Ultrastrong damping high-voltage synchronous motor

A synchronous generator and generator stator technology, which is applied in the fields of synchronous generators and high-voltage synchronous generators, can solve the voltage waveform distortion at the terminals of high-voltage synchronous generators, restrict the load capacity of the generator, and the poor ability to carry non-linear loads, etc. problems, to achieve the effect of suppressing harmonics, improving dynamic performance, reducing surface loss, and improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

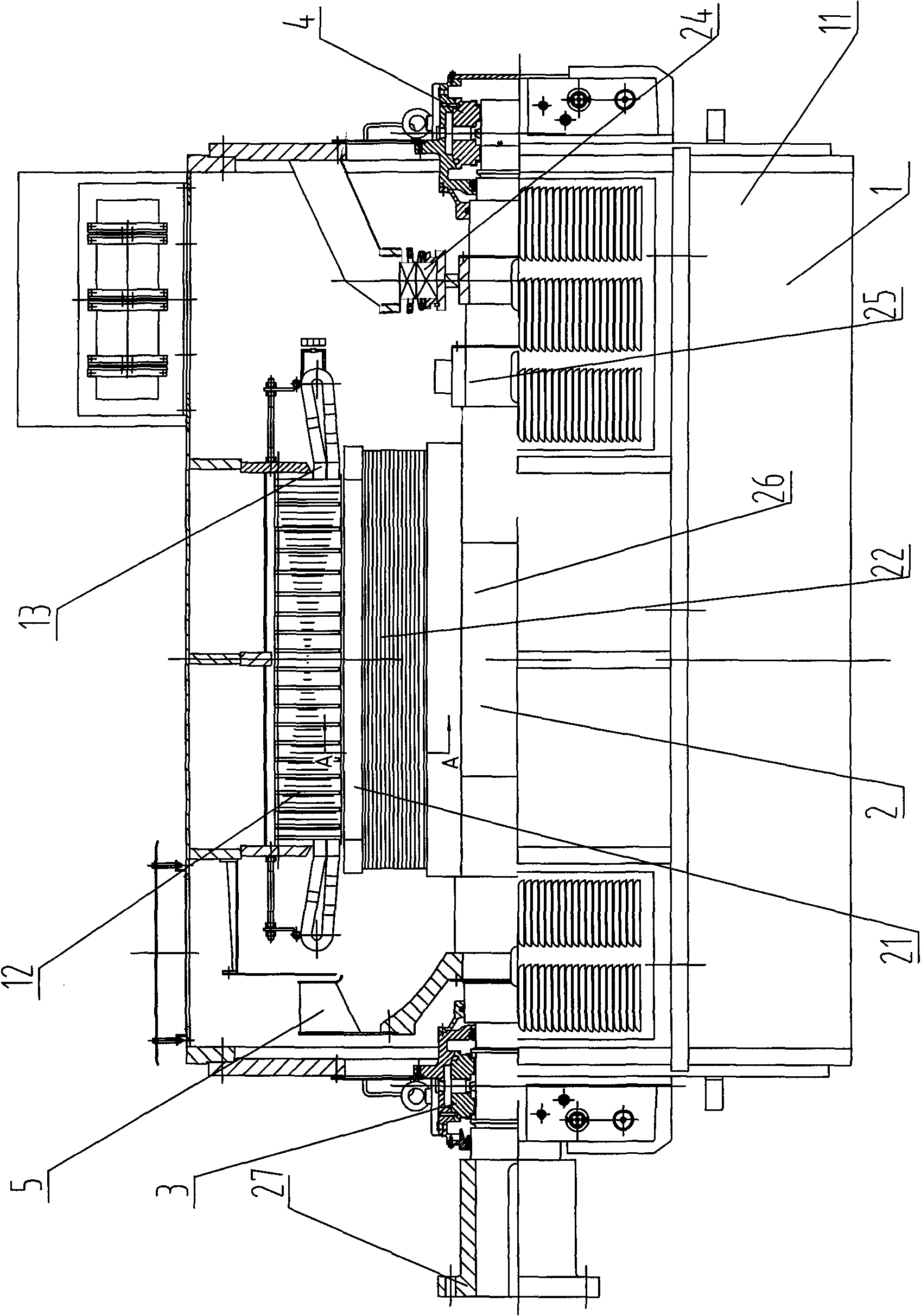

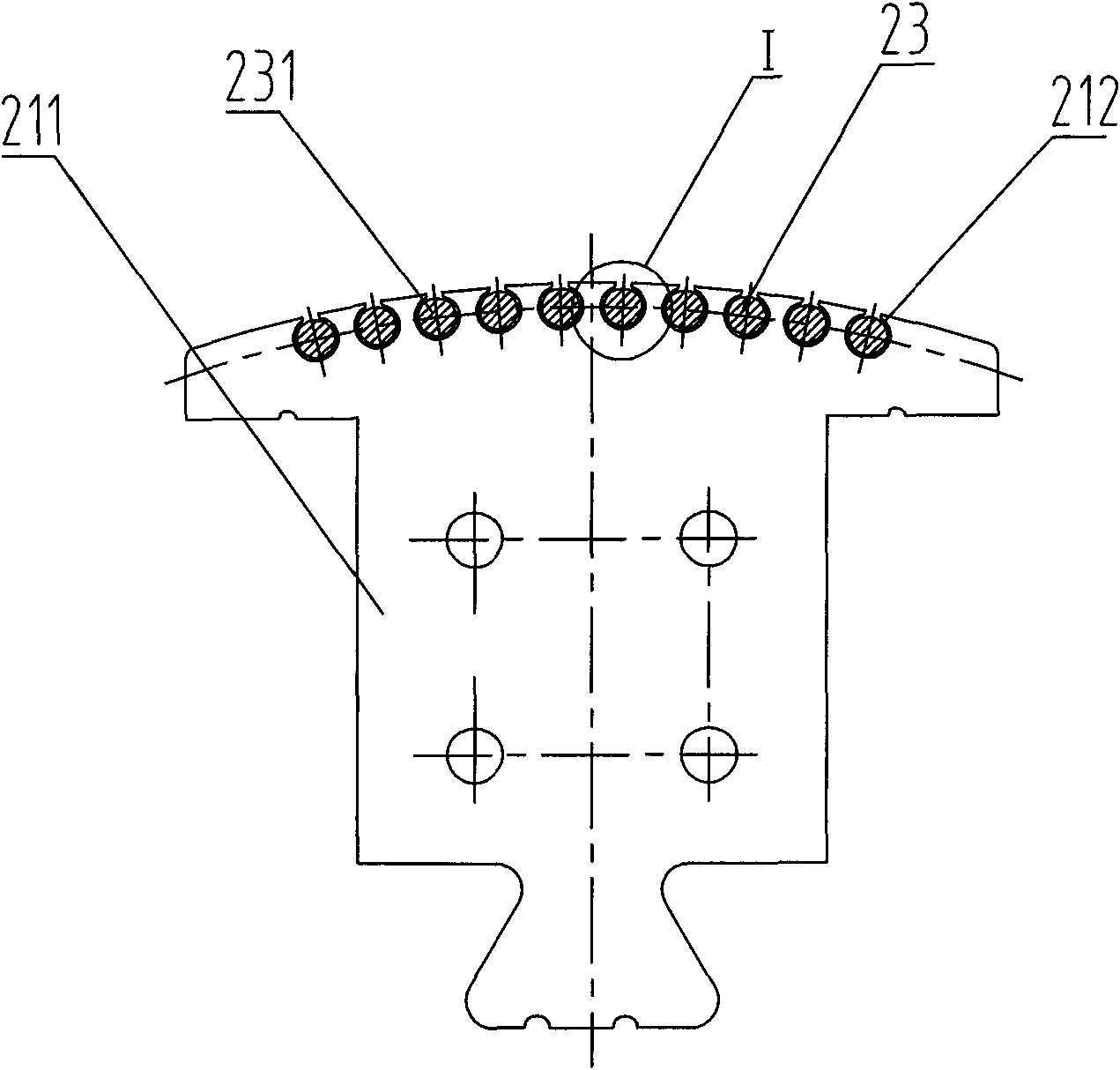

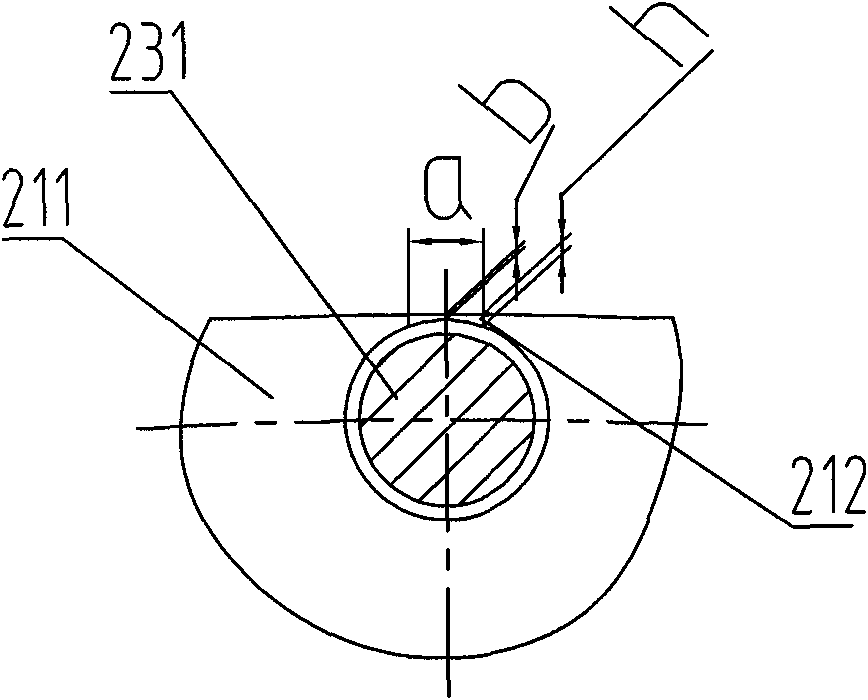

[0016] like Figure 1 ~ Figure 3 As shown, the present invention comprises generator stator 1, generator rotor 2, and generator stator 1 comprises frame 11, iron core 12 and stator coil 13; Generator rotor 2 comprises magnetic pole core 21, magnetic pole coil 22, damping winding 23, AC The exciter rotor 24, the rotary rectifier 25 and the rotating shaft 26, the two ends of the rotating shaft 26 are respectively supported on the base 11 through the shaft extension end bearing 3 and the non-shaft extension end bearing 4, and the shaft extension end of the rotating shaft 26 is equipped with a The semi-coupling 27 connected to the motor, the magnetic pole coil 22 is sleeved outside the magnetic pole core 21. A heat dissipation fan 5 is also installed at the shaft extension bearing 3 of the rotating shaft 26, and an AC exciter rotor 6 is installed at the non-shaft extension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com