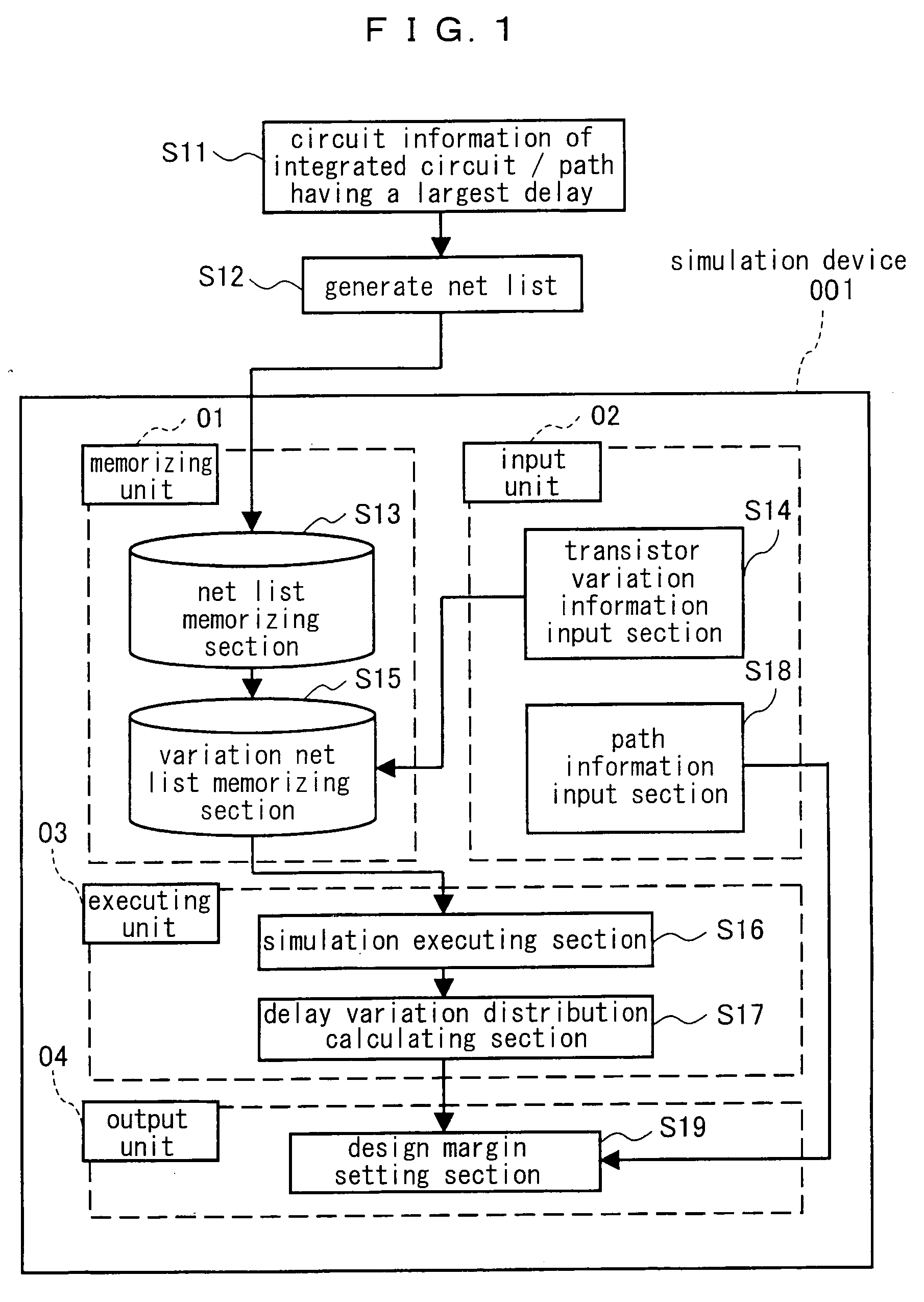

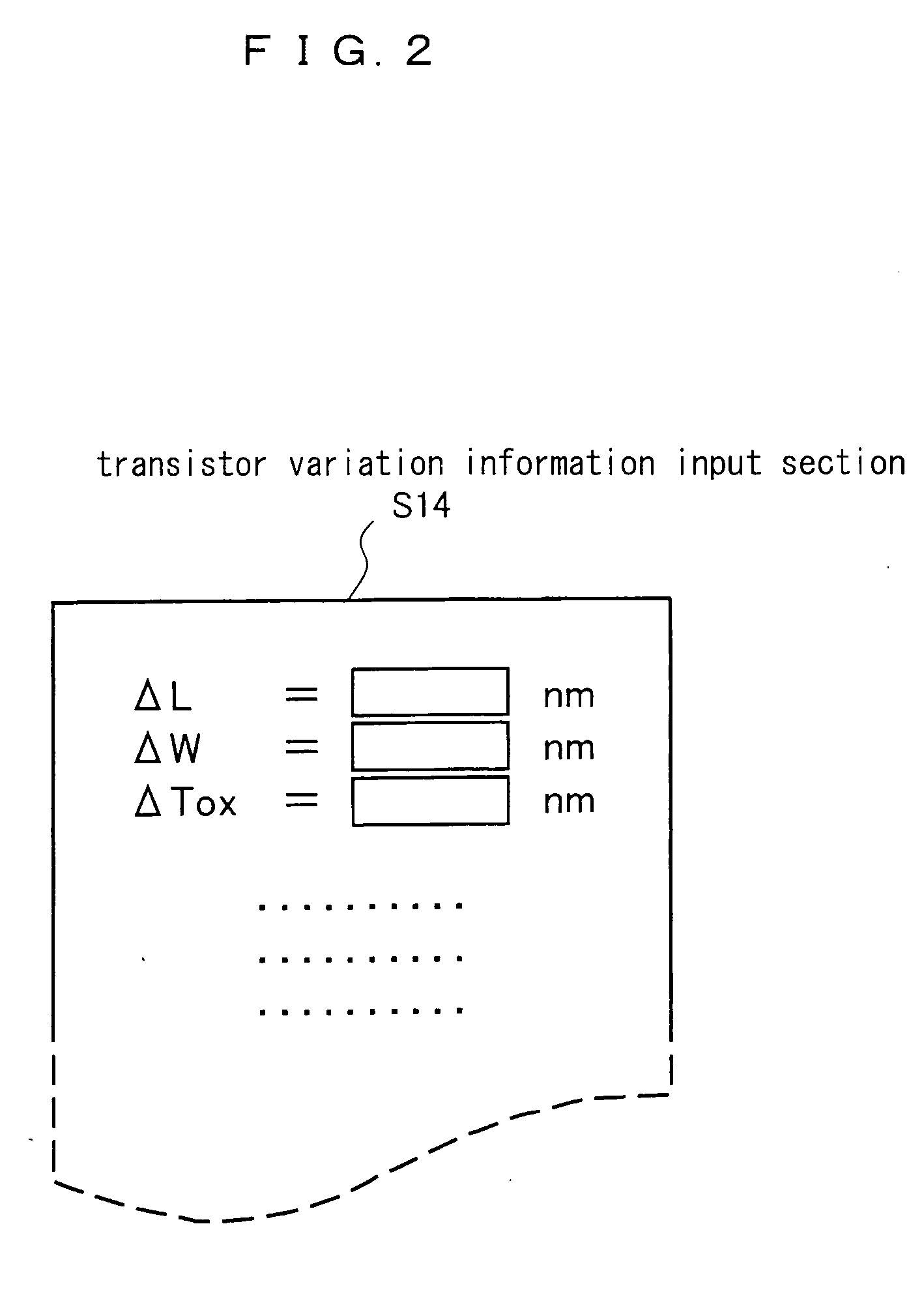

Simulation device for integrated circuit

InactiveUS20060173667A1Improve efficiency levelsPrecise designCAD circuit designSpecial data processing applicationsParallel computingExecution unit

A simulation device for an integrated circuit according to the present invention comprises a first memory unit, a first input unit, a second memory unit, an execute unit, a second input unit and an output unit. A net list of a particular path in inter-cell paths in the integrated circuit comprising a plurality of synchronizing circuit cells is stored in the first memory unit. The first input unit appends a variation information relating to gate lengths, gate widths and the like of transistors to the net list stored in the first memory unit. The variation net list to which the variation information is appended by the first input unit is stored in the second memory unit. The execute unit executes a simulation using the variation net list stored in the second memory unit to thereby calculate a delay variation distribution. The second input unit appends a circuit information to the path. The output unit sets and outputs a design margin of the circuit based on the delay variation distribution calculated by the execute unit and the circuit information appended by the second input unit.

Owner:PANASONIC CORP

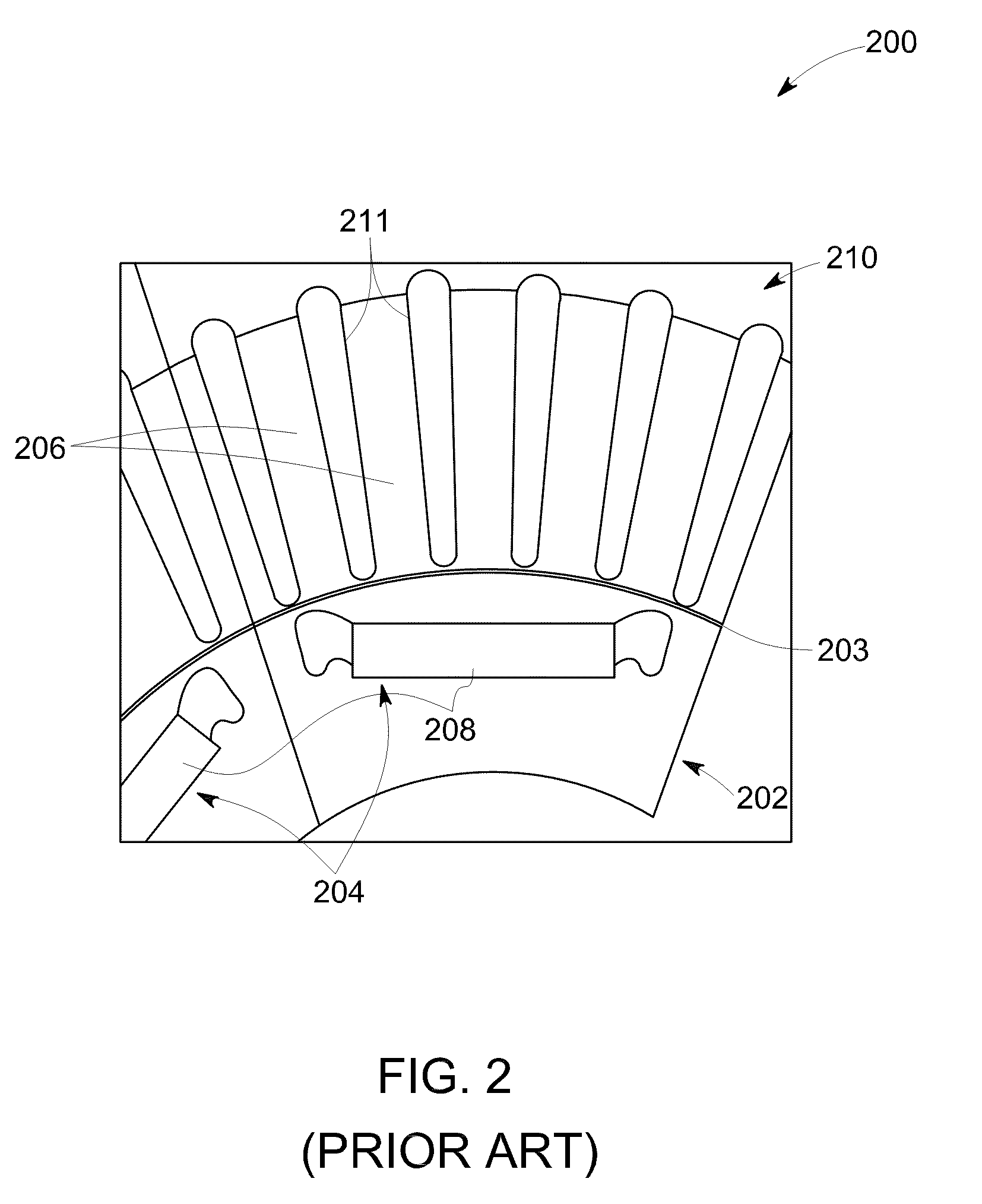

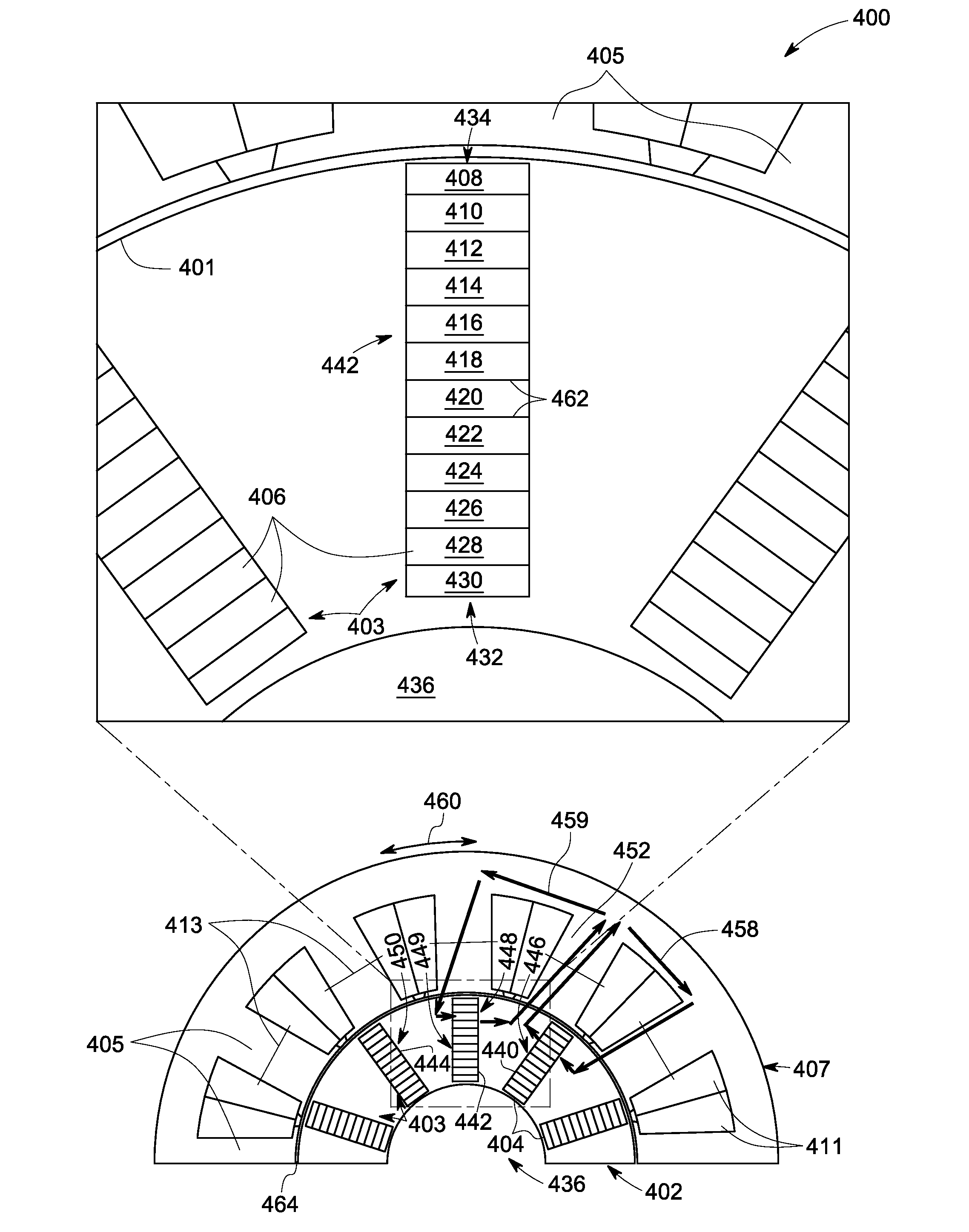

Electric machine

ActiveUS20100253171A1Level of efficiencyImprove efficiency levelsMagnetic circuit rotating partsDC commutatorElectric machineHigh resistivity

An interior permanent magnet electric machine is disclosed. The interior permanent magnet electric machine comprises a rotor comprising a plurality of radially placed magnets each having a proximal end and a distal end, wherein each magnet comprises a plurality of magnetic segments and at least one magnetic segment towards the distal end comprises a high resistivity magnetic material.

Owner:GENERAL ELECTRIC CO

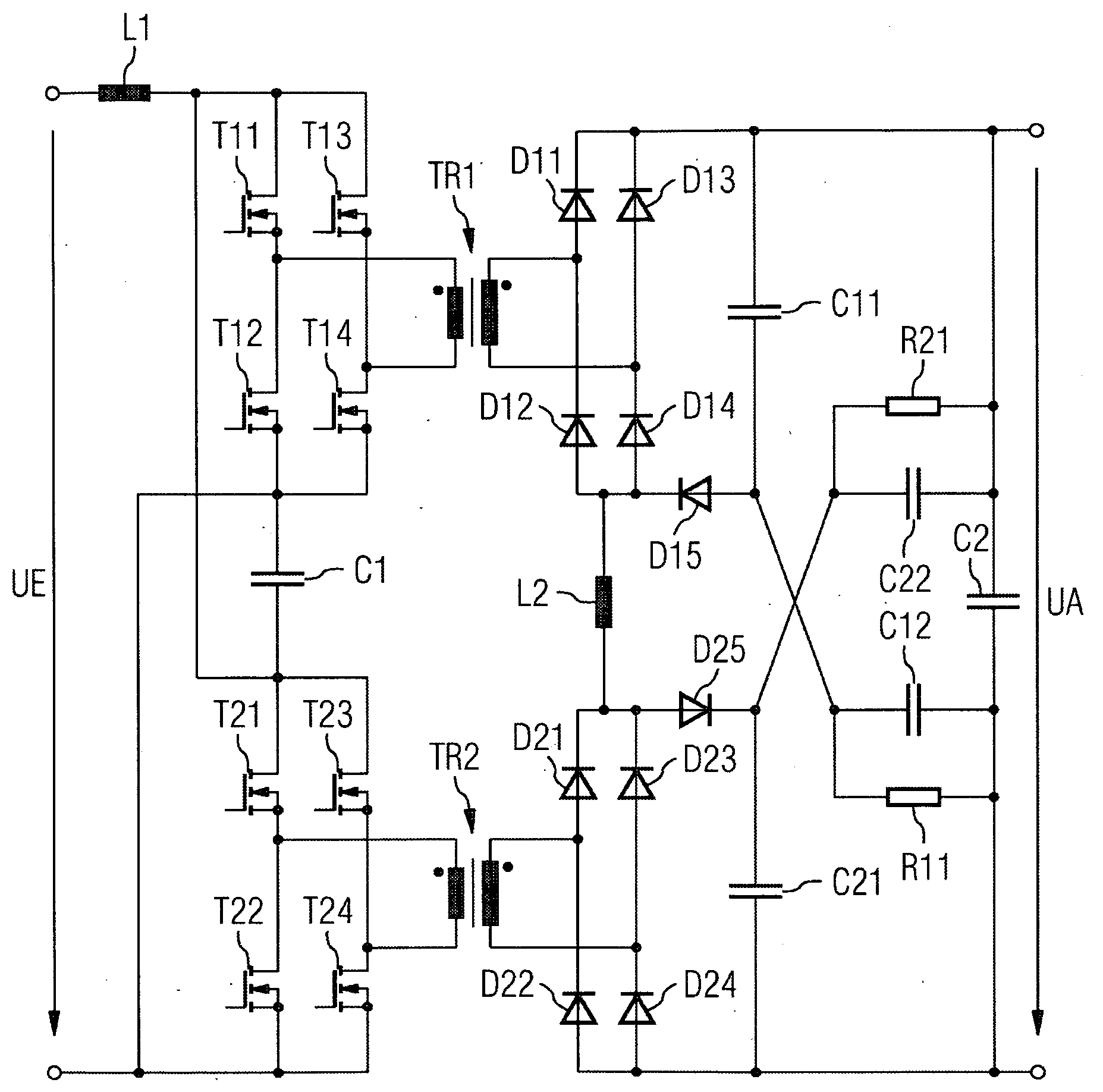

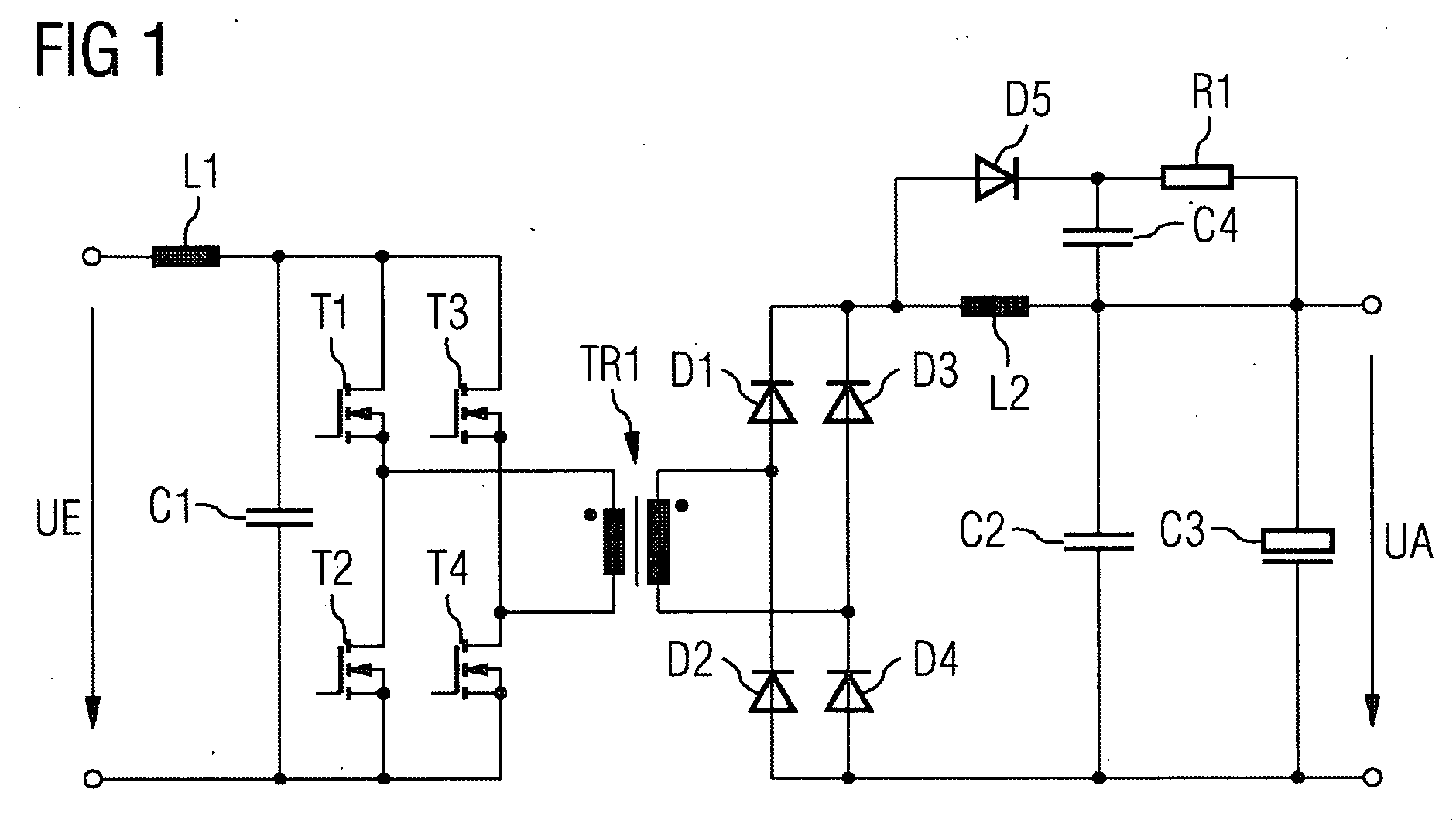

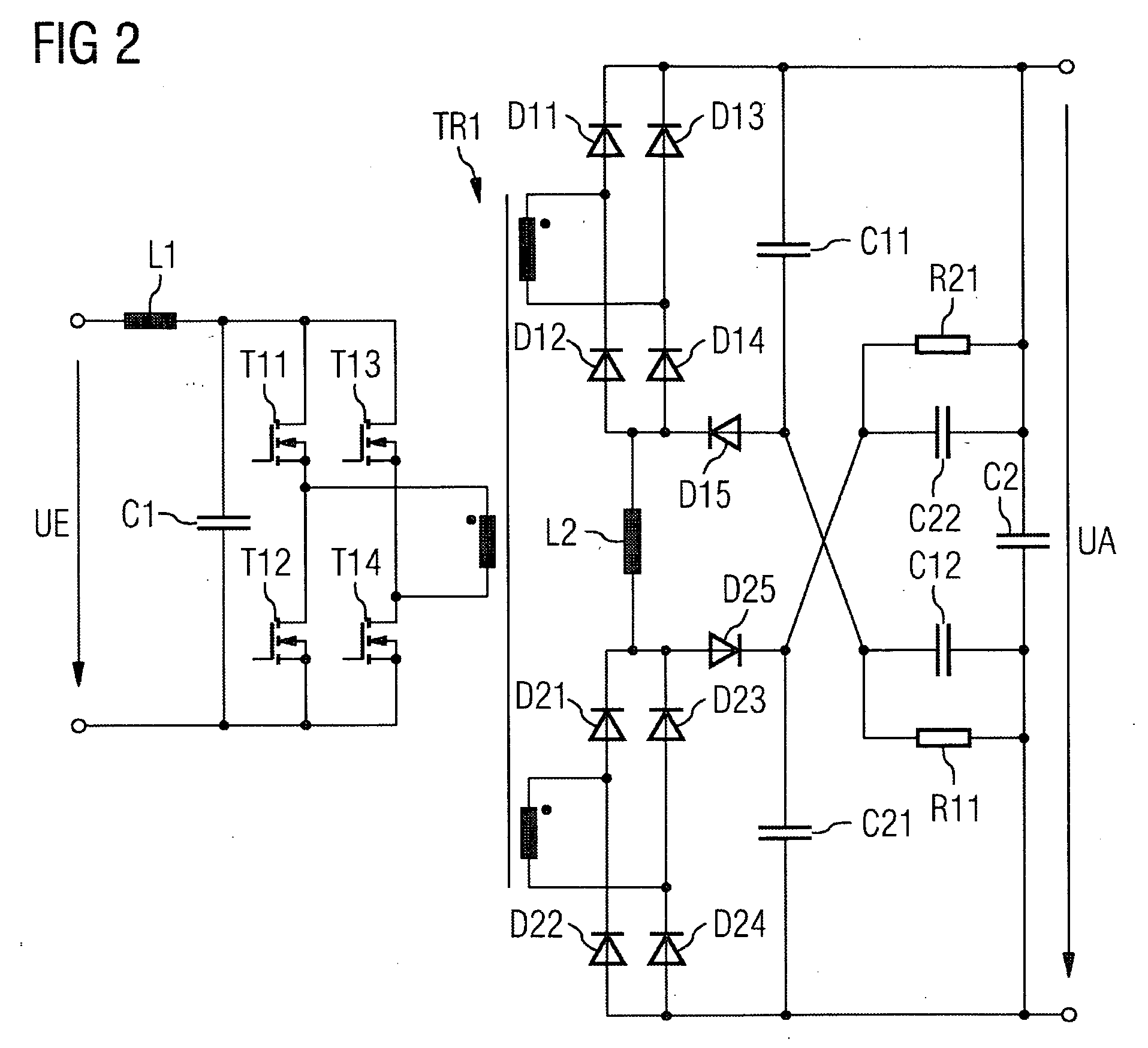

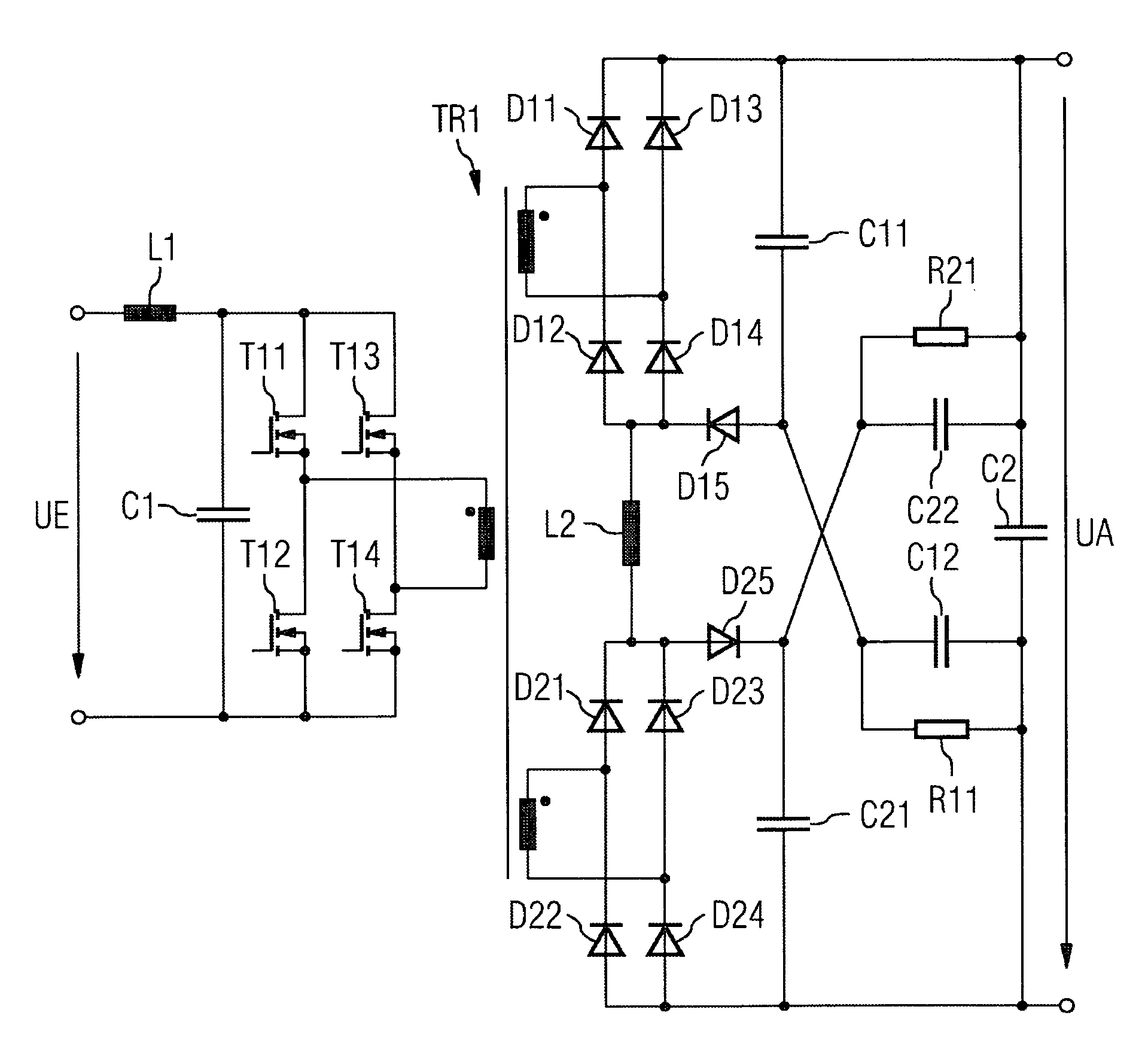

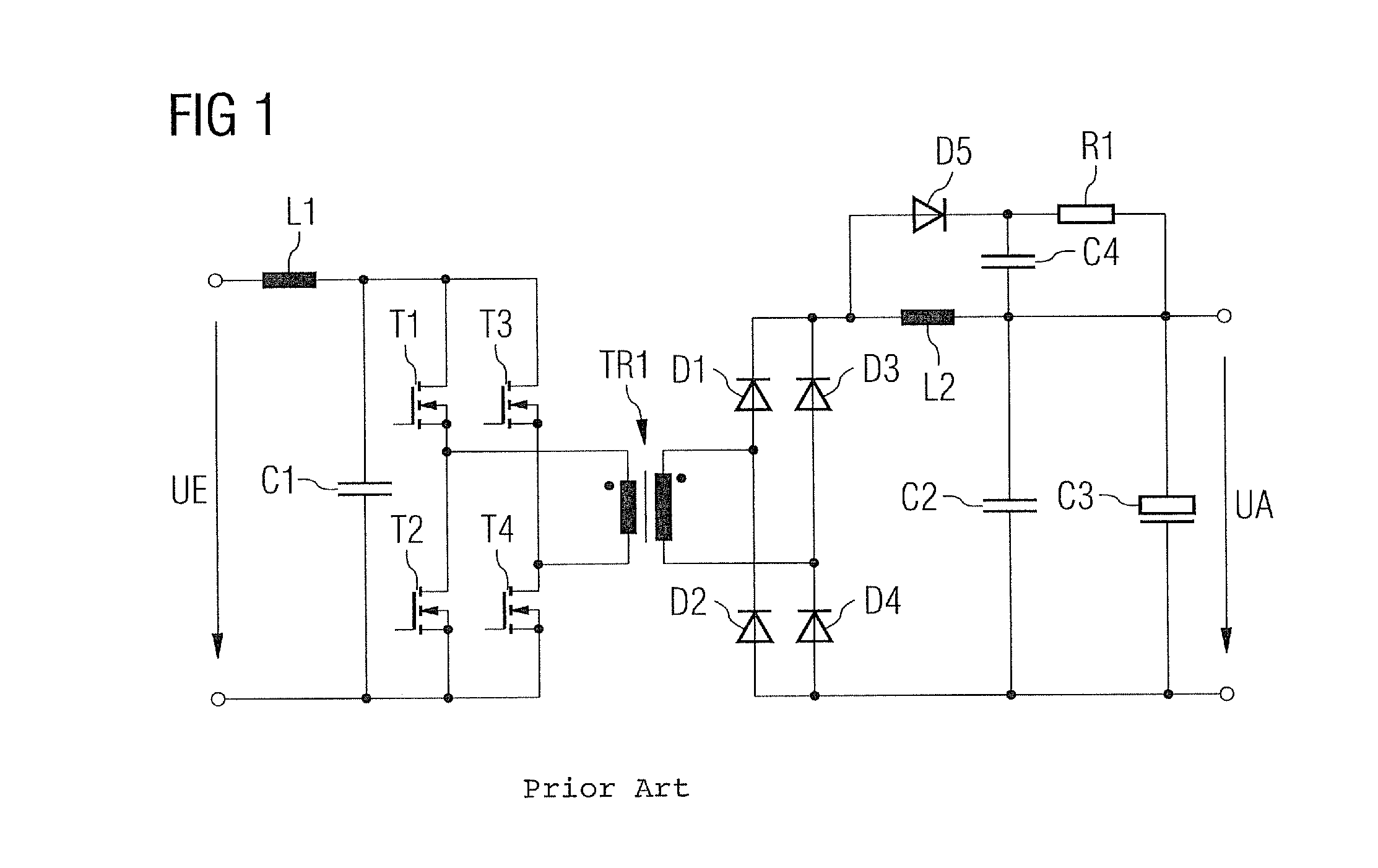

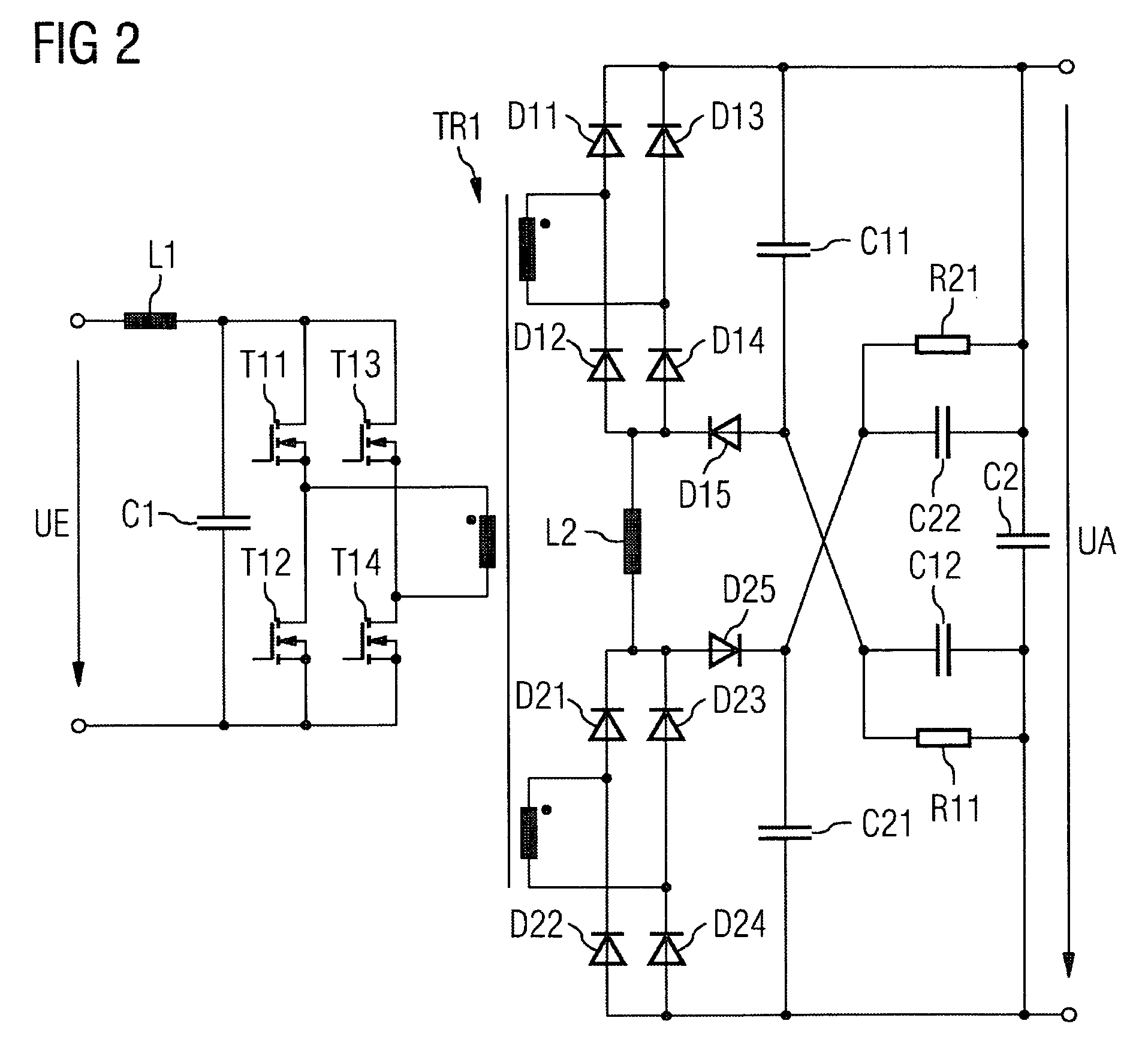

Powering Unit with Full Bridge and Wide Adjusting Range Circuit

InactiveUS20090213622A1Reduce decreaseLow costDc-dc conversionElectric variable regulationFull bridgeBridge type

There is described a powering unit comprising at least one transformer, at least one full bridge circuit via which a primary winding of the transformer is connected to a direct current voltage input, a secondary winding for triggering an output circuit with an output direct current voltage via a bridge-type rectifier circuit as well as an output choke coil and an output capacitor, and a discharge circuit consisting a diode, for a capacitor and of a resistor for reducing the secondary-side peak voltages. The powering unit has another secondary winding, another bridge-type rectifier circuit and another discharge circuit operable to trigger the output circuit with part of the output direct current voltage via the output choke coil and the output capacitor. Thus, there are fewer losses in the resistors and the performance is enhanced.

Owner:SIEMENS AG

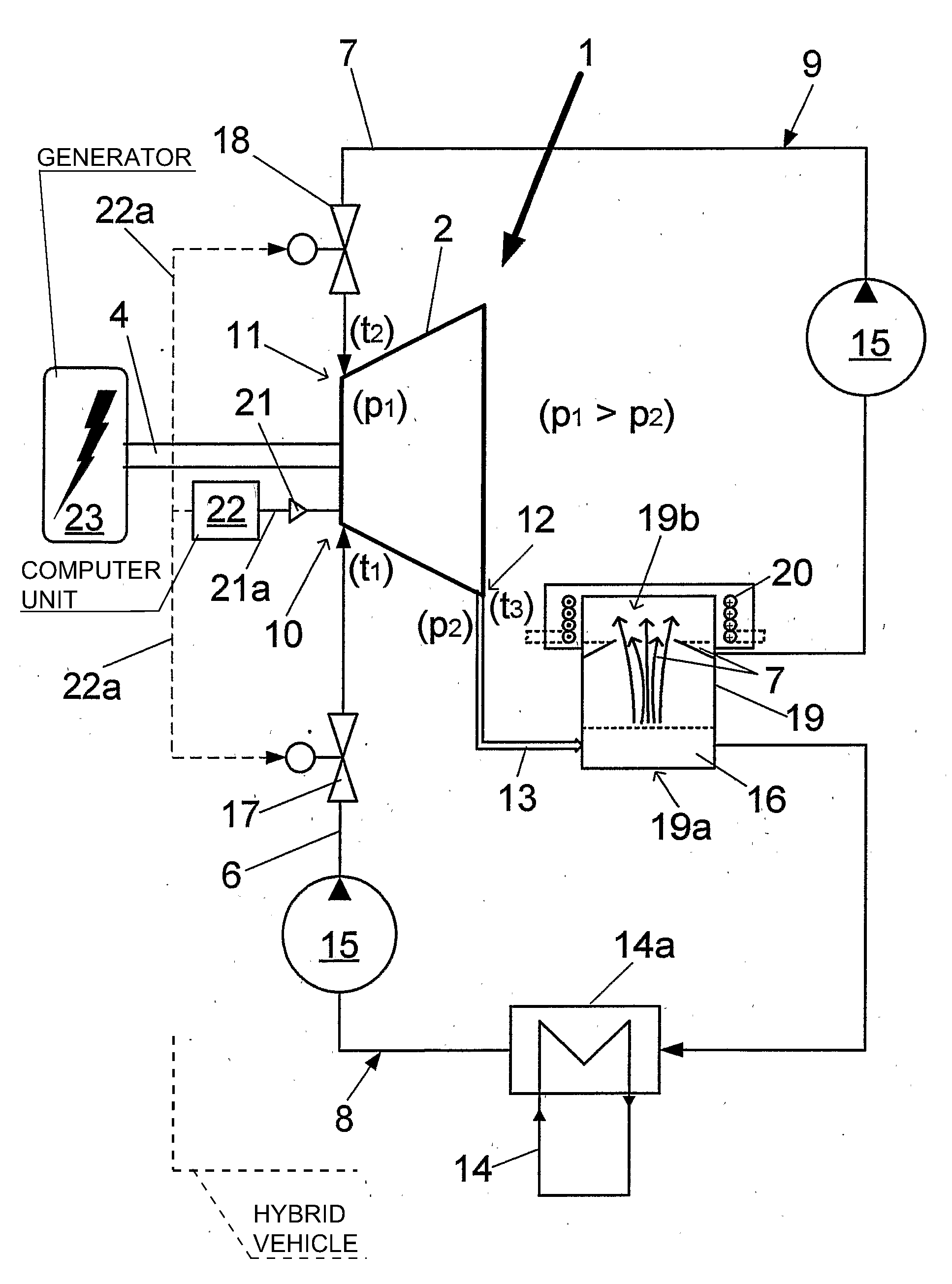

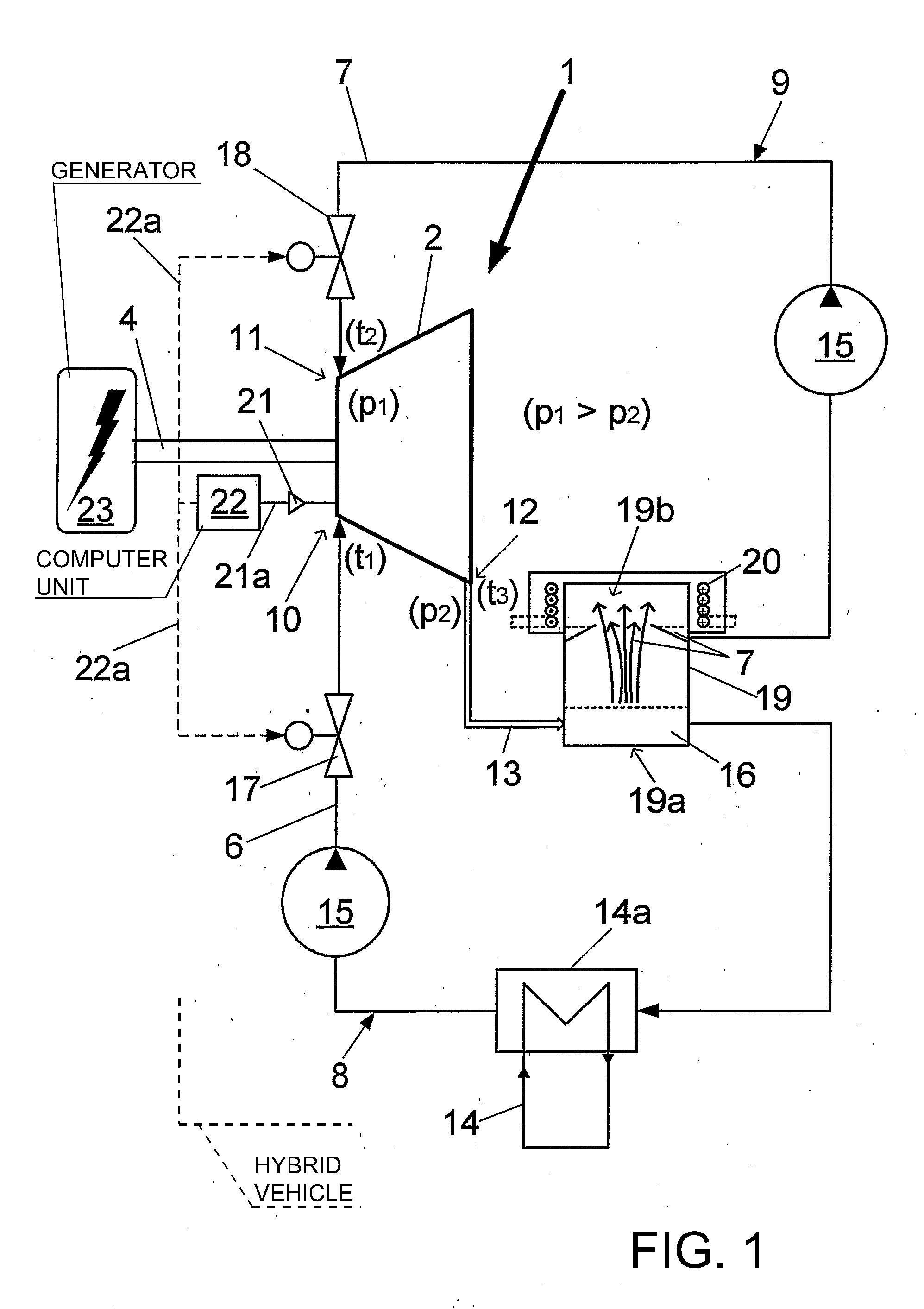

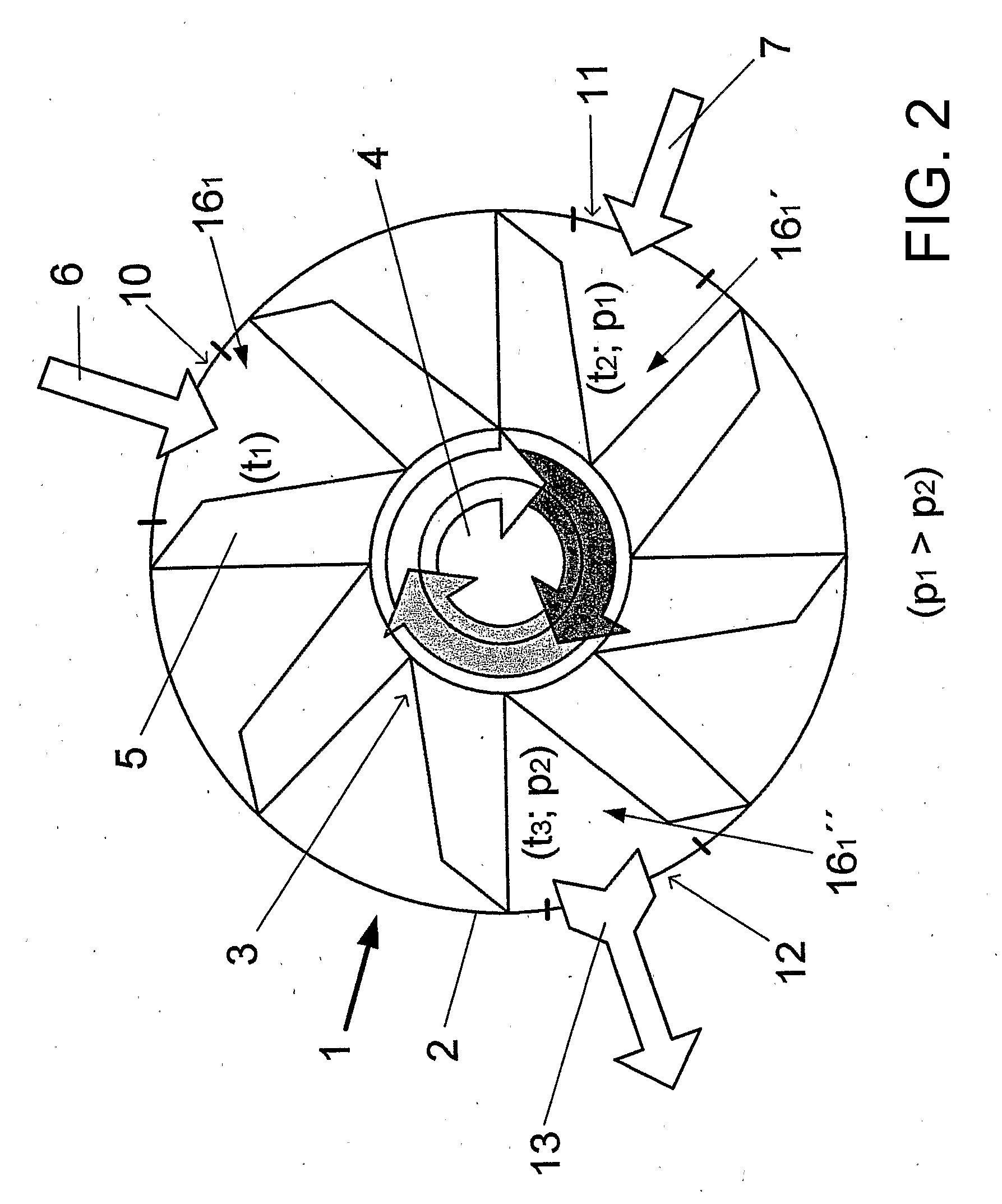

Method and device for generating mechanical energy

InactiveUS20080128188A1Easy to understandUnbalanced blockGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingOverpressureThermal energy

A method for producing mechanical energy with a rotating thermal engine includes using a first liquid working medium and at least one further liquid working medium. The at least one further working medium has a lower boiling temperature than the first working medium. When the at least one further liquid working medium is combined with the first working medium that is enriched with thermal energy, it changes to a gaseous state or expands and produces an overpressure and performs work in such a manner that a torque is applied to a rotating part of the rotating thermal engine. A device for producing mechanical energy is also provided.

Owner:GIECHAU LUTZ

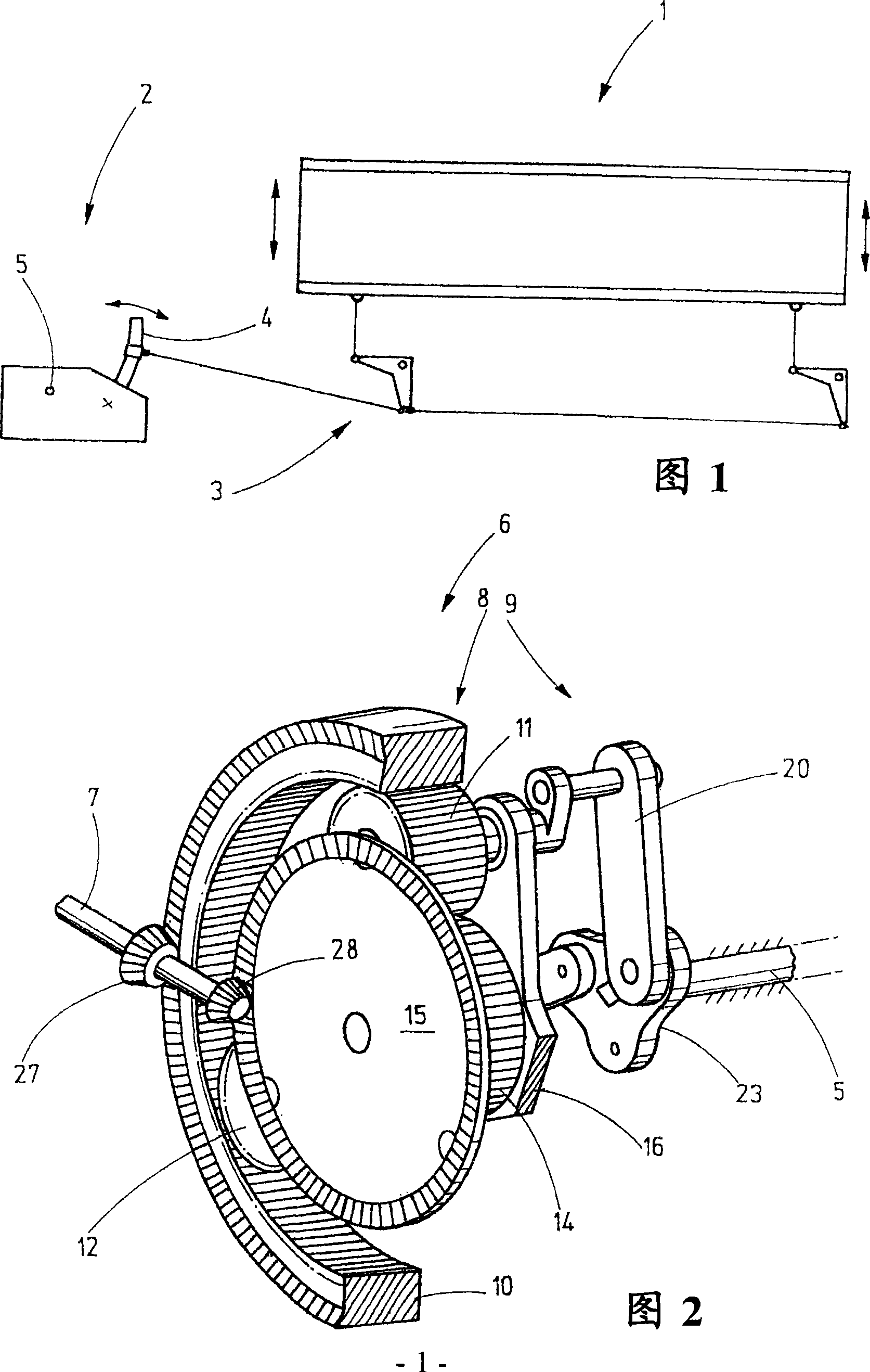

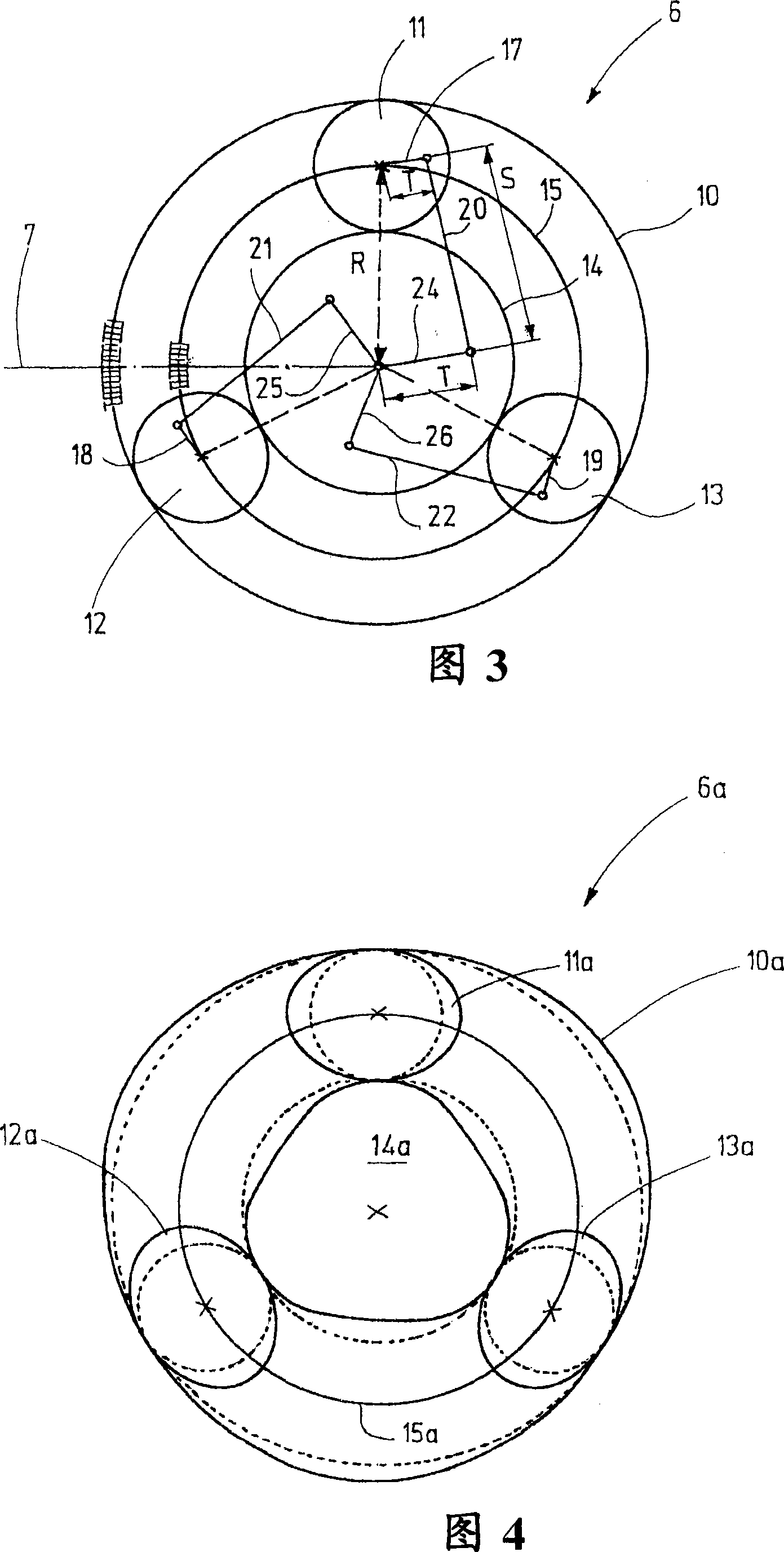

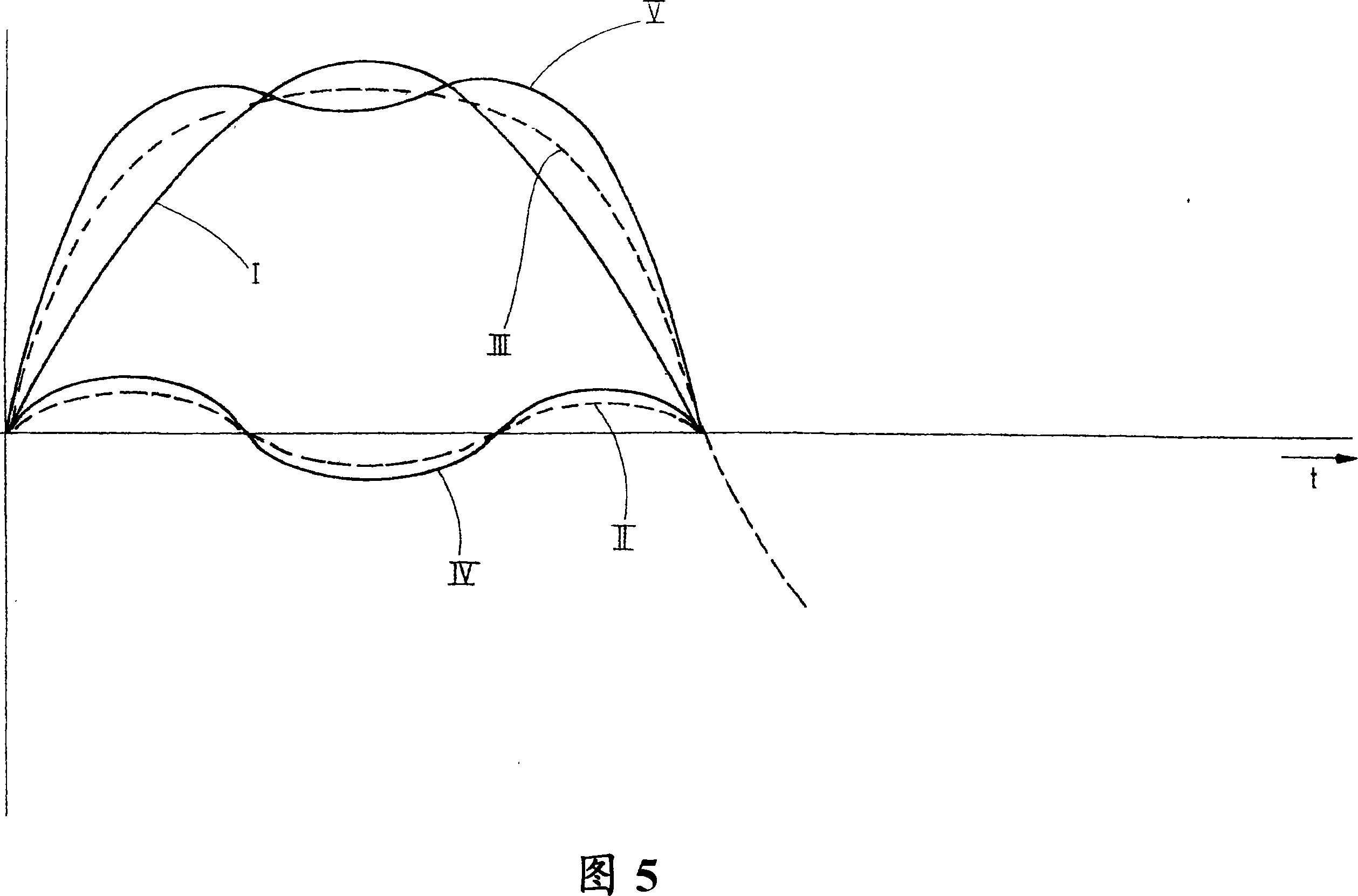

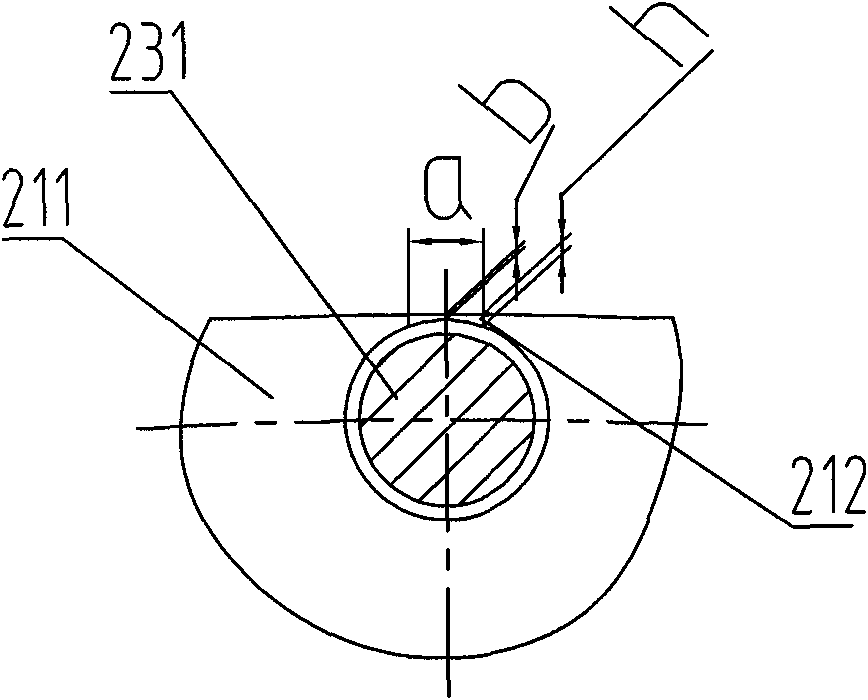

Gear mechanism for a heald shaft drive

InactiveCN101187103AAchieve continuous lubricationOptimize power distributionDobbiesLoomsSpur gearPlanet

The mechanism (6) has a planet gear (11) with an outside toothing that constantly meshes with inside toothing of a hollow gear (10), where the planet gear is rotatably positioned on a planet carrier (15). A sun gear (14) includes an outside toothing that constantly meshes with the toothing of the planet gear. A drive assembly (7) is connected to the hollow gear, planet carrier or the sun gear. An output shaft (5) is connected to the planet gear via a coupling mechanism (9). The planet gear, sun gear and the hollow gear have radii that are variable along the circumference.

Owner:GROZ BECKERT KG

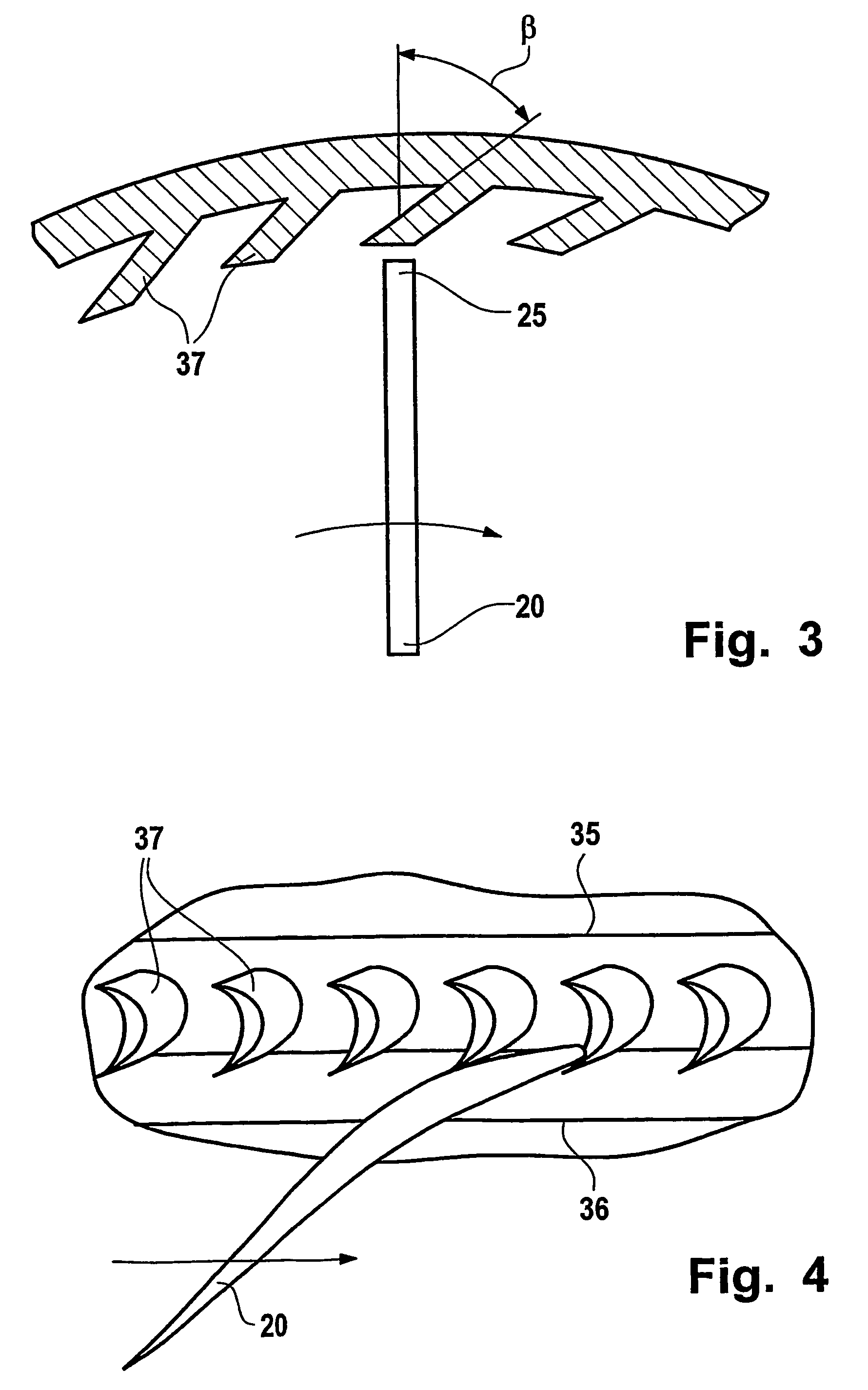

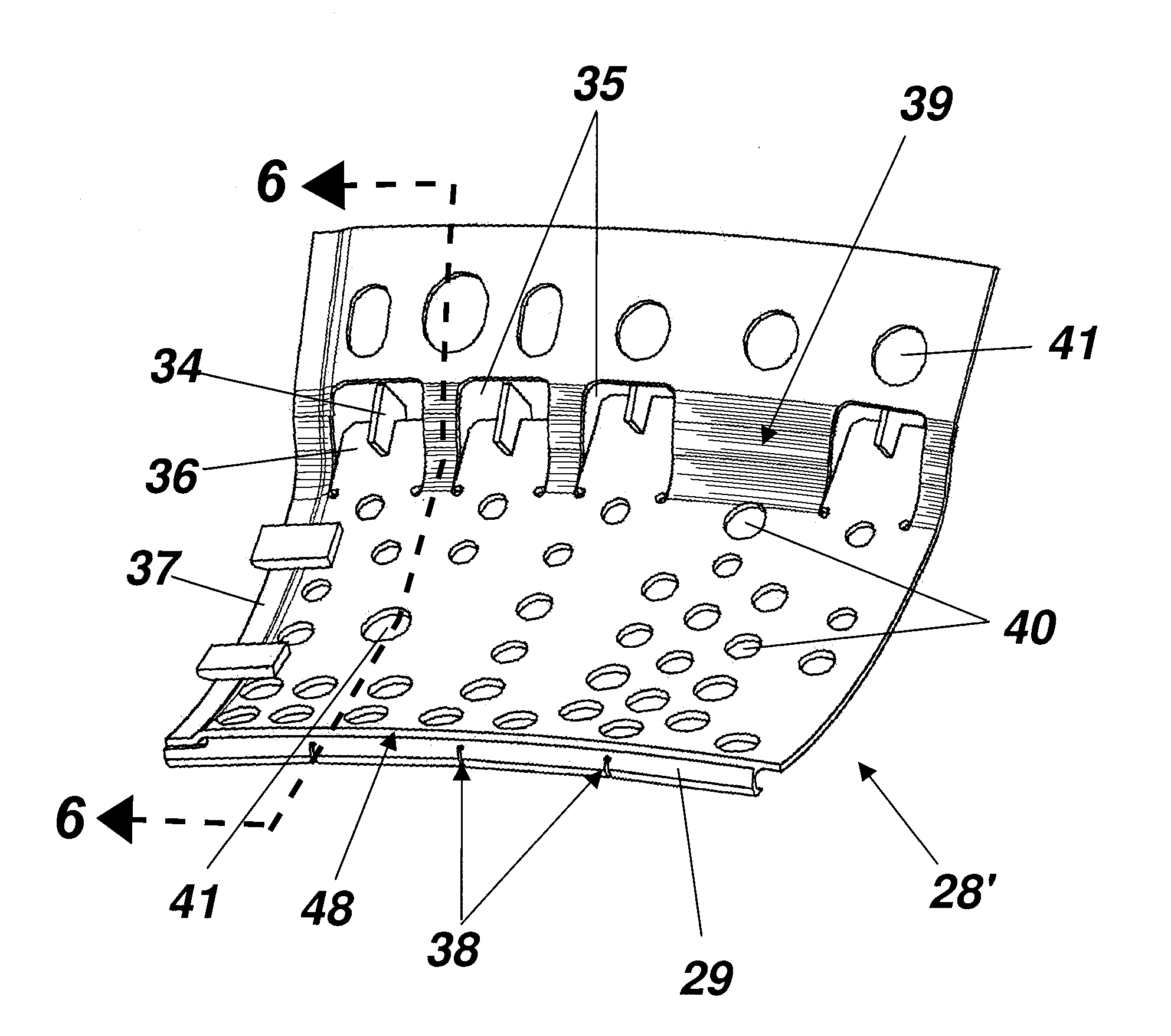

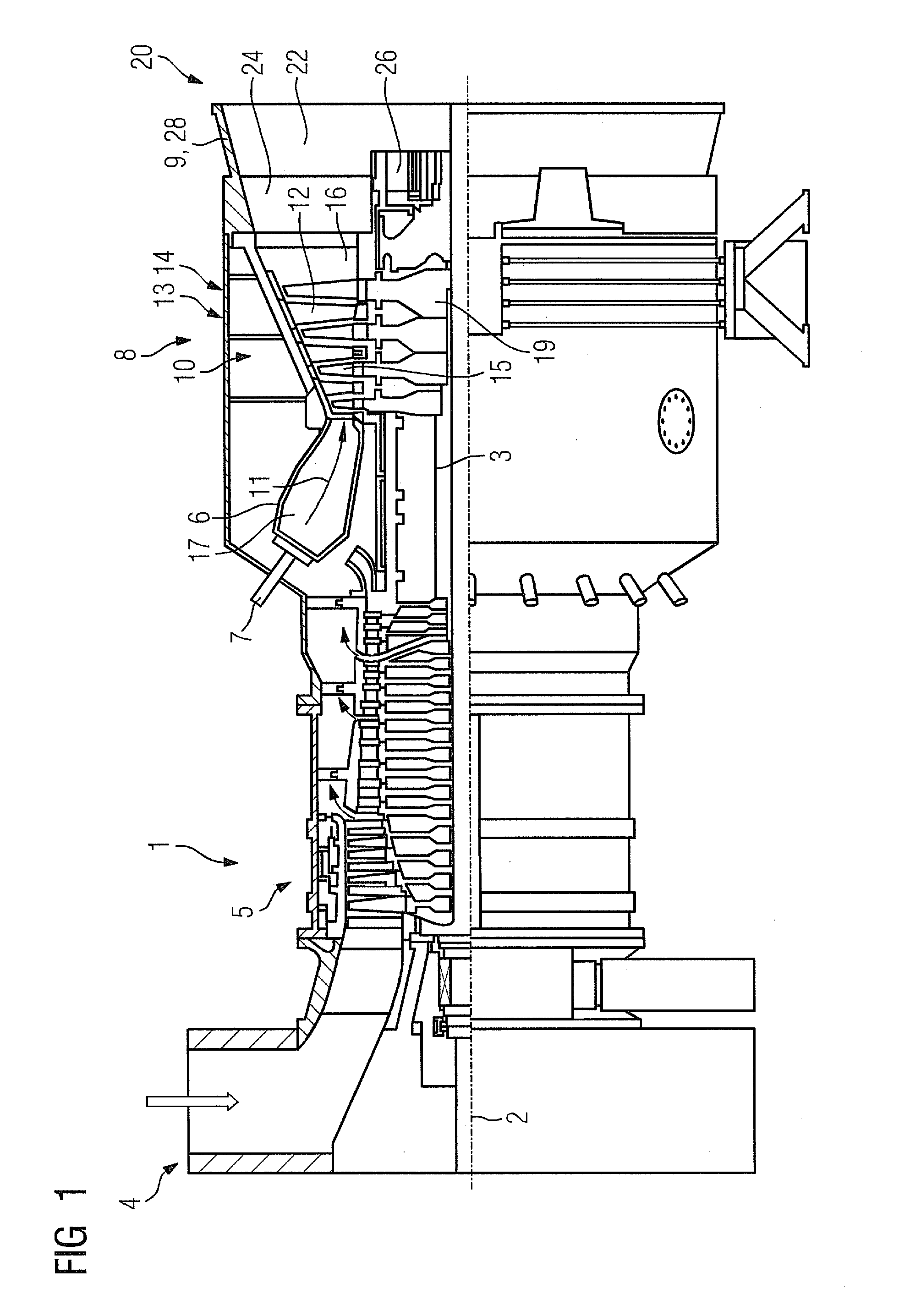

Thermal machine

ActiveUS20110113790A1Reduce lateral flowImprove efficiency levelsContinuous combustion chamberTurbine/propulsion engine coolingCooling mediumAirflow

A thermal machine including a wall defining a hot gas duct for transferring a hot gas stream and a cooling jacket disposed at a distance from the wall on an outside of the hot gas duct so as to define a cooling duct with an inlet and an outlet. The cooling duct is configured to conduct a cooling medium along an external face of the wall from the inlet to an outlet in a direction counter to a flow of hot gas in the hot gas duct. An impingement cooling plate is disposed at the inlet of the cooling duct and includes cooling baffle holes configured such that cooling medium entering the cooling duct through the cooling baffle holes flows in a direction perpendicular to the wall. The impingement cooling plate is positioned such that an inflow-side edge sealingly abuts the wall of the hot gas duct so as to reduce a transverse flow of the cooling medium through the cooling duct.

Owner:GENERAL ELECTRIC TECH GMBH

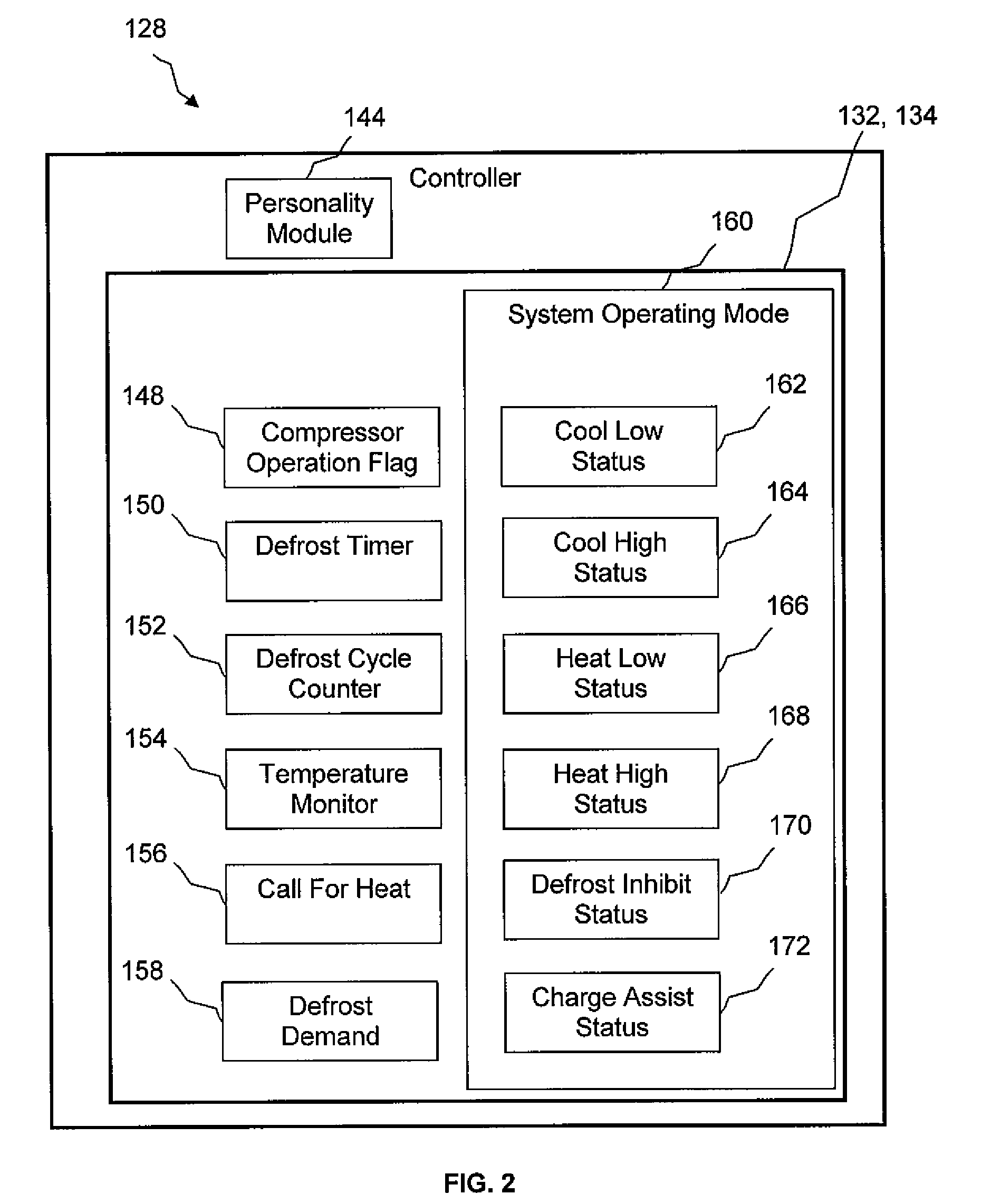

System and Method for Defrost of an HVAC System

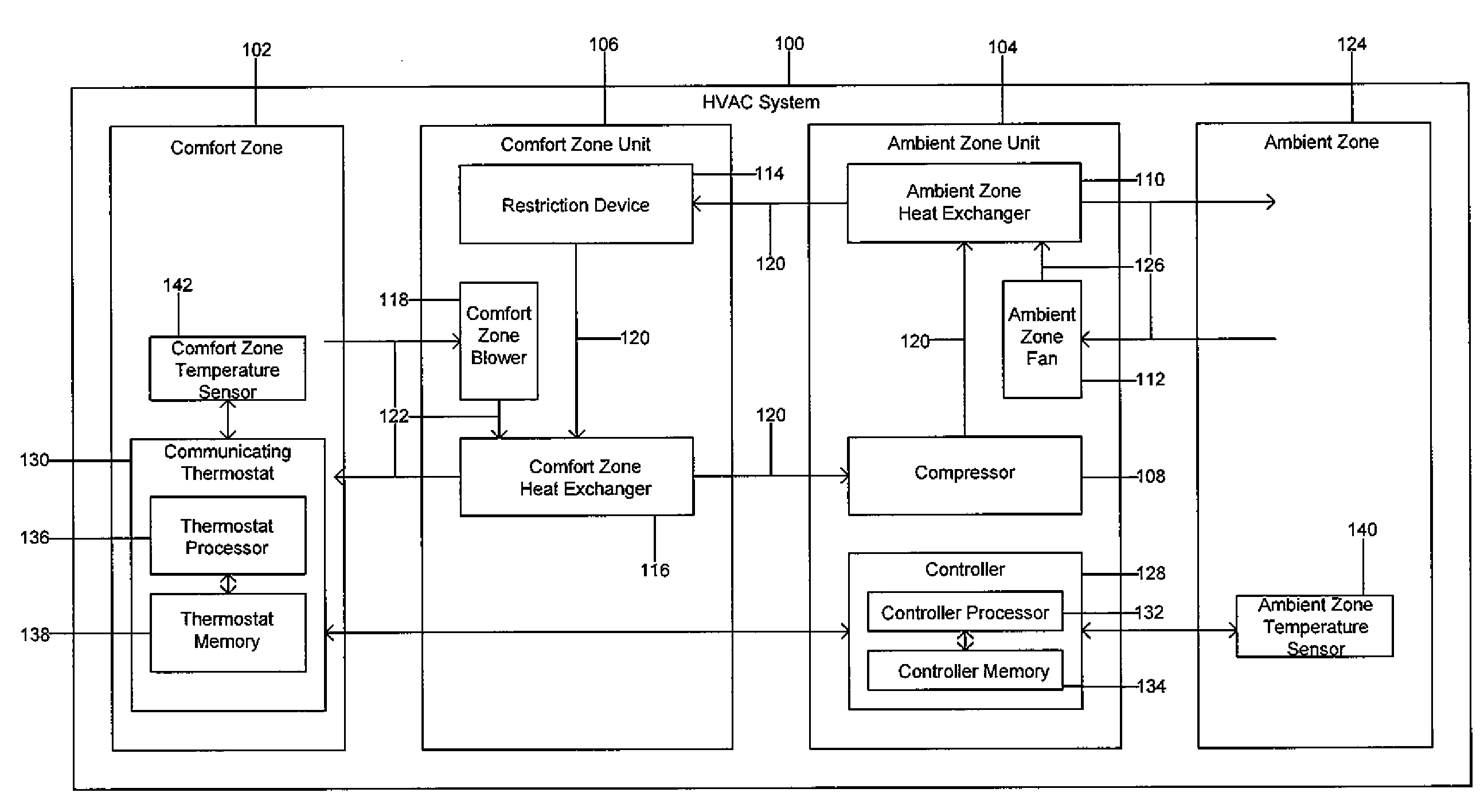

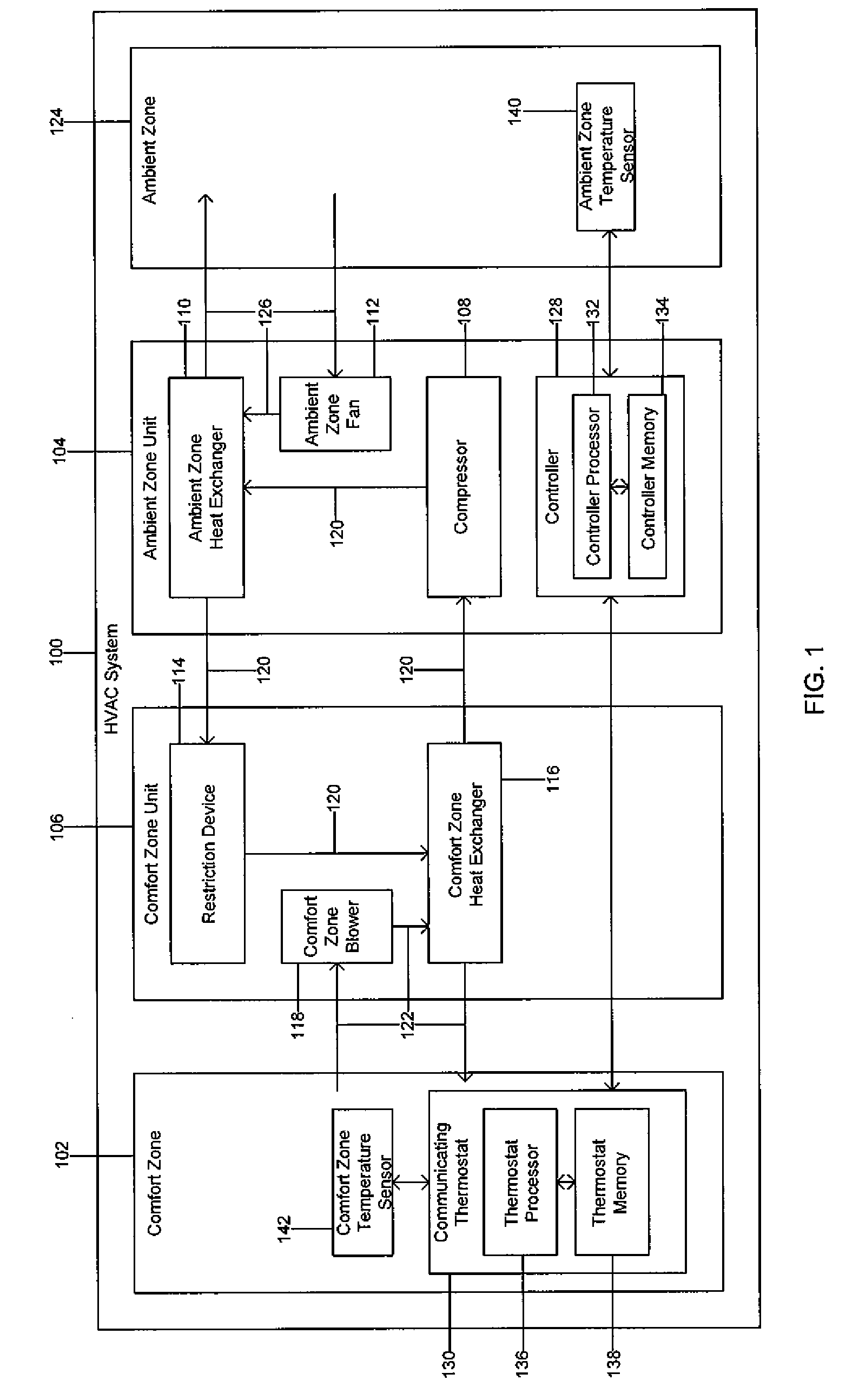

ActiveUS20100125369A1Improve efficiency levelsMechanical apparatusTemperatue controlReal-time computingHVAC

A system and a method are provided for monitoring a condition and selectively executing a certification defrost algorithm for a heating, ventilation, and air conditioning (HVAC) system in response to the status of the monitored condition. A system and a method are provided for selectively operating a certification defrost algorithm in parallel to a field defrost algorithm. A system and a method are also provided for causing a controller to execute a first algorithm and for causing the controller to selectively execute a second algorithm while also executing the first algorithm where each of the first algorithm and the second algorithm are configured to selectively cause the HVAC system to operate in a defrost mode.

Owner:TRANE INT INC

Impingement cooling plate for a hot gas duct of a thermal machine

ActiveUS8272220B2Improve efficiency levelsImprove cooling effectContinuous combustion chamberTurbine/propulsion engine coolingShock coolingCooling medium

A thermal machine including a wall defining a hot gas duct for transferring a hot gas stream and a cooling jacket disposed at a distance from the wall on an outside of the hot gas duct so as to define a cooling duct with an inlet and an outlet. The cooling duct is configured to conduct a cooling medium along an external face of the wall from the inlet to an outlet in a direction counter to a flow of hot gas in the hot gas duct. An impingement cooling plate is disposed at the inlet of the cooling duct and includes cooling baffle holes configured such that cooling medium entering the cooling duct through the cooling baffle holes flows in a direction perpendicular to the wall. The impingement cooling plate is positioned such that an inflow-side edge sealingly abuts the wall of the hot gas duct so as to reduce a transverse flow of the cooling medium through the cooling duct.

Owner:GENERAL ELECTRIC TECH GMBH

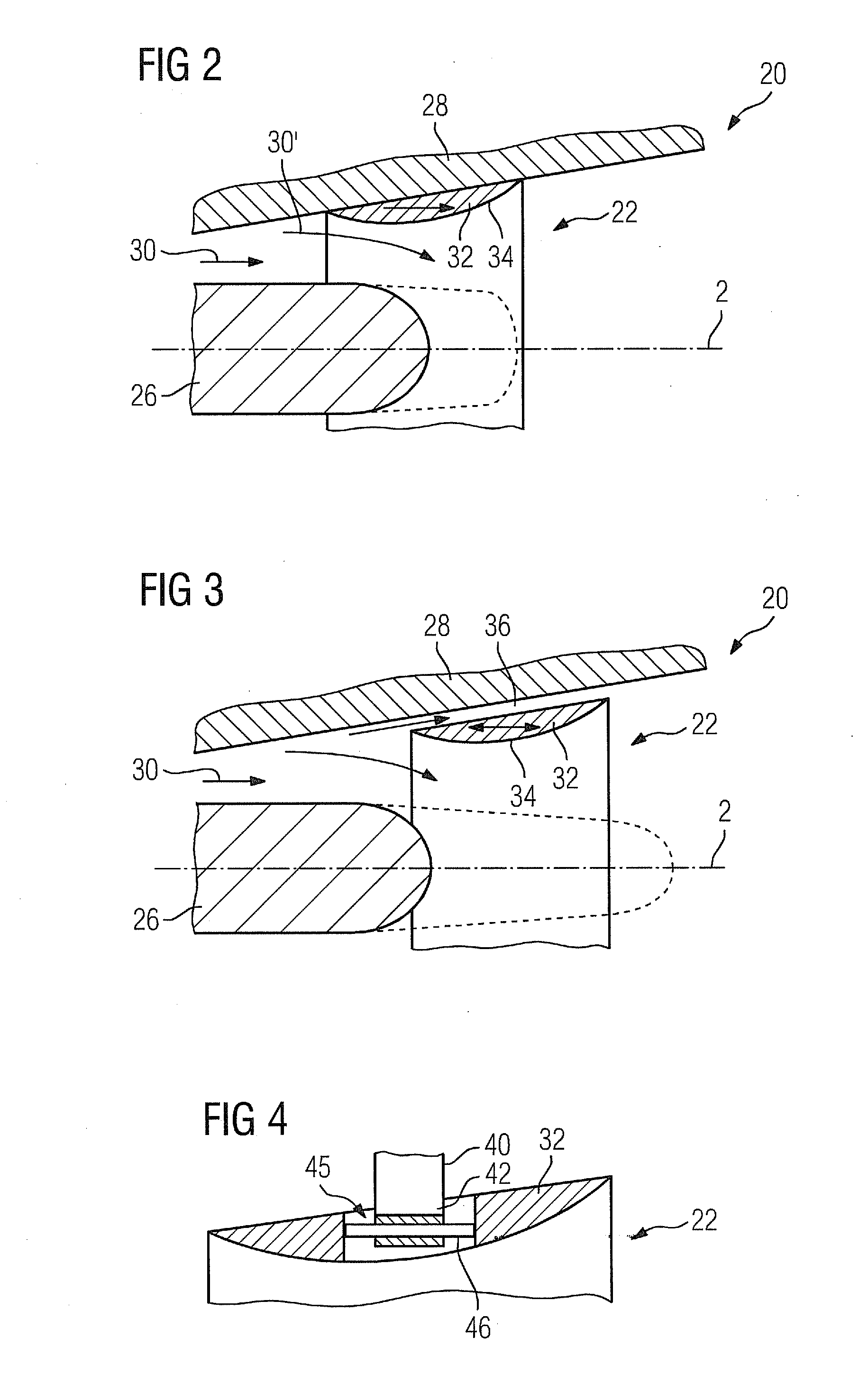

Exhaust gas diffuser for a gas turbine and a method for operating a gas turbine that comprises such an exhaust gas diffuser

InactiveUS20130115044A1Improve efficiency levelsGuaranteed uptimeEngine manufacturePump componentsGas turbinesAerodynamics

An exhaust gas diffuser for a gas turbine is provided. The diffuser has an annular outer wall for guiding the diffuser flow and in which an annular guiding element is arranged concentrically to the outer wall and influences the diffuser flow. The guiding element has a surface which is radially directed inwards and has a circumferential contour that is convex in the longitudinal section to form a displacement element. The guiding element is axially displaceable between two positions so that the guiding element, when in a first position, allows a flow between the guiding element and outer wall and, when in a second position, largely prohibits a flow between the guiding element and outer wall. The aerodynamic effect of the diffuser is improved and simultaneously optimal adapted for a plurality of operational gas turbine states.

Owner:SIEMENS AG

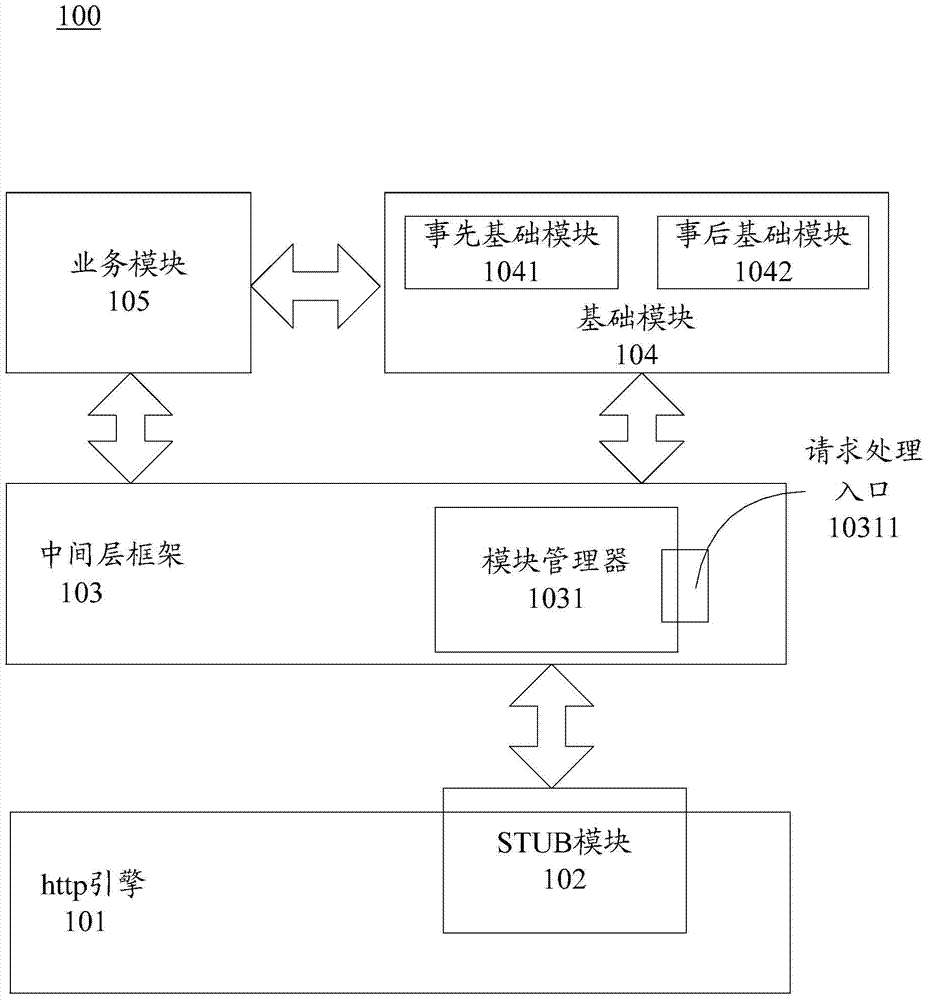

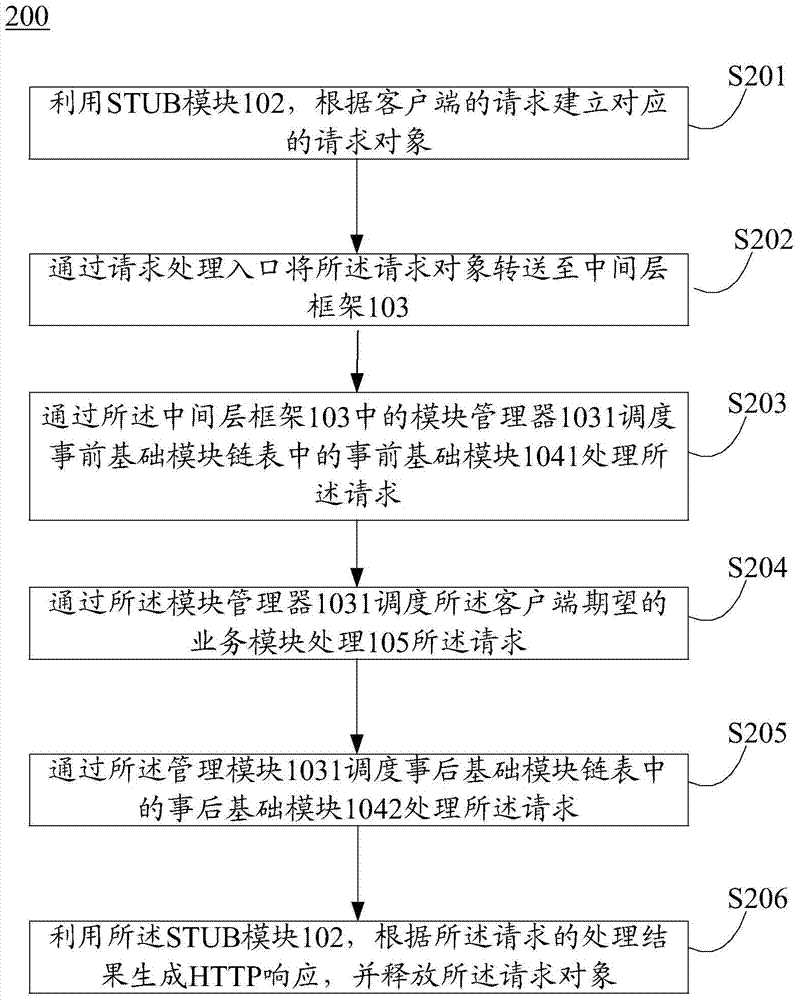

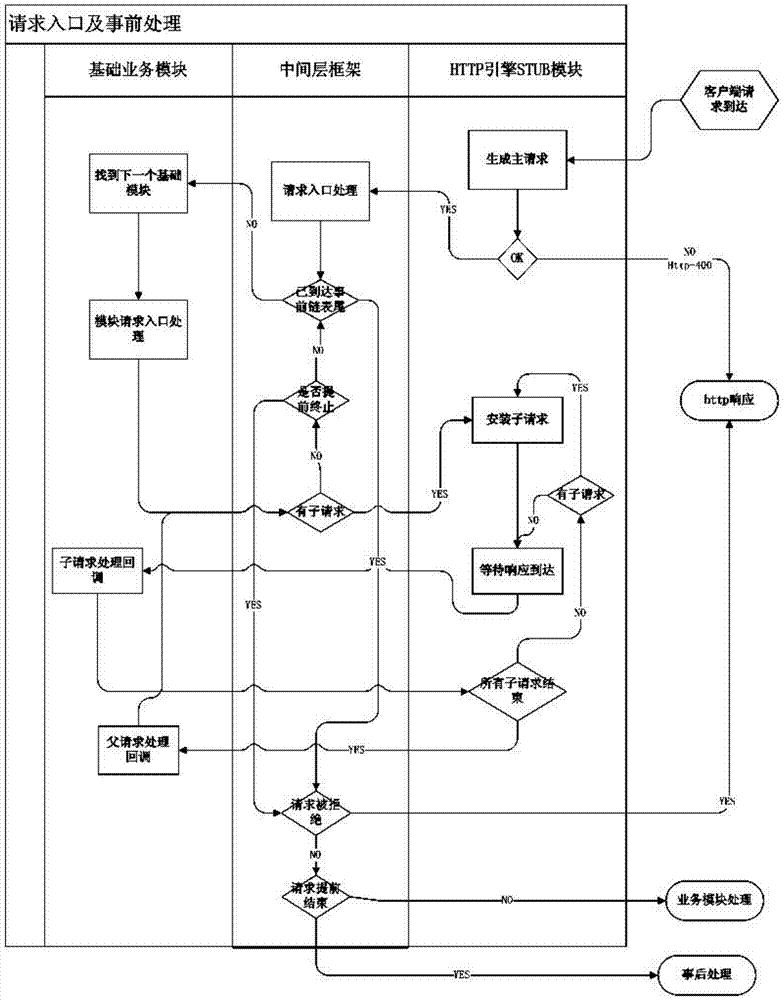

Server application system development framework and running method thereof

The invention discloses a server application system development framework and a running method of the server application system development framework. The method includes the steps that corresponding request objects are established through a STUB module according to requests of clients; the request objects are transferred to a middle layer framework through a request processing entry; before-event basic module processing requests in a before-event basic module linked list are dispatched through a module manager in the middle layer framework; service module processing requests expected by clients are dispatched through the module manager; after-event basic module processing requests in an after-event basic module linked list are dispatched through a management module; HTTP responses are generated with the STUB module according to the processing results of the requests, and the request objects are released. Module extension is simpler, and the module can be extended as long as a simple modular constraint of the middle layer framework is met. The development process is standardized through the request objects and parent and child request structure packaging of the service process. The service development process is a process for establishing the request objects.

Owner:ALIBABA (CHINA) CO LTD

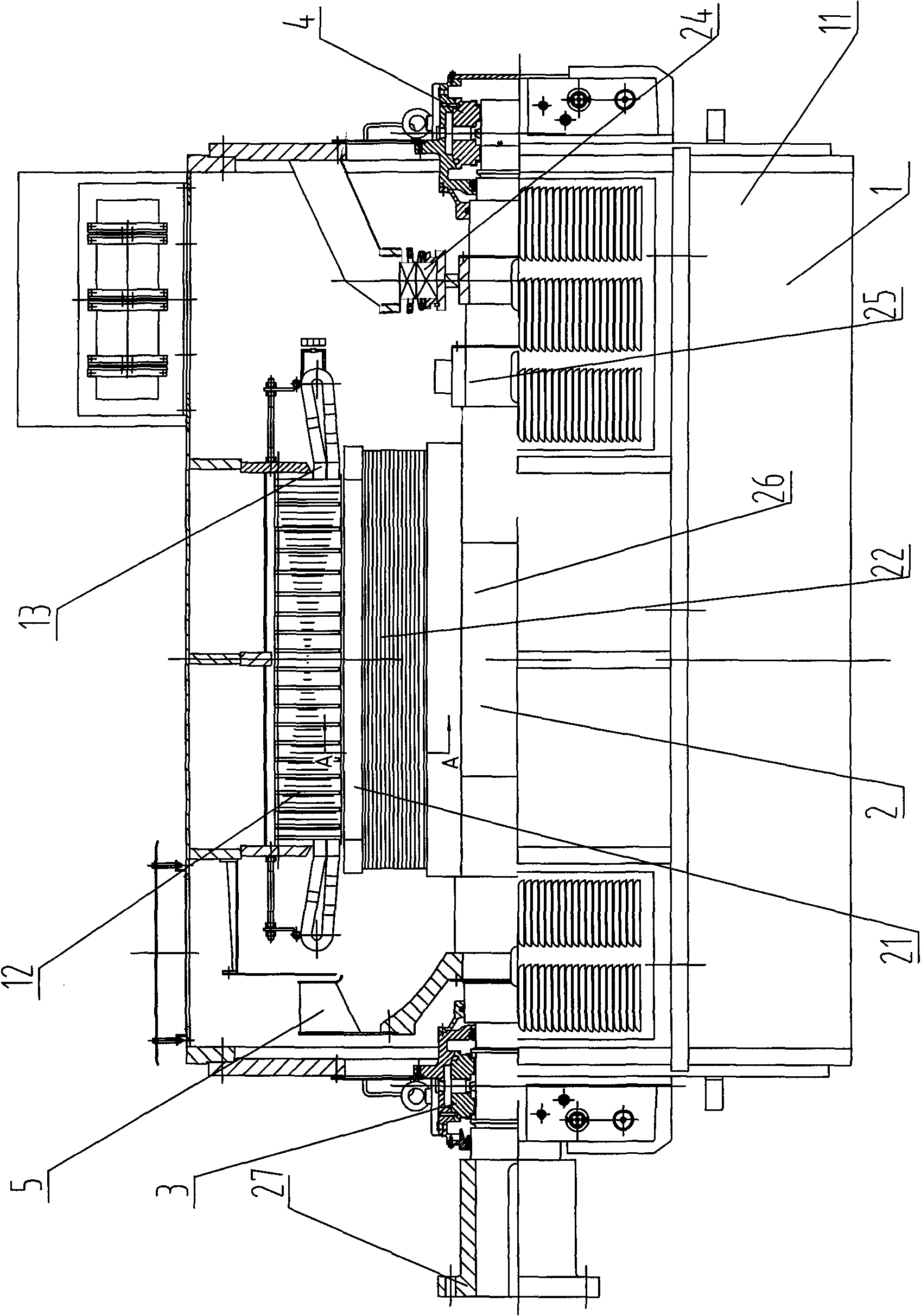

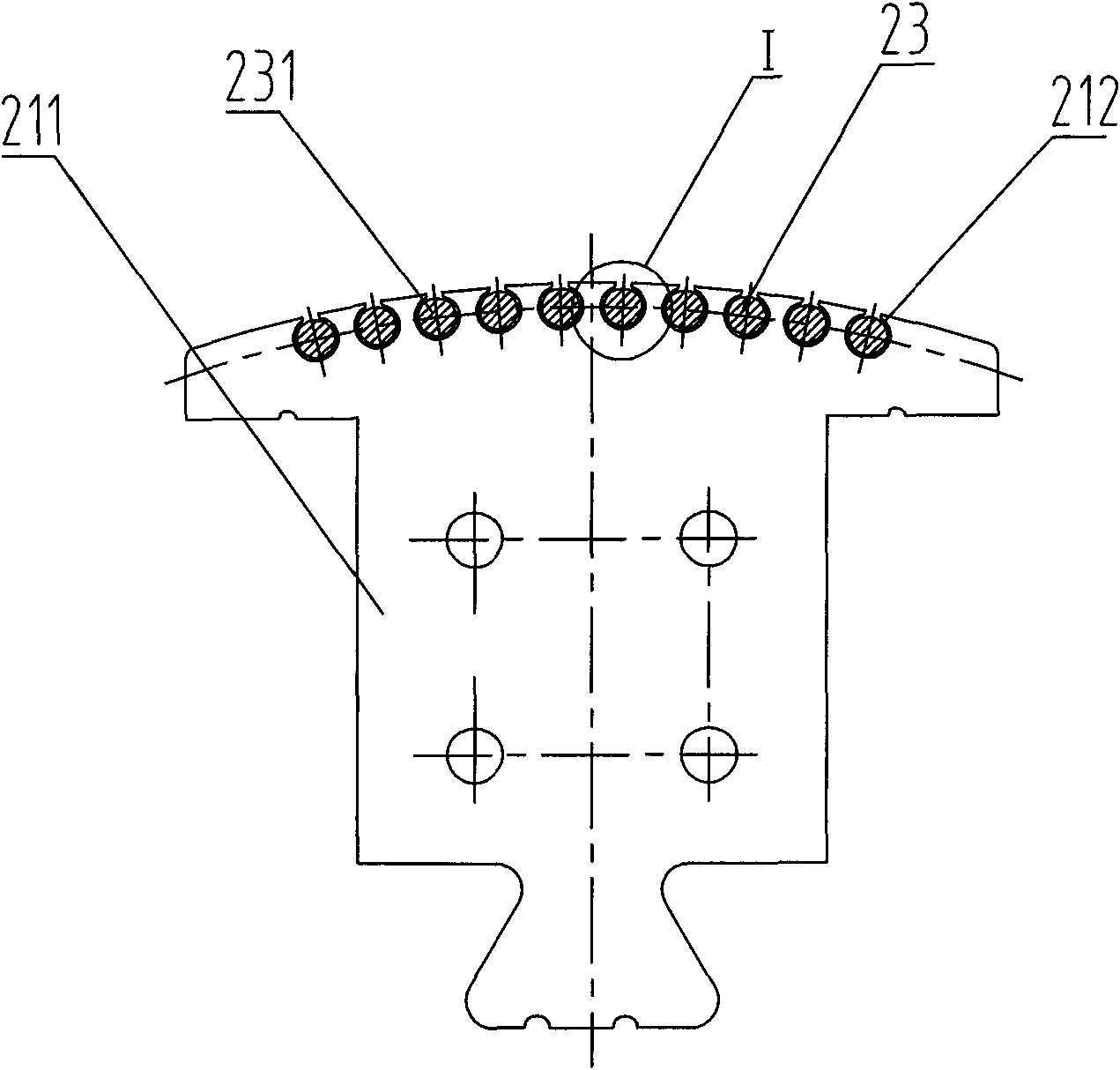

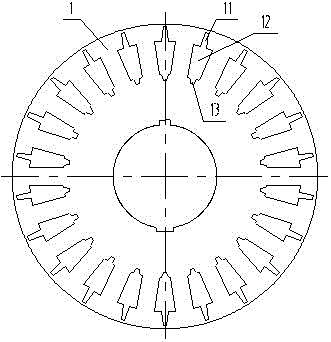

Ultrastrong damping high-voltage synchronous motor

ActiveCN101789660AEnhanced surface eddy current lossImprove damping effectSynchronous generatorsMagnetic circuit rotating partsSynchronous motorHarmonic

The invention discloses an ultrastrong damping high-voltage synchronous motor which comprises a generator stator and a generator rotor, wherein the generator stator comprises a stand, an iron core and a rotor coil, and the generator rotor comprises a magnetic pole iron core, magnetic pole coils, an ultrastrong damping winding, an alternating current exciter rotor, a rotating rectifier and a rotating shaft; and a plurality of magnetic pole coils form a complete magnetic pole winding, a plurality of axial damping slotted holes are uniformly distributed at the radial periphery of the magnetic pole iron core, a plurality of damping winding copper rods respectively penetrates into each damping slotted hole of the magnetic pole iron core, and both ends thereof are respectively welded with a damping ring to form a cage-shaped whole. The width a of a damping hole notch on the magnetic pole iron core is 6-8mm, the depth h is 0.5-1mm, and the distance b to a magnetic pole surface is 0.4-0.5mm. The damping winding of the invention has ultrastrong damping effect, so that the harmonic inhabiting capability and the dynamic performance of the invention are greatly enhanced, thereby greatly improving the capability of carrying nonlinear loads.

Owner:ZHENJIANG ZHONGCHUAN XIANDAI GENERATING EQUIP CO LTD

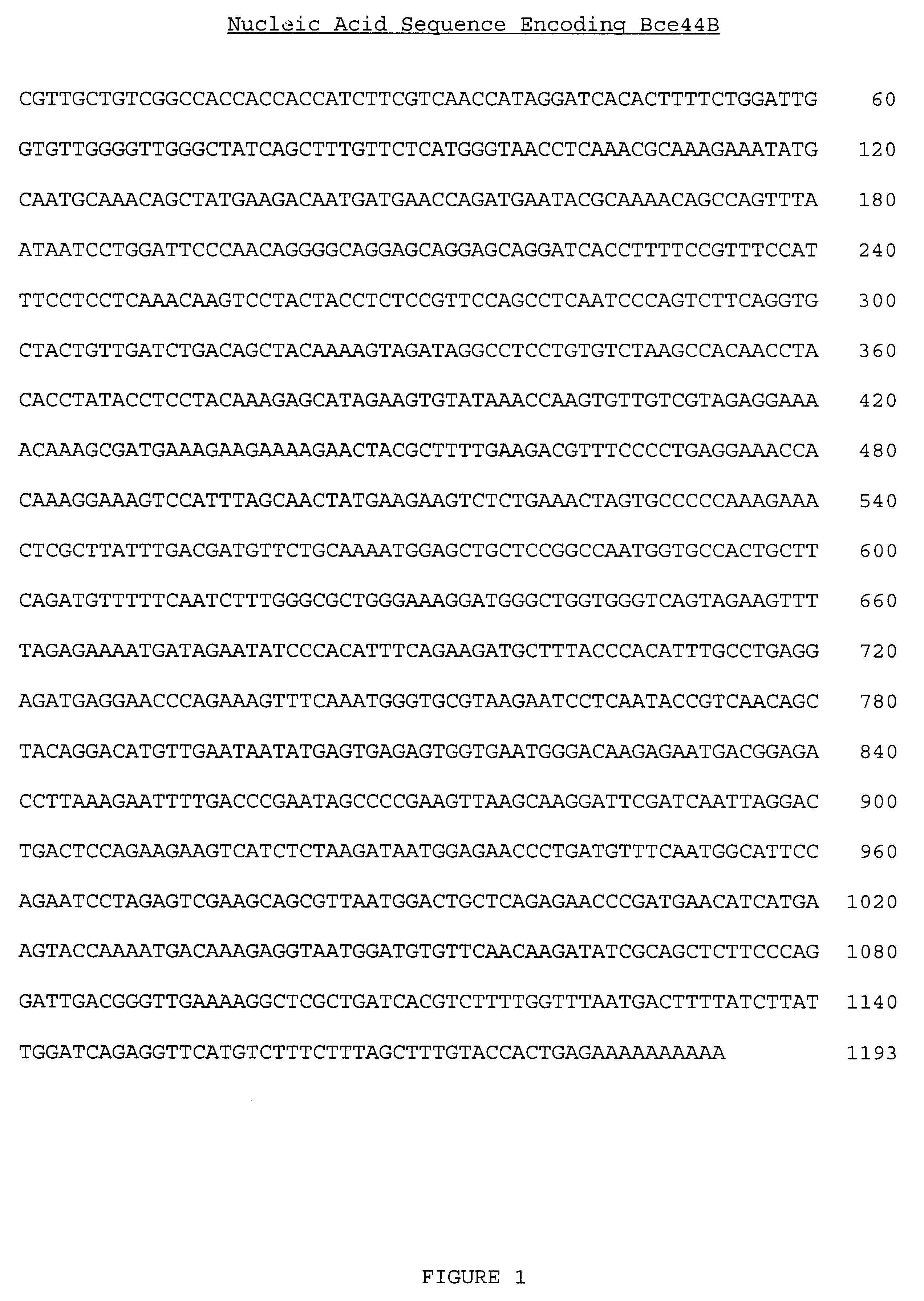

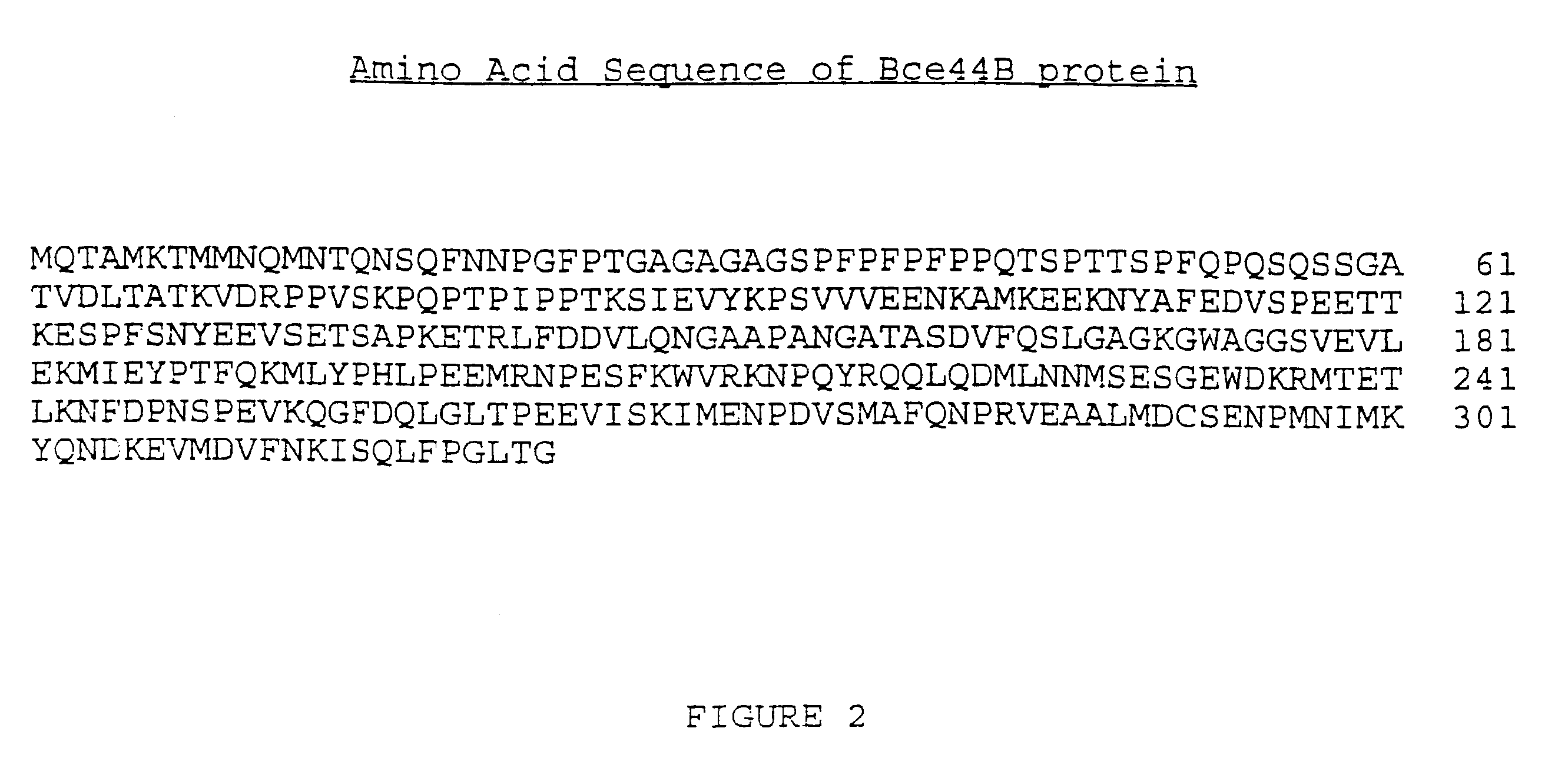

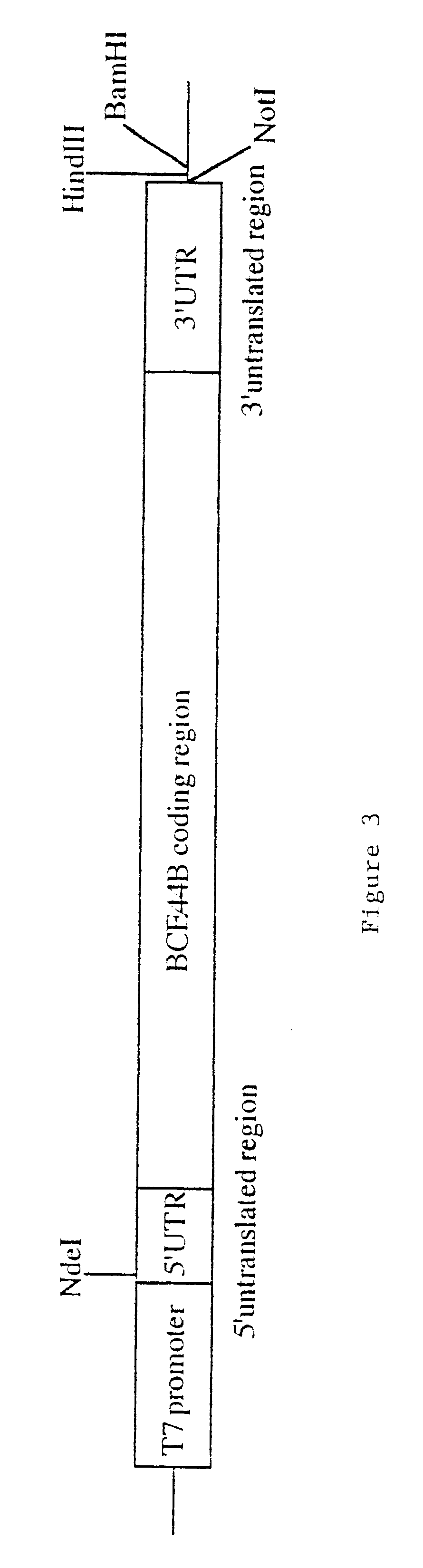

Enhanced transport with a plastid membrane transport protein

InactiveUS6353153B1Improve efficiency levelsReduce the possibilityBacteriaMicrobiological testing/measurementGenetic enhancementCell membrane

A novel method to enhance translocation of molecules across or into cellular membranes using a plastid protein transport gene is described. The method can also be used to incorporate substances into membranes of organisms. Nucleic acid constructs include those which express a plastid protein transport protein or its equivalent in cells of all organisms.

Owner:QUEENS UNIV OF KINGSTON

Powering unit with full bridge and wide adjusting range circuit

InactiveUS8107261B2Low costLess energyEmergency protective circuit arrangementsDc-dc conversionFull bridgeBridge type

Owner:SIEMENS AG

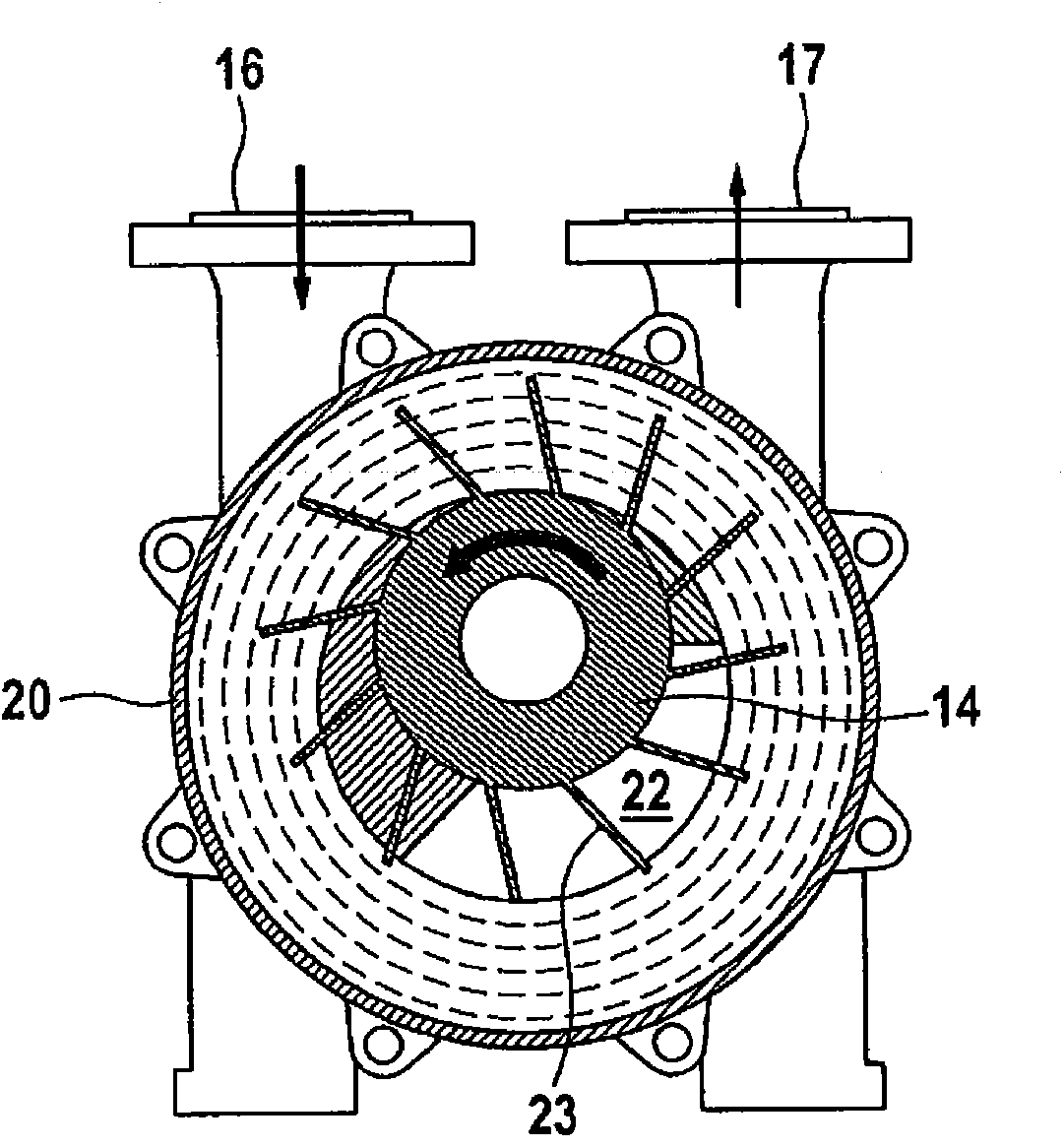

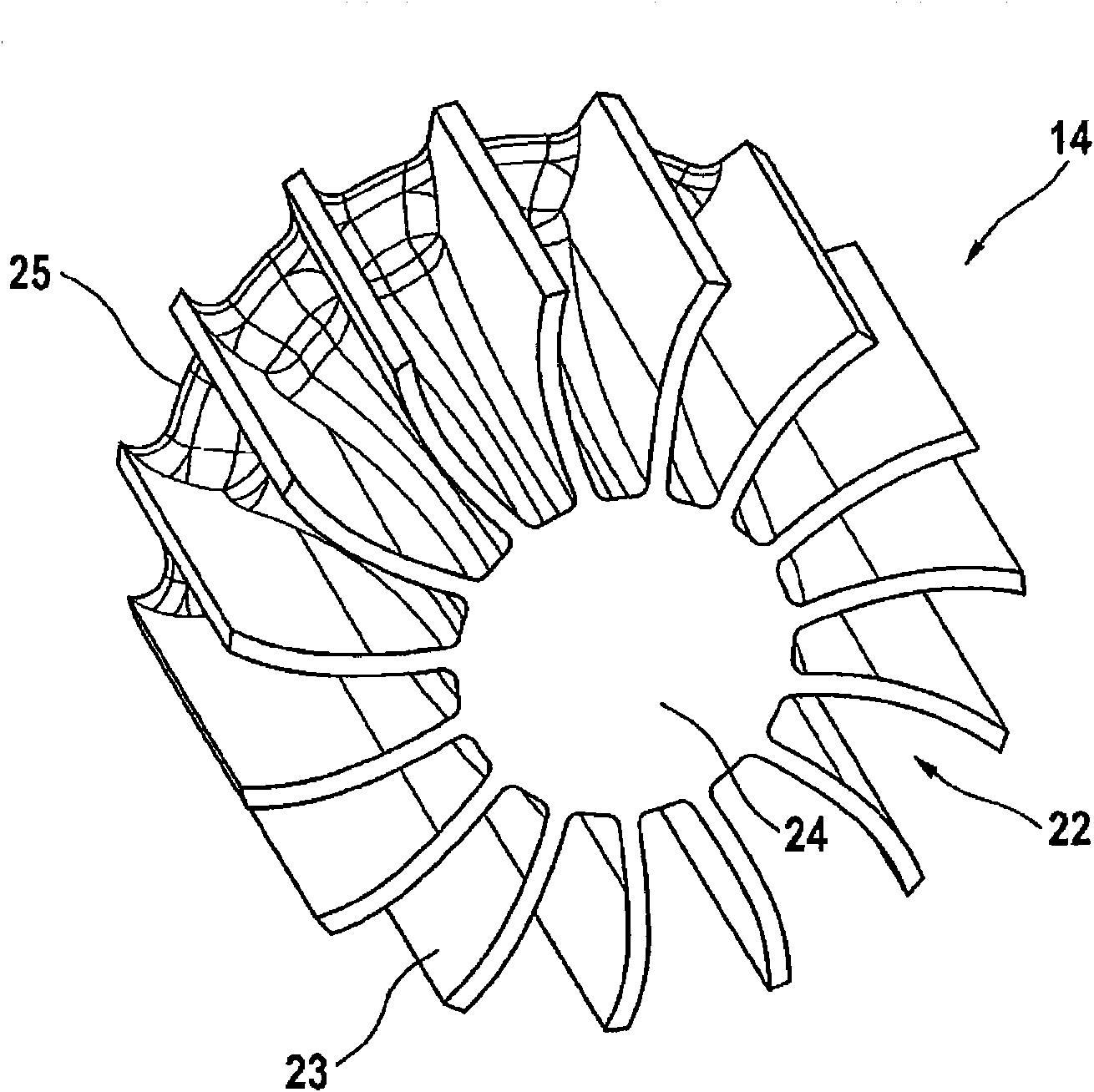

Liquid-ring vacuum pump, and impeller for a liquid-ring vacuum pump

ActiveCN104081004AImprove efficiency levelsImprove Tolerance BalanceRotary piston pumpsMachines/enginesImpellerCavitation

The invention relates to a liquid-ring vacuum pump comprising a pump casing (20) and an impeller (14) that is eccentrically mounted in the pump casing (20). According to the invention, the impeller (14) is made of a material having a modulus of elasticity of less than 4000 N / mm2. The invention further relates to an impeller (14) for such a pump. The disclosed impeller allows the pump to operate closer to the cavitation limit.

Owner:斯特林工业咨询有限公司

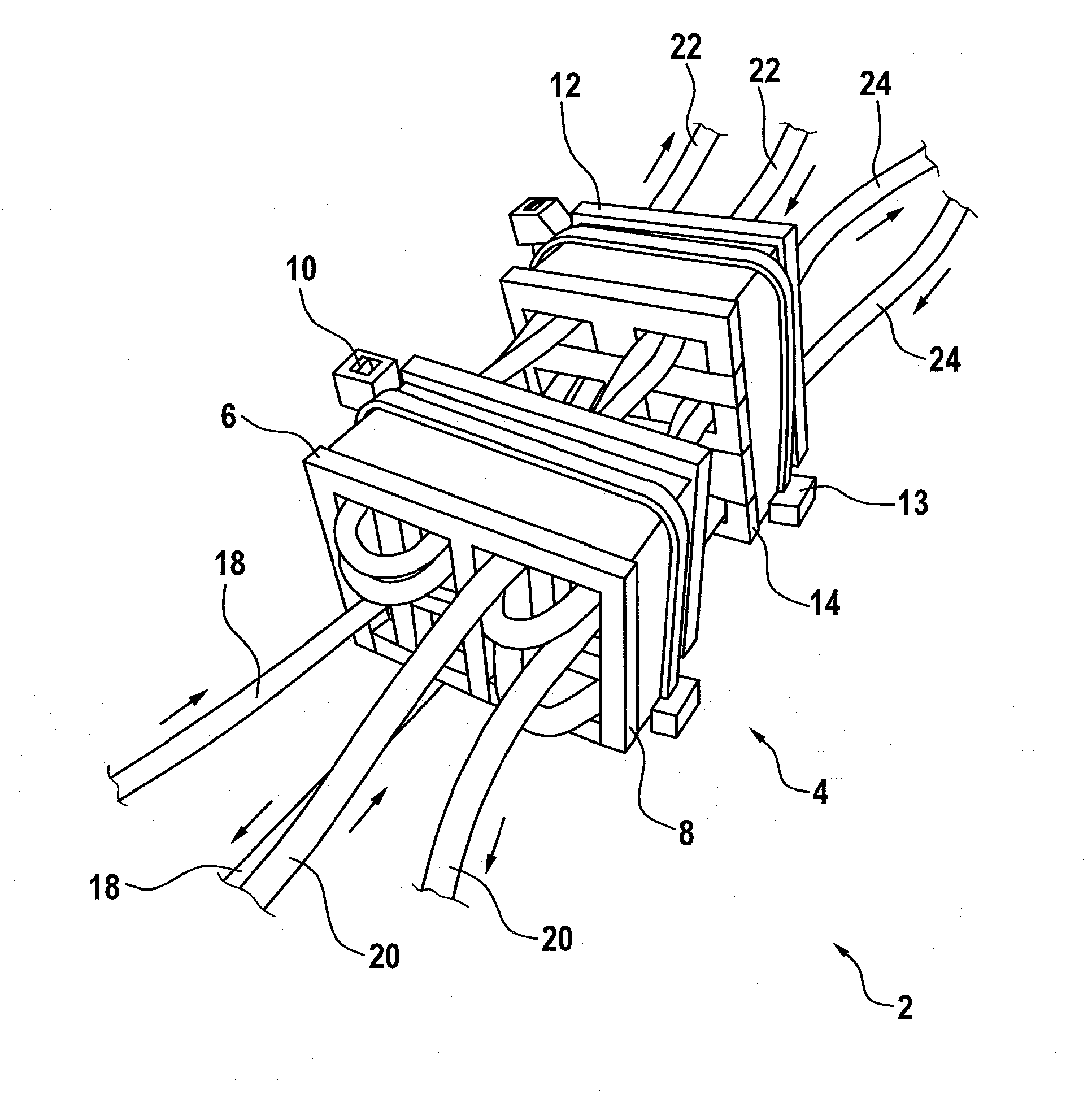

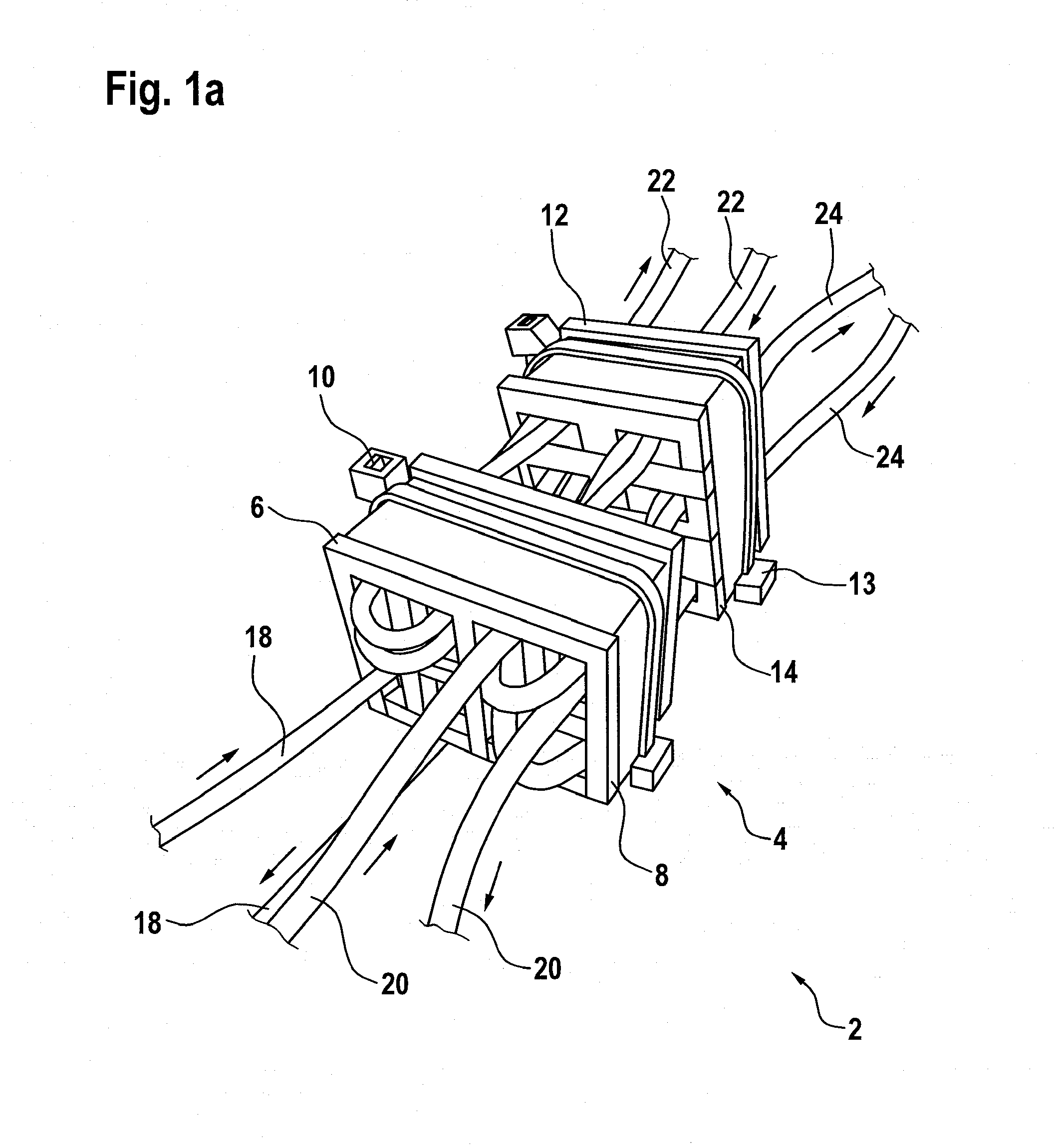

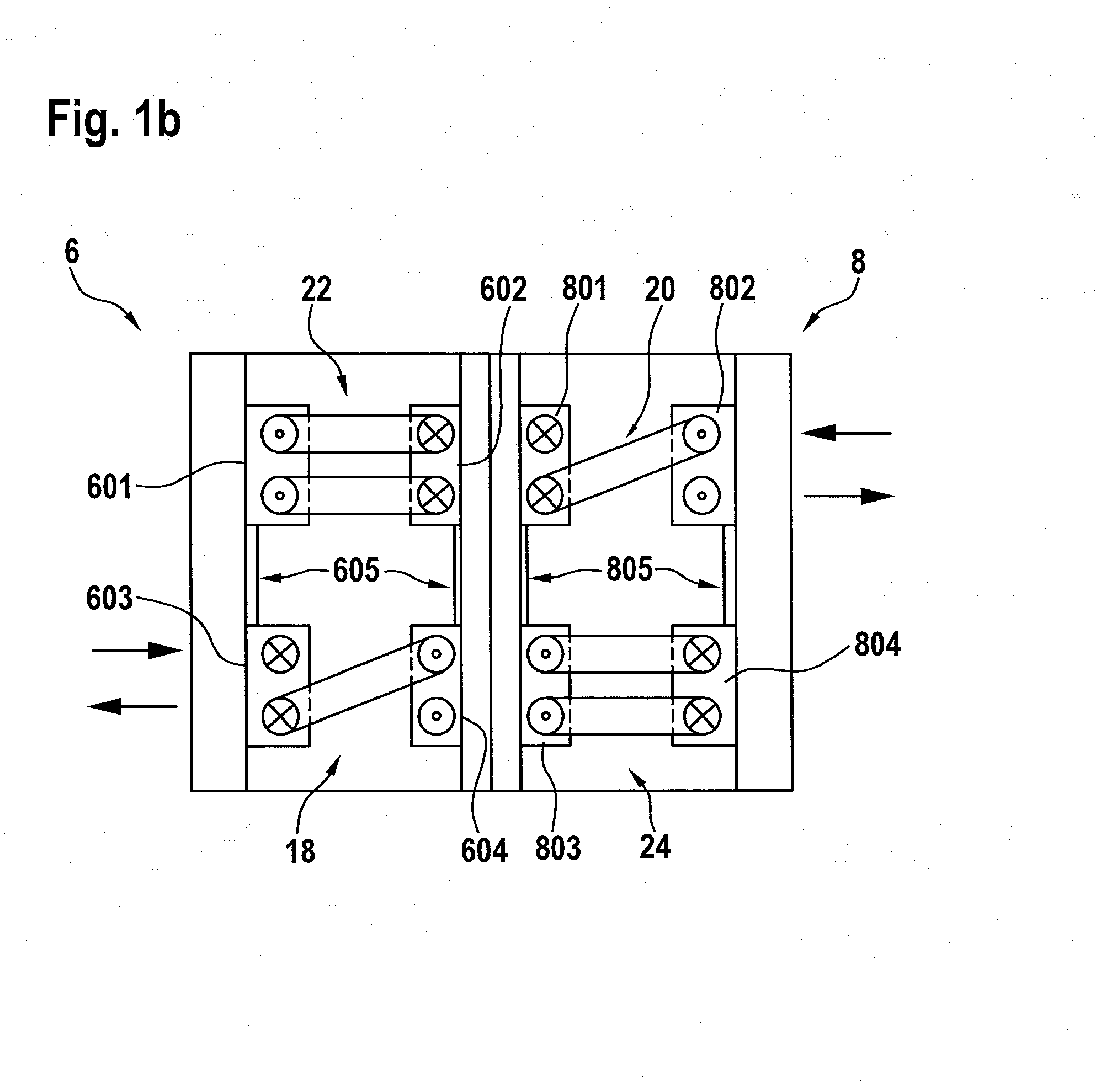

Coupling device for a multi-phase converter

ActiveUS20150028844A1Reduced magnetic modulationSmall core lossesEfficient power electronics conversionApparatus with intermediate ac conversionElectrical conductorEngineering

The invention relates to a coupling device (4) for four phases of a multi-phase converter (2). Said coupling device (4) includes four coupling modules (6, 8, 12, 14), each of which encompasses four parallel through-holes. At least one section of a conductor loop (18, 20, 22, 24) for a phase. At least one section of a conductor loop (18, 20, 22, 24) for a phase penetrates a through-hole of a coupling module (6, 8, 12, 14), sections of conductor loops (18, 20, 22, 24) for at least two phases penetrating all four through-holes of a coupling module (6, 8, 12, 14).

Owner:ROBERT BOSCH GMBH

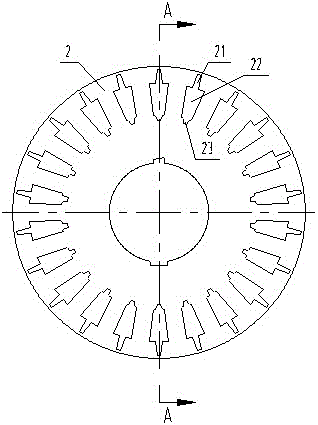

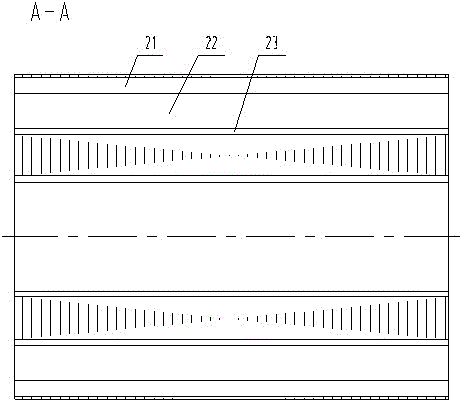

Motor rotor

PendingCN106849575AImprove efficiency levelsPrevent copper strips from movingAsynchronous induction motorsCentering/balancing rotorsPhysicsMotor efficiency

The invention discloses a motor rotor which comprises a rotor core, an inverted trapezoidal copper conducting bar, an outer aluminum conducting bar and an inner aluminum conducting bar. The structure of the motor rotor is characterized in that the rotor core is formed by laminating rotor punching sheets; an outer groove, a middle groove and an inner groove are annually distributed on the outer side of the circumference of the rotor punching sheet; the rotor punching sheets are stacked together to form an outer conducting bar hole, a middle conducting bar hole and an inner conducting bar hole in the rotor core; the inverted trapezoidal copper conducting bar is inserted into the middle conducting bar hole, the outer aluminum conducting bar is casted in the outer conducting bar hole, the inner aluminum conducting bar is casted in the inner conducting bar hole, aluminum end rings are casted on both ends of the rotor core and are provided with aluminum fan blades and aluminum balance columns; the outer aluminum conducting bar, the inner aluminum conducting bar, the aluminum end rings, the aluminum fan blades and the aluminum balance columns are integrally formed and are manufactured via a cast process. The motor rotor is higher in motor efficiency than a cast-aluminum structured rotor, improves copper bar shake and a sealing-off phenomenon compared with an inserted-copper-bar structure, is simpler in process and lower in cost than a cast-copper structure rotor, and has excellent locked-rotor performance of cast-aluminum rotors and double-cage rotors.

Owner:KUNGFU SCI TECH CO LTD

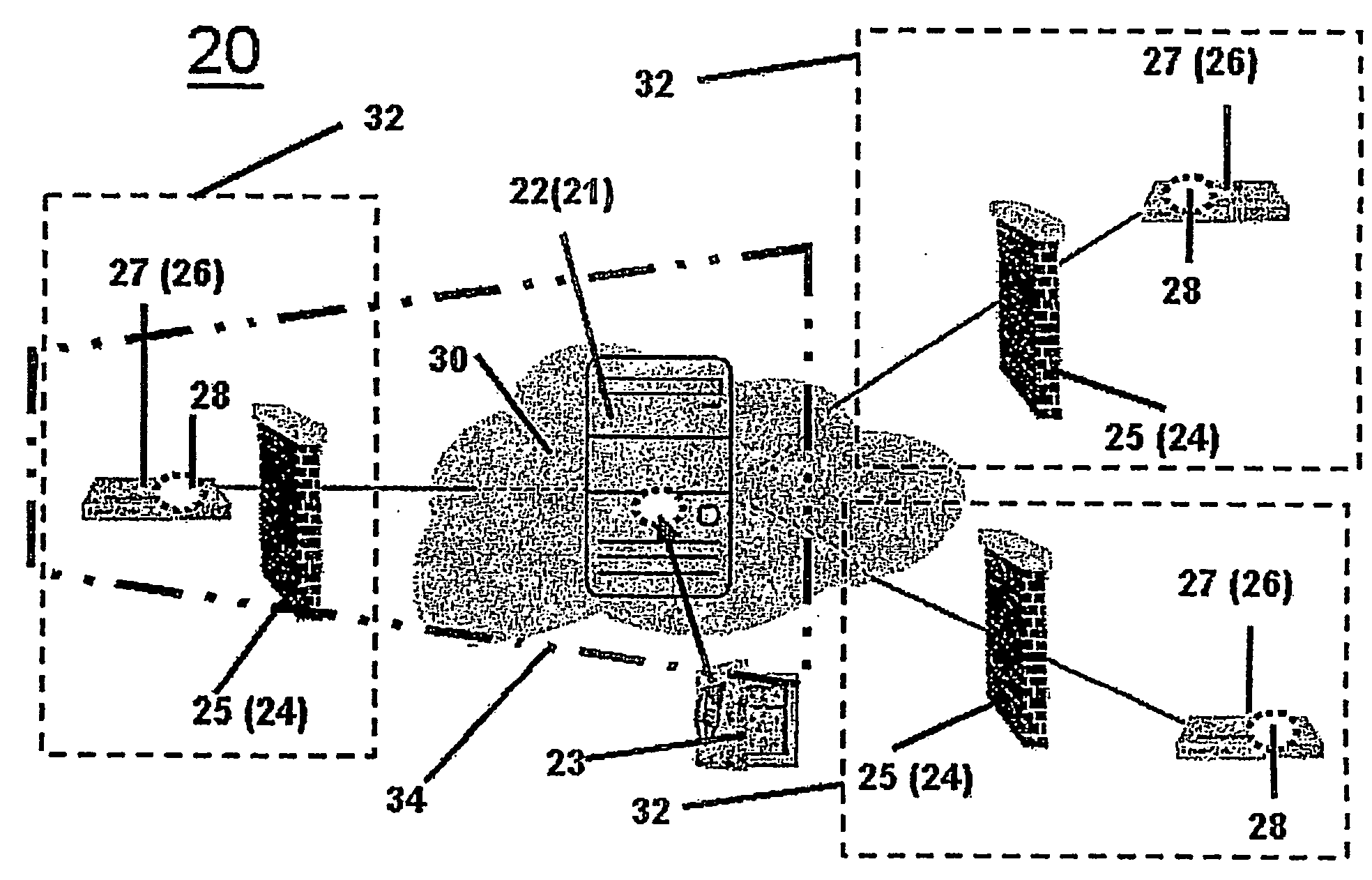

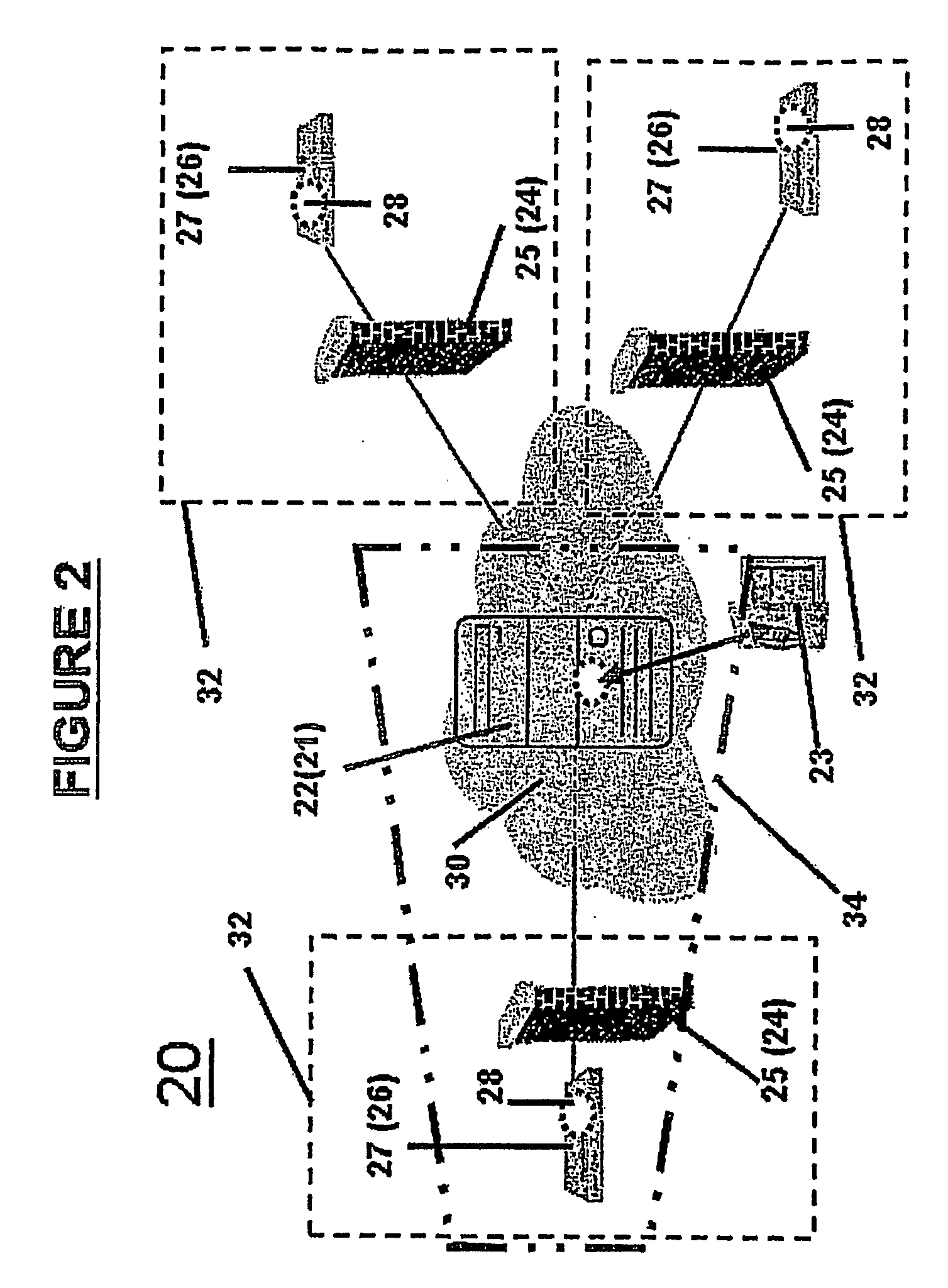

Server, computerized network including same, and method for increasing level of efficiency of a network

InactiveUS20090119359A1Improve efficiency levelsHigh protection levelMultiple digital computer combinationsTransmissionComputer networkData access

A data access engine 22, computerized system 20 and method 40 for increasing a level of efficiency of a network server are disclosed. Data access engine 22 located in first data processing machine 21 is capable of communication with at least one pseudo server 28 located in a second data processing machine 27 (i.e. LAN server 26). The physical separation between data access engine 22 and the server logic and interface of pseudo server 28 is a distinguishing characteristic of the invention. Any request for a subset of data stored in data access engine 22 must be routed through at least one pseudo server 28.

Owner:CYBER ARK SOFTWARE

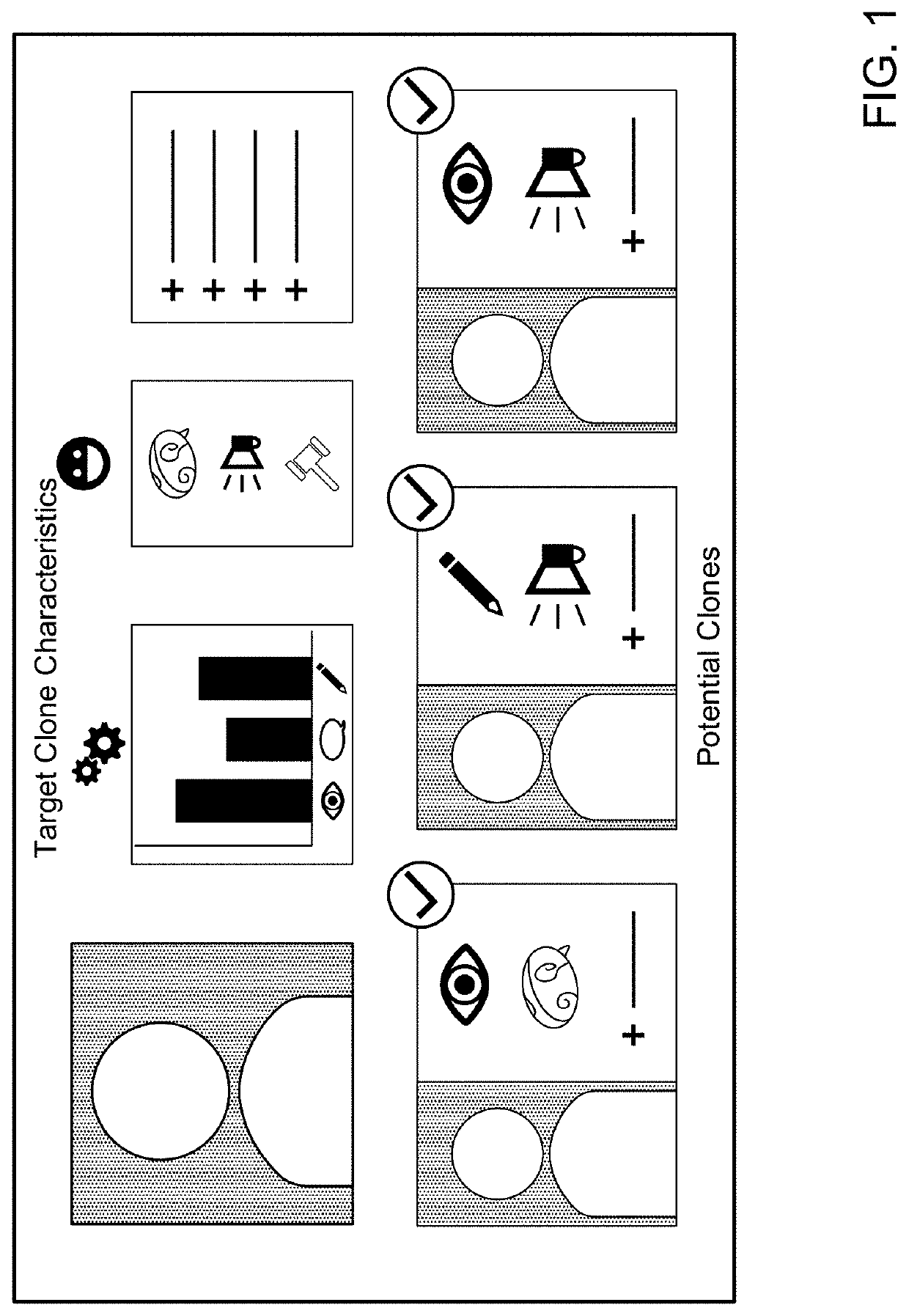

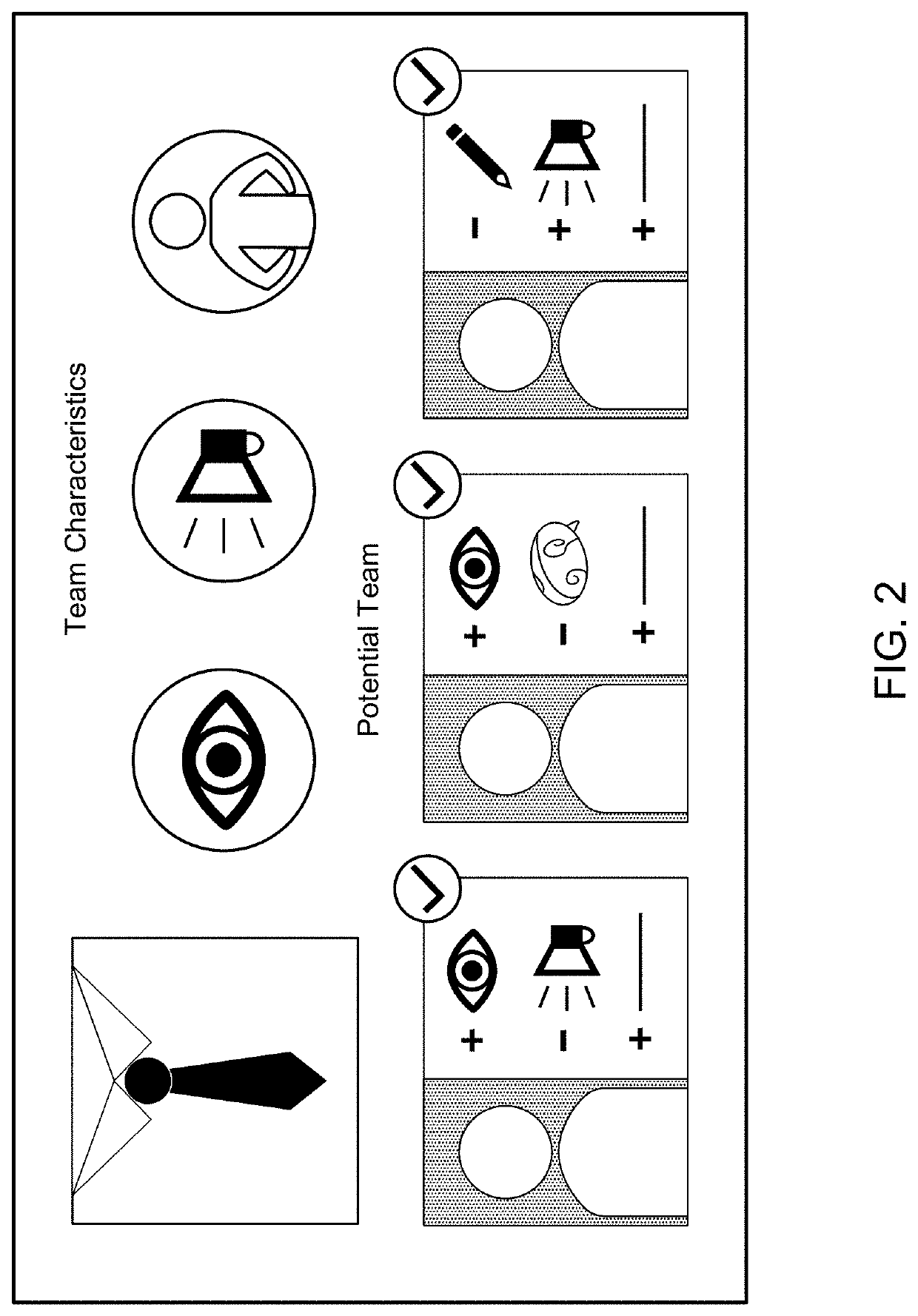

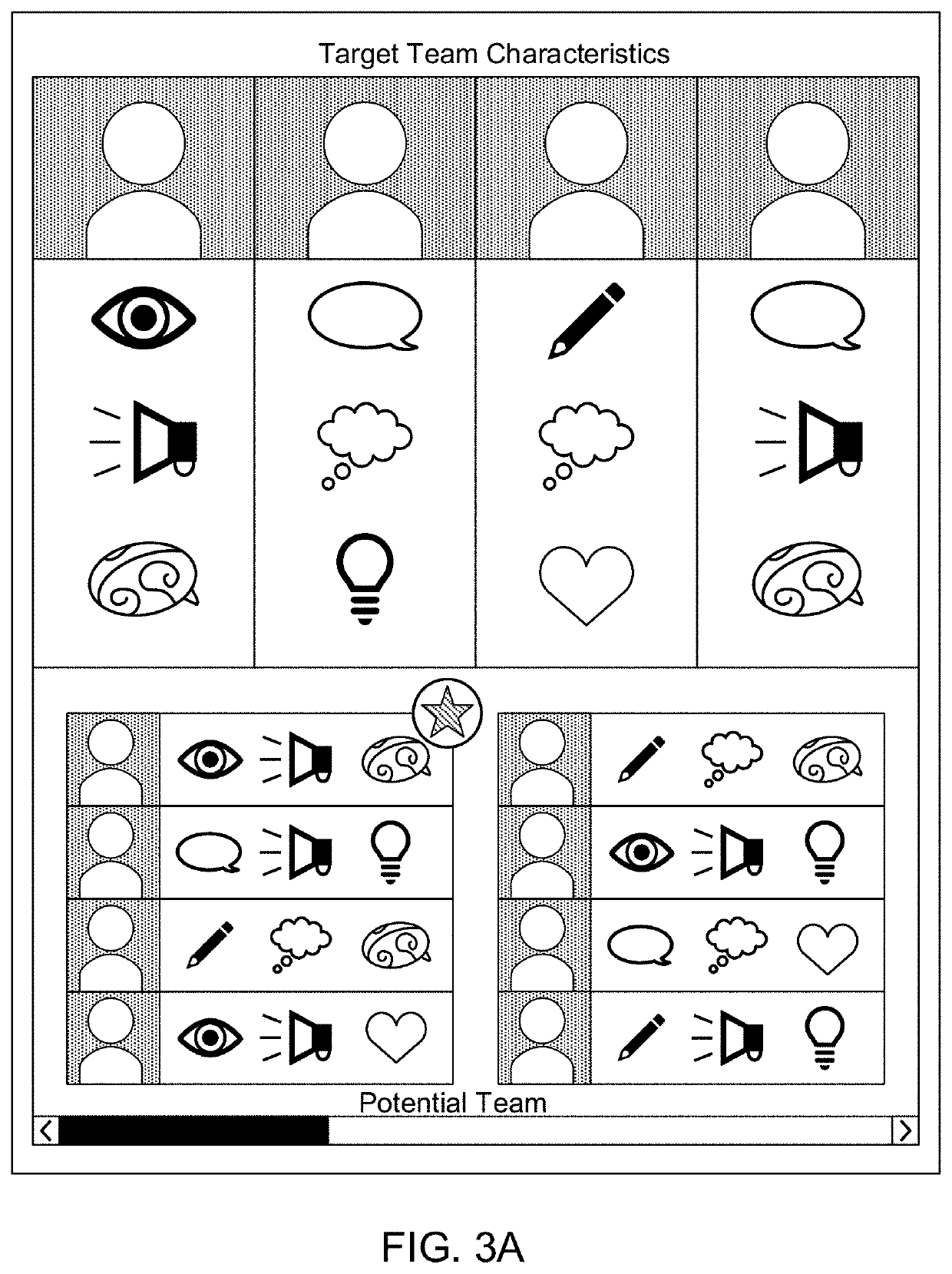

Systems and methods for dynamically cloning a target using behavioral insights

InactiveUS20210056512A1Improve efficiency levelsImprove the level ofDigital data information retrievalOffice automationData miningData science

What is needed is a system and method for using behavioral insights to determine who might be an appropriate placement or replacement within an organization. Accordingly, the present disclosure provides a more effective way to replace positions and teams. In some embodiments, the system may create a target candidate and pull from a pool of candidates to determine best fit using behavioral insights. In some implementations, the system may suggest a candidate based on an employer's requests. For example, an employer may specify they are looking for a candidate just like the one retiring. Based on the retiree, the system may find a viable candidate and present the person to the employer weighing what matches and what does not.

Owner:MISRA RAGHAVENDRA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com